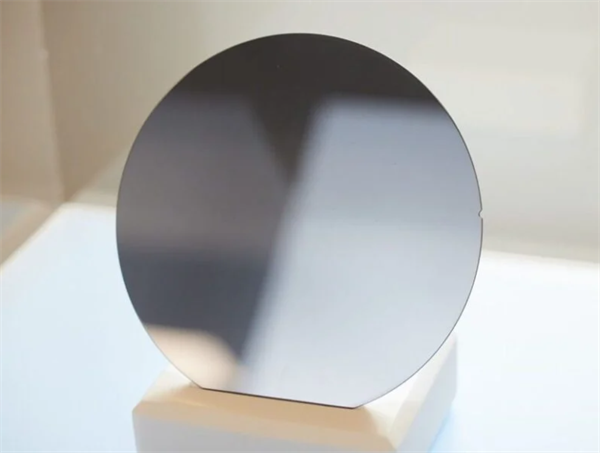

P-mhando yeSiC wafer 4H/6H-P 3C-N 6inch kukora 350 μm ine Primary Flat Oientation

Specification4H/6H-P Type SiC Composite Substrates Yakajairwa parameter tafura

6 inch dhayamita Silicon Carbide (SiC) Substrate Tsanangudzo

| Giredhi | Zero MPD KugadzirwaGiredhi (Z Giredhi) | Standard ProductionGiredhi (P Giredhi) | Dummy Grade (D Giredhi) | ||

| Diameter | 145.5 mm ~ 150.0 mm | ||||

| Ukobvu | 350 μm ± 25 μm | ||||

| Wafer Orientation | -Offakisi: 2.0°-4.0° kuenda ku [1120] ± 0.5° nokuda kwe4H/6H-P, Paakisi:〈111〉± 0.5° nokuda kwe3C-N | ||||

| Micropipe Density | 0 masendimita-2 | ||||

| Resistivity | p-mhando 4H/6H-P | ≤0.1 Ωꞏcm | ≤0.3 Ωꞏcm | ||

| n-mhando 3C-N | ≤0.8 mΩꞏcm | ≤1 m Ωꞏcm | |||

| Yekutanga Flat Oriental | 4H/6H-P | -{1010} ± 5.0° | |||

| 3C-N | -{110} ± 5.0° | ||||

| Primary Flat Length | 32.5 mm ± 2.0 mm | ||||

| Secondary Flat Length | 18.0 mm ± 2.0 mm | ||||

| Secondary Flat Orientation | Silicon yakatarisana kumusoro: 90° CW. kubva Prime flat ± 5.0 ° | ||||

| Kusabatanidzwa kumucheto | 3 mm | 6 mm | |||

| LTV/TTV/Bow/Warp | ≤2.5 μm/≤5 μm/≤15 μm/≤30 μm | ≤10 μm/≤15 μm/≤25 μm/≤40 μm | |||

| Kukasharara | Polish Ra≤1 nm | ||||

| CMP Ra≤0.2 nm | Ra≤0.5 nm | ||||

| Edge Cracks By High Intensity Chiedza | Hapana | Kureba kwekuwedzera ≤ 10 mm, kureba kamwe≤2 mm | |||

| Hex Plates By High Intensity Chiedza | Cumulative area ≤0.05% | Cumulative area ≤0.1% | |||

| Polytype Nzvimbo NeKusimba Kwakanyanya Chiedza | Hapana | Cumulative area≤3% | |||

| Visual Carbon Inclusions | Cumulative area ≤0.05% | Yakawedzerwa nzvimbo ≤3% | |||

| Silicon Surface Scratches By High Intensity Chiedza | Hapana | Cumulative kureba≤1×wafer dhayamita | |||

| Edge Chips High By Intensity Chiedza | Hapana anotenderwa ≥0.2mm hupamhi nekudzika | 5 inotenderwa, ≤1 mm imwe neimwe | |||

| Silicon Surface Kusvibiswa NeKunyanya Kusimba | Hapana | ||||

| Packaging | Multi-wafer Cassette kana Single Wafer Container | ||||

Notes:

※ Miganho yekukanganisa inoshanda kune yese wafer pamusoro kunze kweiyo yekumusoro nzvimbo yekusarudzika. # Iwo mavanga anofanirwa kutariswa paSi face o

Iyo P-mhando SiC wafer, 4H/6H-P 3C-N, ine saizi yayo 6-inch uye 350 μm ukobvu, inoita basa rakakosha mukugadzirwa kwemaindasitiri kweakakwira-kuita magetsi emagetsi. Yayo yakanaka kwazvo yekupisa yekupisa uye yakanyanya kuputsika voltage inoita kuti ive yakakodzera kune zvigadzirwa zvekugadzira senge magetsi switch, diode, uye transistors anoshandiswa munzvimbo dzepamusoro-tembiricha senge mota dzemagetsi, magidhi emagetsi, uye masisitimu emagetsi anovandudzwa. Kugona kwewafe kushanda nemazvo mumamiriro ezvinhu akaomarara kunovimbisa kuita kwakavimbika mumaindasitiri maapplication anoda kuwanda kwemagetsi uye kushanda nesimba. Pamusoro pezvo, yayo yekutanga furati yekumisikidza inobatsira mukurongeka chaiko panguva yekugadzirwa kwechishandiso, kusimudzira kugona kwekugadzira uye kuenderana kwechigadzirwa.

Zvakanakira zveN-mhando SiC composite substrates inosanganisira

- High Thermal Conductivity: P-mhando SiC wafers inonyatso bvisa kupisa, ichiita kuti ive yakanaka kune yakakwirira-tembiricha application.

- High Breakdown Voltage: Inokwanisa kumirisana nemagetsi akakwira, kuve nechokwadi chekuvimbika mumagetsi emagetsi uye akakwira-voltage zvishandiso.

- Kupokana Nenzvimbo Dzakaoma: Yakanakisa kusimba mumamiriro ezvinhu akanyanya, senge tembiricha yepamusoro uye nharaunda dzinoparadza.

- Kushandura Simba Kunoshanda: Iyo P-mhando doping inogonesa kubata kwesimba kwakasimba, ichiita kuti wafer ikwane kune simba rekushandura masisitimu.

- Yekutanga Flat Oriental: Inosimbisa kurongeka chaiko panguva yekugadzira, kuvandudza iko kwechigadzirwa uye kuenderana.

- Mutetepa Chimiro (350 μm): Iyo wafer's yakakwana ukobvu inotsigira kubatanidzwa mune yepamusoro, nzvimbo-inomanikidza zvemagetsi zvishandiso.

Pakazere, iyo P-mhando SiC wafer, 4H/6H-P 3C-N, inopa huwandu hwezvakanakira izvo zvinoita kuti inyatsokodzera maindasitiri nemagetsi maapplication. Yayo yakanyanya kupisa conductivity uye kuparara kwemagetsi inogonesa kushanda kwakavimbika munzvimbo yakakwirira-yekushisa uye yakakwirira-voltage, nepo kuramba kwayo kune yakaoma mamiriro kunovimbisa kusimba. Iyo P-type doping inobvumira kushandurwa kwesimba kwakanyatsoita, ichiita kuti ive yakanakira magetsi emagetsi nemagetsi masisitimu. Pamusoro pezvo, iyo wafer yekutanga furati yekumisikidza inovimbisa kurongeka chaiko panguva yekugadzira, inosimudzira kugadzirwa kunoenderana. Iine ukobvu hwe350 μm, yakanyatso kufanira kubatanidzwa mune yepamusoro, compact zvishandiso.

Detailed Diagram