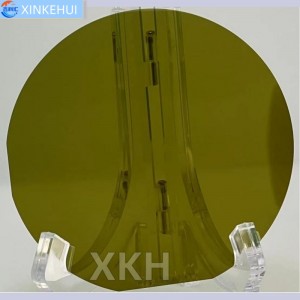

SiC Epitaxial Wafer yeMagetsi Devices - 4H-SiC, N-mhando, Yakaderera Defect Density

Detailed Diagram

Nhanganyaya

SiC Epitaxial Wafer iri pakati pezvigadzirwa zvemazuva ano zvepamusoro-soro semiconductor, kunyanya izvo zvakagadzirirwa kushandiswa kwemasimba makuru, e-frequency, uye kupisa kwepamusoro. Ipfupi yeSilicon Carbide Epitaxial Wafer, SiC Epitaxial Wafer ine yemhando yepamusoro, nhete yeSiC epitaxial layer inokurira pamusoro peSiC substrate yakawanda. Kushandiswa kweSiC Epitaxial Wafer tekinoroji iri kukurumidza kuwedzera mumotokari dzemagetsi, magidhi akangwara, masisitimu emagetsi anovandudzwa, uye aerospace nekuda kwehukuru hwayo hwepanyama uye hwemagetsi zvichienzaniswa neyakajairwa silicon-based wafers.

Kugadzira Nheyo dzeSiC Epitaxial Wafer

Kugadzira SiC Epitaxial Wafer inoda yakanyanya kudzorwa kemikari vapor deposition (CVD) maitiro. Iyo epitaxial layer inokura pane monocrystalline SiC substrate uchishandisa magasi akadai silane (SiH₄), propane (C₃H₈), uye hydrogen (H₂) patembiricha inopfuura 1500 ° C. Iyi yepamusoro-tembiricha epitaxial kukura inovimbisa yakanakisa crystalline kurongeka uye kushoma kukanganisa pakati peepitaxial layer uye substrate.

Iyo nzira inosanganisira akati wandei matanho akakosha:

-

Substrate Kugadzirira: Hwaro hweSiC wafer inocheneswa uye yakakwenenzverwa kutsetseka kweatomu.

-

CVD Kukura: Mune yakakwirira-kuchena reactor, magasi anoita kuti aise imwe-crystal SiC layer pane substrate.

-

Doping Control: N-mhando kana P-mhando doping inounzwa panguva epitaxy kuti iwane inodiwa magetsi emagetsi.

-

Kuongorora uye Metrology: Optical microscopy, AFM, uye X-ray diffraction inoshandiswa kuonesa ukobvu, doping concentration, uye defect density.

Imwe neimwe SiC Epitaxial Wafer inotariswa zvakanyatsonaka kuchengetedza kushivirira kwakasimba mukufanana kweukobvu, kupfava kwepasi, uye resistivity. Iko kugona kukwenenzvera aya ma paramita kwakakosha kune yakakwira-voltage MOSFETs, Schottky diodes, uye mamwe magetsi emagetsi.

Tsanangudzo

| Parameter | Tsanangudzo |

| Categories | Zvishandiso Sayenzi, Imwe Crystal Substrates |

| Polytype | 4H |

| Doping | N Type |

| Diameter | 101 mm |

| Diameter Tolerance | ± 5% |

| Ukobvu | 0.35 mm |

| Makobvu Tolerance | ± 5% |

| Primary Flat Length | 22 mm (± 10%) |

| TTV (Total Thickness Variation) | ≤10 µm |

| Warp | ≤25 µm |

| FWHM | ≤30 Arc-sec |

| Surface Finish | Rq ≤0.35 nm |

Zvishandiso zveSiC Epitaxial Wafer

SiC Epitaxial Wafer zvigadzirwa zvakakosha muzvikamu zvakawanda:

-

Mota dzemagetsi (EVs): SiC Epitaxial Wafer-based devices inowedzera powertrain kunyatsoshanda uye kuderedza uremu.

-

Renewable Energy: Inoshandiswa mumainverters emagetsi ezuva nemhepo.

-

Industrial Power Supplies: Gonesa high-frequency, high-temperature switching nekurasikirwa kwakaderera.

-

Aerospace uye Defense: Yakanakira nharaunda dzakaomarara dzinoda akasimba semiconductors.

-

5G Base Zviteshi: SiC Epitaxial Wafer zvikamu zvinotsigira simba repamusoro density yeRF application.

Iyo SiC Epitaxial Wafer inogonesa compact dhizaini, kukurumidza kushandura, uye yakakwirira simba shanduko inoshanda kana ichienzaniswa nesilicon wafers.

Zvakanakira zveSiC Epitaxial Wafer

SiC Epitaxial Wafer tekinoroji inopa zvakakosha mabhenefiti:

-

High Breakdown Voltage: Inomirisana nemagetsi anosvika gumi akakwira kupfuura Si wafers.

-

Thermal Conductivity: SiC Epitaxial Wafer inobvisa kupisa nekukurumidza, ichibvumira michina kuti imhanye inotonhorera uye yakavimbika.

-

High Switching Speeds: Kurasikirwa kwekuchinja kwepasi kunogonesa kushanda kwepamusoro uye miniaturization.

-

Wide Bandgap: Inovimbisa kugadzikana kune yakakwirira voltages uye tembiricha.

-

Material Robustness: SiC ine makemikari inert uye ine michina yakasimba, yakanakira kunyorera maapplication.

Aya mabhenefiti anoita iyo SiC Epitaxial Wafer zvinhu zvesarudzo zvechizvarwa chinotevera chesemiconductors.

FAQ: SiC Epitaxial Wafer

Q1: Ndeupi musiyano uripo pakati peSiC wafer neSiC Epitaxial Wafer?

A SiC wafer inoreva iyo yakawanda substrate, nepo SiC Epitaxial Wafer inosanganisira yakanyatsokura ine doped layer inoshandiswa mukugadzira mudziyo.

Q2: Ndeapi makubvu anowanikwa eSiC Epitaxial Wafer layers?

Epitaxial layers dzinowanzo siyana kubva pamamicrometer mashoma kusvika pamusoro pe100 μm, zvichienderana nezvinodiwa zvekushandisa.

Q3: Ko SiC Epitaxial Wafer yakakodzera nzvimbo dzepamusoro-tembiricha?

Hongu, SiC Epitaxial Wafer inogona kushanda mumamiriro ari pamusoro pe600 ° C, ichipfuura silicon zvakanyanya.

Q4: Sei kuremara density yakakosha muSiC Epitaxial Wafer?

Lower defect density inovandudza mashandiro emudziyo uye goho, kunyanya kune yakakwira-voltage application.

Q5: Ko N-mhando uye P-mhando SiC Epitaxial Wafers zvese zviripo?

Ehe, marudzi ese ari maviri anogadzirwa uchishandisa chaiyo dopant gasi kutonga panguva ye epitaxial process.

Q6: Ndeapi mawafer saizi akajairwa eSiC Epitaxial Wafer?

Madhayamita akajairwa anosanganisira 2-inch, 4-inch, 6-inch, uye inowedzera 8-inch yekugadzira-vhoriyamu.

Q7: Ko SiC Epitaxial Wafer inokanganisa sei mutengo uye kushanda nesimba?

Nepo pakutanga ichidhura kupfuura silicon, SiC Epitaxial Wafer inoderedza saizi yehurongwa uye kurasikirwa kwemagetsi, ichivandudza huwandu hwemutengo wepamusoro kwenguva refu.