4H-N HPSI SiC wafer 6H-N 6H-P 3C-N SiC Epitaxial wafer yeMOS kana SBD

SiC Substrate SiC Epi-wafer Brief

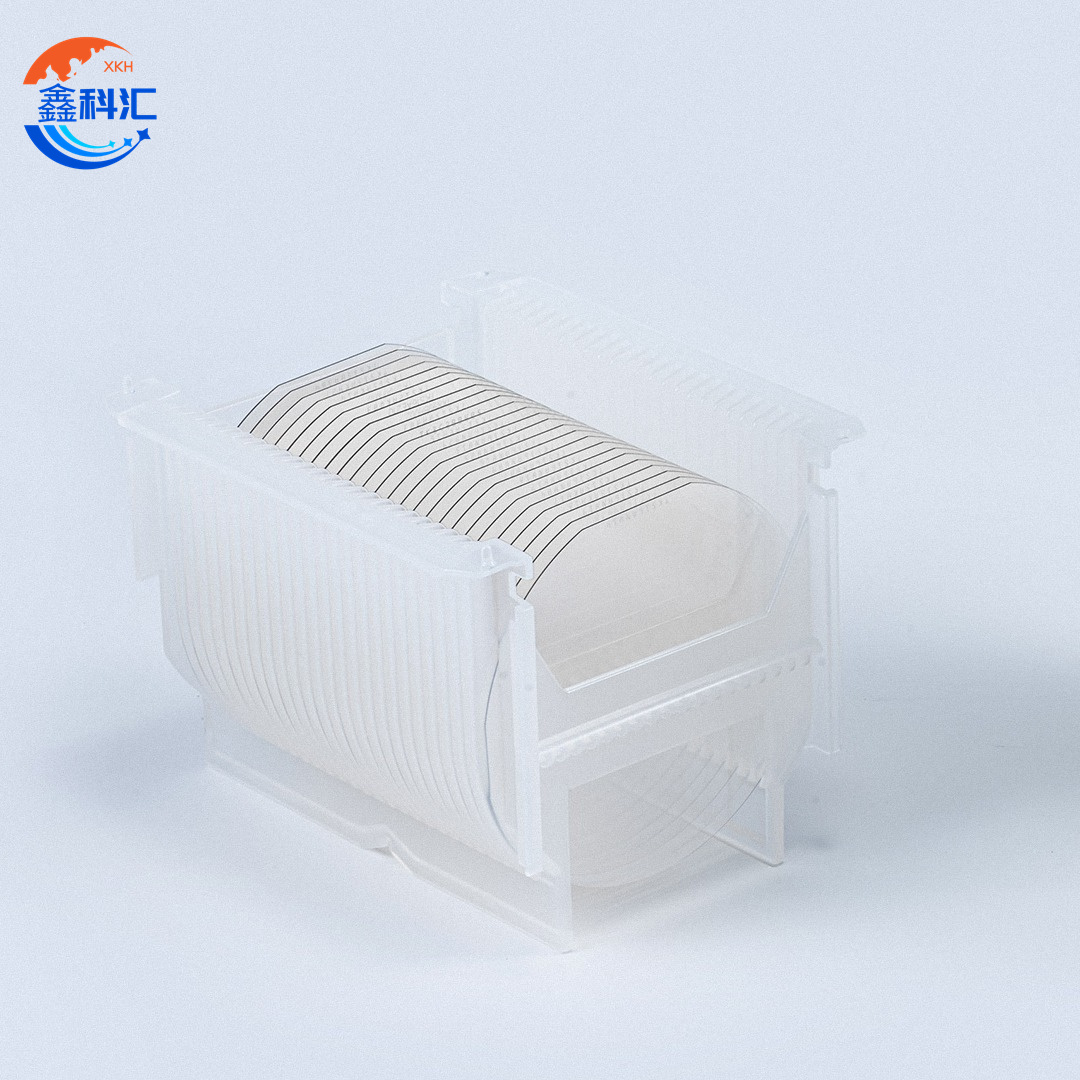

Isu tinopa yakazara-yemhando yepamusoro SiC substrates uye sic wafers mune akawanda polytypes uye doping profiles-kusanganisira 4H-N (n-mhando conductive), 4H-P (p-mhando conductive), 4H-HPSI (yakakwirira-purity semi-insulating), uye 6H-P (p-mhando conductive)-mamita 4 ″ kubva 6 ″ ″ ″ ″, 4 ″ ″ madhayamita, 8 kusvika ku12 ″. Kupfuura ma substrates asina chinhu, yedu yakawedzera kukosha epi wafer kukura masevhisi anoburitsa epitaxial (epi) mawaferi ane akanyatso kudzora ukobvu (1-20 µm), doping concentrations, uye kuremara densities.

Imwe neimwe sic wafer uye epi wafer inoongororwa zvakasimba mu-line (micropipe density <0.1 cm⁻², kushata kwepamusoro Ra <0.2 nm) uye kuzara kwemagetsi maitiro (CV, resistivity mepu) kuve nechokwadi chakasiyana chekristaro kufanana uye kuita. Ingave ichishandiswa kumagetsi emagetsi modules, yakakwira-frequency RF amplifiers, kana optoelectronic zvishandiso (LEDs, photodetectors), yedu SiC substrate uye epi wafer chigadzirwa mitsara inoburitsa kuvimbika, kugadzikana kwemafuta, uye kuparara kwesimba rinodiwa neanhasi anodiwa maapplication.

SiC Substrate 4H-N mhando yezvivakwa uye mashandisiro

-

4H-N SiC substrate Polytype (Hexagonal) Chimiro

Wide bandgap ye ~ 3.26 eV inochengetedza kushanda kwemagetsi kwakagadzikana uye kusimba kwekushisa pasi pekushisa kwepamusoro-soro uye high-electric-field field.

-

SiC substrateN-Type Doping

Kunyatsodzorwa nitrogen doping inoburitsa mutakuri wemutakuri kubva pa1×10¹⁶ kusvika 1×10¹⁹ cm⁻³ uye tembiricha yemagetsi emukamuri-inokwira kusvika ~900 cm²/V·s, zvichideredza kurasikirwa kwekuita.

-

SiC substrateWide Resistivity & Uniformity

Inowanikwa resistivity range ye0.01–10 Ω·cm uye wafer makubvu e350–650 µm ine ±5% kushivirira mune zvese doping uye ukobvu-yakanakira kugadzirwa kwesimba repamusoro-simba.

-

SiC substrateUltra-Low Defect Density

Micropipe density < 0.1 cm⁻² uye basal-ndege dislocation density < 500 cm⁻², kuburitsa > 99% goho remudziyo uye hunhu hwekristaro hwepamusoro.

- SiC substrateExceptional Thermal Conductivity

Thermal conductivity inosvika ~ 370 W/m·K inobatsira kubvisa kupisa kwakanaka, kuwedzera kuvimbika kwechigadzirwa uye kuwanda kwemagetsi.

-

SiC substrateTarget Applications

SiC MOSFETs, Schottky diodes, magetsi modules uye RF zvishandiso zvemagetsi-motokari madhiraivha, solar inverters, maindasitiri madhiraivha, traction masisitimu, uye mamwe anoda simba-emagetsi misika.

6inch 4H-N mhando yeSiC wafer's yakatarwa | ||

| Property | Zero MPD Yekugadzira Giredhi (Z Giredhi) | Dummy Giredhi (D giredhi) |

| Giredhi | Zero MPD Yekugadzira Giredhi (Z Giredhi) | Dummy Giredhi (D giredhi) |

| Diameter | 149.5 mm - 150.0 mm | 149.5 mm - 150.0 mm |

| Poly-mhando | 4H | 4H |

| Ukobvu | 350 µm ± 15 µm | 350 µm ± 25 µm |

| Wafer Orientation | Kunze kweaxis: 4.0 ° yakananga <1120> ± 0.5 ° | Kunze kweaxis: 4.0 ° yakananga <1120> ± 0.5 ° |

| Micropipe Density | ≤ 0.2cm² | ≤ 15 cm² |

| Resistivity | 0.015 - 0.024 Ω·cm | 0.015 - 0.028 Ω·cm |

| Yekutanga Flat Oriental | [10-10] ± 50° | [10-10] ± 50° |

| Primary Flat Length | 475 mm ± 2.0 mm | 475 mm ± 2.0 mm |

| Kusabatanidzwa kumucheto | 3 mm | 3 mm |

| LTV / TIV / Bow / Warp | ≤ 2.5 µm / ≤ 6 µm / ≤ 25 µm / ≤ 35 µm | ≤ 5 µm / ≤ 15 µm / ≤ 40 µm / ≤ 60 µm |

| Kukasharara | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Edge Cracks By High Intensity Chiedza | Cumulative kureba ≤ 20 mm kureba imwe chete ≤ 2 mm | Cumulative kureba ≤ 20 mm kureba imwe chete ≤ 2 mm |

| Hex Plates By High Intensity Chiedza | Cumulative area ≤ 0.05% | Cumulative area ≤ 0.1% |

| Polytype Nzvimbo NeKusimba Kwakanyanya Chiedza | Cumulative area ≤ 0.05% | Yakawedzerwa nzvimbo ≤ 3% |

| Visual Carbon Inclusions | Cumulative area ≤ 0.05% | Kuwedzera nzvimbo ≤ 5% |

| Silicon Surface Scratches By High Intensity Chiedza | Hurefu hwekuwedzera ≤ 1 wafer dhayamita | |

| Edge Chips By High Intensity Chiedza | Hapana anotenderwa ≥ 0.2 mm hupamhi nekudzika | 7 inotenderwa, ≤ 1 mm imwe neimwe |

| Threading Screw Dislocation | <500cm³ | <500cm³ |

| Silicon Surface Kusvibiswa NeKunyanya Kusimba Chiedza | ||

| Packaging | Multi-wafer Cassette Kana Single Wafer Container | Multi-wafer Cassette Kana Single Wafer Container |

8inch 4H-N mhando yeSiC wafer's yakatarwa | ||

| Property | Zero MPD Yekugadzira Giredhi (Z Giredhi) | Dummy Giredhi (D giredhi) |

| Giredhi | Zero MPD Yekugadzira Giredhi (Z Giredhi) | Dummy Giredhi (D giredhi) |

| Diameter | 199.5 mamirimita - 200.0 mamirimita | 199.5 mamirimita - 200.0 mamirimita |

| Poly-mhando | 4H | 4H |

| Ukobvu | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Wafer Orientation | 4.0° yakananga <110> ± 0.5° | 4.0° yakananga <110> ± 0.5° |

| Micropipe Density | ≤ 0.2cm² | ≤ 5cm² |

| Resistivity | 0.015 - 0.025 Ω·cm | 0.015 - 0.028 Ω·cm |

| Noble Orientation | ||

| Kusabatanidzwa kumucheto | 3 mm | 3 mm |

| LTV / TIV / Bow / Warp | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 70 µm | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 100 µm |

| Kukasharara | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Edge Cracks By High Intensity Chiedza | Cumulative kureba ≤ 20 mm kureba imwe chete ≤ 2 mm | Cumulative kureba ≤ 20 mm kureba imwe chete ≤ 2 mm |

| Hex Plates By High Intensity Chiedza | Cumulative area ≤ 0.05% | Cumulative area ≤ 0.1% |

| Polytype Nzvimbo NeKusimba Kwakanyanya Chiedza | Cumulative area ≤ 0.05% | Yakawedzerwa nzvimbo ≤ 3% |

| Visual Carbon Inclusions | Cumulative area ≤ 0.05% | Kuwedzera nzvimbo ≤ 5% |

| Silicon Surface Scratches By High Intensity Chiedza | Hurefu hwekuwedzera ≤ 1 wafer dhayamita | |

| Edge Chips By High Intensity Chiedza | Hapana anotenderwa ≥ 0.2 mm hupamhi nekudzika | 7 inotenderwa, ≤ 1 mm imwe neimwe |

| Threading Screw Dislocation | <500cm³ | <500cm³ |

| Silicon Surface Kusvibiswa NeKunyanya Kusimba Chiedza | ||

| Packaging | Multi-wafer Cassette Kana Single Wafer Container | Multi-wafer Cassette Kana Single Wafer Container |

4H-SiC ndeyepamusoro-inoshanda zvinhu zvinoshandiswa pamagetsi emagetsi, RF zvishandiso, uye yakakwirira-tembiricha maapplication. Iyo "4H" inoreva chimiro chekristaro, icho chine hexagonal, uye iyo "N" inoratidza mhando yedoping inoshandiswa kukwenenzvera kuita kwechinhu.

The4H-SiCtype inonyanya kushandiswa ku:

Power Electronics:Inoshandiswa mumidziyo yakaita sedhiodhi, MOSFETs, uye IGBTs yemagetsi mota powertrains, maindasitiri muchina, uye renewable simba masisitimu.

5G Technology:Iine 5G's kudiwa kwepamusoro-frequency uye yakakwirira-inoshanda zvikamu, kugona kweSiC kubata yakakwira voltages uye kushanda pakupisa kwakanyanya kunoita kuti ive yakanakira base station magetsi amplifiers uye RF zvishandiso.

Solar Energy Systems:SiC's yakanakisa masimba ekubata masimba akanakira photovoltaic (solar simba) inverters uye converters.

Mota dzemagetsi (EVs):SiC inoshandiswa zvakanyanya muEV powertrains kuti iwedzere kushanda nesimba shanduko, yakaderera kupisa kupisa, uye yakakwirira simba density.

SiC Substrate 4H Semi-Insulating mhando yezvivakwa uye mashandisiro

Properties:

-

Micropipe-isina density control maitiro: Inovimbisa kusavapo kwemakropipe, inovandudza substrate mhando.

-

Monocrystalline control maitiro: Inovimbisa imwe kristaro chimiro chekusimudzira zvinhu zvivakwa.

-

Inclusions kudzora maitiro: Inoderedza kuvapo kwetsvina kana inclusions, kuve nechokwadi che substrate yakachena.

-

Resistivity control techniques: Inobvumira kunyatso kudzora kwemagetsi resistivity, iyo yakakosha pakuita kwechishandiso.

-

Kusachena kudzora uye maitiro ekudzora: Inogadzirisa uye inodzikamisa kuiswa kwetsvina kuchengetedza substrate kutendeseka.

-

Substrate nhanho upamhi hwekudzora maitiro: Inopa kutonga kwakaringana pamusoro pehupamhi hwenhanho, kuve nechokwadi chekuenderana pane iyo substrate

6Inch 4H-semi SiC substrate tsanangudzo | ||

| Property | Zero MPD Yekugadzira Giredhi (Z Giredhi) | Dummy Giredhi (D giredhi) |

| Dhayamita (mm) | 145 mm - 150 mm | 145 mm - 150 mm |

| Poly-mhando | 4H | 4H |

| Ukobvu (um) | 500 ± 15 | 500 ± 25 |

| Wafer Orientation | Paaxis: ± 0.0001 ° | Paakisi: ±0.05° |

| Micropipe Density | ≤ 15 cm-2 | ≤ 15 cm-2 |

| Kusagadzikana (Ωcm) | ≥ 10E3 | ≥ 10E3 |

| Yekutanga Flat Oriental | (0-10)° ± 5.0° | (10-10)° ± 5.0° |

| Primary Flat Length | Notch | Notch |

| Kusabatanidzwa kumucheto (mm) | ≤ 2.5 µm / ≤ 15 µm | ≤ 5.5 µm / ≤ 35 µm |

| LTV / Bowl / Warp | ≤ 3 µm | ≤ 3 µm |

| Kukasharara | Polish Ra ≤ 1.5 µm | Polish Ra ≤ 1.5 µm |

| Edge Chips By High Intensity Chiedza | ≤ 20 µm | ≤ 60 µm |

| Kupisa Plates NeChiedza Chakanyanya Kusimba | Kuwedzera ≤ 0.05% | Kuwedzera ≤ 3% |

| Polytype Nzvimbo NeKusimba Kwakanyanya Chiedza | Visual Carbon Inclusions ≤ 0.05% | Kuwedzera ≤ 3% |

| Silicon Surface Scratches By High Intensity Chiedza | ≤ 0.05% | Kuwedzera ≤ 4% |

| Edge Chips NeHigh Intensity Chiedza (Size) | Hazvibvumirwi> 02 mm Kufara uye Kudzika | Hazvibvumirwi> 02 mm Kufara uye Kudzika |

| The Aiding screw Dilation | ≤ 500 µm | ≤ 500 µm |

| Silicon Surface Kusvibiswa NeKunyanya Kusimba Chiedza | ≤ 1 x 10^5 | ≤ 1 x 10^5 |

| Packaging | Multi-wafer Cassette kana Single Wafer Container | Multi-wafer Cassette kana Single Wafer Container |

4-Inch 4H-Semi Insulating SiC Substrate Tsanangudzo

| Parameter | Zero MPD Yekugadzira Giredhi (Z Giredhi) | Dummy Giredhi (D giredhi) |

|---|---|---|

| Zvinhu Zvenyama | ||

| Diameter | 99.5 mm - 100.0 mm | 99.5 mm - 100.0 mm |

| Poly-mhando | 4H | 4H |

| Ukobvu | 500 μm ± 15 μm | 500 μm ± 25 μm |

| Wafer Orientation | Paaxis: <600h> 0.5° | Paaxis: <000h> 0.5° |

| Electrical Properties | ||

| Micropipe Density (MPD) | ≤1 cm⁻² | ≤15 cm⁻² |

| Resistivity | ≥150 Ω·cm | ≥1.5 Ω·cm |

| Geometric Tolerances | ||

| Yekutanga Flat Oriental | (0x10) ± 5.0° | (0x10) ± 5.0° |

| Primary Flat Length | 52.5 mm ± 2.0 mm | 52.5 mm ± 2.0 mm |

| Secondary Flat Length | 18.0 mm ± 2.0 mm | 18.0 mm ± 2.0 mm |

| Secondary Flat Orientation | 90 ° CW kubva kuPrime flat ± 5.0 ° (Si kutarisana kumusoro) | 90 ° CW kubva kuPrime flat ± 5.0 ° (Si kutarisana kumusoro) |

| Kusabatanidzwa kumucheto | 3 mm | 3 mm |

| LTV / TTV / Bow / Warp | ≤2.5 μm / ≤5 μm / ≤15 μm / ≤30 μm | ≤10 μm / ≤15 μm / ≤25 μm / ≤40 μm |

| Surface Quality | ||

| Kushata Kwepamusoro (Polish Ra) | ≤1 nm | ≤1 nm |

| Surface roughness (CMP Ra) | ≤0.2 nm | ≤0.2 nm |

| Edge Cracks (High-Intensity Chiedza) | Hazvibvumirwi | Kureba kwekuwedzera ≥10 mm, kutsemuka kamwe chete ≤2 mm |

| Hexagonal Plate Defects | ≤0.05% yakawedzera nzvimbo | ≤0.1% yakawedzera nzvimbo |

| Polytype Inclusion Nzvimbo | Hazvibvumirwi | ≤1% yakawedzera nzvimbo |

| Visual Carbon Inclusions | ≤0.05% yakawedzera nzvimbo | ≤1% yakawedzera nzvimbo |

| Silicon Surface Scratches | Hazvibvumirwi | ≤1 wafer dhayamita yakawedzera kureba |

| Edge Chips | Hapana anotenderwa (≥0.2 mm hupamhi/kudzika) | ≤5 machipisi (imwe neimwe ≤1 mm) |

| Silicon Surface Kusvibiswa | Hazvina kutaurwa | Hazvina kutaurwa |

| Packaging | ||

| Packaging | Multi-wafer cassette kana single-wafer mudziyo | Multi-wafer cassette kana |

Application:

TheSiC 4H Semi-Insulating substratesanonyanya kushandiswa mune yakakwirira-simba uye yakakwirira-frequency zvigadzirwa zvemagetsi, kunyanya muRF munda. Aya ma substrates akakosha kune akasiyana maapplication anosanganisiramicrowave communication systems, phased array radar,uyemichina yemagetsi isina waya. Yavo yakakwirira yekupisa yekupisa uye yakanakisa hunhu hwemagetsi inoita kuti ive yakakodzera kune inoda maapplication mumagetsi emagetsi uye masisitimu ekutaurirana.

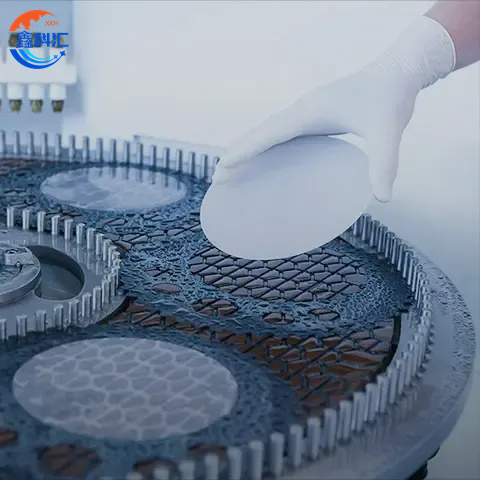

SiC epi wafer 4H-N mhando yezvivakwa uye kushandisa

SiC 4H-N Type Epi Wafer Properties uye maApplication

Zvivakwa zveSiC 4H-N Rudzi rweEpi Wafer:

Material Maumbirwo:

SiC (Silicon Carbide): Inozivikanwa nekuoma kwayo kwakatanhamara, yakakwira yekupisa conductivity, uye yakanakisa magetsi emagetsi, SiC yakanakira midziyo yemagetsi inoshanda kwazvo.

4H-SiC Polytype: Iyo 4H-SiC polytype inozivikanwa nehupamhi hwepamusoro uye kugadzikana mumagetsi ekushandisa.

N-mhando Doping: N-type doping (doped with nitrogen) inopa yakanakisa kufamba kweelectronic, zvichiita kuti SiC ikwane kune yakakwirira-frequency uye yakakwirira-simba maapplication.

High Thermal Conductivity:

SiC wafers ane yepamusoro yekupisa conductivity, kazhinji kubva120–200 W/m·K, zvichivabvumira kunyatsogadzirisa kupisa mumagetsi emagetsi epamusoro senge transistors uye diode.

Wide Bandgap:

Nebhandi re3.26 eV, 4H-SiC inogona kushanda nepamusoro-soro, mafrequency, uye tembiricha zvichienzaniswa neyakajairwa silicon-based zvishandiso, zvichiita kuti ive yakanaka kune yakakwirira-inoshanda, yepamusoro-yekuita maapplication.

Electrical Properties:

SiC's high electron mobility uye conductivity inoita kuti ive yakakodzeramagetsi emagetsi, inopa kukurumidza kushandura kumhanya uye yakakwirira ikozvino uye voltage kubata simba, zvichiita kuti iwedzere kushanda nesimba manejimendi masisitimu.

Mechanical uye Chemical Resistance:

SiC ndechimwe chezvinhu zvakaomarara, yechipiri chete kudhaimani, uye inoshingirira zvakanyanya kuoxidation uye ngura, zvichiita kuti igare munzvimbo dzakaoma.

Zvishandiso zveSiC 4H-N Type Epi Wafer:

Power Electronics:

SiC 4H-N mhando epi wafers anoshandiswa zvakanyanya mukatisimba MOSFETs, IGBTs,uyediodesnokutikushandura simbamumasisitimu akadaisolar inverters, motokari dzemagetsi,uyesimba rekuchengetedza maitiro, inopa kuwedzera kwekuita uye kushanda nesimba.

Mota dzemagetsi (EVs):

In motokari yemagetsi powertrains, mota controllers,uyekuchaja zviteshi, SiC wafers anobatsira kuwana zvirinani bhatiri, kukurumidza kuchaja, uye kunatsiridza kuita kwesimba rese nekuda kwekugona kwavo kubata simba rakakura uye tembiricha.

Renewable Energy Systems:

Solar Inverters: SiC wafers anoshandiswa mukatisolar energy systemsyekushandura DC simba kubva kune solar panels kuenda kuAC, ichiwedzera mashandiro ehurongwa hwese uye kuita.

Mhepo Turbines: SiC tekinoroji inoshandiswa mukatimhepo turbine control systems, kugadzirisa kugadzirwa kwemagetsi uye kutendeuka kushanda zvakanaka.

Aerospace uye Dziviriro:

SiC wafers akanakira kushandiswa mukatizvemagetsi zvemuchadengauyezvikumbiro zvechiuto, kusanganisiraradar systemsuyesatellite zvemagetsi, uko kukwirira kwemwaranzi kuramba uye kugadzikana kwekupisa kwakakosha.

Yepamusoro-Tembiricha uye Yakakwira-Frequency Application:

SiC wafers anokunda mukatihigh-temperature electronics, inoshandiswa muinjini dzendege, spacecraft,uyemaindasitiri kudziyisa hurongwa, sezvavanochengetedza kushanda mumamiriro ekupisa kwakanyanya. Pamusoro pezvo, yavo yakakura bhendi inobvumira kushandiswa mukatihigh-frequency applicationskufananaRF zvishandisouyemicrowave kutaurirana.

| 6-inch N-mhando epit axial tsanangudzo | |||

| Parameter | unit | Z-MOS | |

| Type | Condutivity / Dopant | - | N-mhando / Nitrogen |

| Buffer Layer | Buffer Layer Thickness | um | 1 |

| Buffer Layer Thickness Tolerance | % | ±20% | |

| Buffer Layer Concentration | cm-3 | 1.00E+18 | |

| Buffer Layer Concentration Tolerance | % | ±20% | |

| 1st Epi Layer | Epi Layer Ukobvu | um | 11.5 |

| Epi Layer Ukobvu Uniformity | % | ±4% | |

| Epi Layers Kukobvu Kushivirira ((Spec- Max , Maminitsi)/Special) | % | ±5% | |

| Epi Layer Concentration | cm-3 | 1E 15~ 1E 18 | |

| Epi Layer Concentration Tolerance | % | 6% | |

| Epi Layer Concentration Uniformity (σ /zvinoreva) | % | ≤5% | |

| Epi Layer Concentration Uniformity <(max-min)/(max+min> | % | ≤ 10% | |

| Epitaixal Wafer Shape | Bow | um | ≤±20 |

| WARP | um | ≤30 | |

| TTV | um | ≤ 10 | |

| LTV | um | ≤2 | |

| General Characteristics | Kureba kwekukwenya | mm | ≤30mm |

| Edge Chips | - | HAKUNA | |

| Defects defination | ≥97% (Yakayerwa ne2*2, Killer defects inosanganisira: Kukanganisa kunosanganisira Micropipe/Makomba makuru, Karoti, Triangular | ||

| Metal kusvibiswa | maatomu/cm² | d f i ≤5E10 maatomu/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Package | Packing specifications | pcs/bhokisi | multi-wafer cassette kana single wafer mudziyo |

| 8-inch N-mhando epitaxial tsanangudzo | |||

| Parameter | unit | Z-MOS | |

| Type | Condutivity / Dopant | - | N-mhando / Nitrogen |

| Buffer layer | Buffer Layer Thickness | um | 1 |

| Buffer Layer Thickness Tolerance | % | ±20% | |

| Buffer Layer Concentration | cm-3 | 1.00E+18 | |

| Buffer Layer Concentration Tolerance | % | ±20% | |

| 1st Epi Layer | Epi Layers Ukobvu Avhareji | um | 8~12 |

| Epi Layers Hukobvu Uniformity (σ/kureva) | % | ≤2.0 | |

| Epi Layers Hukobvu Kushivirira ((Spec -Max, Min)/Special) | % | ±6 | |

| Epi Layers Net Avhareji Doping | cm-3 | 8E+15 ~2E+16 | |

| Epi Layers Net Doping Uniformity (σ/kureva) | % | ≤5 | |

| Epi Layers Net DopingTolerance ((Spec -Max, | % | ± 10.0 | |

| Epitaixal Wafer Shape | Mi)/S) Warp | um | ≤50.0 |

| Bow | um | ± 30.0 | |

| TTV | um | ≤ 10.0 | |

| LTV | um | ≤4.0 (10mm×10mm) | |

| General Hunhu | Makwara | - | Cumulative kureba≤ 1/2Wafer dhayamita |

| Edge Chips | - | ≤2 machipisi, Yese radius≤1.5mm | |

| Surface Metals Kusvibiswa | maatomu/cm2 | ≤5E10 maatomu/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Defect Inspection | % | ≥ 96.0 (2X2 Kukanganisa kunosanganisira Micropipe / Makomba Makuru, Karoti, Triangular defects, Downfalls, Linear/IGSF-s, BPD) | |

| Surface Metals Kusvibiswa | maatomu/cm2 | ≤5E10 maatomu/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Package | Packing specifications | - | multi-wafer cassette kana single wafer mudziyo |

SiC wafer's Q&A

Q1: Ndeapi mabhenefiti akakosha ekushandisa SiC wafers pamusoro pechinyakare silicon wafers mumagetsi emagetsi?

A1:

SiC wafers inopa akati wandei akakosha mabhenefiti pamusoro pechinyakare silicon (Si) mawafer mumagetsi emagetsi, anosanganisira:

Kubudirira Kwepamusoro: SiC ine bandgap yakafara (3.26 eV) kana ichienzaniswa nesilicon (1.1 eV), ichibvumira michina kuti ishande pamagetsi epamusoro, ma frequency, uye tembiricha. Izvi zvinotungamirira kuderera kwesimba kurasikirwa uye kushanda kwepamusoro mumashandisi ekushandura simba.

High Thermal Conductivity: SiC's thermal conductivity yakakwirira kudarika iyo yesilicon, zvichiita kuti zviri nani kupisa kupisa mumagetsi e-high-power applications, izvo zvinovandudza kuvimbika uye hupenyu hwemagetsi emagetsi.

Yakakwira Voltage uye Yazvino Kubata: Zvishandiso zveSiC zvinogona kubata yakakwira voltage uye mazinga azvino, zvichiita kuti dzive dzakakodzera kushandiswa kwesimba repamusoro senge mota dzemagetsi, masisitimu emagetsi emagetsi, uye madhiraivha emuindasitiri.

Kukurumidza Kuchinja Kumhanya: Zvishandiso zveSiC zvine kukurumidza kushandura masimba, izvo zvinobatsira mukuderedza kurasikirwa kwesimba uye saizi yehurongwa, zvichiita kuti ive yakanaka kune yakakwira-frequency application.

Q2: Ndeapi mashandisirwo makuru eSiC wafers muindasitiri yemotokari?

A2:

Muindasitiri yemotokari, SiC wafers anonyanya kushandiswa mu:

Motokari yeMagetsi (EV) Powertrains: SiC-based components likeinvertersuyesimba MOSFETskunatsiridza kugona uye kuita kwemagetsi emagetsi emagetsi emagetsi nekugonesa kukurumidza kushandura kumhanya uye yakakwirira simba density. Izvi zvinotungamira kuhupenyu hurefu hwebhatiri uye zvirinani kuita mota kwese.

On-Board Charger: Zvishandiso zveSiC zvinobatsira kuvandudza kushanda kwe-on-board kuchaja masisitimu nekugonesa kukurumidza kuchaja nguva uye zvirinani kutonga kwemafuta, izvo zvakakosha kuti maEVs atsigire zviteshi zvekuchaja zvine simba.

Battery Management Systems (BMS): SiC tekinoroji inovandudza kugona kwebhatiri manejimendi masisitimu, zvichibvumira kudzorwa kwemagetsi zviri nani, kubata kwesimba repamusoro, uye hupenyu hurefu hwebhatiri.

DC-DC Converters: SiC wafers anoshandiswa mukatiDC-DC converterskushandura high-voltage DC simba kune yakaderera-voltage DC simba zvinobudirira, izvo zvakakosha mumotokari dzemagetsi kutonga simba kubva kubhatiri kuenda kuzvinhu zvakasiyana mumotokari.

Kuita kwepamusoro kweSiC muhigh-voltage, high-temperature, uye high-effective applications inoita kuti ive yakakosha pakuchinja kweindasitiri yemotokari kuenda kumagetsi.

6inch 4H-N mhando yeSiC wafer's yakatarwa | ||

| Property | Zero MPD Yekugadzira Giredhi (Z Giredhi) | Dummy Giredhi (D giredhi) |

| Giredhi | Zero MPD Yekugadzira Giredhi (Z Giredhi) | Dummy Giredhi (D giredhi) |

| Diameter | 149.5 mm - 150.0 mm | 149.5 mm - 150.0 mm |

| Poly-mhando | 4H | 4H |

| Ukobvu | 350 µm ± 15 µm | 350 µm ± 25 µm |

| Wafer Orientation | Kunze kweaxis: 4.0 ° yakananga <1120> ± 0.5 ° | Kunze kweaxis: 4.0 ° yakananga <1120> ± 0.5 ° |

| Micropipe Density | ≤ 0.2cm² | ≤ 15 cm² |

| Resistivity | 0.015 – 0.024 Ω·cm | 0.015 – 0.028 Ω·cm |

| Yekutanga Flat Oriental | [10-10] ± 50° | [10-10] ± 50° |

| Primary Flat Length | 475 mm ± 2.0 mm | 475 mm ± 2.0 mm |

| Kusabatanidzwa kumucheto | 3 mm | 3 mm |

| LTV / TIV / Bow / Warp | ≤ 2.5 µm / ≤ 6 µm / ≤ 25 µm / ≤ 35 µm | ≤ 5 µm / ≤ 15 µm / ≤ 40 µm / ≤ 60 µm |

| Kukasharara | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Edge Cracks By High Intensity Chiedza | Cumulative kureba ≤ 20 mm kureba imwe chete ≤ 2 mm | Cumulative kureba ≤ 20 mm kureba imwe chete ≤ 2 mm |

| Hex Plates By High Intensity Chiedza | Cumulative area ≤ 0.05% | Cumulative area ≤ 0.1% |

| Polytype Nzvimbo NeKusimba Kwakanyanya Chiedza | Cumulative area ≤ 0.05% | Yakawedzerwa nzvimbo ≤ 3% |

| Visual Carbon Inclusions | Cumulative area ≤ 0.05% | Kuwedzera nzvimbo ≤ 5% |

| Silicon Surface Scratches By High Intensity Chiedza | Hurefu hwekuwedzera ≤ 1 wafer dhayamita | |

| Edge Chips By High Intensity Chiedza | Hapana anotenderwa ≥ 0.2 mm hupamhi nekudzika | 7 inotenderwa, ≤ 1 mm imwe neimwe |

| Threading Screw Dislocation | <500cm³ | <500cm³ |

| Silicon Surface Kusvibiswa NeKunyanya Kusimba Chiedza | ||

| Packaging | Multi-wafer Cassette Kana Single Wafer Container | Multi-wafer Cassette Kana Single Wafer Container |

8inch 4H-N mhando yeSiC wafer's yakatarwa | ||

| Property | Zero MPD Yekugadzira Giredhi (Z Giredhi) | Dummy Giredhi (D giredhi) |

| Giredhi | Zero MPD Yekugadzira Giredhi (Z Giredhi) | Dummy Giredhi (D giredhi) |

| Diameter | 199.5 mm - 200.0 mm | 199.5 mm - 200.0 mm |

| Poly-mhando | 4H | 4H |

| Ukobvu | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Wafer Orientation | 4.0° yakananga <110> ± 0.5° | 4.0° yakananga <110> ± 0.5° |

| Micropipe Density | ≤ 0.2cm² | ≤ 5cm² |

| Resistivity | 0.015 – 0.025 Ω·cm | 0.015 – 0.028 Ω·cm |

| Noble Orientation | ||

| Kusabatanidzwa kumucheto | 3 mm | 3 mm |

| LTV / TIV / Bow / Warp | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 70 µm | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 100 µm |

| Kukasharara | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Edge Cracks By High Intensity Chiedza | Cumulative kureba ≤ 20 mm kureba imwe chete ≤ 2 mm | Cumulative kureba ≤ 20 mm kureba imwe chete ≤ 2 mm |

| Hex Plates By High Intensity Chiedza | Cumulative area ≤ 0.05% | Cumulative area ≤ 0.1% |

| Polytype Nzvimbo NeKusimba Kwakanyanya Chiedza | Cumulative area ≤ 0.05% | Yakawedzerwa nzvimbo ≤ 3% |

| Visual Carbon Inclusions | Cumulative area ≤ 0.05% | Kuwedzera nzvimbo ≤ 5% |

| Silicon Surface Scratches By High Intensity Chiedza | Hurefu hwekuwedzera ≤ 1 wafer dhayamita | |

| Edge Chips By High Intensity Chiedza | Hapana anotenderwa ≥ 0.2 mm hupamhi nekudzika | 7 inotenderwa, ≤ 1 mm imwe neimwe |

| Threading Screw Dislocation | <500cm³ | <500cm³ |

| Silicon Surface Kusvibiswa NeKunyanya Kusimba Chiedza | ||

| Packaging | Multi-wafer Cassette Kana Single Wafer Container | Multi-wafer Cassette Kana Single Wafer Container |

6Inch 4H-semi SiC substrate tsanangudzo | ||

| Property | Zero MPD Yekugadzira Giredhi (Z Giredhi) | Dummy Giredhi (D giredhi) |

| Dhayamita (mm) | 145 mm - 150 mm | 145 mm - 150 mm |

| Poly-mhando | 4H | 4H |

| Ukobvu (um) | 500 ± 15 | 500 ± 25 |

| Wafer Orientation | Paaxis: ± 0.0001 ° | Paakisi: ±0.05° |

| Micropipe Density | ≤ 15 cm-2 | ≤ 15 cm-2 |

| Kusagadzikana (Ωcm) | ≥ 10E3 | ≥ 10E3 |

| Yekutanga Flat Oriental | (0-10)° ± 5.0° | (10-10)° ± 5.0° |

| Primary Flat Length | Notch | Notch |

| Kusabatanidzwa kumucheto (mm) | ≤ 2.5 µm / ≤ 15 µm | ≤ 5.5 µm / ≤ 35 µm |

| LTV / Bowl / Warp | ≤ 3 µm | ≤ 3 µm |

| Kukasharara | Polish Ra ≤ 1.5 µm | Polish Ra ≤ 1.5 µm |

| Edge Chips By High Intensity Chiedza | ≤ 20 µm | ≤ 60 µm |

| Kupisa Plates NeChiedza Chakanyanya Kusimba | Kuwedzera ≤ 0.05% | Kuwedzera ≤ 3% |

| Polytype Nzvimbo NeKusimba Kwakanyanya Chiedza | Visual Carbon Inclusions ≤ 0.05% | Kuwedzera ≤ 3% |

| Silicon Surface Scratches By High Intensity Chiedza | ≤ 0.05% | Kuwedzera ≤ 4% |

| Edge Chips NeHigh Intensity Chiedza (Size) | Hazvibvumirwi> 02 mm Kufara uye Kudzika | Hazvibvumirwi> 02 mm Kufara uye Kudzika |

| The Aiding screw Dilation | ≤ 500 µm | ≤ 500 µm |

| Silicon Surface Kusvibiswa NeKunyanya Kusimba Chiedza | ≤ 1 x 10^5 | ≤ 1 x 10^5 |

| Packaging | Multi-wafer Cassette kana Single Wafer Container | Multi-wafer Cassette kana Single Wafer Container |

4-Inch 4H-Semi Insulating SiC Substrate Tsanangudzo

| Parameter | Zero MPD Yekugadzira Giredhi (Z Giredhi) | Dummy Giredhi (D giredhi) |

|---|---|---|

| Zvinhu Zvenyama | ||

| Diameter | 99.5 mm - 100.0 mm | 99.5 mm - 100.0 mm |

| Poly-mhando | 4H | 4H |

| Ukobvu | 500 μm ± 15 μm | 500 μm ± 25 μm |

| Wafer Orientation | Paaxis: <600h> 0.5° | Paaxis: <000h> 0.5° |

| Electrical Properties | ||

| Micropipe Density (MPD) | ≤1 cm⁻² | ≤15 cm⁻² |

| Resistivity | ≥150 Ω·cm | ≥1.5 Ω·cm |

| Geometric Tolerances | ||

| Yekutanga Flat Oriental | (0×10) ± 5.0° | (0×10) ± 5.0° |

| Primary Flat Length | 52.5 mm ± 2.0 mm | 52.5 mm ± 2.0 mm |

| Secondary Flat Length | 18.0 mm ± 2.0 mm | 18.0 mm ± 2.0 mm |

| Secondary Flat Orientation | 90 ° CW kubva kuPrime flat ± 5.0 ° (Si kutarisana kumusoro) | 90 ° CW kubva kuPrime flat ± 5.0 ° (Si kutarisana kumusoro) |

| Kusabatanidzwa kumucheto | 3 mm | 3 mm |

| LTV / TTV / Bow / Warp | ≤2.5 μm / ≤5 μm / ≤15 μm / ≤30 μm | ≤10 μm / ≤15 μm / ≤25 μm / ≤40 μm |

| Surface Quality | ||

| Kushata Kwepamusoro (Polish Ra) | ≤1 nm | ≤1 nm |

| Surface roughness (CMP Ra) | ≤0.2 nm | ≤0.2 nm |

| Edge Cracks (High-Intensity Chiedza) | Hazvibvumirwi | Kureba kwekuwedzera ≥10 mm, kutsemuka kamwe chete ≤2 mm |

| Hexagonal Plate Defects | ≤0.05% yakawedzera nzvimbo | ≤0.1% yakawedzera nzvimbo |

| Polytype Inclusion Nzvimbo | Hazvibvumirwi | ≤1% yakawedzera nzvimbo |

| Visual Carbon Inclusions | ≤0.05% yakawedzera nzvimbo | ≤1% yakawedzera nzvimbo |

| Silicon Surface Scratches | Hazvibvumirwi | ≤1 wafer dhayamita yakawedzera kureba |

| Edge Chips | Hapana anotenderwa (≥0.2 mm hupamhi/kudzika) | ≤5 machipisi (imwe neimwe ≤1 mm) |

| Silicon Surface Kusvibiswa | Hazvina kutaurwa | Hazvina kutaurwa |

| Packaging | ||

| Packaging | Multi-wafer cassette kana single-wafer mudziyo | Multi-wafer cassette kana |

| 6-inch N-mhando epit axial tsanangudzo | |||

| Parameter | unit | Z-MOS | |

| Type | Condutivity / Dopant | - | N-mhando / Nitrogen |

| Buffer Layer | Buffer Layer Thickness | um | 1 |

| Buffer Layer Thickness Tolerance | % | ±20% | |

| Buffer Layer Concentration | cm-3 | 1.00E+18 | |

| Buffer Layer Concentration Tolerance | % | ±20% | |

| 1st Epi Layer | Epi Layer Ukobvu | um | 11.5 |

| Epi Layer Ukobvu Uniformity | % | ±4% | |

| Epi Layers Kukobvu Kushivirira ((Spec- Max , Maminitsi)/Special) | % | ±5% | |

| Epi Layer Concentration | cm-3 | 1E 15~ 1E 18 | |

| Epi Layer Concentration Tolerance | % | 6% | |

| Epi Layer Concentration Uniformity (σ /zvinoreva) | % | ≤5% | |

| Epi Layer Concentration Uniformity <(max-min)/(max+min> | % | ≤ 10% | |

| Epitaixal Wafer Shape | Bow | um | ≤±20 |

| WARP | um | ≤30 | |

| TTV | um | ≤ 10 | |

| LTV | um | ≤2 | |

| General Characteristics | Kureba kwekukwenya | mm | ≤30mm |

| Edge Chips | - | HAKUNA | |

| Defects defination | ≥97% (Yakayerwa ne2*2, Killer defects inosanganisira: Kukanganisa kunosanganisira Micropipe/Makomba makuru, Karoti, Triangular | ||

| Metal kusvibiswa | maatomu/cm² | d f i ≤5E10 maatomu/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Package | Packing specifications | pcs/bhokisi | multi-wafer cassette kana single wafer mudziyo |

| 8-inch N-mhando epitaxial tsanangudzo | |||

| Parameter | unit | Z-MOS | |

| Type | Condutivity / Dopant | - | N-mhando / Nitrogen |

| Buffer layer | Buffer Layer Thickness | um | 1 |

| Buffer Layer Thickness Tolerance | % | ±20% | |

| Buffer Layer Concentration | cm-3 | 1.00E+18 | |

| Buffer Layer Concentration Tolerance | % | ±20% | |

| 1st Epi Layer | Epi Layers Ukobvu Avhareji | um | 8~12 |

| Epi Layers Hukobvu Uniformity (σ/kureva) | % | ≤2.0 | |

| Epi Layers Hukobvu Kushivirira ((Spec -Max, Min)/Special) | % | ±6 | |

| Epi Layers Net Avhareji Doping | cm-3 | 8E+15 ~2E+16 | |

| Epi Layers Net Doping Uniformity (σ/kureva) | % | ≤5 | |

| Epi Layers Net DopingTolerance ((Spec -Max, | % | ± 10.0 | |

| Epitaixal Wafer Shape | Mi)/S) Warp | um | ≤50.0 |

| Bow | um | ± 30.0 | |

| TTV | um | ≤ 10.0 | |

| LTV | um | ≤4.0 (10mm×10mm) | |

| General Hunhu | Makwara | - | Cumulative kureba≤ 1/2Wafer dhayamita |

| Edge Chips | - | ≤2 machipisi, Yese radius≤1.5mm | |

| Surface Metals Kusvibiswa | maatomu/cm2 | ≤5E10 maatomu/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Defect Inspection | % | ≥ 96.0 (2X2 Kukanganisa kunosanganisira Micropipe / Makomba Makuru, Karoti, Triangular defects, Downfalls, Linear/IGSF-s, BPD) | |

| Surface Metals Kusvibiswa | maatomu/cm2 | ≤5E10 maatomu/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Package | Packing specifications | - | multi-wafer cassette kana single wafer mudziyo |

Q1: Ndeapi mabhenefiti akakosha ekushandisa SiC wafers pamusoro pechinyakare silicon wafers mumagetsi emagetsi?

A1:

SiC wafers inopa akati wandei akakosha mabhenefiti pamusoro pechinyakare silicon (Si) mawafer mumagetsi emagetsi, anosanganisira:

Kubudirira Kwepamusoro: SiC ine bandgap yakafara (3.26 eV) kana ichienzaniswa nesilicon (1.1 eV), ichibvumira michina kuti ishande pamagetsi epamusoro, ma frequency, uye tembiricha. Izvi zvinotungamirira kuderera kwesimba kurasikirwa uye kushanda kwepamusoro mumashandisi ekushandura simba.

High Thermal Conductivity: SiC's thermal conductivity yakakwirira kudarika iyo yesilicon, zvichiita kuti zviri nani kupisa kupisa mumagetsi e-high-power applications, izvo zvinovandudza kuvimbika uye hupenyu hwemagetsi emagetsi.

Yakakwira Voltage uye Yazvino Kubata: Zvishandiso zveSiC zvinogona kubata yakakwira voltage uye mazinga azvino, zvichiita kuti dzive dzakakodzera kushandiswa kwesimba repamusoro senge mota dzemagetsi, masisitimu emagetsi emagetsi, uye madhiraivha emuindasitiri.

Kukurumidza Kuchinja Kumhanya: Zvishandiso zveSiC zvine kukurumidza kushandura masimba, izvo zvinobatsira mukuderedza kurasikirwa kwesimba uye saizi yehurongwa, zvichiita kuti ive yakanaka kune yakakwira-frequency application.

Q2: Ndeapi mashandisirwo makuru eSiC wafers muindasitiri yemotokari?

A2:

Muindasitiri yemotokari, SiC wafers anonyanya kushandiswa mu:

Motokari yeMagetsi (EV) Powertrains: SiC-based components likeinvertersuyesimba MOSFETskunatsiridza kugona uye kuita kwemagetsi emagetsi emagetsi emagetsi nekugonesa kukurumidza kushandura kumhanya uye yakakwirira simba density. Izvi zvinotungamira kuhupenyu hurefu hwebhatiri uye zvirinani kuita mota kwese.

On-Board Charger: Zvishandiso zveSiC zvinobatsira kuvandudza kushanda kwe-on-board kuchaja masisitimu nekugonesa kukurumidza kuchaja nguva uye zvirinani kutonga kwemafuta, izvo zvakakosha kuti maEVs atsigire zviteshi zvekuchaja zvine simba.

Battery Management Systems (BMS): SiC tekinoroji inovandudza kugona kwebhatiri manejimendi masisitimu, zvichibvumira kudzorwa kwemagetsi zviri nani, kubata kwesimba repamusoro, uye hupenyu hurefu hwebhatiri.

DC-DC Converters: SiC wafers anoshandiswa mukatiDC-DC converterskushandura high-voltage DC simba kune yakaderera-voltage DC simba zvinobudirira, izvo zvakakosha mumotokari dzemagetsi kutonga simba kubva kubhatiri kuenda kuzvinhu zvakasiyana mumotokari.

Kuita kwepamusoro kweSiC muhigh-voltage, high-temperature, uye high-effective applications inoita kuti ive yakakosha pakuchinja kweindasitiri yemotokari kuenda kumagetsi.