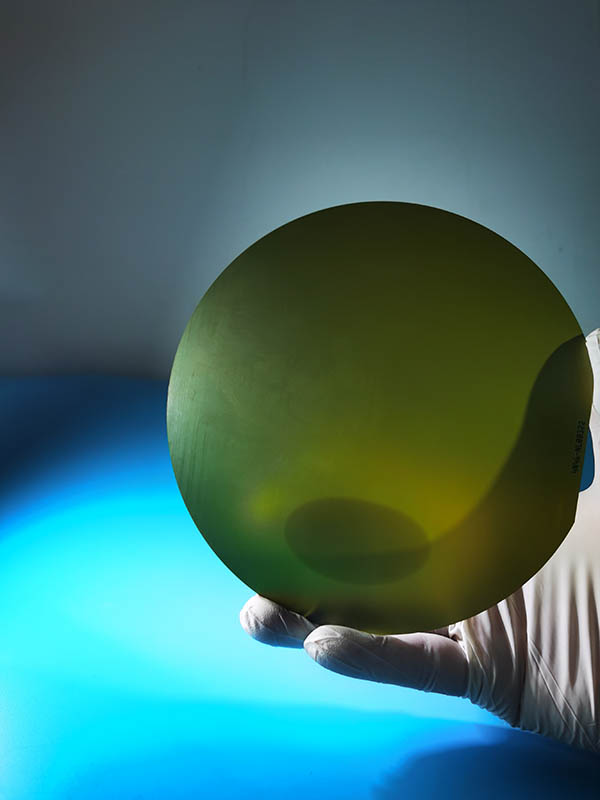

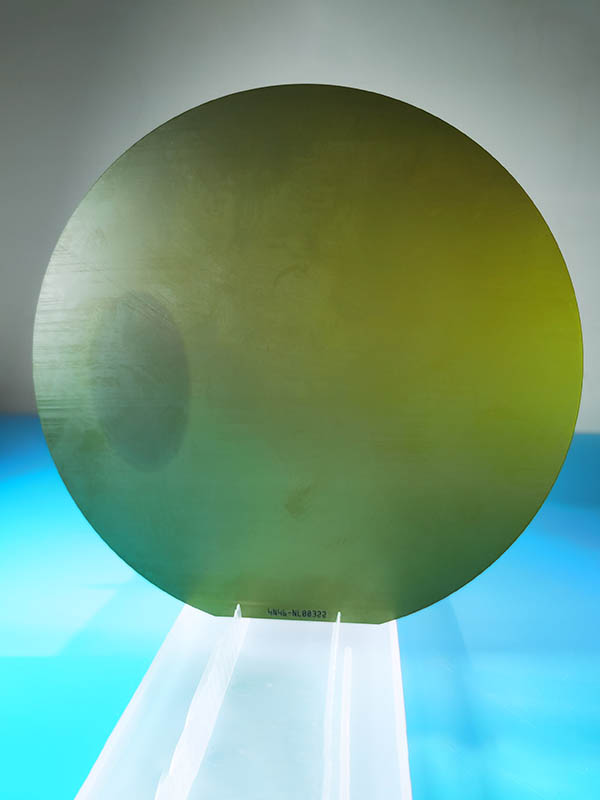

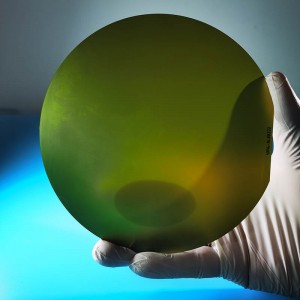

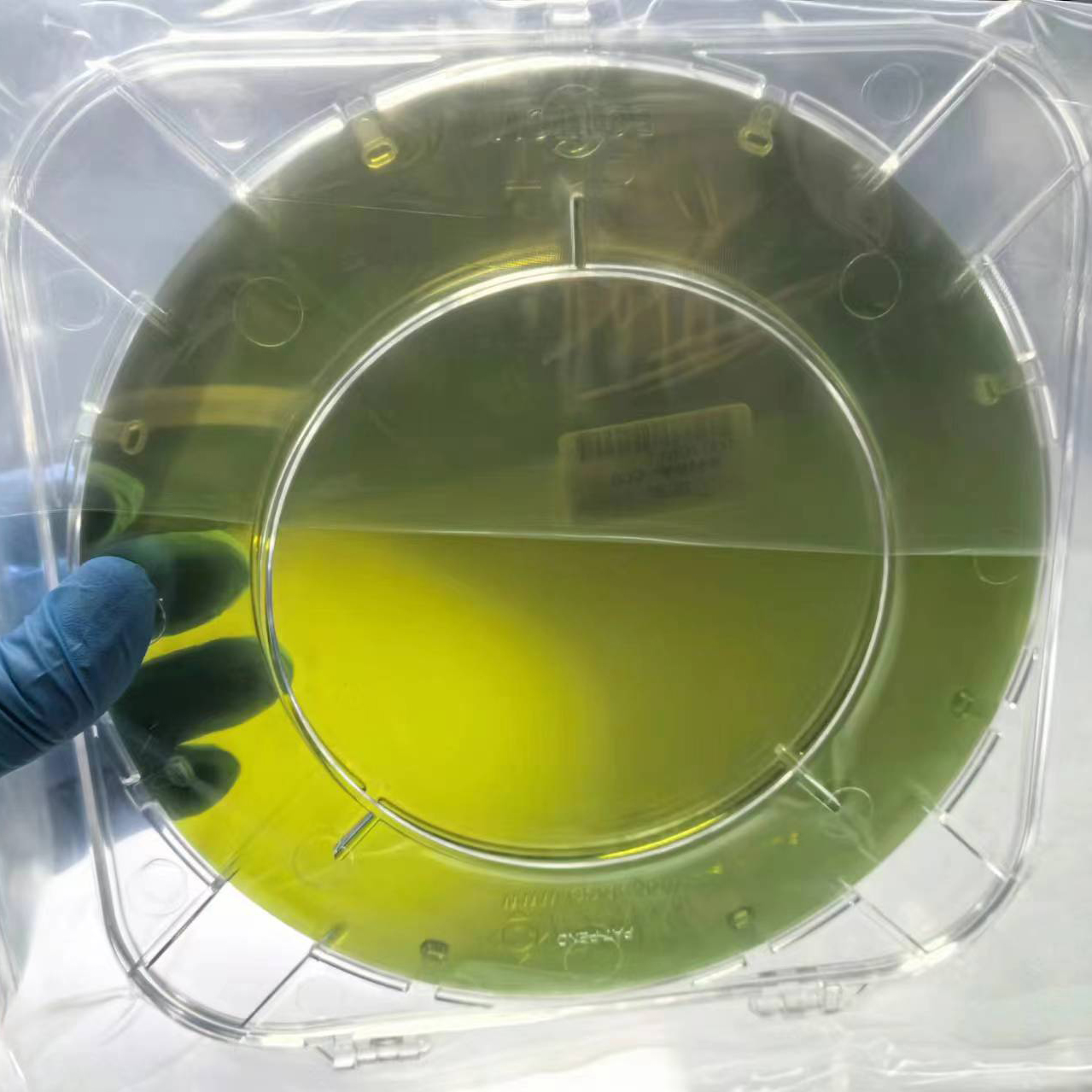

8Inch 200mm 4H-N SiC Wafer Conductive dummy research giredhi

Nekuda kwekusiyana kwayo kwemuviri uye zvemagetsi zvivakwa, 200mm SiC wafer semiconductor zvinhu zvinoshandiswa kugadzira yakakwirira-inoshanda, yakakwirira-tembiricha, inodzivirira mwaranzi, uye yakakwirira-frequency zvigadzirwa zvemagetsi. 8inch SiC substrate mutengo uri kudzikira zvishoma nezvishoma sezvo tekinoroji inowedzera uye kudiwa kuri kukura. Zvichangobva kuitika tekinoroji zvinotungamira mukugadzirwa kwehukuru hwe200mm SiC wafers. Iwo mabhenefiti makuru eSiC wafer semiconductor zvinhu mukuenzanisa neSi neGaAs wafers: Iyo yemagetsi munda simba re4H-SiC panguva yekuputsika kweavalanche inopfuura hurongwa hwehukuru hwepamusoro kupfuura hunoenderana kukosha kweSi neGaAs. Izvi zvinotungamira mukudzikira kwakanyanya mune-nyika resistivity Ron. Yakaderera pa-state resistivity, yakasanganiswa nepamusoro-soro density uye yekupisa conductivity, inobvumira kushandiswa kwekufa kudiki kwemagetsi emagetsi. Iyo yakakwira yekupisa conductivity yeSiC inoderedza kupisa kwekupisa kwechip. Iyo yemagetsi zvimiro zvemidziyo yakavakirwa eSiC wafers yakagadzikana zvakanyanya nekufamba kwenguva uye pane tembiricha yakagadzikana, iyo inovimbisa kuvimbika kwakanyanya kwezvigadzirwa. Silicon carbide inopesana zvakanyanya neradiation yakaoma, iyo isingaderedze zvemagetsi zvimiro zvechip. Iyo yakanyanya kudzikisira tembiricha yekushandisa yekristaro (inopfuura 6000C) inokutendera iwe kuti ugadzire yakavimbika michina yemamiriro ekushanda akaomarara uye yakakosha maapplication. Parizvino, isu tinokwanisa kupa diki batch 200mmSiC wafers zvakatsiga uye nekuenderera uye nekuva nezvimwe stock mudura.

Tsanangudzo

| Number | Item | Unit | Kugadzirwa | Tsvakurudzo | Dummy |

| 1. Parameters | |||||

| 1.1 | polytype | -- | 4H | 4H | 4H |

| 1.2 | pamusoro pekutarisa | ° | <11-20>4±0.5 | <11-20>4±0.5 | <11-20>4±0.5 |

| 2. Magetsi parameter | |||||

| 2.1 | dopant | -- | n-mhando Nitrogen | n-mhando Nitrogen | n-mhando Nitrogen |

| 2.2 | resistivity | uyo ·cm | 0.015~0.025 | 0.01~0.03 | NA |

| 3. Mechanical parameter | |||||

| 3.1 | dhayamita | mm | 200±0.2 | 200±0.2 | 200±0.2 |

| 3.2 | ukobvu | μm | 500±25 | 500±25 | 500±25 |

| 3.3 | Notch orientation | ° | [1- 100]±5 | [1- 100]±5 | [1- 100]±5 |

| 3.4 | Notch Depth | mm | 1~1.5 | 1~1.5 | 1~1.5 |

| 3.5 | LTV | μm | ≤5(10mm*10mm) | ≤5(10mm*10mm) | ≤10(10mm*10mm) |

| 3.6 | TTV | μm | ≤10 | ≤10 | ≤15 |

| 3.7 | Bow | μm | -25~25 | -45~45 | -65~65 |

| 3.8 | Warp | μm | ≤30 | ≤50 | ≤70 |

| 3.9 | AFM | nm | Ra≤0.2 | Ra≤0.2 | Ra≤0.2 |

| 4. Chimiro | |||||

| 4.1 | micropipe density | e/cm2 | ≤2 | ≤10 | ≤50 |

| 4.2 | metal content | maatomu/cm2 | ≤1E11 | ≤1E11 | NA |

| 4.3 | TSD | e/cm2 | ≤500 | ≤1000 | NA |

| 4.4 | BPD | e/cm2 | ≤2000 | ≤5000 | NA |

| 4.5 | TED | e/cm2 | ≤7000 | ≤10000 | NA |

| 5. Hunhu hwakanaka | |||||

| 5.1 | pamberi | -- | Si | Si | Si |

| 5.2 | pamusoro pekupedzisira | -- | Si-face CMP | Si-face CMP | Si-face CMP |

| 5.3 | particle | ea/wafer | ≤100(saizi≥0.3μm) | NA | NA |

| 5.4 | scratch | ea/wafer | ≤5, Hurefu Hwose≤200mm | NA | NA |

| 5.5 | Edge chips/indents/cracks/stains/contamination | -- | Hapana | Hapana | NA |

| 5.6 | Polytype nzvimbo | -- | Hapana | Nzvimbo ≤10% | Nzvimbo ≤30% |

| 5.7 | pamberi pemaka | -- | Hapana | Hapana | Hapana |

| 6. Back quality | |||||

| 6.1 | back finish | -- | C-chiso MP | C-chiso MP | C-chiso MP |

| 6.2 | scratch | mm | NA | NA | NA |

| 6.3 | Back defects kumucheto machipisi/indents | -- | Hapana | Hapana | NA |

| 6.4 | Back roughness | nm | Ra≤5 | Ra≤5 | Ra≤5 |

| 6.5 | Kumaka kumashure | -- | Notch | Notch | Notch |

| 7. Mupendero | |||||

| 7.1 | kumucheto | -- | Chamfer | Chamfer | Chamfer |

| 8. Package | |||||

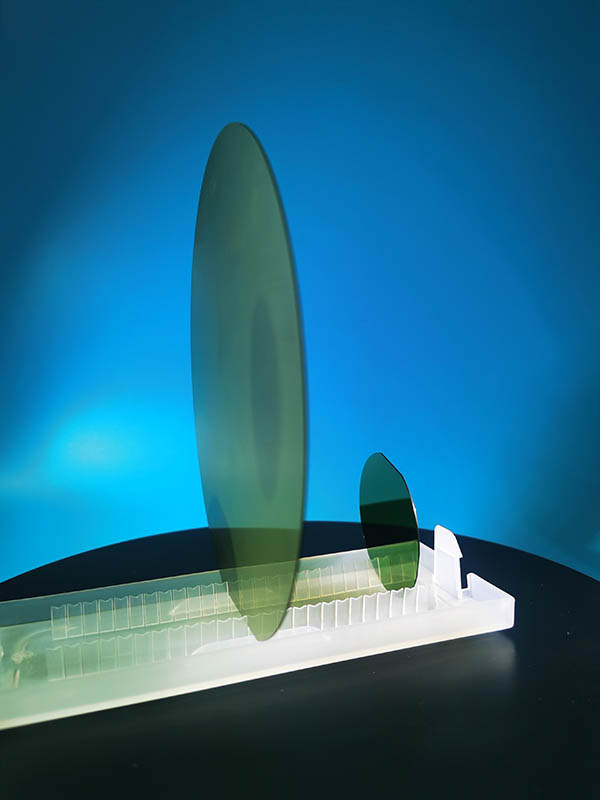

| 8.1 | kurongedza | -- | Epi-yakagadzirira ne vacuum kurongedza | Epi-yakagadzirira ne vacuum kurongedza | Epi-yakagadzirira ne vacuum kurongedza |

| 8.2 | kurongedza | -- | Multi-wafer kurongedza makaseti | Multi-wafer kurongedza makaseti | Multi-wafer kurongedza makaseti |

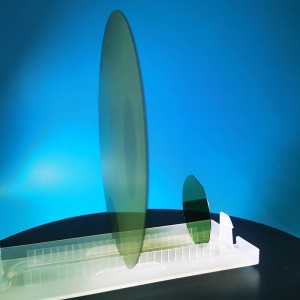

Detailed Diagram