TGV Glass inoisa 12inch wafer Girazi kubaya

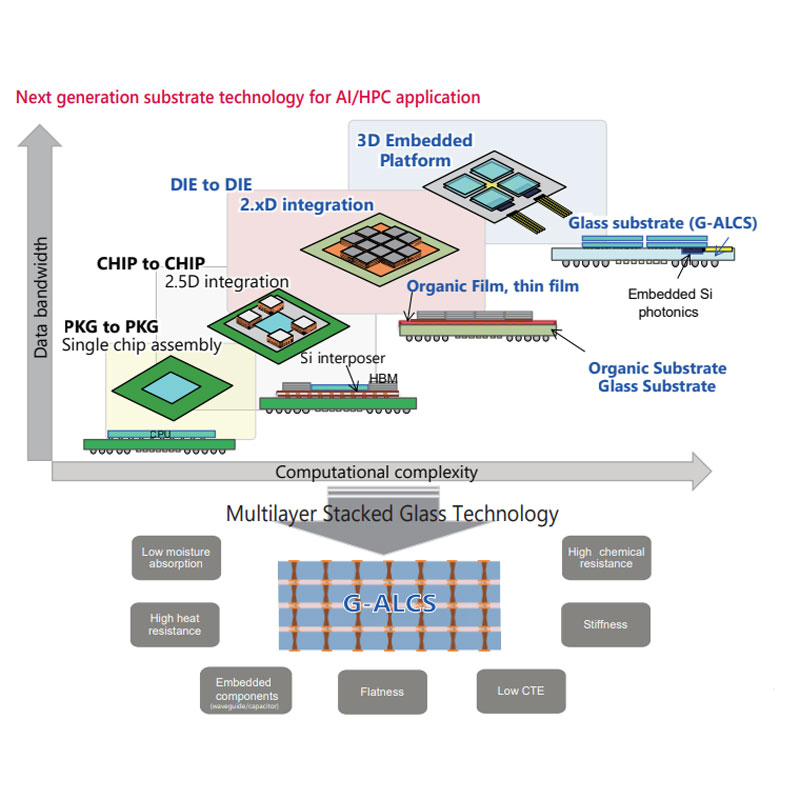

Girazi substrates inoita zviri nani maererano nemafuta ekupisa, kugadzikana kwemuviri, uye anowedzera kupisa uye asinganyanyi kutarisana nehondo kana deformation matambudziko nekuda kwekupisa kwakanyanya;

Mukuwedzera, iyo yakasarudzika magetsi emhando yegirazi musimboti inobvumira yakaderera kurasikirwa kwedielectric, ichibvumira yakajeka chiratidzo uye kufambisa kwesimba. Nekuda kweizvozvo, kurasikirwa kwesimba panguva yekufambisa kwechiratidzo kunoderedzwa uye kushanda kwese kwechip kunokwidziridzwa. Ukobvu hwegirazi musimboti substrate hunogona kudzikiswa nehafu kana ichienzaniswa neABF plastiki, uye kutetepa kunonatsiridza kufambisa kwechiratidzo uye kushanda nesimba.

Gomba kugadzira tekinoroji yeTGV:

Laser induced etching nzira inoshandiswa kukwevera inoenderera mberi denaturation zone kuburikidza nepulsed laser, uye ipapo iyo laser yakarapwa girazi inoiswa muhydrofluoric acid mhinduro ye etching. Iyo etching rate ye denaturation zone girazi muhydrofluoric acid inokurumidza kupfuura iyo yegirazi isina undenaturated kuumba kuburikidza nemakomba.

TGV zadza:

Kutanga, TGV mapofu maburi anogadzirwa. Chechipiri, mutsara wemhodzi wakaiswa mukati megomba reTGV remapofu nephysical vapor deposition (PVD). Yetatu, pasi-kumusoro electroplating inowana seamless kuzadza kweTGV; Pakupedzisira, kuburikidza nekubatana kwenguva pfupi, kugaya shure, kemikari mechanical polishing (CMP) kuratidzwa kwemhangura, kusabatanidzwa, kugadzira TGV metal-filled transfer plate.

Detailed Diagram