Sapphire Crystal Kukura Kwevira KY Kyropoulos Nzira yeSapphire Wafer uye Optical Window Production

Kushanda Nheyo

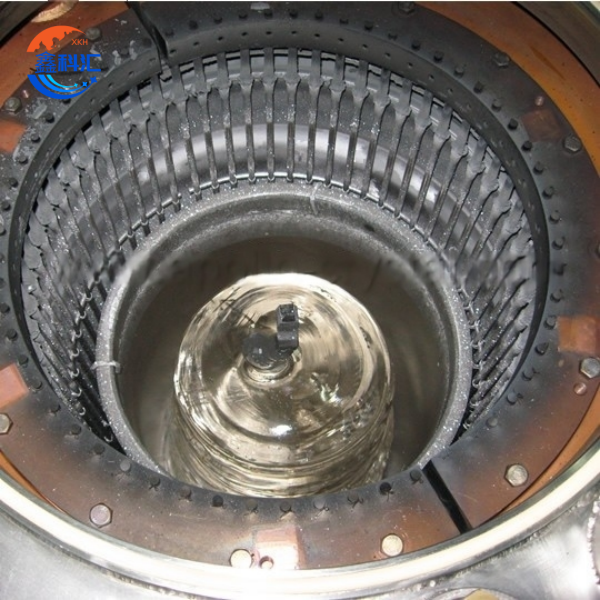

Musimboti weiyo nzira yeKY unosanganisira kunyunguduka kwepamusoro-kuchena Al₂O₃ zviwanikwa mu tungsten / molybdenum crucible pa2050 ° C. Kirasi yembeu inodzikiswa mukati mekunyunguduka, inoteverwa nekudzora kubviswa (0.5-10 mm / h) uye kutenderera (0.5-20 rpm) kuti iwane inotungamira kukura kwea-Al₂O₃ imwe chete makristasi. Zvinhu zvakakosha zvinosanganisira:

• Makristasi makuru-akareba (max. Φ400 mm × 500 mm)

• Low-stress optical-grade sapphire (wavefront distortion <λ/8 @ 633 nm)

• Doped crystals (semuenzaniso, Ti³⁰ doping yestar sapphire)

Core System Zvikamu

1. High-Temperature Melting System

• Tungsten-molybdenum composite crucible (max. temp. 2300°C)

• Multi-zone graphite hita (± 0.5°C tembiricha yekudzora)

2. Crystal Kukura System

• Servo-inotyairwa kudhonza nzira (± 0.01 mm nemazvo)

• Magnetic fluid rotary seal (0–30 rpm stepless speed regulation)

3. Thermal Field Control

• 5-zone yakazvimirira tembiricha kutonga (1800–2200°C)

• Chinochinjika chinodzivirira kupisa (±2°C/cm gradient)

• Vacuum & Atmosphere System

• 10⁻⁴ Pa high vacuum

• Ar/N₂/H₂ kudzora gasi rakasanganiswa

4. Intelligent Monitoring

• CCD real-time crystal diameter monitoring

• Multi-spectral melt level yekuona

KY vs. CZ Method Kuenzanisa

| Parameter | Nzira yeKY | CZ nzira |

| Max. Crystal Size | Φ400 mm | Φ200 mm |

| Chiyero chekukura | 5–15 mm/h | 20–50 mm/h |

| Defect Density | <100/cm² | 500–1000/cm² |

| Kushandiswa Kwemagetsi | 80–120 kWh/kg | 50–80 kWh/kg |

| Typical Applications | Optical windows / mawafer makuru | LED substrates / zvishongo |

Key Applications

1. Optoelectronic Windows

• Military IR domes (transmittance >85%@3–5 μm)

• UV laser windows (kutsungirira 200 W/cm² simba density)

2. Semiconductor Substrates

• GaN epitaxial wafers (2–8 inch, TTV <10 μm)

• SOI substrates (surface roughness <0.2 nm)

3. Consumer Electronics

• girazi rekuvhara kamera kamera (Mohs kuoma 9)

• Smartwatch inoratidza (10× scratch kuramba kunatsiridza)

4. Specialized Materials

• High-purity IR optics (absorption coefficient <10⁻³ cm⁻¹)

• Mahwindo ekuona nyukireya reactor (kushivirira kwemwaranzi: 10¹⁶ n/cm²)

Zvakanakira zveKyropoulos (KY) Sapphire Crystal Kukura Equipment

Iyo Kyropoulos (KY) nzira-yakavakirwa safire kristaro kukura michina inopa isingaenzaniswi hunyanzvi hwakanakira, ichiimisa seyekucheka-kumucheto mhinduro yekugadzirwa kwemaindasitiri. Mabhenefiti akakosha anosanganisira:

1. Huru-Diameter Kugona—: Kukwanisa kurima makristasi esafire anosvika 12 inches (300 mm) , mudhayamita, zvichiita kuti kugadzirwa kwepamusoro-soro kwewafers uye optical components for advanced applications seGaN epitaxy nemafafitera egiredhi remauto.

2. Ultra-Low Defect Density: Inowana dislocation densities <100/cm² kuburikidza neyakagadziridzwa dhizaini yemumunda uye tembiricha chaiyo gradient kutonga, kuve nechokwadi chepamusoro chekristaro kuperera kune optoelectronic zvishandiso.

3. High-Quality Optical Performance : Inoendesa transmittance> 85% kuyambuka inoonekwa kune infrared spectra (400–5500 nm), yakakosha kune UV laser windows uye infrared optics.

4. Yepamberi Otomatiki: Inoratidzira servo-inotyairwa yekudhonza masisitimu (± 0.01 mm kunyatsojeka) uye magineti fluid rotary seals (0–30 rpm stepless control), kuderedza kupindira kwevanhu uye kusimbisa kuenderana.

5. Flexible Doping Options: Inotsigira gadziriso nemadopants akaita seCr³⁰ (yeruby) uye Ti³⁰ (yenyeredzi safiro), ichipa misika yeniche mune optoelectronics uye zvishongo.

6. Kushanda Kwesimba: Yakakwenenzverwa thermal insulation (tungsten-molybdenum crucible) inoderedza kushandiswa kwesimba kusvika ku80–120 kWh/kg, kukwikwidza nedzimwe nzira dzekukura.

7. Scalable Production: Inowana kubuda pamwedzi kwe5,000+ wafers, nekukurumidza kutenderera nguva (8-10 mazuva e30-40 kg makristasi), yakasimbiswa neanopfuura mazana maviri epasi rose kuiswa.

.

8. Kugara Kwemauto-Gredhi: Inosanganisa madhizaini asingachinji nemwaranzi uye zvinhu zvinodzivirira kupisa (zvinoshingirira 10¹⁶ n/cm²), zvakakosha pakushandisa muchadenga nenyukireya.

Aya magadzirirwo anosimbisa nzira yeKY seye goridhe chiyero chekugadzira yakakwirira-inoshanda makristasi esafire, kutyaira kufambira mberi mu5G kutaurirana, quantum computing, uye tekinoroji yekudzivirira.

XKH Services

XKH inopa yakazara turnkey mhinduro, yesafire crystal yekukura masisitimu, inosanganisira kuisirwa, kugadzirisa maitiro, uye kudzidziswa kwevashandi kuve nechokwadi chekubatana kwekushanda. Isu tinoendesa pre-yakasimbiswa yekukura mabikirwo (50+) akarongedzerwa kune akasiyana siyana maindasitiri, achidzikisa zvakanyanya R&D nguva yevatengi. Nezve mashandisirwo ane hunyanzvi, kusimudzira kwetsika masevhisi anogonesa kugadzirisa mhango (Φ200–400 mm) uye advanced doping masisitimu (Cr/Ti/Ni), inotsigira yakakwirira-inoshanda optical zvinhu uye neradiation-resistant materials.

Value-akawedzera masevhisi anosanganisira mushure mekukura kugadzirisa senge kucheka, kukuya, uye kukwenenzverwa, kunowedzerwa nehuwandu hwakazara hwezvigadzirwa zvesafire senge wafers, machubhu, uye gemstone blanks. Izvi zvinopihwa zvinopa zvikamu kubva kune zvemagetsi zvevatengi kuenda kune aerospace. Tsigiro yedu yehunyanzvi inovimbisa waranti yemwedzi makumi maviri nemana uye chaiyo-nguva yekuongorora kureba, kuve nechokwadi chekushomeka nguva yekudzikira uye kugadzirwa kwakasimba.