Semiconductor Laser Lift-Off Equipment Revolutionize Ingot Kutetepa

Detailed Diagram

Kusuma Chigadzirwa cheSemiconductor Laser Lift-Off Equipment

Iyo Semiconductor Laser Lift-Off Equipment ndeye yakasarudzika maindasitiri mhinduro yakagadzirirwa kunyatsoita uye isiri-yekubata kutetepa kwema semiconductor ingots kuburikidza nelaser-induced lift-off maitiro. Iyi yepamberi sisitimu inoita basa rakakosha mumaitiro emazuva ano semiconductor wafering, kunyanya mukugadzirwa kweakanyanya-tete mawafer emagetsi emagetsi epamusoro-soro, maLED, uye zvishandiso zveRF. Nekugonesa kupatsanurwa kwezvikamu zvitete kubva kune akawanda ingots kana donor substrates, Semiconductor Laser Lift-Off Equipment inoshandura ingot kutetepa nekubvisa mechanical sawing, kugaya, uye makemikari etching matanho.

Kutetepa kwechinyakare kwema semiconductor ingots, senge gallium nitride (GaN), silicon carbide (SiC), nesafire, kunowanzo shanda zvakanyanya, kutambisa, uye kunowanzoita microcracks kana kukuvara kwepasi. Kusiyana neizvi, Semiconductor Laser Lift-Off Equipment inopa isingaparadzi, yakasarudzika imwe nzira inoderedza kurasikirwa kwezvinhu uye kushushikana kwepasi uku uchiwedzera kubereka. Inotsigira zvakasiyana-siyana zvekristalline uye zvinhu zvakasanganiswa uye zvinogona kubatanidzwa zvisina musono mumberi-kumagumo kana midstream semiconductor yekugadzira mitsetse.

Iine configurable laser wavelengths, adaptive yekutarisa masisitimu, uye vacuum-inoenderana wafer chucks, ichi chishandiso chakanyatso kunyatsokodzera ingot slicing, lamella kusikwa, uye yekupedzisira-yakaonda firimu dhizach kune yakatwasuka mudziyo zvimiro kana heteroepitaxial layer kutamiswa.

Parameter yeSemiconductor Laser Lift-Off Equipment

| Wavelength | IR/SHG/THG/FHG |

|---|---|

| Pulse Width | Nanosecond, Picosecond, Femtosecond |

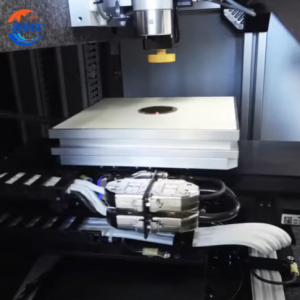

| Optical System | Fixed optical system kana Galvano-optical system |

| XY Stage | 500 mm × 500 mm |

| Processing Range | 160 mm |

| Movement Speed | Max 1,000 mm/sec |

| Kudzokorora | ± 1 μm kana pasi |

| Absolute Position Accuracy: | ± 5 μm kana pasi |

| Wafer Size | 2-6 inches kana customized |

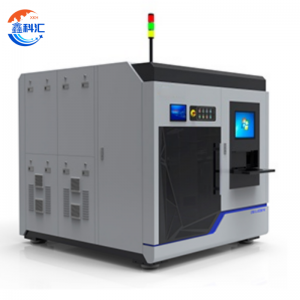

| Kudzora | Windows 10, 11 uye PLC |

| Power Supply Voltage | AC 200 V ±20 V, Chikamu chimwe chete, 50/60 kHz |

| External Dimensions | 2400 mm (W) × 1700 mm (D) × 2000 mm (H) |

| Kurema | 1,000 kg |

Kushanda Nheyo yeSemiconductor Laser Lift-Off Equipment

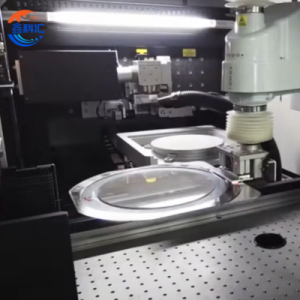

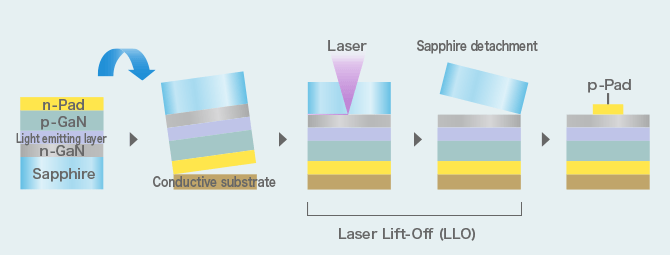

Iyo yakakosha mashandiro eSemiconductor Laser Lift-Off Equipment inotsamira pane yakasarudzika photothermal decomposition kana ablation pane iyo interface pakati peinopa ingot uye epitaxial kana target layer. A high-energy UV laser (kazhinji KrF pa248 nm kana solid-state UV lasers yakatenderedza 355 nm) inotariswa kuburikidza neyakajeka kana semi-pachena vanopa zvinhu, uko simba rinonyudzwa zvakasarudzwa pakudzika kwakafanotemerwa.

Uku kunyudzwa kwesimba kwenzvimbo kunogadzira chikamu chegasi chakanyanya-kudzvanywa kana kupisa kwekuwedzera dhiri pane iyo interface, iyo inotangisa kuchena kwakachena kweiyo wafer yepamusoro kana mudziyo layer kubva kune ingot base. Maitiro acho akanyatso gadziridzwa nekugadzirisa maparamendi akadai sepulse hupamhi, laser fluence, scanning kumhanya, uye z-axis focal kudzika. Mhedzisiro yacho ichidimbu chakatetepa-kazhinji chiri muchikamu che10 kusvika ku50 µm-chakanyatsoparadzaniswa kubva kune ingot yemubereki pasina mabrasion.

Iyi nzira yekusimudza-laser yeingot thinning inodzivirira kurasikirwa kwekerf uye kukuvara kwepamusoro kwakabatana nedhaimani waya sawing kana mechanical lapping. Inochengetedzawo kutendeseka kwekristaro uye inoderedza kudzika kwepasi zvinodiwa, ichiita Semiconductor Laser Lift-Off Equipment chishandiso chinoshandura mutambo wechizvarwa chinotevera kugadzira wafer.

Zvishandiso zveSemiconductor Laser Lift-Off Equipment

Semiconductor Laser Lift-Off Equipment inowana kushanda kwakakura muingot kutetepa mukati memhando yezvigadzirwa zvepamberi nemhando dzemidziyo, kusanganisira:

-

GaN neGaAs Ingot Thinning yeMagetsi eMagetsi

Inogonesa kusikwa kwakaonda kwewafer kwepamusoro-kushanda, yakaderera-inodzivirira simba transistors uye diode.

-

SiC Substrate Reclamation uye Lamella Separation

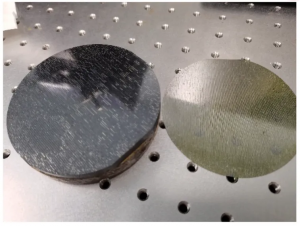

Inobvumira wafer-scale kusimudzwa kubva muhuwandu hweSiC substrates kune yakatwasuka mudziyo zvimiro uye wafer kushandiswazve.

-

LED Wafer Slicing

Inofambisa kusimudzwa kweGaN layers kubva kune gobvu sapphire ingots kugadzira ekupedzisira-akatetepa e LED substrates.

-

RF uye Microwave Device Fabrication

Inotsigira ultra-thin high-electron-mobility transistor (HEMT) zvimiro zvinodiwa mu5G uye radar masisitimu.

-

Epitaxial Layer Transfer

Inonyatso bvisa epitaxial layers kubva kune crystalline ingots kuti ishandiswezve kana kubatanidzwa mune heterostructures.

-

Thin-Film Solar Cells uye Photovoltaics

Inoshandiswa kupatsanura zvinyoro zvinyoro zvinyoro zvemasero anochinjika kana akanyanya kushanda nesimba ezuva.

Mune imwe neimwe yeaya madomasi, Semiconductor Laser Lift-Off Equipment inopa isingaenzaniswi kutonga pamusoro pekufanana kwehukobvu, kunaka kwepasi, uye kutendeseka.

Zvakanakira Laser-Yakavakirwa Ingot Thinning

-

Zero-Kerf Zvinhu Kurasikirwa

Kuenzaniswa neyechinyakare wafer slicing nzira, iyo laser process inoguma ingangoita 100% kushandiswa kwezvinhu.

-

Minimal Stress uye Warping

Kusimudza-kusingabatanidze kunobvisa kuzununguka kwemuchina, kuderedza uta hwewafer uye kuumbwa kwe microcrack.

-

Surface Quality Preservation

Hapana post-kutetepa kupeta kana kupukuta kunodiwa muzviitiko zvakawanda, sezvo laser lift-off inochengetedza yepamusoro-yepamusoro kuvimbika.

-

High throughput uye otomatiki Yakagadzirira

Inokwanisa kugadzirisa mazana ema substrates pashift ine otomatiki kurodha / kurodha.

-

Inochinjika kune Zvishandiso Zvakawanda

Inoenderana neGaN, SiC, safire, GaAs, uye inobuda III-V zvinhu.

-

Yakachengeteka Nezvakatipoteredza

Inoderedza kushandiswa kweabrasives uye makemikari ane hutsinye anowanikwa mune slurry-based thinning process.

-

Shandisazve Substrate

Donor ingots inogona kudzokororwa kune akawanda ekusimudza-kutenderera, ichidzikisa zvakanyanya mutengo wezvinhu.

Mibvunzo Inowanzo bvunzwa (FAQ) yeSemiconductor Laser Lift-Off Equipment

-

Q1: Ndeupi ukobvu huwandu hunogona kuwanikwa neSemiconductor Laser Lift-Off Equipment kune zvimedu zvewafa?

A1:Yakajairika simendi ukobvu hunobva pa10 µm kusvika ku100 µm zvichienderana nechinhu uye magadzirirwo.Q2: Michina iyi inogona kushandiswa kuonda ingots yakagadzirwa neopaque zvinhu seSiC?

A2:Ehe. Nekugadzirisa iyo laser wavelength uye optimization interface engineering (semuenzaniso, zvibairo zvinopindirana), kunyange zvishoma opaque zvinhu zvinogona kugadziriswa.Q3: Iyo donor substrate inowirirana sei pamberi pelaser kusimudzwa?

A3:Iyo sisitimu inoshandisa sub-micron vision-based alignment modules ine mhinduro kubva kune fiducial mamaki uye pamusoro pekutarisa scans.Q4: Ndeipi inotarisirwa kutenderera nguva yeimwe laser lift-off operation?

A4:Zvichienderana nehukuru hwewaferi uye ukobvu, maitiro akajairwa anotora kubva pa2 kusvika ku10 maminetsi.Q5: Maitiro acho anoda nzvimbo yakachena yekamuri here?

A5:Kunyange zvisingasungirwe, kusanganisa kwemukamuri yekuchenesa kunokurudzirwa kuchengetedza utsanana hwesubstrate uye goho remudziyo panguva yekushanda kwepamusoro-soro.

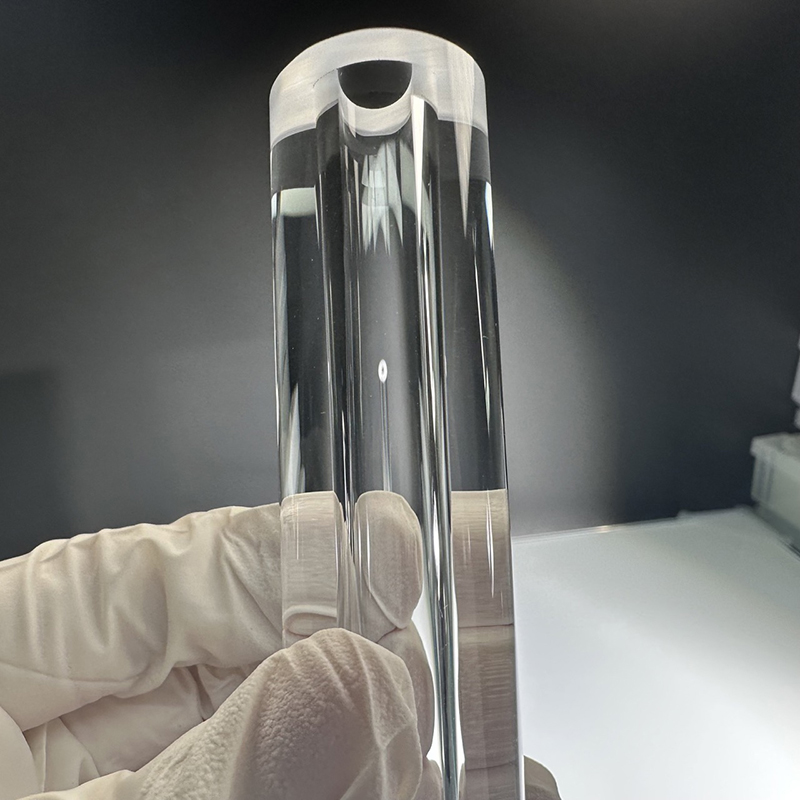

Nezvedu

XKH inyanzvi mukusimudzirwa kwepamusoro-soro, kugadzira, uye kutengesa kwegirazi remaziso uye zvinhu zvitsva zvekristaro. Zvigadzirwa zvedu zvinoshanda zvemagetsi zvemagetsi, zvemagetsi zvevatengi, uye mauto. Isu tinopa Sapphire optical components, nharembozha lens inovhara, Ceramics, LT, Silicon Carbide SIC, Quartz, uye semiconductor crystal wafers. Nehunyanzvi hunyanzvi uye yekucheka-kumucheto michina, isu tinokunda mune isiri-yakajairwa chigadzirwa kugadzirisa, tichivavarira kuve inotungamira optoelectronic zvinhu zvepamusoro-tech bhizinesi.