SiO₂ Quartz Wafer Quartz Wafers SiO₂ MEMS Tembiricha 2″ 3″ 4″ 6″ 8″ 12″

Detailed Diagram

Nhanganyaya

Quartz wafers anoita basa rinokosha mukusimudzira zvigadzirwa zvemagetsi, semiconductor, uye optics maindasitiri. Inowanikwa mune smartphones inotungamira GPS yako, yakanyudzwa mune yakakwirira-frequency base zviteshi zvinogonesa 5G network, uye yakabatanidzwa mumidziyo yekugadzira inotevera-gen microchips, wafers wequartz akakosha. Aya epamusoro-akachena ma substrates anogonesa hunyanzvi mune zvese kubva kuquantum computing kusvika kumberi mafotonics. Kunyangwe ichitorwa kubva kune imwe yemaminerari ePasi akanyanya kuwanda, mawaferi equartz anogadzirwa kune anoshamisa mwero wekurongeka uye kuita.

Chii chinonzi Quartz Wafers

Quartz wafers matete, madhisiki edenderedzwa akagadzirwa kubva kune Ultra-pure synthetic quartz crystal. Inowanikwa mumadhayamita akajairwa kubva pa2 kusvika pa12 inches, mawafer equartz anowanzo siyana muukobvu kubva pa0.5 mm kusvika pa6 mm. Kusiyana neakasikwa quartz, iyo inoumba isingawanzo prismatic makristasi, synthetic quartz inokura pasi peyakanyatso kudzora lab mamiriro, ichigadzira mayunifomu ekristaro zvimiro.

Iyo inherent crystallinity yequartz wafers inopa isingaenzaniswi makemikari kuramba, optical transparency, uye kugadzikana pasi pekushisa kwepamusoro uye kushushikana kwemagetsi. Aya maficha anoita quartz wafers chikamu chehwaro cheiyo chaiyo michina inoshandiswa mukufambisa data, kunzwa, computation, uye laser-based tekinoroji.

Quartz Wafer Zvinotsanangurwa

| Quartz Type | 4 | 6 | 8 | 12 |

|---|---|---|---|---|

| Size | ||||

| Diameter (inch) | 4 | 6 | 8 | 12 |

| Ukobvu (mm) | 0.05–2 | 0.25–5 | 0.3–5 | 0.4–5 |

| Diameter Tolerance (inch) | ±0.1 | ±0.1 | ±0.1 | ±0.1 |

| Hukobvu Kushivirira (mm) | Customizable | Customizable | Customizable | Customizable |

| Optical Properties | ||||

| Refractive Index @365 nm | 1.474698 | 1.474698 | 1.474698 | 1.474698 |

| Refractive Index @546.1 nm | 1.460243 | 1.460243 | 1.460243 | 1.460243 |

| Refractive Index @1014 nm | 1.450423 | 1.450423 | 1.450423 | 1.450423 |

| Yemukati Transmittance (1250–1650 nm) | >99.9% | >99.9% | >99.9% | >99.9% |

| Total Transmittance (1250–1650 nm) | >92% | >92% | >92% | >92% |

| Machining Quality | ||||

| TTV (Total Thickness Variation, µm) | <3 | <3 | <3 | <3 |

| Kufuratira (µm) | ≤15 | ≤15 | ≤15 | ≤15 |

| Kushata Kwepamusoro (nm) | ≤1 | ≤1 | ≤1 | ≤1 |

| Kukotama (µm) | <5 | <5 | <5 | <5 |

| Zvinhu Zvenyama | ||||

| Density (g/cm³) | 2.20 | 2.20 | 2.20 | 2.20 |

| Mudiki's Modulus (GPa) | 74.20 | 74.20 | 74.20 | 74.20 |

| Mohs Kuoma | 6–7 | 6–7 | 6–7 | 6–7 |

| Shear Modulus (GPa) | 31.22 | 31.22 | 31.22 | 31.22 |

| Poisson's Ratio | 0.17 | 0.17 | 0.17 | 0.17 |

| Compressive Strength (GPA) | 1.13 | 1.13 | 1.13 | 1.13 |

| Tensile Simba (MPa) | 49 | 49 | 49 | 49 |

| Dielectric Constant (1 MHz) | 3.75 | 3.75 | 3.75 | 3.75 |

| Thermal Properties | ||||

| Strain Point (10¹⁴.⁵ Pa·s) | 1000°C | 1000°C | 1000°C | 1000°C |

| Annealing Point (10¹³ Pa·s) | 1160°C | 1160°C | 1160°C | 1160°C |

| Kupfava (10⁷.⁶ Pa·s) | 1620°C | 1620°C | 1620°C | 1620°C |

Zvishandiso zveQuartz Wafers

Quartz wafers akajairwa-engineer kuti asangane nezvinodiwa zvekushandisa mumaindasitiri anosanganisira:

Electronics uye RF Devices

- Quartz wafers ndiwo musimboti kune quartz crystal resonators uye oscillator inopa masaini masaini emafoni, mayuniti eGPS, makomputa, uye isina waya yekutaurirana michina.

- Kuwedzera kwavo kuderera kwemafuta uye yakakwira Q-factor inoita kuti quartz wafers ikwane kune yakakwirira-kugadzikana nguva maseketi uye RF mafirita.

Optoelectronics uye Imaging

- Quartz wafers inopa yakanakisa UV uye IR transmittance, ichiita kuti ive yakakodzera kune optical lenzi, danda kupatsanura, laser windows, uye madetector.

- Kupokana kwavo nemwaranzi kunogonesa kushandiswa mune yakakwirira-simba fizikisi uye space zviridzwa.

Semiconductor uye MEMS

- Quartz wafers anoshanda sema substrates epamusoro-frequency semiconductor maseketi, kunyanya muGaN neRF application.

- MuMEMS (Micro-Electro-Mechanical Systems), mawaferi equartz anoshandura masaini masaini kuita emagetsi kuburikidza nepiezoelectric athari, achigonesa masensa senge gyroscopes uye accelerometers.

Advanced Manufacturing & Labs

- Yakakwirira-kuchena quartz wafers anoshandiswa zvakanyanya mumakemikari, biomedical, uye photonic labs emeso maseru, UV cuvettes, uye yakakwirira-temp sampuli kubata.

- Kuenderana kwavo nenzvimbo dzakanyanyisa kunoita kuti ive yakakodzera kumakamuri eplasma uye maturusi ekuisa.

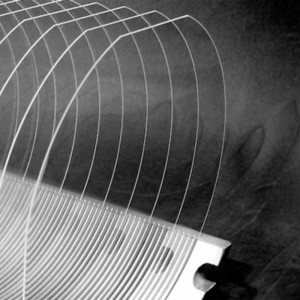

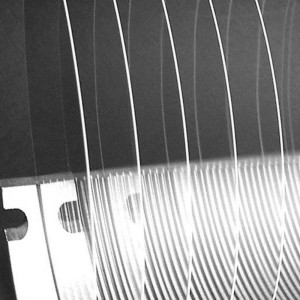

Magadzirirwo eQuartz Wafers

Kune maviri ekutanga nzira dzekugadzira dze quartz wafers:

Yakasanganiswa Quartz Wafers

Mafused quartz wafers anogadzirwa nekunyungudutsa echisikigo quartz granules muamorphous girazi, obva acheka nekupukuta iyo yakasimba block kuita matete mawafer. Aya ma quartz wafers anopa:

- Yakasarudzika UV kujeka

- Kupisa kwakakura kwekushanda kwemhando (> 1100°C)

- Yakanakisa thermal shock resistance

Izvo zvakakodzerwa nemidziyo yelithography, mabiru ekupisa, uye mahwindo emeso asi haana kukodzera piezoelectric application nekuda kwekushaikwa kwecrystalline kurongeka.

Yakagadzirwa Quartz Wafers

Yakagadzirwa quartz wafers inokura zvakagadzirirwa kugadzira makristasi asina kukanganisa ane chaiyo lattice inotaridzika. Aya mawafer akagadzirirwa maapplication anoda:

- Makona chaiwo akachekwa (X-, Y-, Z-, AT-cut, nezvimwewo)

- High-frequency oscillators uye SAW mafirita

- Optical polarizers uye advanced MEMS zvishandiso

Maitiro ekugadzira anosanganisira kukura kwembeu mu autoclaves, inoteverwa nekucheka, kutarisisa, annealing, uye polishing.

Inotungamira Quartz Wafer Suppliers

Vatengesi vepasirese vane hunyanzvi hwepamusoro-chaiyo quartz wafers vanosanganisira:

- Heraeus(Germany) - yakasanganiswa uye yakagadzirwa quartz

- Shin-Etsu Quartz(Japan) - yakakwirira-kuchena wafer mhinduro

- WaferPro(USA) - yakafara dhayamita quartz wafers uye substrates

- Korth Kristalle(Germany) - zvimedu zvekristaro zvekugadzira

Basa Rinoshanduka reQuartz Wafers

Quartz wafers anoenderera mberi nekushanduka sezvinhu zvakakosha mune inosimukira tech landscapes:

- Miniaturization- Quartz wafers ari kugadzirwa ane akasimba kushivirira kune compact mudziyo wekubatanidza.

- Higher Frequency Electronics-Magadzirirwo matsva equartz wafer ari kusundira mummWave uye THz madomasi e6G uye radar.

- Next-Gen Sensing-Kubva kumotokari dzinozvimiririra kuenda kumaindasitiri IoT, ma sensors equartz ari kuwedzera kukosha.

Mibvunzo inowanzo bvunzwa nezve quartz wafers

1. Chii chinonzi quartz wafer?

A quartz wafer idhishi rakatetepa, rakatsetseka rakagadzirwa kubva kucrystalline silicon dioxide (SiO₂), rinowanzo gadzirwa muyakajairwa semiconductor saizi (semuenzaniso, 2", 3", 4", 6", 8", kana 12 "). Inozivikanwa nekuchena kwayo kwepamusoro, kugadzikana kwemafuta, uye kujeka kwemaziso, quartz wafer inoshandiswa se substrate kana mutakuri mumhando dzakasiyana-siyana dzepamusoro-soro dzekushandisa semiconductor kugadzirwa, MEMS zvishandiso, optical masisitimu, uye vacuum maitiro.

2. Ndeupi musiyano pakati pe quartz ne silica gel?

Quartz icrystalline yakasimba fomu yesilicon dioxide (SiO₂), nepo silica gel iri amorphous uye porous fomu yeSiO₂, inowanzoshandiswa se desiccant kutora unyoro.

- Quartz yakaoma, yakajeka, uye inoshandiswa mumagetsi, optical, uye maindasitiri ekushandisa.

- Silica gel inoratidzika sediki diki kana granules uye inonyanya kushandiswa kudzora humidity mukurongedza, zvemagetsi, uye kuchengetedza.

3. Makristasi equartz anoshandiswa chii?

Makristasi eQuartz anoshandiswa zvakanyanya mumagetsi uye optics nekuda kweiyo piezoelectric zvivakwa (anogadzira chaji yemagetsi pasi pekunetseka kwemagetsi). Zvishandiso zvakajairika zvinosanganisira:

- Oscillators uye frequency control(semuenzaniso, mawachi equartz, wachi, mamicrocontrollers)

- Optical components(semuenzaniso, lenses, waveplates, windows)

- Resonators uye mafiritamuRF nemidziyo yekutaurirana

- Sensorsnokuda kwekumanikidza, kukurumidza, kana simba

- Semiconductor kugadzirwase substrates kana process windows

4. Nei quartz ichishandiswa mumamicrochips?

Quartz inoshandiswa mune zvine chekuita nemicrochip nekuti inopa:

- Thermal kugadzikanapanguva yekupisa kwepamusoro-soro senge diffusion uye annealing

- Kuiswa kwemagetsinekuda kweiyo dielectric properties

- Chemical resistancekune asidhi uye zvinonyungudutsa zvinoshandiswa mukugadzira semiconductor

- Dimensional precisionuye kuderera kwekuwedzera kwekushisa kwekugadzirisa lithography yakavimbika

- Nepo quartz pachayo isingashandiswe seyakashanda semiconductor zvinhu (sesilicon), inoita basa rakakosha rekutsigira munzvimbo yekugadzira-kunyanya mumavira, makamuri, uye mafotomask substrates.

Nezvedu

XKH inyanzvi mukusimudzirwa kwepamusoro-soro, kugadzira, uye kutengesa kwegirazi remaziso uye zvinhu zvitsva zvekristaro. Zvigadzirwa zvedu zvinoshanda zvemagetsi zvemagetsi, zvemagetsi zvevatengi, uye mauto. Isu tinopa Sapphire optical components, nharembozha lens inovhara, Ceramics, LT, Silicon Carbide SIC, Quartz, uye semiconductor crystal wafers. Nehunyanzvi hunyanzvi uye yekucheka-kumucheto michina, isu tinokunda mune isiri-yakajairwa chigadzirwa kugadzirisa, tichivavarira kuve inotungamira optoelectronic zvinhu zvepamusoro-tech bhizinesi.