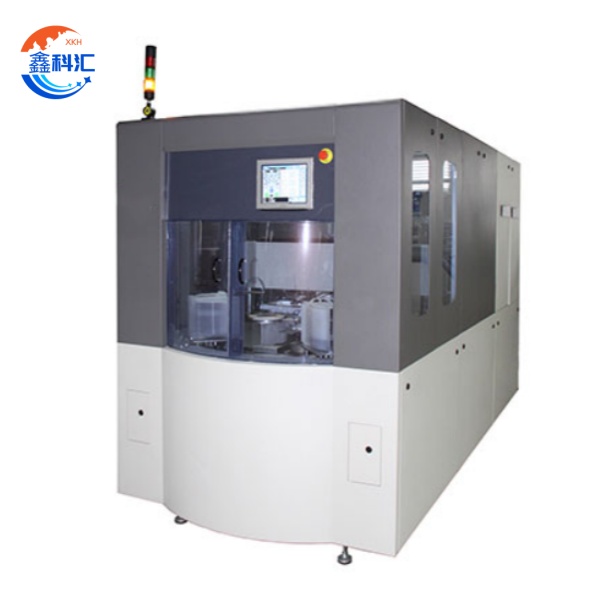

Wafer Thinning Equipment ye 4 Inch-12 Inch Sapphire/SiC/Si Wafers Processing

Kushanda Nheyo

Iyo wafer thinning process inoshanda nematanho matatu:

Kukuya Kwakashata: Gumbo redhaimani (grit size 200–500 μm) rinobvisa 50–150 μm yezvinhu pa3000–5000 rpm kukurumidza kuderedza ukobvu.

Kukuya Kwakanaka: Gumbo rakatsetseka (grit size 1–50 μm) rinoderedza ukobvu kusvika pa20–50 μm pa<1 μm/s kuderedza kukuvadzwa kwepasi.

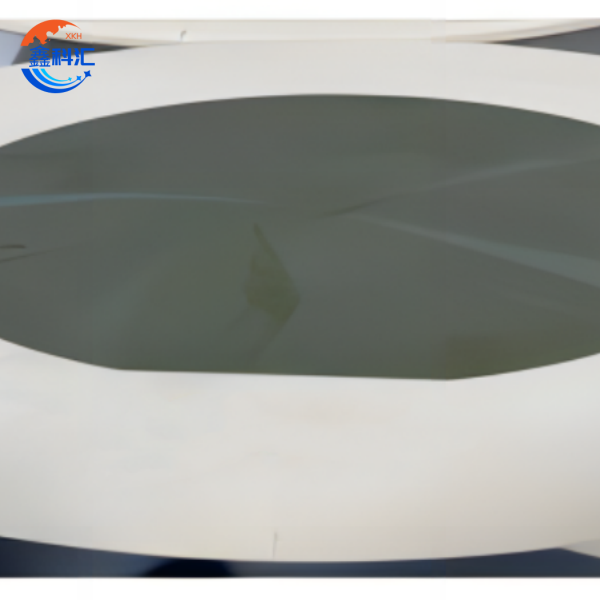

Polishing (CMP): A kemikari-mechanicha slurry inobvisa yakasara kukuvara, kuwana Ra <0.1 nm.

Zvinoenderana Zvinhu

Silicon (Si): Yakajairwa yeCMOS wafers, yakatetepa kusvika 25 μm ye 3D stacking.

Silicon Carbide (SiC): Inoda akasarudzika mavhiri edhaimondi (80% dhaimondi concentration) yekugadzikana kwekupisa.

Sapphire (Al₂O₃): Yakatetepa kusvika pa50 μm yeUV LED maapplication.

Core System Zvikamu

1. Grinding System

Dual-Axis Grinder: Inosanganisa coarse / yakanaka kukuya mupuratifomu imwe chete, ichidzikisa kutenderera nguva ne40%.

Aerostatic Spindle: 0-6000 rpm kumhanya siyana ne <0.5 μm radial runout.

2. Wafer Handling System

Vacuum Chuck: > 50 N inobata simba ne ± 0.1 μm kunyatsomira.

Robotic Arm: Inotakura 4-12-inch wafers pa100 mm/s.

3. Control System

Laser Interferometry: Chaiyo-nguva ukobvu yekutarisa (chisarudzo 0.01 μm).

AI-Inotyairwa Feedforward: Inofanotaura kupfeka kwemavhiri uye inogadzirisa paramita otomatiki.

4. Kutonhodza & Kuchenesa

Ultrasonic Kuchenesa: Inobvisa zvimedu> 0.5 μm ine 99.9% kunyatsoita.

Deionized Mvura: Inotonhorera wafer kusvika <5 ° C pamusoro pe ambient.

Core Zvakanakira

1. Ultra-High Precision: TTV (Total Thickness Variation) <0.5 μm, WTW (Mukati-Wafer Makobvu Kusiyana) <1 μm.

2. Multi-Process Kubatanidzwa: Inobatanidza kukuya, CMP, uye plasma etching mumushini mumwe.

3. Kuenderana kwezvinhu:

Silicon: kuderedzwa kwehukobvu kubva 775 μm kusvika 25 μm.

SiC: Inowana <2 μm TTV yeRF application.

Doped Wafers: Phosphorus-doped InP wafers ane <5% resistivity Drift.

4. Smart Automation: Kubatanidzwa kweMES kunoderedza kukanganisa kwevanhu ne70%.

5. Kushanda Kwesimba: 30% yakaderera simba rekushandisa kuburikidza neregenerative braking.

Key Applications

1. Advanced Packaging

• 3D ICs: Wafer thinning inogonesa kuturikidzana kwakatwasuka kwelogic/memory machipisi (eg, HBM stacks), kuwana 10× yepamusoro bandwidth uye 50% kuderedza kushandiswa kwemagetsi kuchienzaniswa ne2.5D mhinduro. Iyo midziyo inotsigira hybrid bonding uye TSV (Kuburikidza neSilicon Via) kubatanidzwa, yakakosha kune AI/ML processors inoda <10 μm yekubatanidza pitch. Semuyenzaniso, gumi nemaviri-inch wafers akatetepa kusvika 25 μm anobvumira kurongedza 8+ akaturikidzana uchichengeta <1.5% warpage, yakakosha kune mota LiDAR masisitimu.

• Fan-Out Packaging: Nekudzikisa ukobvu hwewafer kusvika pa30 μm, kureba kwekubatanidza kunopfupikiswa ne50%, kuderedza kunonoka kwechiratidzo (<0.2 ps/mm) uye kugonesa 0.4 mm ultra-thin chipsets for mobile SoCs. Maitiro acho anowedzera kushushikana-kudzoreredzwa kukuya algorithms kudzivirira warpage (> 50 μm TTV kutonga), kuve nechokwadi kuvimbika mune yakakwirira-frequency RF zvikumbiro.

2. Power Electronics

• IGBT Modules: Kuonda kusvika ku50 μm kunoderedza kupisa kwekushisa kusvika ku <0.5 ° C/W, zvichiita kuti 1200V SiC MOSFETs ishande pa 200 ° C junction tembiricha. Midziyo yedu inoshandisa akawanda-nhanho kukuya (yakaomarara: 46 μm grit → yakanaka: 4 μm grit) kubvisa kukuvadzwa kwepasi, kuwana> gumi,000 kutenderera kweanopisa bhasikoro kuvimbika. Izvi zvakakosha kune EV inverters, uko 10 μm-yakakora SiC wafers inovandudza switching kumhanya ne30%.

• GaN-on-SiC Power Devices: Wafer kutetepa kusvika ku80 μm kunonatsiridza kufamba kwemaerekitironi (μ > 2000 cm²/V·s) ye650V GaN HEMTs, kuderedza kurasikirwa kwekuita ne18%. Iyo maitiro inoshandisa laser-inobatsirwa dicing, kudzivirira kutsemuka panguva yekutetepa, kuwana <5 μm edge chipping yeRF simba amplifiers.

3. Optoelectronics

• GaN-on-SiC LEDs: 50 μm sapphire substrates inovandudza chiedza chekubudisa chiedza (LEE) kusvika ku85% (vs. 65% ye 150 μm wafers) nekuderedza kutora photon. Midziyo yedu yekupedzisira-yakaderera TTV kutonga (<0.3 μm) inova nechokwadi chekubuda kwe LED mukati me 12-inch wafers, yakakosha kune Micro-LED kuratidza inoda <100nm wavelength kufanana.

• Silicon Photonics: 25μm-yakakora silicon wafers inogonesa 3 dB / cm yakaderera kupararira kurasikirwa mumawaveguides, yakakosha kune 1.6 Tbps transceivers optical. Iyo nzira inobatanidza CMP kutsvedzerera kuderedza kushata kwepamusoro kuRa <0.1 nm, inosimudzira kubatanidza kushanda zvakanaka ne40%.

4. MEMS Sensors

• Accelerometers: 25 μm silicon wafers anobudirira SNR > 85 dB (vs. 75 dB ye 50 μm wafers) nekuwedzera proof-mass displacement senitivity. Yedu mbiri-axis grinding system inotsiva mafambiro ekushushikana, kuve nechokwadi kuti <0.5% senitivity inokukurwa pamusoro -40°C kusvika 125°C. Zvishandiso zvinosanganisira kuona kuparara kwemotokari uye AR/VR kufamba kwekutevera.

• Kuonda kunosvika 40 μm kunogonesa 0–300 kuyera mabhara—ne<0.1% FS hysteresis. Uchishandisa kwenguva pfupi bonding (magirazi anotakura), maitiro anodzivirira kuputsika kwewaferi panguva yekumashure etching, kuwana <1 μm overpressure kushivirira kune maindasitiri IoT sensors.

• Technical Synergy: Midziyo yedu yakapfava inobatanidza kukuya, CMP, uye plasma etching kugadzirisa matambudziko akasiyana-siyana (Si, SiC, Sapphire). Semuenzaniso, GaN-on-SiC inoda kukuya yakasanganiswa (mavhiri ediamond + plasma) kuenzanisa kuomarara uye kuwedzera kwemafuta, nepo MEMS sensors inoda sub-5 nm pamusoro roughness kuburikidza neCMP polishing.

• Impact yeIndasitiri: Nekugonesa mawafer akatetepa, epamusoro-soro, tekinoroji iyi inotyaira zvitsva muAI chips, 5G mmWave modules, nemagetsi anochinjika, ane TTV tolerances <0.1 μm yezviratidziro zvinopetwa uye <0.5 μm yemotokari LiDAR sensors.

XKH's Services

1. Customized Solutions

Scalable Configurations: 4-12-inch kamuri madhizaini ane otomatiki kurodha / kurodha.

Rutsigiro rweDoping: Tsika mabikirwo eEr/Yb-doped makristasi uye InP/GaAs wafers.

2. End-to-End Support

Kuvandudza Maitiro: Yemahara muyedzo unomhanya ne optimization.

Global Training: Tekinoroji workshops gore negore pamusoro pekugadzirisa uye kugadzirisa matambudziko.

3. Multi-Material Processing

SiC: Wafer kutetepa kusvika ku100 μm ine Ra <0.1 nm.

Safire: 50μm ukobvu kune UV laser windows (transmittance> 92%@200 nm).

4. Value-Added Services

Consumable Supply: Diamond mavhiri (2000+ wafers / hupenyu) uye CMP slurries.

Mhedziso

Iyi wafer yekutetepa michina inopa indasitiri inotungamira chaiyo, yakawanda-yezvinhu zvakasiyana-siyana, uye yakangwara otomatiki, zvichiita kuti ive yakakosha pakubatanidzwa kwe3D uye magetsi emagetsi. XKH masevhisi akazara-kubva pakugadzirisa kusvika ku-post-processing-ve nechokwadi chekuti vatengi vanowana mutengo unoshanda uye hunyanzvi hwekuita mukugadzira semiconductor.