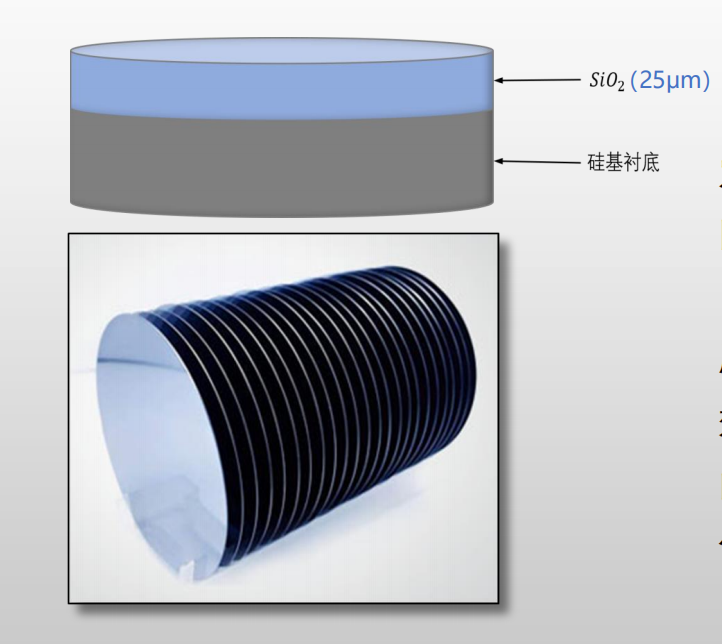

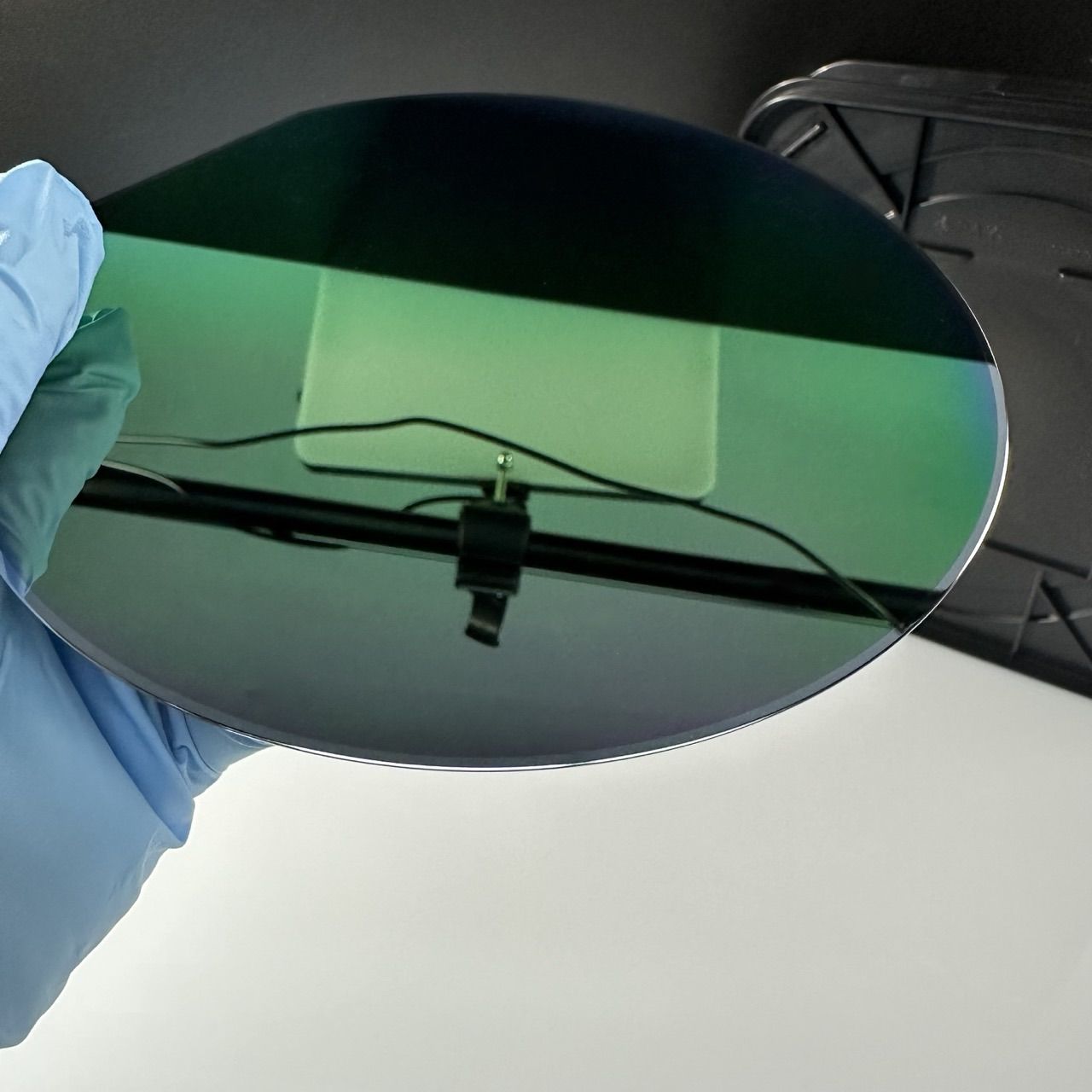

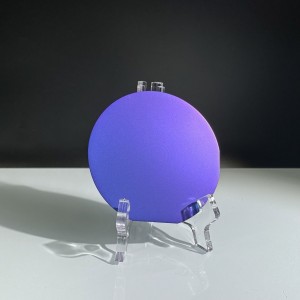

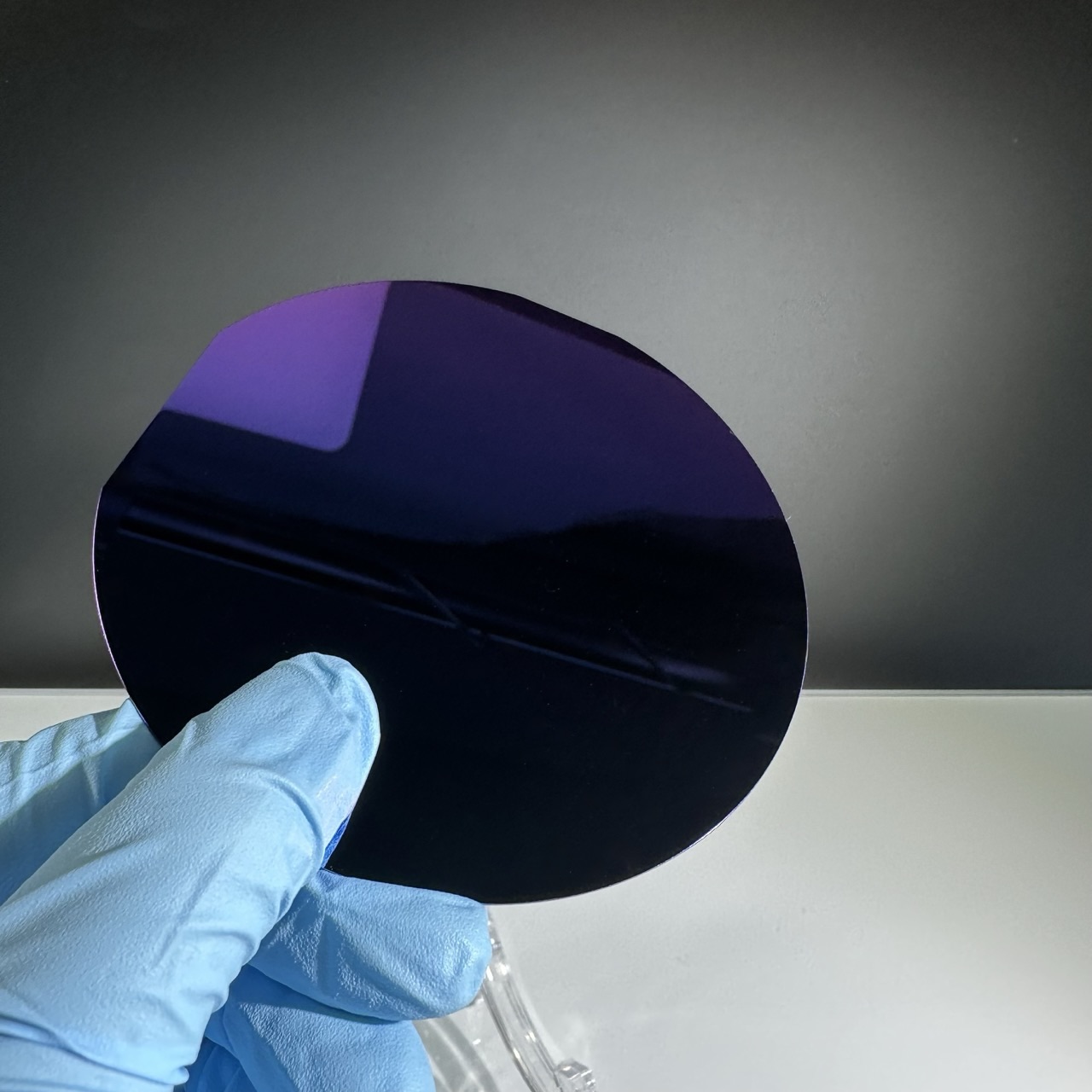

SiO2 Mutete Firimu Thermal Oxide Silicon wafer 4inch 6inch 8inch 12inch

Sumo yewafer box

Iyo huru nzira yekugadzira oxidized silicon wafers kazhinji inosanganisira anotevera matanho: monocrystalline silicon kukura, kucheka kuita mawafers, polishing, kuchenesa uye oxidation.

Monocrystalline silicon kukura: Chekutanga, monocrystalline silicon inokura pakupisa kwakanyanya nenzira dzakadai seyeCzochralski nzira kana iyo Float-zone nzira. Iyi nzira inogonesa kugadzirira kwesilicon imwe chete makristasi ane kuchena kwepamusoro uye kutendeka kwelatisi.

Dicing: Iyo yakura monocrystalline silicon inowanzo mu cylindrical chimiro uye inoda kucheka kuita mawafer matete kuti ashandiswe sewafer substrate. Kucheka kunowanzoitwa nemucheki wedhaimondi.

Kupenya: Pamusoro pechipfuwo chakachekwa chinogona kunge chisina kuenzana uye chinoda kukwenenzverwa kwemakemikari-muchina kuti uwane nzvimbo yakatsetseka.

Kuchenesa: Mucheka wakakwenenzverwa unocheneswa kubvisa tsvina neguruva.

Oxidizing: Pakupedzisira, zvimedu zvesilicon zvinoiswa muchoto chepamusoro-soro kuitira kurapwa kweoxidizing kuti iite chidziviriro chesilicon dioxide kuti ivandudze maitiro ayo emagetsi uye simba remagetsi, pamwe nekushanda sechinhu chinodzivirira mumasekete akabatanidzwa.

Iko kushandiswa kukuru kweoxidized silicon wafers kunosanganisira kugadzirwa kwemasekete akabatanidzwa, kugadzirwa kwemasero ezuva, uye kugadzirwa kwezvimwe zvigadzirwa zvemagetsi. Silicon oxide wafers anoshandiswa zvakanyanya mumunda we semiconductor zvinhu nekuda kweakanakisa makina zvivakwa, dimensional uye kugadzikana kwemakemikari, kugona kushanda pakupisa kwakanyanya uye kudzvinyirira kwakanyanya, pamwe neakanaka insulating uye optical properties.

Zvayakanakira zvinosanganisira chimiro chekristaro chakakwana, chimiro chemakemikari akachena, zviyero zvakaringana, zvakanaka mechanical properties, etc. Izvi zvinogadzira silicon oxide wafers kunyanya kukodzera kugadzirwa kwepamusoro-kushanda kwakabatanidzwa matunhu uye mamwe ma microelectronic madivayiri.

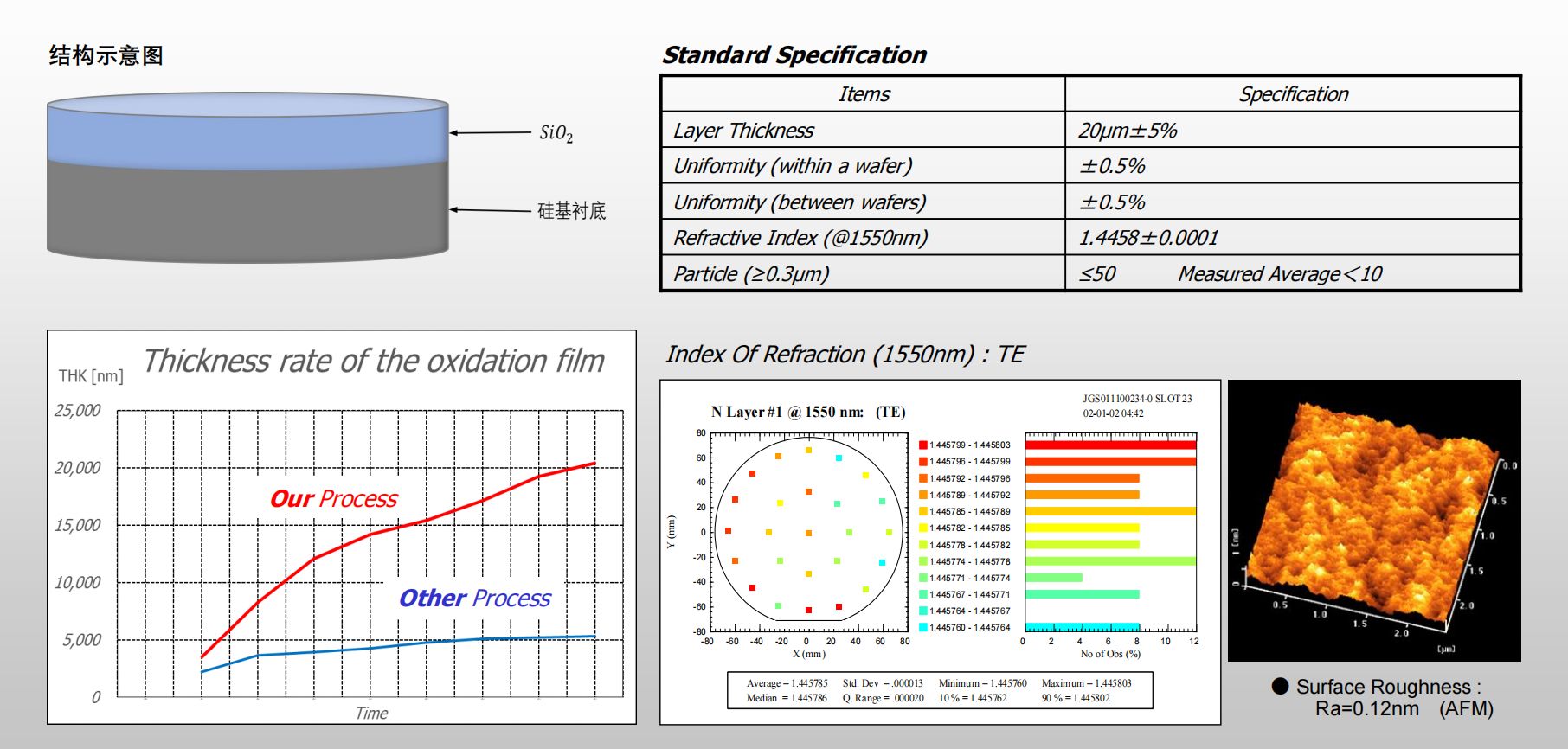

Detailed Diagram