Wafer Oientation System yeCrystal Oientation Measurement

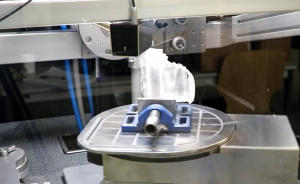

Equipment Introduction

Wafer orientation midziyo ndeyechokwadi midziyo yakavakirwa paX-ray diffraction (XRD) misimboti, inonyanya kushandiswa mukugadzira semiconductor, optical materials, ceramics, uye mamwe maindasitiri ezvinyorwa zvecrystalline.

Izvi zviridzwa zvinotarisa crystal lattice kutaridzika uye inotungamira chaiyo yekucheka kana kupukuta maitiro. Zvinhu zvakakosha zvinosanganisira:

- High-precision zviyero:Inokwanisa kugadzirisa crystallographic ndege dzine angular resolution pasi kusvika 0.001 ° .

- Sample yakakura kuenderana:Inotsigira mawafer anosvika 450 mm muhupamhi uye huremu hwe30 kg, akakodzera zvinhu zvakaita sesilicon carbide (SiC), safiro, uye silicon (Si).

- Modular dhizaini:Anowedzera mashandiro anosanganisira kuzunguza curve kuongororwa, 3D pamusoro chirema mepu, uye stacking zvishandiso zveakawanda-sample processing.

Key Technical Parameters

| Parameter Category | Yakajairika Values/Configuration |

| X-ray Source | Cu-Kα (0.4 × 1 mm yakatarisa nzvimbo), 30 kV inomhanyisa voltage, 0–5 mA inogadziriswa chubhu ikozvino |

| Angular Range | θ: -10° kusvika +50°; 2θ: -10° kusvika +100° |

| Kururama | Tilt angle resolution: 0.001 °, kuona kuremara kwepamusoro: ± 30 arcseconds (inozunguza curve) |

| Scanning Speed | Omega scan inopedza yakazara lattice kutaridzika mumasekondi mashanu; Theta scan inotora ~1 miniti |

| Muenzaniso Stage | V-groove, pneumatic suction, multi-angle kutenderera, inoenderana ne2-8-inch wafers |

| Expandable Functions | Rocking curve analysis, 3D mepu, stacking mudziyo, Optical defect yekuona (zvikwambo, GBs) |

Working Principle

1. X-ray Diffraction Foundation

- X-rays inodyidzana neatomic nuclei uye maerekitironi mucrystal lattice, ichigadzira diffraction mapatani. Mutemo waBragg ( nλ = 2d sinθ ) unotonga hukama huri pakati pemakona ekusiyanisa ( θ) ne lattice spacing (d).

Detector anotora aya mapatani, ayo anoongororwa kuvakazve chimiro checrystallographic.

2. Omega Scanning Technology

- Iyo kristaro inotenderera ichitenderera ichitenderedza axis yakagadziriswa nepo X-rays ichivhenekera.

- Madhigirii anounganidza masiginecha ediffraction mundege dzakawanda dzecrystallographic, zvichigonesa kugadzwa kwakazara kwelattice mumasekondi mashanu.

3. Rocking Curve Analysis

- Fixed crystal angle ine akasiyana eX-ray incidence angles kuyera peak wide (FWHM), kuongorora hurema hwelatisi uye kunetsa.

4. Automated Control

- PLC uye touchscreen interfaces inogonesa preset yekucheka angles, chaiyo-nguva mhinduro, uye kubatanidzwa nemichina yekucheka yekuvhara-loop control.

Advantages uye Features

1. Kurongeka uye Kubudirira

- Angular accuracy ± 0.001 °, defect yekuona kugadziriswa <30 arcseconds.

- Omega scan speed i200 × nekukurumidza pane yechinyakare Theta scans.

2. Modularity uye Scalability

- Inokwidziridzwa kune yakasarudzika maapplication (semuenzaniso, SiC wafers, turbine blades).

- Inosanganisirwa neMES masisitimu eiyo chaiyo-nguva kugadzirwa kwekutarisa.

3. Kugarisana uye Kugadzikana

- Inogashira sampuli dzisina kuumbwa (semuenzaniso, dzakatsemuka dzesafire ingots).

- Air-cooled design inoderedza zvinodiwa zvekugadzirisa.

4. Intelligent Operation

- Kamwe-tinya calibration uye akawanda-basa kugadzirisa.

- Auto-calibration ine referensi makristasi kuderedza kukanganisa kwevanhu.

Applications

1. Semiconductor Manufacturing

- Wafer dicing orientation: Inosarudza Si, SiC, GaN wafer yekumisikidza yekugonesa kucheka kunyatsoita.

- Defect mepu: Inozivisa madhiri epamusoro kana kutsemuka kuti uvandudze goho rechip.

2. Optical Materials

- Nonlinear makristasi (semuenzaniso, LBO, BBO) yemidziyo yelaser.

- Sapphire wafer reference surface marking ye LED substrates.

3. Ceramics uye Composites

- Inoongorora kutaridzika kwezviyo muSi3N4 uye ZrO2 kune yakakwirira-tembiricha maapplication.

4. Research uye Quality Control

- Makunivhesiti / maLab ekuvandudza zvinhu (semuenzaniso, alloys akakwira-entropy).

- Industrial QC kuti ive nechokwadi chekuenderana.

XKH's Services

XKH inopa yakazara lifecycle tekinoroji tsigiro yewafer yekumisikidza zviridzwa, zvinosanganisira kuisirwa, process parameter optimization, rocking curve ongororo, uye 3D pamusoro chirema mepu. Tailored mhinduro (semuenzaniso, ingot stacking tekinoroji) inopihwa kuti iwedzere semiconductor uye yekuona zvinhu kugadzirwa zvakanaka neinopfuura 30%. Chikwata chakazvitsaurira chinoitisa pa-saiti kudzidziswa, nepo 24/7 tsigiro iri kure uye nekukurumidza spare chikamu kutsiva inovimbisa kuvimbika kwemidziyo.