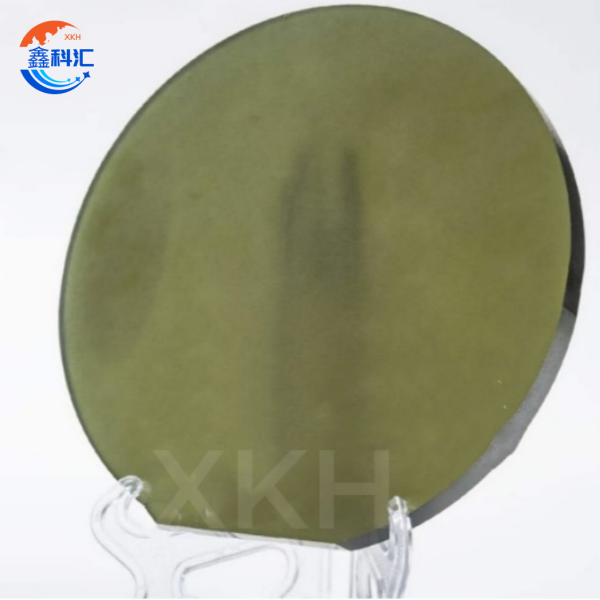

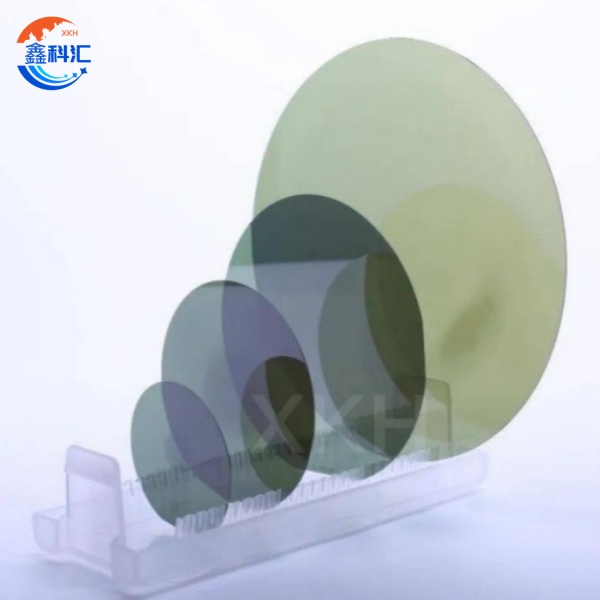

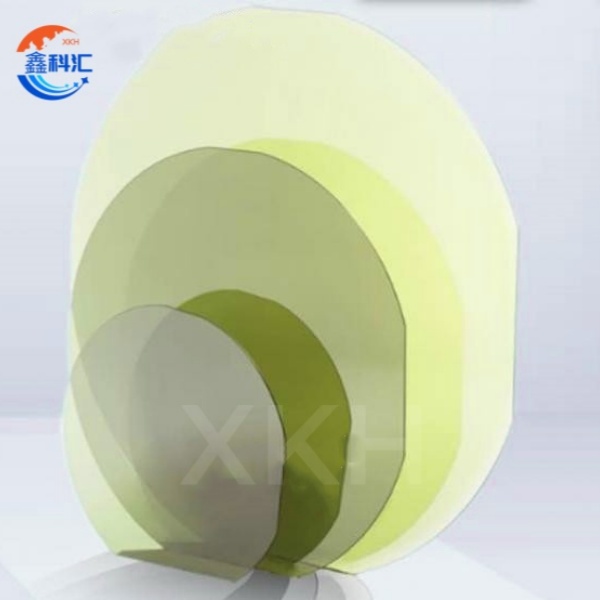

12 inch SIC substrate silicon carbide prime giredhi dhayamita 300mm hombe saizi 4H-N Inokodzera yakakwirira simba mudziyo kupisa kupisa

Product maitiro

1. High thermal conductivity: thermal conductivity yesilicon carbide inopfuura 3 nguva yesilicon, iyo yakakodzera kune simba guru rekushandisa kupisa kupisa.

2. High breakdown field simba: Kuparara kwemunda simba ndeye 10 nguva yesilicon, yakakodzera kushandiswa kwepamusoro-kudzvinyirira.

3.Wide bandgap: The bandgap ndeye 3.26eV (4H-SiC), yakakodzera kutonhora kwepamusoro uye kushandiswa kwepamusoro.

4. Kuoma kwepamusoro: Mohs kuoma ndeye 9.2, yechipiri chete kune diamond, yakanakisa kupfeka kusagadzikana uye simba remagetsi.

5. Kugadzikana kwekemikari: yakasimba corrosion resistance, kushanda kwakadzikama mukupisa kwepamusoro uye nzvimbo yakaoma.

6. Hukuru hukuru: 12 inch (300mm) substrate, kuvandudza kushanda kwekugadzira, kuderedza mari yeyuniti.

7.Low defect density: high quality single crystal kukura tekinoroji kuve nechokwadi chekushomeka kwekushomeka uye kusimba kwakanyanya.

Product main application direction

1. Magetsi emagetsi:

Mosfets: Inoshandiswa mumotokari dzemagetsi, madhiraivha emuindasitiri uye madhiraivha emagetsi.

Diodes: akadai seSchottky diodes (SBD), anoshandiswa kugadzirisa zvakanaka uye kushandura magetsi.

2. Rf zvishandiso:

Rf simba amplifier: inoshandiswa mu5G yekutaurirana base zviteshi uye setiraiti kutaurirana.

Microwave zvishandiso: Inokodzera radar uye isina waya yekutaurirana masisitimu.

3. Motokari itsva dzine simba:

Magetsi dhiraivha masisitimu: mota controllers uye inverters yemagetsi mota.

Kuchaja murwi: Power module yekukurumidza kuchaja michina.

4. Zvishandiso zveindasitiri:

Yakakwira voltage inverter: yeindasitiri mota kutonga uye simba manejimendi.

Smart grid: Yekufambisa kweHVDC uye magetsi emagetsi emagetsi.

5. Muchadenga:

Yepamusoro tembiricha yemagetsi: yakakodzera kune yakakwira tembiricha nharaunda dzeaerospace midziyo.

6. Nzvimbo yekutsvakurudza:

Wide bandgap semiconductor tsvagiridzo: yekuvandudza kwezvinhu zvitsva zvesemiconductor uye zvishandiso.

Iyo 12-inch silicon carbide substrate imhando yepamusoro-inoshanda semiconductor zvinhu substrate ine yakanakisa zvivakwa senge yakakwira yekupisa conductivity, yakakwirira yekuparara kwemunda simba uye rakakura band gap. Inoshandiswa zvakanyanya mumagetsi emagetsi, redhiyo frequency zvishandiso, mota nyowani dzesimba, kutonga kwemaindasitiri uye aerospace, uye chinhu chakakosha kusimudzira kuvandudzwa kwechizvarwa chinotevera chezvishandiso zvemagetsi zvine simba uye zvine simba.

Nepo silicon carbide substrates parizvino iine mashoma akananga maapplication mumagetsi evatengi akadai semagirazi eAR, kugona kwavo mukutonga kwesimba kwakanaka uye miniaturized zvemagetsi zvinogona kutsigira huremu, hwepamusoro-kushanda kwemagetsi ekugadzirisa emangwana AR/VR zvishandiso. Parizvino, kusimudzira kukuru kwesilicon carbide substrate yakanamirwa muminda yemaindasitiri senge mota nyowani dzesimba, zvivakwa zvekutaurirana uye maindasitiri otomatiki, uye inosimudzira semiconductor indasitiri kusimudzira mune inoshanda uye yakavimbika gwara.

XKH yakazvipira kupa emhando yepamusoro 12 "SIC substrates ine yakazara tekinoroji rutsigiro uye masevhisi, anosanganisira:

1. Kugadzirwa kwakagadzirirwa: Zvinoenderana nezvinodiwa nemutengi kupa akasiyana resistivity, crystal orientation uye pamusoro pekurapa substrate.

2. Maitiro ekugadzirisa: Ipa vatengi nerutsigiro rwehunyanzvi hwekukura epitaxial, kugadzirwa kwemidziyo uye mamwe maitiro ekuvandudza mashandiro echigadzirwa.

3. Kuedza uye certification: Ipai kuomarara chirema chekuonekwa uye chemhando yetifiketi kuti ive nechokwadi chekuti substrate inosangana nezviyero zveindasitiri.

4.R&d kubatirana: Pamwechete gadzirai michina mitsva yesilicon carbide nevatengi kusimudzira hunyanzvi hwetekinoroji.

Data chati

| 1 2 inch Silicon Carbide (SiC) Substrate Kutsanangurwa | |||||

| Giredhi | ZeroMPD Kugadzirwa Giredhi(Z Giredhi) | Standard Production Giredhi(P Giredhi) | Dummy Grade (D giredhi) | ||

| Diameter | 3 0 0 mm ~ 305mm | ||||

| Ukobvu | 4H-N | 750μm±15 μm | 750μm±25 μm | ||

| 4H-SI | 750μm±15 μm | 750μm±25 μm | |||

| Wafer Orientation | Kunze kweaxis : 4.0° yakananga <1120 >±0.5° ye4H-N, Paaxis: <0001>±0.5° ye4H-SI | ||||

| Micropipe Density | 4H-N | ≤0.4cm-2 | ≤4cm-2 | ≤25cm-2 | |

| 4H-SI | ≤5cm-2 | ≤10cm-2 | ≤25cm-2 | ||

| Resistivity | 4H-N | 0.015~0.024 Ω·cm | 0.015~0.028 Ω·cm | ||

| 4H-SI | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |||

| Yekutanga Flat Oriental | {10-10} ±5.0° | ||||

| Primary Flat Length | 4H-N | N/A | |||

| 4H-SI | Notch | ||||

| Kusabatanidzwa kumucheto | 3 mm | ||||

| LTV/TTV/Bow/Warp | ≤5μm/≤15μm/≤35 μm/≤55 μm | ≤5μm/≤15μm/≤35 □ μm/≤55 □ μm | |||

| Kukasharara | Polish Ra≤1 nm | ||||

| CMP Ra≤0.2 nm | Ra≤0.5 nm | ||||

| Edge Cracks By High Intensity Chiedza Hex Plates By High Intensity Chiedza Polytype Nzvimbo NeKusimba Kwakanyanya Chiedza Visual Carbon Inclusions Silicon Surface Scratches By High Intensity Chiedza | Hapana Cumulative area ≤0.05% Hapana Cumulative area ≤0.05% Hapana | Cumulative kureba ≤ 20 mm, single kureba≤2 mm Cumulative area ≤0.1% Cumulative area≤3% Yakawedzerwa nzvimbo ≤3% Cumulative kureba≤1×wafer dhayamita | |||

| Edge Chips By High Intensity Chiedza | Hapana anotenderwa ≥0.2mm hupamhi nekudzika | 7 inotenderwa, ≤1 mm imwe neimwe | |||

| (TSD) Threading screw dislocation | ≤500 cm-2 | N/A | |||

| (BPD) Base plane dislocation | ≤1000 cm-2 | N/A | |||

| Silicon Surface Kusvibiswa NeKunyanya Kusimba Chiedza | Hapana | ||||

| Packaging | Multi-wafer Cassette Kana Single Wafer Container | ||||

| Notes: | |||||

| 1 Miganho yekuremara inoshanda kune yese wafer pamusoro kunze kweiyo yekumucheto nzvimbo yekusarudzika. 2Kukwenya kunofanirwa kutariswa paSi face chete. 3 Iyo dislocation data inongobva kuKOH etched wafers. | |||||

XKH icharamba ichiisa mari mukutsvaga nekusimudzira kusimudzira kubudirira kwe12-inch silicon carbide substrates muhukuru hukuru, hurema hwakaderera uye hutsika hwepamusoro, apo XKH inoongorora mashandisirwo ayo munzvimbo dziri kubuda dzakadai semagetsi emagetsi (zvakadai semagetsi modules yeAR / VR zvishandiso) uye quantum computing. Nekudzikisa mutengo uye kuwedzera kugona, XKH ichaunza budiriro kune iyo semiconductor indasitiri.

Detailed Diagram