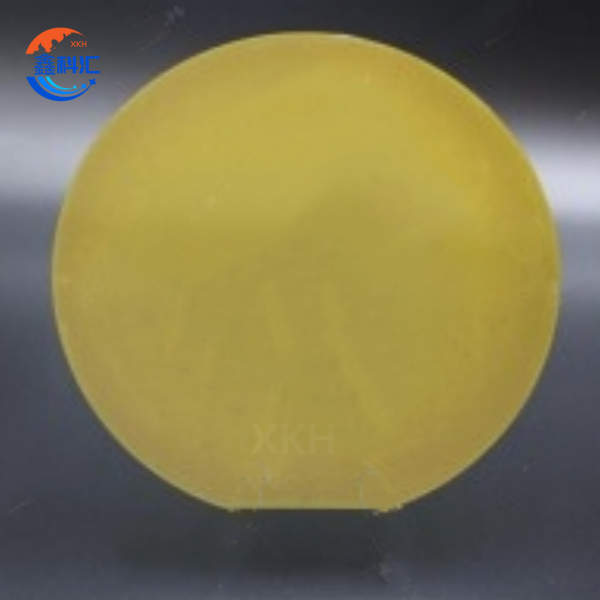

6 inch Conductive single crystal SiC pane polycrystalline SiC composite substrate Diameter 150mm P mhando N mhando

Technical parameters

| Saizi | 6 inch |

| Diameter: | 150 mm |

| Ukobvu: | 400-500 μm |

| Monocrystalline SiC Film Parameters | |

| Polytype: | 4H-SiC kana 6H-SiC |

| Doping Concentration: | 1×10¹⁴ - 1×10¹⁸ cm⁻³ |

| Ukobvu: | 5-20 μm |

| Sheet Resistance: | 10-1000 Ω/sq |

| Electron Mobility: | 800-1200 cm²/Vs |

| Hole Mobility: | 100-300 cm²/Vs |

| Polycrystalline SiC Buffer Layer Parameters | |

| Ukobvu: | 50-300 μm |

| Thermal Conductivity: | 150-300 W/m·K |

| Monocrystalline SiC Substrate Parameters | |

| Polytype: | 4H-SiC kana 6H-SiC |

| Doping Concentration: | 1×10¹⁴ - 1×10¹⁸ cm⁻³ |

| Ukobvu: | 300-500 μm |

| Saizi yezviyo: | > 1 mm |

| Kushata Kwepamusoro: | <0.3 mm RMS |

| Mechanical & Electrical Properties | |

| Kuoma: | 9-10 Mohs |

| Compressive Strength: | 3-4 GPA |

| Tensile Simba: | 0.3-0.5 GPA |

| Breakdown Field Strength: | > 2 MV/cm |

| Total Dose Tolerance: | > 10 Mrad |

| Single Event Effect Resistance: | > 100 MeV·cm²/mg |

| Thermal Conductivity: | 150-380 W/m·K |

| Operating Temperature Range: | -55 kusvika 600 ° C |

Hunhu Hunokosha

Iyo 6-inch conductive monocrystalline SiC pane polycrystalline SiC composite substrate inopa yakasarudzika chiyero chechimiro chechinhu uye kuita, ichiita kuti ive yakakodzera kune inoda nharaunda maindasitiri:

1.Cost-Effectiveness: Iyo polycrystalline SiC base inoderedza zvakanyanya mari ichienzaniswa ne-yakazara-monocrystalline SiC, nepo monocrystalline SiC inoshanda layer inovimbisa dhizaini-giredhi kushanda, yakanakira kudhura-sensitive application.

2.Exceptional Electrical Properties: The monocrystalline SiC layer inoratidza kufamba kwepamusoro kwekutakura (> 500 cm² / V · s) uye yakaderera density, inotsigira high-frequency uye high-power device kushandiswa.

3.High-Temperature Stability: SiC's inherent high-temperature resistance (> 600 ° C) inoita kuti substrate inosanganiswa irambe yakagadzikana pasi pemamiriro ezvinhu akaipisisa, zvichiita kuti ive yakakodzera kumotokari yemagetsi uye kushandiswa kwemagetsi emabhizimisi.

4.6-inch Yakamisikidzwa Wafer Size: Kana ichienzaniswa neyechinyakare 4-inch SiC substrates, iyo 6-inch fomati inowedzera chip goho nepamusoro pe30%, ichidzikisa per-unit mudziyo mutengo.

5.Conductive Design: Pre-doped N-type kana P-type layers inoderedza ion implantation matanho mukugadzirwa kwechigadzirwa, kuvandudza kushanda kwekugadzira uye goho.

6.Superior Thermal Management: Iyo polycrystalline SiC base's thermal conductivity (~ 120 W / m · K) inosvika kune monocrystalline SiC, inonyatsogadzirisa matambudziko ekupisa kupisa mumagetsi emagetsi makuru.

Aya maitiro anoisa iyo 6-inch conductive monocrystalline SiC pane polycrystalline SiC composite substrate semhinduro yemakwikwi kumaindasitiri akadai sesimba rinodzokororwa, chekufambisa njanji, uye aerospace.

Primary Applications

Iyo 6-inch conductive monocrystalline SiC pane polycrystalline SiC composite substrate yakave yakabudirira kuiswa munzvimbo dzinoverengeka dzinodiwa zvakanyanya:

1.Electric Vehicle Powertrains: Inoshandiswa mu-high-voltage SiC MOSFETs uye diode kuwedzera inverter kunyatsoshanda uye kuwedzera bhatiri renji (semuenzaniso, Tesla, BYD mienzaniso).

2.Industrial Motor Drives: Inogonesa kutonhora kwepamusoro-soro, high-switching-frequency power modules, kuderedza kushandiswa kwesimba mumichina inorema uye mhepo turbines.

3.Photovoltaic Inverters: Zvigadzirwa zveSiC zvinovandudza kushanduka kwezuva (> 99%), nepo substrate yakasanganiswa inowedzera kuderedza mari yehurongwa.

4.Rail Transportation: Inoshandiswa mumatanho ekushandura kwepamusoro-speed rail uye subway systems, ichipa high-voltage resistance (> 1700V) uye compact form factor.

5.Aerospace: Yakanakira setiraiti simba masisitimu uye ndege injini yekudzora maseketi, inokwanisa kutsungirira kutonhora kwakanyanya uye nemwaranzi.

Mukugadzira kunoshanda, iyo 6-inch conductive monocrystalline SiC pane polycrystalline SiC composite substrate inoenderana zvizere neyakajairwa SiC mudziyo maitiro (semuenzaniso, lithography, etching), isingade imwe mari yekuwedzera mari.

XKH Services

XKH inopa rutsigiro rwakakwana rweiyo 6-inch conductive monocrystalline SiC pane polycrystalline SiC inoumbwa substrate, inovhara R&D mukugadzirwa kwakawanda:

1.Customization: Adjustable monocrystalline layer thickness (5–100 μm), doping concentration (1e15–1e19 cm⁻³), uye crystal orientation (4H/6H-SiC) kuti isangane nemhando dzakasiyana-siyana zvinodiwa.

2.Wafer Processing: Kupiwa kwakawanda kwe6-inch substrates nemusana kutetepa uye metallization masevhisi ekubatanidza plug-uye-kutamba.

3.Technical Validation: Inosanganisira XRD crystallinity analysis, Hall effect test, uye thermal resistance measurement kuti ikurumidze kugadzirisa zvinhu.

4.Rapid Prototyping: 2- kusvika 4-inch samples (maitiro akafanana) emasangano ekutsvakurudza kuti akurumidze kufambira mberi.

5.Failure Analysis & Optimization: Material-level solutions yekugadzirisa matambudziko (eg, epitaxial layer defects).

Basa redu nderekumisa 6-inch conductive monocrystalline SiC pane polycrystalline SiC composite substrate seyakasarudzika mutengo-kuita mhinduro yeSiC magetsi emagetsi, ichipa kupera-kusvika-kumagumo rutsigiro kubva kune prototyping kusvika vhoriyamu kugadzirwa.

Mhedziso

Iyo 6-inch conductive monocrystalline SiC pane polycrystalline SiC composite substrate inowana nhanho yekubudirira pakati pekuita uye mutengo kuburikidza neyakagadziridza mono/polycrystalline hybrid chimiro. Sezvo mota dzemagetsi dzichiwanda uye Indasitiri 4.0 kufambira mberi, iyi substrate inopa hwaro hwezvinhu hwakavimbika hwemagetsi emagetsi echizvarwa chinotevera. XKH inogamuchirwa kubatirana kuti uwedzere kuongorora kugona kweSiC tekinoroji.