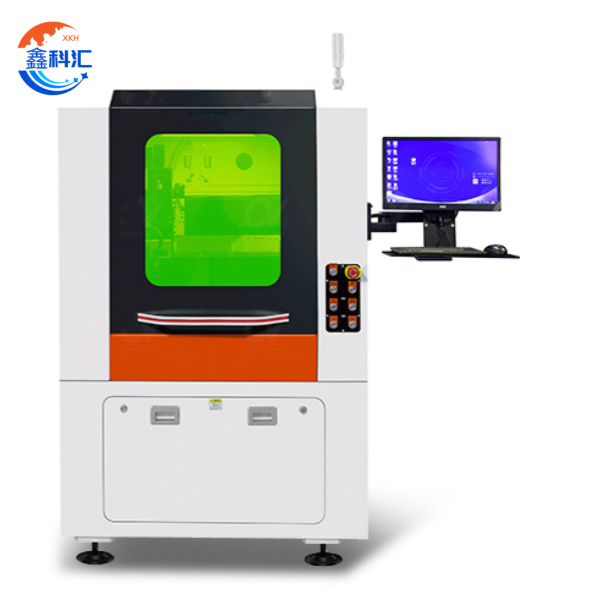

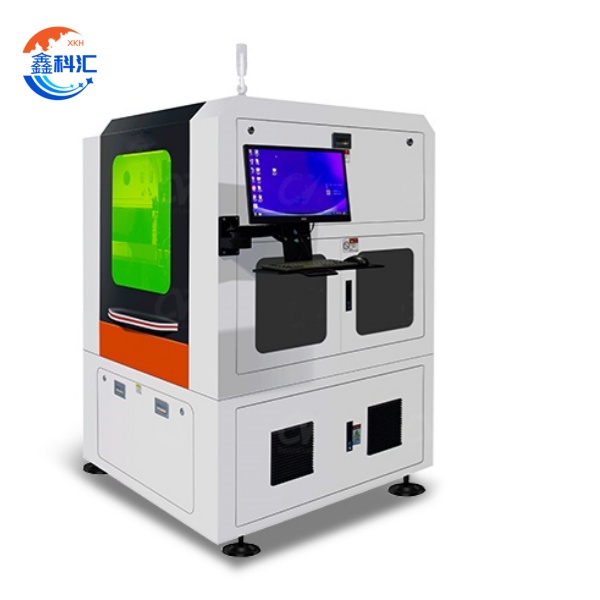

Diki tafura Laser punching muchina 1000W-6000W shoma aperture 0.1MM inogona kushandiswa simbi girazi zvedongo zvinhu.

Inoshanda zvinhu

1. Metal zvinhu: zvakadai sealuminium, mhangura, titanium alloy, simbi isina tsvina, nezvimwewo.

2. Zvisiri-metallic zvinhu: sepurasitiki (kusanganisira polyethylene PE, polypropylene PP, polyester PET nemamwe mafirimu epurasitiki), girazi (kusanganisira girazi rakajairika, girazi rakakosha senge girazi chena, girazi reK9, girazi reborosilicate rakakwirira, girazi requartz, nezvimwewo, asi girazi rakanyorova nekuda kwechimiro chayo checeramic, girasi rinodziya nekuda kwekukosha kwayo, girasi rinodziya uye girazi rinopisa on.

3. Composite material: inoumbwa nezvinhu zviviri kana kupfuura zvine zvimiro zvakasiyana kuburikidza nemitoo yemuviri kana kemikari, ine hunhu hwakanakisa hwakazara.

4.Special zvinhu: Munzvimbo dzakananga, laser punching michina inogonawo kushandiswa kugadzirisa zvimwe zvakakosha zvinhu.

Specification parameters

| Zita | Data |

| Laser simba: | 1000W-6000W |

| Kucheka chokwadi: | ±0.03MM |

| Minimum-value aperture: | 0.1MM |

| Urefu hwekucheka: | 650MM×800MM |

| Positional accuracy: | ≤±0.008MM |

| Kudzokororwa kwechokwadi: | 0.008MM |

| Kucheka gasi: | Air |

| Fixed modhi: | Pneumatic edge clamping, fixture rutsigiro |

| Driving system: | Magnetic kuturika linear mota |

| Kucheka ukobvu | 0.01MM-3MM |

Technical zvakanakira

1.Efficient drilling: Kushandiswa kwe-high-energy laser beam ye-non-contact processing, nokukurumidza, 1 yechipiri kupedzisa kushandiswa kwemakomba maduku.

2.High precision: Nekunyatso kudzora simba, pulse frequency uye kutarisa nzvimbo ye laser, basa rekuchera ne micron precision inogona kuwanikwa.

3. Inoshandiswa zvakanyanya: inogona kugadzirisa zvakasiyana-siyana zvebrittle, zvakaoma kugadzirisa uye zvinhu zvakakosha, zvakadai sepurasitiki, rabha, simbi (simbi isina tsvina, aluminium, mhangura, titanium alloy, nezvimwewo), girazi, ceramics nezvimwe zvakadaro.

4. Intelligent operation: The laser punching machine yakashongedzerwa neyepamusoro nhamba yekudzora hurongwa, iyo ine hungwaru zvakanyanya uye nyore kubatanidza nekombuta inobatsirwa dhizaini uye komputa inobatsira yekugadzira system kuona nekukurumidza hurongwa uye optimization yekupfuura yakaoma uye kugadzirisa nzira.

Mamiriro ekushanda

1.Kusiyana-siyana: inogona kuita zvakasiyana-siyana zvakaoma maumbirwo egomba kugadzirisa, zvakadai semakomba akatenderera, makomba emativi, maburi matatu uye mamwe maburi akakosha.

2.Hunhu hwepamusoro: Hunhu hwegomba hwakakwirira, mupendero wakatsetseka, hapana kunzwa kwakashata, uye deformation idiki.

3.Automation: Inogona kupedzisa micro-hole processing nehukuru hwakafanana hwekuvhara uye kugovera yunifomu panguva imwe chete, uye inotsigira boka rekugadzirisa gomba pasina kupindira kwebhuku.

Equipment features

■ Saizi shoma yemidziyo, kugadzirisa dambudziko renzvimbo yakamanikana.

■ High precision, gomba guru rinogona kusvika 0.005mm.

■ Midziyo iri nyore kushandisa uye iri nyore kushandisa.

■ Chiedza chechiedza chinogona kuchinjwa maererano nezvinhu zvakasiyana-siyana, uye kuenderana kwakasimba.

∎ Nzvimbo diki inokanganisa kupisa, kushomeka kweoxidation yakatenderedza maburi.

Nzvimbo yekushandisa

1. Electronics indasitiri

●Printed Circuit Board (PCB) kubaya:

Microhole machining: Inoshandiswa kugadzira ma microholes ane dhayamita isingasviki 0.1mm paPCBS kusangana nezvinodiwa zvehigh-density interconnect (HDI) mabhodhi.

Mapofu uye akavigwa makomba: Machina mapofu uye akavigwa makomba mu-multi-layer PCBS kuvandudza mashandiro uye kubatanidzwa kwebhodhi.

● Semiconductor kurongedza:

Lead frame drilling: Maburi chaiwo anogadzirwa mu semiconductor lead frame yekubatanidza chip kudunhu rekunze.

Wafer yekucheka rubatsiro: Bhowa maburi muwafer kubatsira mukucheka kunotevera uye kurongedza maitiro.

2. Precision michina

●Micro parts processing:

Precision giya kudhiraivha: Machina akakwira-chaiyo maburi pamagiya madiki ekunyatso kufambisa masisitimu.

Sensor component drilling: Machining microholes pane zvikamu zve sensor kuti uvandudze kunzwa uye kupindura kumhanya kwe sensor.

●Kugadzira Mold:

Mold inotonhorera gomba: Machining kutonhora gomba pane jekiseni mold kana kufa kukanda mold kuti ikwidzise kupisa kwekupisa kuita kwe mold.

Vent processing: Machina madiki maburi pane mold kuderedza kuumba kukanganisa.

3. Zvishandiso zvekurapa

●Minimally invasive Surgical Instruments:

Catheter perforation: Microholes inogadziriswa mune zvishoma invasive yekuvhiya catheters yekuendesa zvinodhaka kana kuyerera kwemvura.

Endoscope components: Precision maburi anogadzirwa mulenzi kana mudziyo musoro we endoscope kuti uvandudze mashandiro echiridzwa.

●Drug delivery System:

Microneedle array drilling: Machining microholes pane chigamba chezvinodhaka kana microneedle array kudzora mwero wekuburitswa kwezvinodhaka.

Biochip drilling: Microholes inogadziriswa pane biochips ye cell tsika kana kuonekwa.

4. Optical midziyo

●Fiber optic connector:

Optical fiber end gole drilling: Machining microholes pamagumo echiso che optical connector kuti uvandudze optical signal transmission performance.

Fiber array machining: Kugadzira maburi akanyanya-chaiyo pafiber array plate kune akawanda-channel optical kutaurirana.

●Optical sefa:

Sefa kudhiraivha: Machina mamicroholes pane yekuona sefa kuti uwane kusarudzwa kweakananga wavelengths.

Diffractive element machining: Machining microholes pane diffractive optical zvinhu zvelaser beam kupatsanura kana kuumbwa.

5. Kugadzirwa kwemotokari

● Fuel jekiseni system:

Jekiseni nozzle punching: Kugadzira diki-maburi pane jekiseni nozzle kukwidziridza mafuta atomization maitiro uye kunatsiridza kugona kwekupisa.

● Kugadzira sensor:

Pressure sensor drilling: Machining microholes pane yekumanikidza sensor diaphragm kuti uvandudze kunzwa uye kurongeka kwe sensor.

● Simba rebhatiri:

Battery pole chip drilling: Machining microholes pa lithium bhatiri pole chips kuvandudza electrolyte kupinda uye ion kutakura.

XKH inopa huwandu hwakazara hwese-yekumira masevhisi kune diki tafura laser perforators, kusanganisira asi isina kuganhurirwa kune: Nyanzvi yekutengesa kubvunza, yakagadziridzwa dhizaini dhizaini, yemhando yepamusoro yemidziyo yekuisa, kuisirwa kwakanaka uye kutumira, yakadzama kudzidziswa kwekushanda, kuve nechokwadi chekuti vatengi vanowana yakanyanya kunaka, yakarurama uye isina hanya sevhisi ruzivo mukuita punching process.

Detailed Diagram