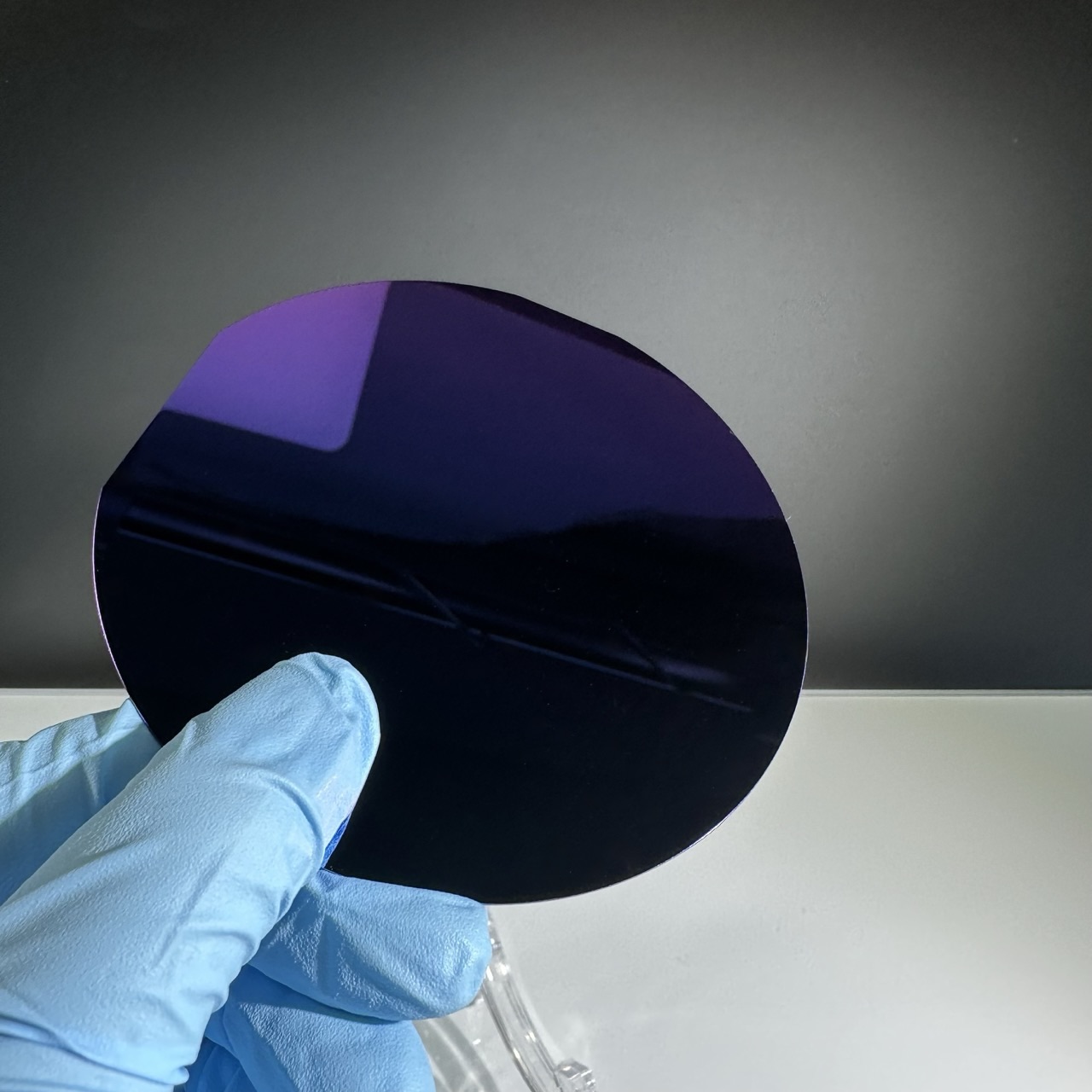

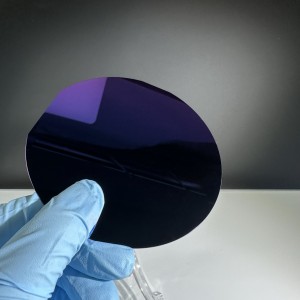

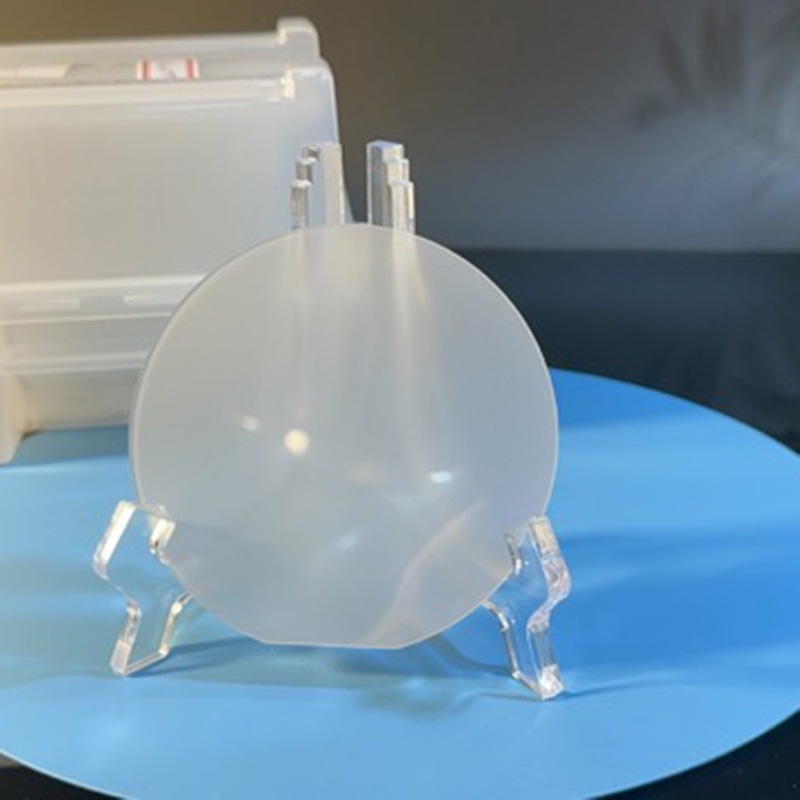

Silicon Dioxide wafer SiO2 wafer gobvu Yakakwenenzverwa, Prime Uye Test Giredhi

Sumo yewafer box

| Product | Thermal Oxide (Si+SiO2) zvitete |

| Kugadzira Nzira | LPCVD |

| Surface polishing | SSP/DSP |

| Diameter | 2inch/3inch/4inch/5inch/6inch |

| Type | P mhando / N mhando |

| Oxidation Layer ukobvu | 100nm ~ 1000nm |

| Orientation | <100> <111> |

| Electrical resistivity | 0.001-25000(Ω•cm) |

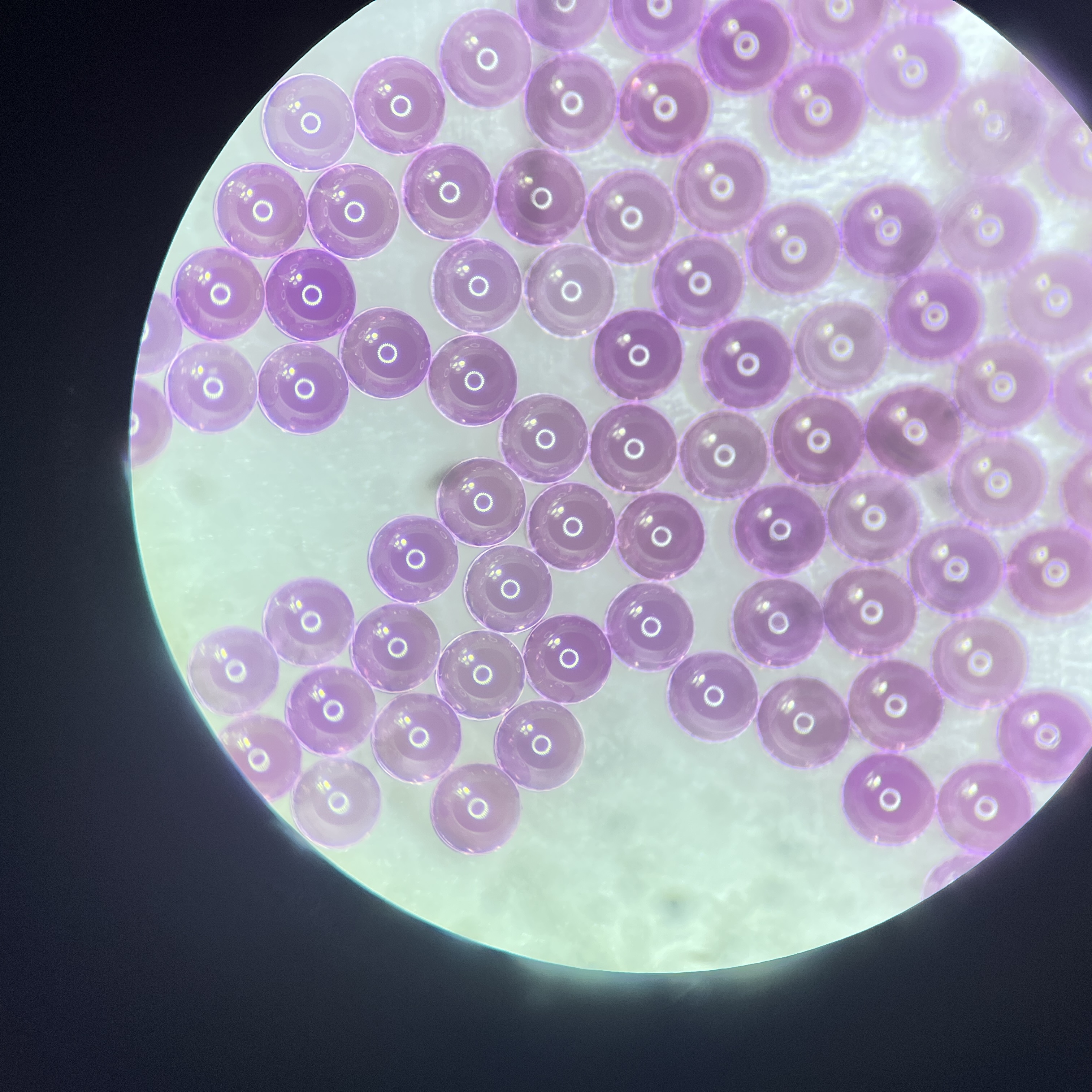

| Application | Inoshandiswa synchrotron radiation sampuli inotakura, PVD/CVD coating se substrate, magnetron sputtering kukura sampuli, XRD, SEM,Atomic simba, infrared spectroscopy, fluorescence spectroscopy uye kumwe kuongorora bvunzo substrates, molecular beam epitaxial kukura substrates, X-ray kuongororwa kwecrystalline semiconductors. |

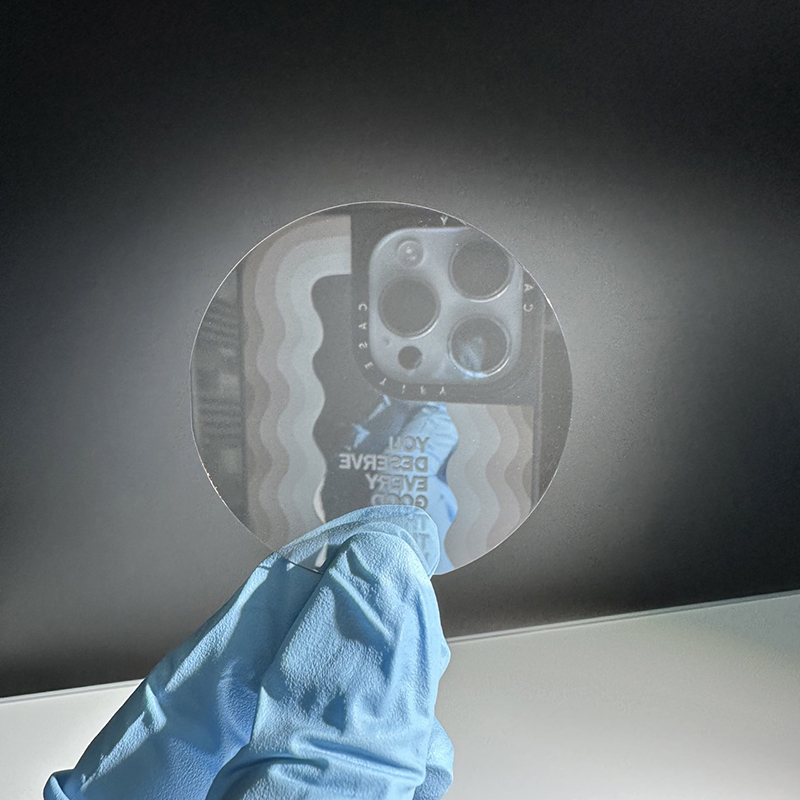

Silicon oxide wafers ari silicon dioxide mafirimu anokura pamusoro pesilicon wafers nenzira yeokisijeni kana mhute yemvura pakupisa kwakanyanya (800 ° C ~ 1150 ° C) uchishandisa thermal oxidation process neatmospheric pressure furnace tube equipment.Ukobvu hwekuita hunobva pa50 nanometers kusvika ku2 microns, tembiricha yekushanda inosvika 1100 degrees Celsius, nzira yekukura yakakamurwa kuita "okisijeni yemvura" uye "okisijeni yakaoma" marudzi maviri.Thermal Oxide "yakakura" oxide layer, ine yakakwirira kufanana, nani densification uye yakakwirira dielectric simba pane CVD yakaiswa oxide layer, zvichikonzera hukuru hwemhando.

Dry Oxygen Oxidation

Silicon inopindirana neokisijeni uye iyo oxide layer inogara ichienda kune substrate layer.Dry oxidation inofanirwa kuitwa patembiricha kubva pa850 kusvika 1200°C, ine mwero wakaderera wekukura, uye inogona kushandiswa kuMOS insulated gedhi kukura.Dry oxidation inosarudzwa pamusoro pekunyorova oxidation kana yemhando yepamusoro, yekupedzisira-yakaonda silicon oxide layer inodiwa.Dry oxidation simba: 15nm ~ 300nm.

2. Wet Oxidation

Iyi nzira inoshandisa mhute yemvura kuumba oxide layer nekupinda muchoto chubhu pasi pekupisa kwakanyanya.Iyo densification yekunyorova oxidation yeokisijeni yakashata zvishoma pane yakaoma okisijeni oxidation, asi kana ichienzaniswa neyakaoma okisijeni oxidation yakanakira iyo ine yakakwirira yekukura mwero, yakakodzera kupfuura 500nm firimu kukura.Wet oxidation simba: 500nm ~ 2µm.

AEMD's atmospheric pressure oxidation furnace chubhu ndeye Czech horizontal furnace chubhu, iyo inoratidzwa nehupamhi hwekuita kugadzikana, yakanaka firimu kufanana uye yepamusoro particle control.Iyo silicon oxide furnace chubhu inogona kugadzira anosvika makumi mashanu mawafer pachubhu, ane yakanakisa intra- uye inter-wafers kufanana.

Detailed Diagram