Ion Beam Kupukuta Muchina wesafire SiC Si

Detailed Diagram

Chigadzirwa Overview yeIon Beam Kupolisha Machine

Iyo Ion Beam Figuring uye Polishing Machine yakavakirwa pamusimboti weiyo sputtering. Mukati mekamuri-yakakwirira-vacuum, ion sosi inogadzira plasma, iyo inokwidziridzwa kuita yakakwirira-simba ion danda. Iri danda rinobhomba pamusoro pechikamu chemaziso, richibvisa zvinhu pachiyero cheatomu kuti riwane kururamisa kwepamusoro-soro uye kupedza.

Senge isiri-yekubata maitiro, ion beam polishing inobvisa kushushikana kwemechani uye inodzivirira kukuvadzwa kwepasi, zvichiita kuti ive yakanakira kugadzira yakakwirira-chaiyo optics inoshandiswa mune zvenyeredzi, aerospace, semiconductors, uye advanced research application.

Kushanda Nheyo yeIon Beam Kupukuta Muchina

Ion Generation

Inert gasi (semuenzaniso, argon) inounzwa mukamuri yekutsvaira uye ionized kuburikidza nekubuda kwemagetsi kuita plasma.

Kumhanyisa & Beam Kuumbwa

Maion anokwidziridzwa kusvika kumazana akawanda kana zviuru zvema electron volts (eV) uye akaumbwa kuita yakagadzikana, yakanangwa danda nzvimbo.

Kubviswa kwezvinhu

Iyo ion beam inomwaya maatomu kubva pamusoro pasina kutanga maitiro emakemikari.

Kuona Kukanganisa & Kuronga Nzira

Kutsauka kwechimiro chepamusoro kunoyerwa ne interferometry. Kubvisa mabasa anoshandiswa kuona nguva dzekugara uye kugadzira yakagadziridzwa maturusi nzira.

Yakavharwa-Loop Kururamisa

Iterative kutenderera kwekugadzirisa uye kuyerwa kunoenderera kusvika RMS/PV chaiyo tarisiro yawanikwa.

Zvinhu zvakakosha zveIon Beam Kupolisha Machine

Universal Surface Kuenderana- Magadzirirwo akafuratira, akatenderera, aspherical, uye akasununguka maficha

Ultra-Stable Removal Rate- Inogonesa sub-nanometer nhamba kugadzirisa

Kukuvadza-Kusina Kugadziriswa-Hapana hurema hwepasi pevhu kana shanduko yezvimiro

Kushanda Kwakafanana-Inoshanda zvakaenzana pamidziyo yekuomarara kwakasiyana

Low/Medium Frequency Correction-Inobvisa zvikanganiso pasina kugadzira yepakati / yakakwira-frequency artifacts

Low Maintenance Chinodiwa-Kushanda kwenguva refu kuenderera nekuderera kushoma nguva

Main Tekinoroji Madiro eIon Beam Kupukuta Muchina

| Item | Tsanangudzo |

| Processing Method | Ion sputtering munzvimbo yakakwirira-vacuum |

| Processing Type | Isiri-yekusangana kwepamusoro figuring & polishing |

| Max Workpiece Saizi | Φ4000 mm |

| Motion Axes | 3-axis / 5-axis |

| Kubvisa Kugadzikana | ≥95% |

| Surface Accuracy | PV <10 nm; RMS ≤ 0.5 nm (yakajairika RMS <1 nm; PV <15 nm) |

| Frequency Kugadzirisa Kugona | Inobvisa yakaderera-yepakati frequency kukanganisa pasina kuunza mid/high frequency kukanganisa |

| Continuous Operation | 3-5 mavhiki pasina vacuum kugadzirisa |

| Maintenance Cost | Low |

Kugadzirisa Kugona kweIon Beam Kupukuta Muchina

Inotsigirwa Surface Types

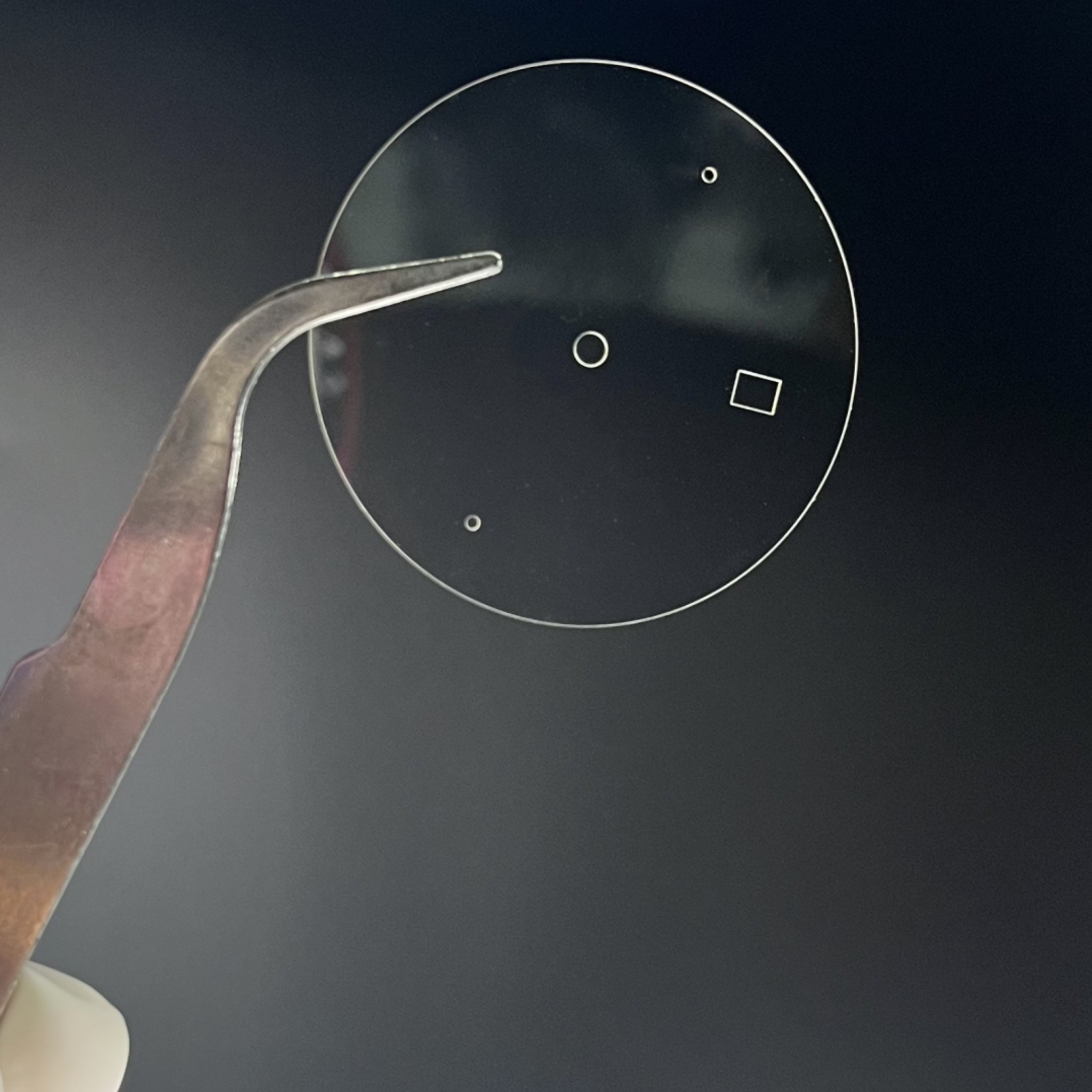

Nyore: Yakatsetseka, yakatenderera, prism

Complex: Symmetric/asymmetric asphere, off-axis asphere, cylindrical

Special: Ultra-thin optics, slat optics, hemispherical optics, conformal optics, phase plates, freeform surfaces.

Zvishandiso Zvinotsigirwa

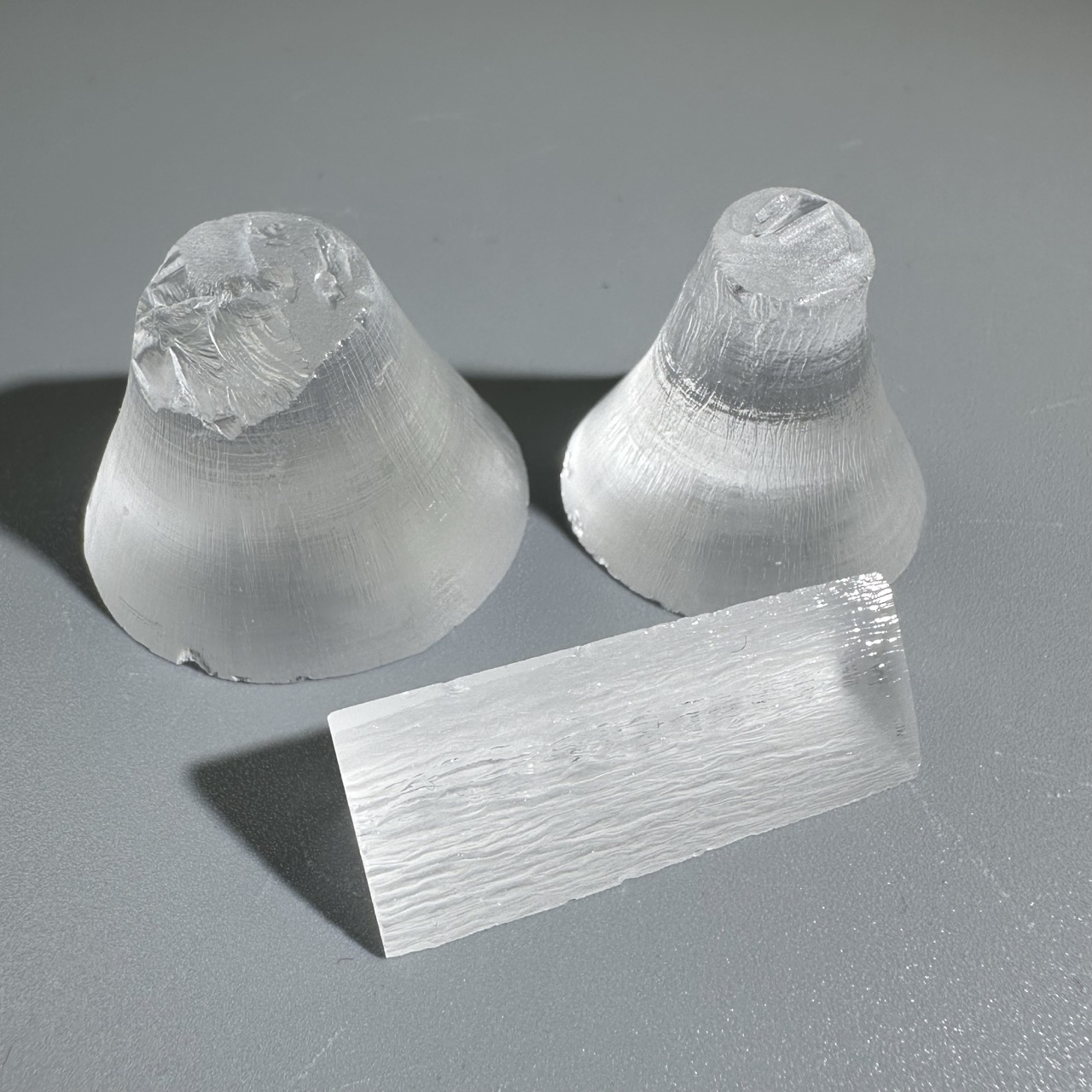

Girazi remaziso: Quartz, microcrystalline, K9, nezvimwe.

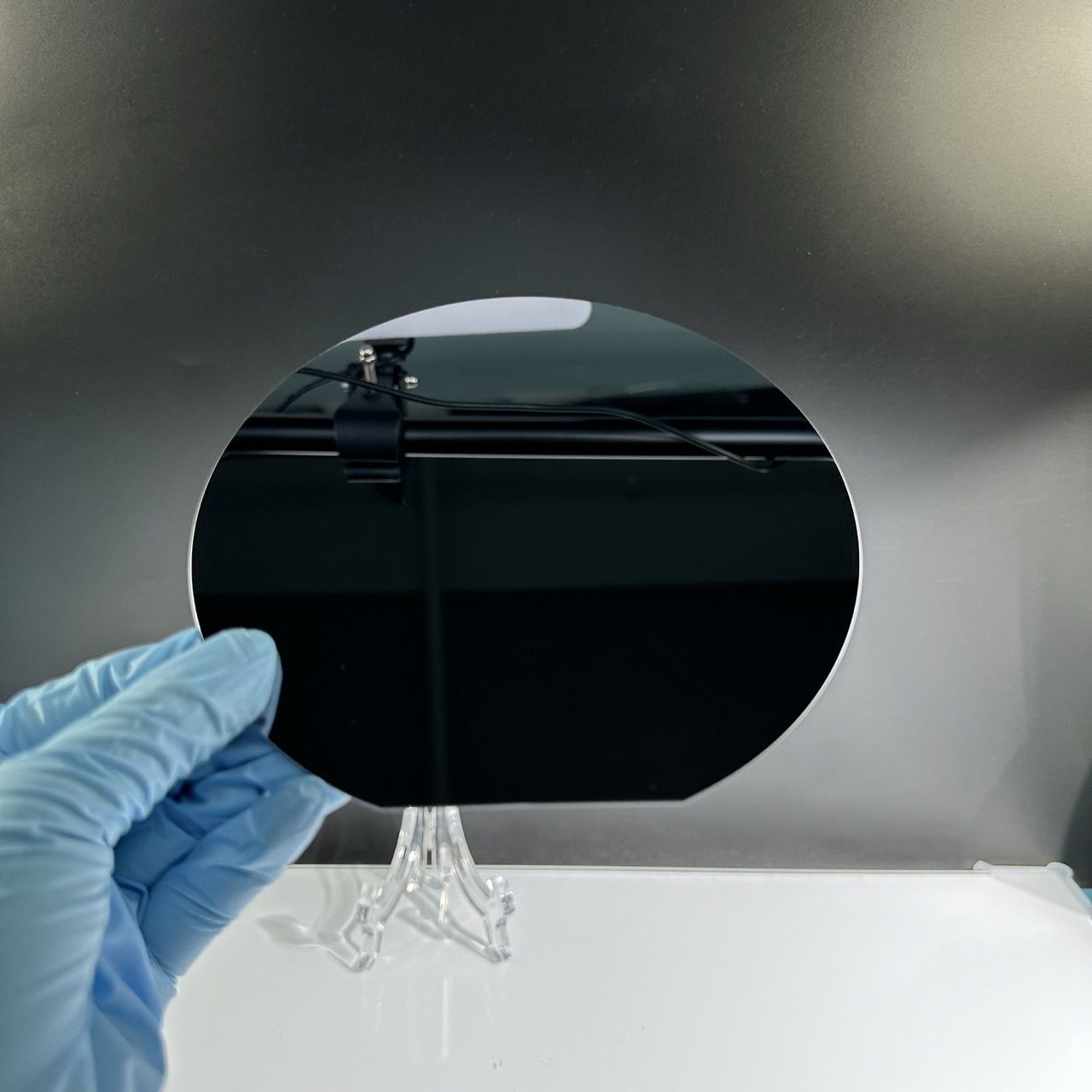

Infrared zvinhu: Silicon, germanium, nezvimwe.

Metals: Aluminium, Stainless simbi, titanium alloy, nezvimwe.

Makristasi: YAG, single-crystal silicon carbide, nezvimwe.

Zvakaoma / brittle zvinhu: Silicon carbide, nezvimwe.

Surface Hunhu / Precision

PV <10 nm

RMS ≤ 0.5 nm

Kugadzirisa Nyaya Zvidzidzo zveIon Beam Kupukuta Muchina

Nyaya 1 - Standard Flat Mirror

Workpiece: D630 mm quartz flat

Mhedzisiro: PV 46.4 nm; RMS 4.63 nm

Nyaya yechipiri - X-ray Reflective Mirror

Workpiece: 150 × 30 mm silicon flat

Mhedzisiro: PV 8.3 nm; RMS 0.379 nm; Mutserendende 0.13 µrad

Nyaya 3 - Off-Axis Mirror

Workpiece: D326 mm kure-axis pasi girazi

Mhedzisiro: PV 35.9 nm; RMS 3.9 nm

FAQ yeMagirazi eQuartz

FAQ – Ion Beam Polishing Machine

Q1: Chii chinonzi ion beam polishing?

A1:Ion beam polishing inzira isingabatanidzi iyo inoshandisa danda rakatariswa reion (senge argon ions) kubvisa zvinhu kubva panzvimbo yebasa. Iwo maion anokwidziridzwa uye anonangidzirwa kumusoro, zvichikonzera kubviswa kwezvinhu zveatomiki, zvichikonzera kupera kwakatsetseka. Iyi nzira inobvisa kushushikana kwemechini uye kukuvara kwepasi, zvichiita kuti ive yakakodzera kune chaiyo optical zvikamu.

Q2: Ndeapi marudzi enzvimbo anogona iyo Ion Beam Polishing Machine process?

A2:TheIon Beam Polishing Machineinogona kugadzirisa akasiyana siyana, kusanganisira akareruka optical components seflats, spheres, uye prism, pamwe chete nejometri dzakaoma seaspheres, off-axis aspheres,uyefreeform surfaces. Inonyanya kushanda pazvinhu zvakaita segirazi remaziso, infrared optics, simbi, uye zvakaoma/brittle zvinhu.

Q3: Ndezvipi zvinhu zvinogona kushanda neIon Beam Polishing Machine?

A3:TheIon Beam Polishing Machineinogona kukwenenzvera zvakasiyana siyana zvezvinhu, zvinosanganisira:

-

Optical girazi: Quartz, microcrystalline, K9, nezvimwe.

-

Infrared zvinhu: Silicon, germanium, nezvimwe.

-

Metals: Aluminium, simbi isina tsvina, titanium alloy, nezvimwe.

-

Crystal zvinhu: YAG, single-crystal silicon carbide, nezvimwe.

-

Zvimwe zvinhu zvakaoma/zvakaoma: Silicon carbide, nezvimwe.

Nezvedu

XKH inyanzvi mukusimudzirwa kwepamusoro-soro, kugadzira, uye kutengesa kwegirazi remaziso uye zvinhu zvitsva zvekristaro. Zvigadzirwa zvedu zvinoshanda zvemagetsi zvemagetsi, zvemagetsi zvevatengi, uye mauto. Isu tinopa Sapphire optical components, nharembozha lens inovhara, Ceramics, LT, Silicon Carbide SIC, Quartz, uye semiconductor crystal wafers. Nehunyanzvi hunyanzvi uye yekucheka-kumucheto michina, isu tinokunda mune isiri-yakajairwa chigadzirwa kugadzirisa, tichivavarira kuve inotungamira optoelectronic zvinhu zvepamusoro-tech bhizinesi.