Zvidimbu zvegirazi reSoda-Lime - Zvakanyatsogadzirwa uye Zvinodhura Zvikuru kune Maindasitiri

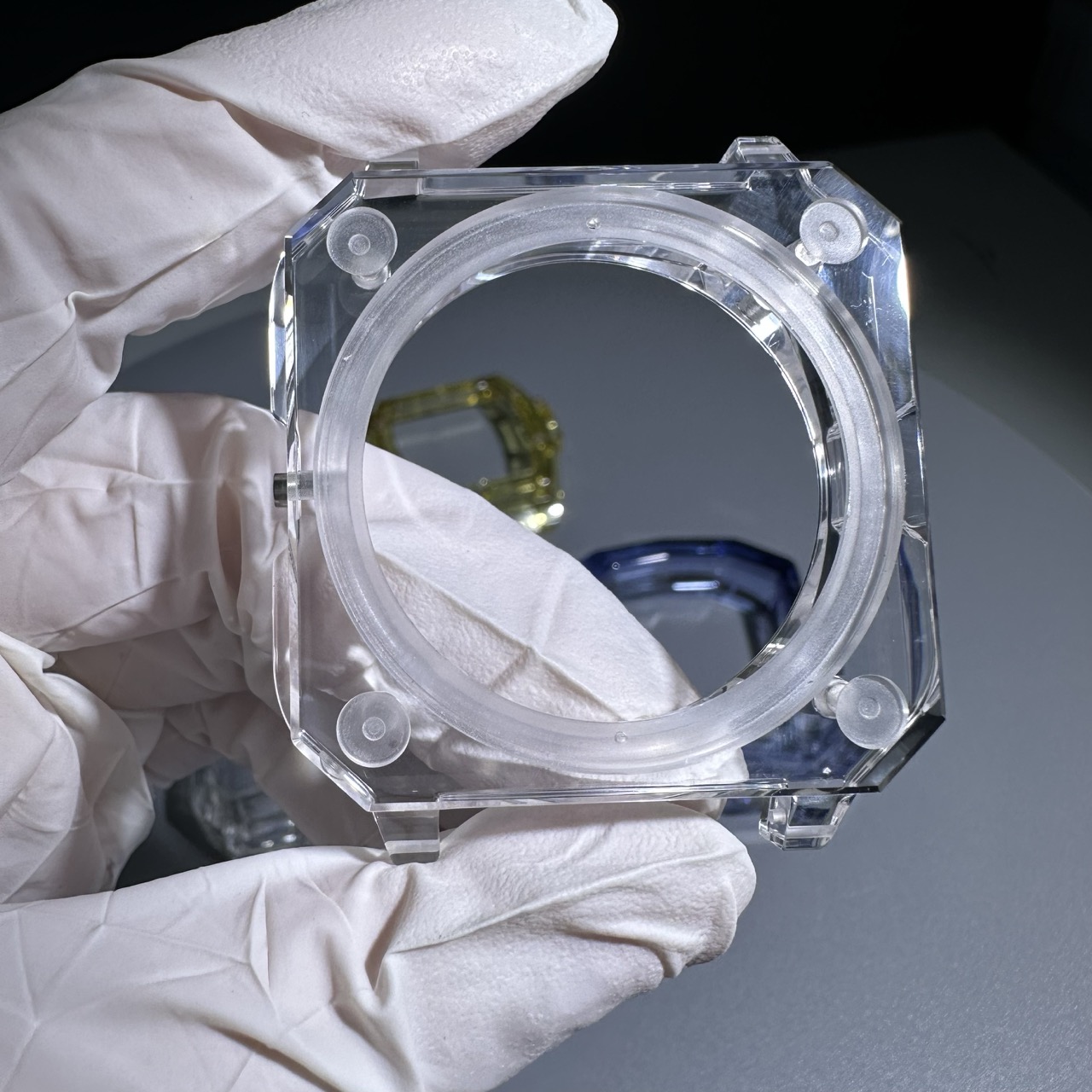

Dhayagiramu Yakadzama

Pfupiso yeGirazi reQuartz

Zvigadziko zveSoda-limemawafer egirazi akagadzirwa negirazi repamusoro-soro resoda-lime silicate — chinhu chinoshandiswa zvakasiyana-siyana uye chinodhura zvishoma chinoshandiswa zvakanyanya mumaindasitiri ekuona, emagetsi, uye ekuputira. Inozivikanwa nekufambiswa kwayo kwakanaka kwechiedza, kunaka kwenzvimbo yakati sandara, uye kugadzikana kwemuchina, girazi resoda-lime rinopa hwaro hwakavimbika hwemhando dzakasiyana dzekuisa zvidimbu zvakatetepa, photolithography, uye mashandisirwo emurabhoritari.

Kushanda kwayo kwakaringana uye kwakaringana kunoita kuti ive sarudzo inoshanda kune ese ari maviri R&D uye nharaunda dzekugadzira huwandu.

Zvinhu Zvikuru & Mabhenefiti

-

Kujeka Kwakanyanya Kwemaziso:Kutapurirana kwakasiyana-siyana mu spectrum inooneka (400–800 nm), kwakakodzera kuongororwa kwemaziso uye kufungidzira.

-

Nzvimbo Yakatsetseka Yakakwenenzverwa:Mativi ese ari maviri anogona kukweshwa zvakanaka kuti pave nekukweshana kwakaderera (<2 nm), zvichiita kuti pave nekunamatira kwakanaka pakupeta.

-

Kugadzikana kweDimensional:Inochengetedza kutwasuka uye kufanana kwakafanana, inoenderana nekurongeka kwakarurama uye gadziriro dzemetrology.

-

Zvinhu Zvinodhura Zvishoma:Inopa imwe nzira inodhura zvishoma pane borosilicate kana fused silica substrates yekushandisa tembiricha yakajairwa.

-

Kugona kushandiswa:Inochekwa, kuboorwa, kana kugadzirwa zviri nyore kuti ishandiswe nemagadzirirwo emagetsi kana emagetsi.

-

Kuenderana kweMakemikari:Inoenderana ne photoresists, manamati, uye zvinhu zvakawanda zvakatetepa zvekuisa firimu (ITO, SiO₂, Al, Au).

Nekusanganiswa kwayo kwekujeka, simba, uye kugona kutenga zvinhu zviri nyore,girazi resoda-limeichiri chimwe chezvinhu zvinonyanya kushandiswa mumarabhoritari, mumashopu ekuona, uye munzvimbo dzekuputira dzakatetepa.

Kugadzira & Hunhu Hwepamusoro

Imwe neimwesubstrate yesoda-limeyakagadzirwa uchishandisa girazi remhando yepamusoro rinochekwa nemazvo, kukweshwa, uye kukweshwa mativi maviri kuti riite kuti nzvimbo yacho ive yakati sandara.

Matanho akajairika ekugadzira anosanganisira:

-

Maitiro Ekuyangarara:Kugadzira magirazi akaenzana, akanyatsoti sandara, achishandisa tekinoroji yekunyungudutsa tin float.

-

Kucheka & Kuumba:Kucheka ne laser kana dhaimani kuita denderedzwa kana rectangular substrate.

-

Kukwesha Kwakanaka:Kusvika pakutsetseka kwepamusoro uye kutsvedzerera kwemhando yepamusoro kune rimwe kana mativi ese ari maviri.

-

Kuchenesa & Kurongedza:Kucheneswa kweUltrasonic mumvura yakabviswa maion, kuongororwa kusina zvidimbu, uye kurongedza mukamuri rakachena.

Maitiro aya anoita kuti pave nekuenderana kwakanaka uye kupedzwa kwepamusoro kwakakodzera basa rekugadzira machira kana kugadzira zvinhu zvidiki.

Mashandisirwo

Zvigadziko zveSoda-limeanoshandiswa mumhando dzakasiyana-siyana dzesainzi, optical, uye semiconductor applications, kusanganisira:

-

Mahwindo & Magirazi eOptical:Mapurati epasi ekuputira magirazi uye kugadzira mafirita.

-

Kuiswa Kwemafirimu Matete:Zvishandiso zvakanaka zvekutakura maITO, SiO₂, TiO₂, uye mafirimu esimbi.

-

Tekinoroji yekuratidza:Inoshandiswa mumagirazi ekumashure, mukuchengetedza zviratidziro, uye mukuenzanisa sampuli.

-

Tsvagiridzo yeSemiconductor:Zvifambiso zvekutakura zvakachipa kana mawafer ekuyedza mukuita kwephotolithography.

-

Mapuratifomu eLaser & Sensor:Zvinhu zvinotsigira zviri pachena zvekuyedza kuongorora magirazi (optical alignment) uye kuongorora mapurobe (probe).

-

Kushandiswa Kwedzidzo & Kuedza:Inoshandiswa zvakanyanya mumarabhoritari pakuedza kuputira, kutema, uye kubatanidza.

Magadzirirwo Akajairika

| Paramita | Tsanangudzo |

|---|---|

| Zvinhu | Girazi reSoda-Lime Silicate |

| Dhayamita | 2", 3", 4", 6", 8" (yakagadzirirwa zviripo) |

| Ukobvu | 0.3–1.1 mm muyero |

| Kupedzisa Kwepamusoro | Yakapukutwa nemativi maviri kana kuti yakapukutwa nemativi maviri |

| Kufara | ≤15 µm |

| Kuoma Kwepamusoro (Ra) | <2 nm |

| Kutapurirana | ≥90% (Nzvimbo inoonekwa: 400–800 nm) |

| Kuwanda kwevanhu | 2.5 g/cm³ |

| Kuwanda kweThermal Coefficient | ~9 × 10⁻⁶ /K |

| Kuoma | ~6 Mohs |

| Refractive Index (nD) | ~1.52 |

Mibvunzo Inowanzo bvunzwa

Mubvunzo 1: Ndezvipi zvinoshandiswa pakugadzira soda-lime substrates?

A: Dzinoshandiswa sezvinhu zvekutanga zvekuputira zvidimbu zvitete, kuyedza kwemaziso, kuyedza photolithography, uye kugadzira mahwindo emaziso nekuda kwekujeka kwawo uye kusatsetseka kwawo.

Mubvunzo wechipiri: Ko ma substrates e soda-lime anogona kutsungirira kupisa kwakanyanya here?

A: Dzinogona kushanda kusvika pa300°C. Kuti dzisanyanya kupisa, dzinokurudzirwa kushandisa borosilicate kana fused silica substrates.

Mubvunzo wechitatu: Ko ma substrates akakodzera here kuisa coating?

A: Ehe, nzvimbo dzavo dzakatsetseka uye dzakachena dzakanakira kuiswa kwemhepo inodziya (PVD), kuiswa kwemhepo inodziya nemakemikari (CVD), uye maitiro ekubuda kwemvura inodziya.

Mubvunzo wechina: Kugadzirisa zvinhu kunogoneka here?

A: Ehe. Saizi, maumbirwo, ukobvu, uye kupedzisa kwemupendero zvakagadzirwa zvinoenderana nezvinodiwa zvekushandisa.

Mubvunzo 5: Dzinoenzaniswa sei ne substrates dzeborosilicate?

A: Girazi reSoda-lime rinodhura zvishoma uye riri nyore kugadzira asi harina simba rekupisa uye remakemikari zvakanyanya kana tichienzanisa negirazi reborosilicate.

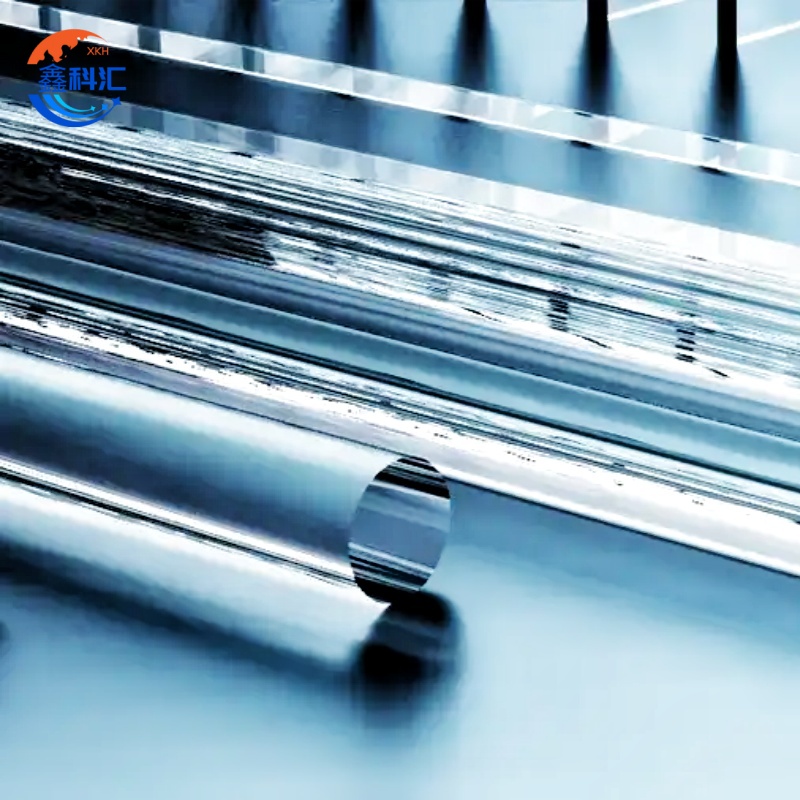

Nezvedu

XKH inonyanya kugadzira, kugadzira, uye kutengesa magirazi egirazi egirazi uye zvinhu zvitsva zvekristaro. Zvigadzirwa zvedu zvinopa zvigadzirwa zvemagetsi, zvemagetsi zvevatengi, uye zvemauto. Tinopa zvikamu zveSapphire optical, malenzi efoni, Ceramics, LT, Silicon Carbide SIC, Quartz, uye mawafer egirazi esemiconductor. Tine hunyanzvi uye michina yemazuva ano, tinobudirira mukugadzirisa zvigadzirwa zvisiri zvemazuva ano, tichivavarira kuva bhizinesi rinotungamira rezvigadzirwa zvemagetsi.