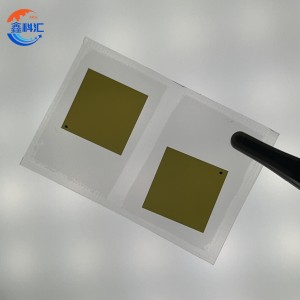

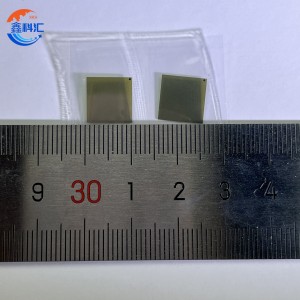

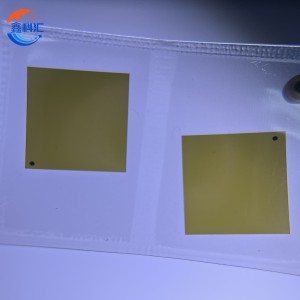

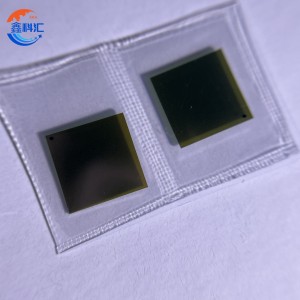

Silicon Carbide (SiC) Imwe-Crystal Substrate - 10×10mm Wafer

Yakadzama Dhiagiramu yeSilicon Carbide (SiC) substrate wafer

Mhedziso yeSilicon Carbide (SiC) substrate wafer

The10 × 10mm Silicon Carbide (SiC) imwe-crystal substrate waferndeyepamusoro-inoshanda semiconductor zvinhu zvakagadzirirwa inotevera-chizvarwa magetsi emagetsi uye optoelectronic application. Inoratidzira yakasarudzika yekupisa yekupisa, yakakura bandgap, uye yakanakisa kugadzikana kwemakemikari, Silicon Carbide (SiC) substrate wafer inopa hwaro hwemidziyo inoshanda nemazvo pasi petembiricha yepamusoro, yakakwirira frequency, uye yakakwirira voltage mamiriro. Aya ma substrates akachekwa mukati10 × 10mm mativi machipisi, yakanakira kutsvagisa, prototyping, uye kugadzira mudziyo.

Kugadzira Nheyo yeSilicon Carbide (SiC) substrate wafer

Silicon Carbide (SiC) substrate wafer inogadzirwa kuburikidza nePhysical Vapor Transport (PVT) kana sublimation nzira dzekukura. Maitiro acho anotanga nepamusoro-kuchena SiC poda yakatakurwa mugirafu crucible. Pasi petembiricha yakanyanyisa inodarika 2,000 ° C uye nharaunda inodzorwa, hupfu hunodzika kuita mhute uye hunoisazve pakiristaro yembeu yakanyatsotariswa, ichigadzira hombe, kuremara-kudukupiswa imwe crystal ingot.

Kana iyo SiC boule yakura, inoenda:

- Ingot slicing: Precision diamond wire saw anocheka SiC ingot kuita wafers kana machipisi.

- Kurovera nekukuya: Zviso zvakatsikwa kuti zvibvise masaha uye kuwana ukobvu hwakafanana.

- Chemical Mechanical Polishing (CMP): Inowana epi-yakagadzirira girazi kupera nekudzika kwakanyanya kwepasi roughness.

- Optional doping: Nitrogen, aluminium, kana boron doping inogona kuunzwa kuti igadzirise zvinhu zvemagetsi (n-type kana p-type).

- Kuongorora kwemhando: Yepamberi metrology inovimbisa wafer flatness, ukobvu kufanana, uye hurema density inosangana neyakaomesesa semiconductor-giredhi zvinodiwa.

Iyi yakawanda-nhanho maitiro inoguma yakasimba 10 × 10mm Silicon Carbide (SiC) substrate wafer machipisi akagadzirira epitaxial kukura kana yakananga kugadzirwa kwechigadzirwa.

Material Hunhu hweSilicon Carbide (SiC) substrate wafer

Iyo Silicon Carbide (SiC) substrate wafer inonyanya kugadzirwa4H-SiC or 6H-SiCpolytypes:

-

4H-SiC:Inoratidzira yakakwira erekitironi kufamba, ichiita kuti ive yakakodzera kumagetsi emagetsi akadai seMOSFET uye Schottky diode.

-

6H-SiC:Inopa yakasarudzika zvivakwa zveRF uye optoelectronic zvikamu.

Yakakosha yemuviri zvimiro zveSilicon Carbide (SiC) substrate wafer:

-

Wide bandgap:~ 3.26 eV (4H-SiC) - inogonesa high breakdown voltage uye kuderera kwekuchinja kurasikirwa.

-

Thermal conductivity:3-4.9 W / cm · K - inobvisa kupisa zvinobudirira, kuve nechokwadi chekugadzikana mumasimba emasimba makuru.

-

Kuoma:~ 9.2 pachikero cheMohs - inochengetedza kusimba kwemagetsi panguva yekugadzirisa uye kushanda kwechigadzirwa.

Zvishandiso zveSilicon Carbide (SiC) substrate wafer

Iko kushandiswa kwakasiyana-siyana kweSilicon Carbide (SiC) substrate wafer inoita kuti ive yakakosha mumaindasitiri akawanda:

Magetsi Emagetsi: Nheyo dzeMOSFETs, IGBTs, uye Schottky diode dzinoshandiswa mumotokari dzemagetsi (EVs), magetsi emagetsi emuindasitiri, uye mainverters emagetsi emagetsi.

RF & Microwave Devices: Inotsigira transistors, amplifiers, uye radar zvikamu zve5G, setiraiti, uye kudzivirira maapplication.

Optoelectronics: Inoshandiswa muUV LEDs, mafotodetectors, uye laser diode uko yakakwirira UV pachena uye kugadzikana kwakakosha.

Aerospace & Dziviriro: Yakavimbika substrate kune yakakwirira-tembiricha, nemwaranzi-yakaomeswa zvemagetsi.

Masangano ekutsvagisa & maYunivhesiti: Yakanakira zvinhu zvesainzi zvidzidzo, prototype kuvandudza mudziyo, uye kuyedza mitsva epitaxial maitiro.

Zvinotsanangurwa zveSilicon Carbide (SiC) substrate wafer Chips

| Property | Value |

|---|---|

| Size | 10mm × 10mm mativi |

| Ukobvu | 330–500 μm (inogoneka) |

| Polytype | 4H-SiC kana 6H-SiC |

| Orientation | C-ndege, off-axis (0°/4°) |

| Surface Finish | Single-side kana kaviri-side polished; epi-yakagadzirira iripo |

| Doping Options | N-mhando kana P-mhando |

| Giredhi | Research giredhi kana mudziyo giredhi |

FAQ yeSilicon Carbide (SiC) substrate wafer

Q1: Chii chinoita kuti Silicon Carbide (SiC) substrate wafer iwedzere kune echinyakare silicon wafers?

SiC inopa 10 × yakakwirira kuparara kwemunda simba, yepamusoro kupisa kupisa, uye kuderera kwekuchinja kurasikirwa, zvichiita kuti ive yakakodzera kune yakakwirira-inoshanda, yakakwirira-simba zvishandiso izvo nesilicon isingagoni kutsigira.

Q2: Ko iyo 10 × 10mm Silicon Carbide (SiC) substrate wafer inogona kupihwa ne epitaxial layers?

Ehe. Isu tinopa epi-yakagadzirira ma substrates uye tinogona kuendesa mawafer ane tsika epitaxial layers kusangana nechaiyo magetsi mudziyo kana LED kugadzira zvinodiwa.

Q3: Saizi yetsika uye doping mazinga aripo here?

Zvamazvirokwazvo. Nepo 10 × 10mm machipisi ari akajairwa kutsvagisa uye sampling yemidziyo, zviyero zvetsika, ukobvu, uye maprofile edoping anowanikwa pakukumbira.

Q4: Anogara sei mawafer aya munzvimbo dzakanyanyisa?

SiC inochengetedza kutendeseka kwechimiro uye kushanda kwemagetsi pamusoro pe600 ° C uye pasi pemwaranzi yakakura, zvichiita kuti ive yakanaka kune aerospace uye echiuto-giredhi zvemagetsi.

Nezvedu

XKH inyanzvi mukusimudzirwa kwepamusoro-soro, kugadzira, uye kutengesa kwegirazi remaziso uye zvinhu zvitsva zvekristaro. Zvigadzirwa zvedu zvinoshanda zvemagetsi zvemagetsi, zvemagetsi zvevatengi, uye mauto. Isu tinopa Sapphire optical components, nharembozha lens inovhara, Ceramics, LT, Silicon Carbide SIC, Quartz, uye semiconductor crystal wafers. Nehunyanzvi hunyanzvi uye yekucheka-kumucheto michina, isu tinokunda mune isiri-yakajairwa chigadzirwa kugadzirisa, tichivavarira kuve inotungamira optoelectronic zvinhu zvepamusoro-tech bhizinesi.