12inch Fully Automatic Precision Dicing Saw Equipment Wafer Dedicated Cutting System yeSi/SiC & HBM (Al)

Technical parameters

| Parameter | Tsanangudzo |

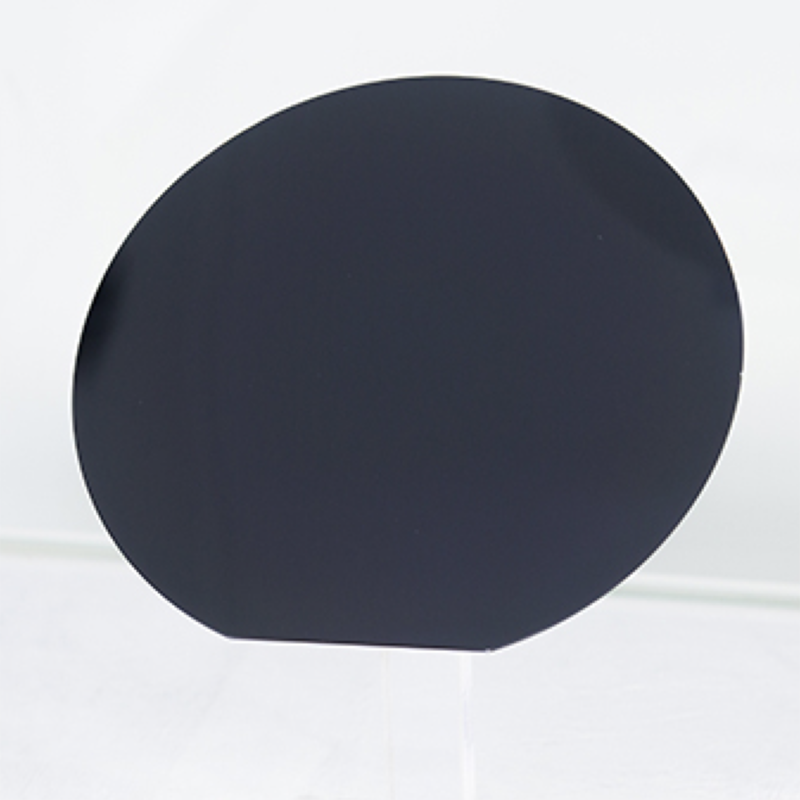

| Saizi Yekushanda | Φ8", Φ12" |

| Spindle | Dual-axis 1.2/1.8/2.4/3.0, Max 60000 rpm |

| Blade Size | 2" ~ 3" |

| Y1 / Y2 Axis

| Imwe-nhanho kuwedzera: 0.0001 mm |

| Kumira kwechokwadi: <0.002 mm | |

| Kucheka kureba: 310 mm | |

| X Axis | Feed speed range: 0.1–600 mm/s |

| Z1 / Z2 Axis

| Imwe-nhanho kuwedzera: 0.0001 mm |

| Kumira kwechokwadi: ≤ 0.001 mm | |

| θ Axis | Kumira kwechokwadi: ± 15" |

| Yekuchenesa Station

| Kutenderera kumhanya: 100-3000 rpm |

| Nzira yekuchenesa: Kusuka otomatiki & kupukuta-kuomesa | |

| Kushanda Voltage | 3-chikamu 380V 50Hz |

| Zviyero (W×D×H) | 1550×1255×1880 mm |

| Kurema | 2100 kg |

Kushanda Nheyo

Iyo midziyo inowana yakakwirira-chaiyo yekucheka kuburikidza neanotevera matekinoroji:

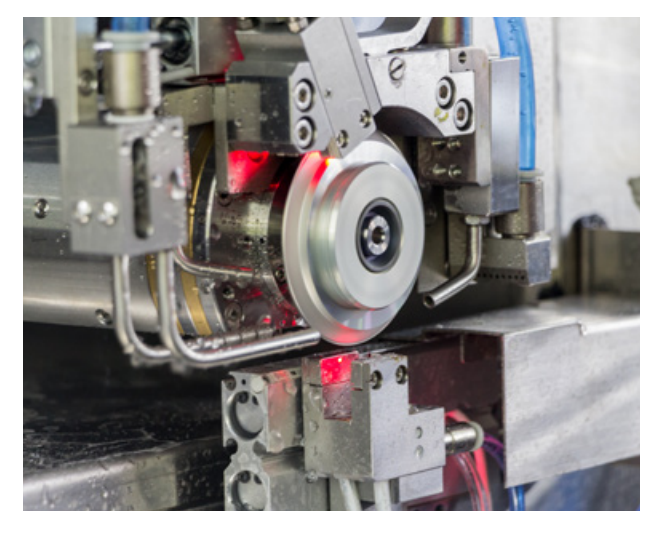

1.High-Rigidity Spindle System: Kutenderera kunotenderera kusvika ku60,000 RPM, yakagadzirwa nedhaimondi blades kana laser yekucheka misoro kuti ienderane kune zvakasiyana-siyana zvinhu.

2.Multi-Axis Motion Control: X/Y/Z-axis positioning accuracy ye ± 1μm, yakabatanidzwa ne-high-precision grating scales kuti ive nechokwadi chekutsauka-kusina kucheka nzira.

3.Intelligent Visual Alignment: High-resolution CCD (5 megapixels) inoziva kamwe chete kucheka migwagwa uye inobhadhara kurwisana kwezvinhu kana kukanganisa.

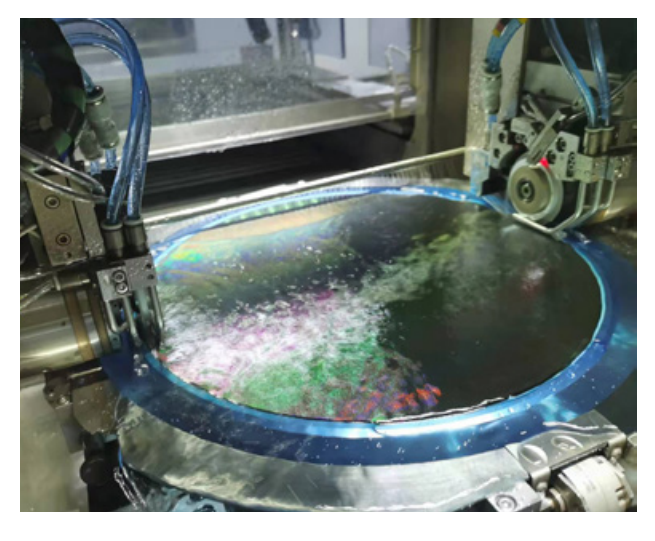

4.Cooling & Dust Removal: Yakabatanidzwa yakachena mvura inotonhorera system uye vacuum suction guruva kubvisa kuderedza kupisa kwemafuta uye kusvibiswa kwechidimbu.

Kucheka Modes

1.Blade Dicing: Inokodzera zvechinyakare semiconductor zvinhu seSi neGaAs, ine kerf upamhi hwe50–100μm.

2.Stealth Laser Dicing: Inoshandiswa kune ultra-thin wafers (<100μm) kana zvinhu zvisina kusimba (eg, LT / LN), zvichiita kuti kupatsanurwa kusina kunetseka.

Typical Applications

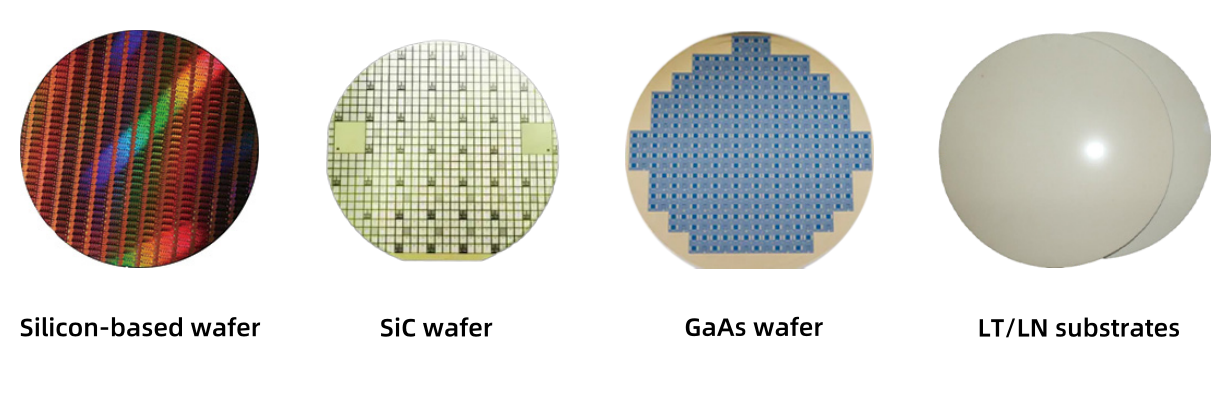

| Inowirirana Material | Munda Wekushandisa | Processing Zvinodiwa |

| Silicon (Si) | ICs, MEMS sensors | Yakakwirira-chaiyo kucheka, kucheka <10μm |

| Silicon Carbide (SiC) | Zvishandiso zvemagetsi (MOSFET/diode) | Yakaderera-kukuvadza kucheka, thermal manejimendi optimization |

| Gallium Arsenide (GaAs) | RF zvishandiso, optoelectronic chips | Micro-crack kudzivirira, utsanana kudzora |

| LT/LN Substrates | SAW mafirita, optical modulators | Kutemerwa-kusina kucheka, kuchengetedza piezoelectric zvivakwa |

| Ceramic Substrates | Power modules, LED kurongedza | High-hardness material processing, mupendero flatness |

| QFN/DFN Frames | Advanced kurongedza | Multi-chip panguva imwe chete yekucheka, kunyatsoita optimization |

| WLCSP Wafers | Wafer-level kurongedza | Dicing-isina kukuvara kweakanyanya-mutete wafers (50μm) |

Zvakanakira

1. High-speed cassette frame scanning ine maaramu ekudzivirira kudhumhana, kukurumidza kutamisa nzvimbo, uye simba rakasimba rekugadzirisa kukanganisa.

2. Optimized dual-spindle cutting mode, kuvandudza kushanda kweinenge 80% kana ichienzaniswa ne-single-spindle systems.

3. Precision-imported ball screws, linear guides, uye Y-axis grating scale yakavharwa-loop control, inovimbisa kugadzikana kwenguva refu kwepamusoro-chaiyo machining.

4. Kunyatsogadzirisa kurodha / kusunungura, kuisa nzvimbo, kugadzirisa kutema, uye kuongorora kerf, zvakanyanya kuderedza mushandisi (OP) basa rekushanda.

5.Gantry-style spindle mounting structure, ine hushoma huviri-blade spacing ye 24mm, ichigonesa kuchinjika kuchinjika kune mbiri-spindle yekucheka maitiro.

Features

1.High-precision isiri-contact urefu chiyero.

2.Multi-wafer dual-blade kucheka pane imwe tray.

3.Automatic calibration, kerf inspection, uye blade breakage monitoring systems.

4.Inotsigira maitiro akasiyana-siyana ane selectable automatic alignment algorithms.

5.Fault self-correction performance uye real-time multi-position monitoring.

6.First-cut chekuongorora kukwanisa post-initial dicing.

7.Customizable factory automation modules uye mamwe mabasa ekusarudza.

Equipment Services

Isu tinopa rutsigiro rwakakwana kubva pakusarudzwa kwemidziyo kusvika pakugadzirisa kwenguva refu:

(1) Customized Development

Kurudzira blade/laser yekucheka mhinduro dzinobva pane zvinhu zvinhu (semuenzaniso, SiC kuoma, GaAs brittleness).

· Ipa yemahara sampuli yekuyedza kuona yekucheka mhando (inosanganisira chipping, kerf upamhi, kushata kwepamusoro, nezvimwewo).

(2) Kudzidzira Unyanzvi

· Basic Kudzidziswa: Equipment mashandiro, parameter gadziriso, yekugara kugadzirisa.

· Dzidzo dzepamberi: Maitiro optimization yezvinhu zvakaoma (semuenzaniso, kusagadzikana-yekucheka kucheka kweLT substrates).

(3) Mushure-Kutengesa Kutsigira

· 24/7 Mhinduro: Remote diagnostics kana pane-saiti rubatsiro.

· Spare Parts Supply: Yakachengetwa maspindles, blades, uye optical zvinhu zvekukurumidza kutsiva.

· Kuchengetedza Kuchengetedza: Kugaro gadzirisa kuchengetedza kurongeka uye kuwedzera hupenyu hwebasa.

Zvatiri Zvakanakira

✔ Chiitiko cheIndasitiri: Kubatira 300+ yepasirese semiconductor uye vagadziri vemagetsi.

✔ Cutting-Edge Tekinoroji: Yakanyatso mutsara madhairekitori uye servo masisitimu anovimbisa kugadzikana-inotungamira indasitiri.

✔ Global Service Network: Kuvharwa muAsia, Europe, uye North America kune rutsigiro rwenzvimbo.

Kuti uedze kana kubvunza, taura nesu!