Silicon carbide ceramic tray sucker Silicon carbide ceramic chubhu inopa yakanyanya tembiricha sintering tsika kugadzirisa

Main features:

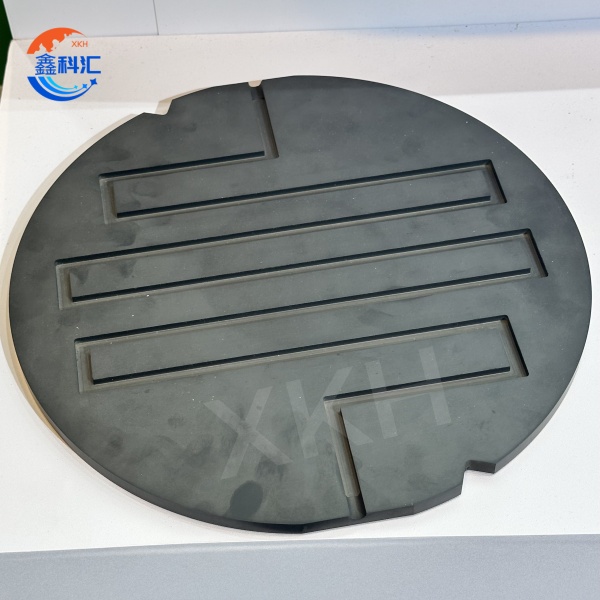

1. Silicon carbide ceramic tray

-Kuomarara kwepamusoro uye kuramba kwekupfeka: kuomarara kuri padyo nedhaimani, uye kunogona kumirisana nekupfeka kwemuchina mukugadzira wafer kwenguva yakareba.

- High thermal conductivity uye yakaderera thermal yekuwedzera coefficient: kukurumidza kupisa kupisa uye kugadzikana kwedimensional, kudzivirira deformation inokonzerwa nekushushikana kwekupisa.

- Yakakwirira flatness uye pamusoro pekupedzisira: Iyo yepasi flatness iri kusvika kune micron level, kuve nechokwadi chekubatana kwakazara pakati pewafer nedhisiki, kuderedza kusvibiswa uye kukuvara.

Kemikari kugadzikana: Yakasimba corrosion kuramba, yakakodzera kunyorova kuchenesa uye etching maitiro mukugadzira semiconductor.

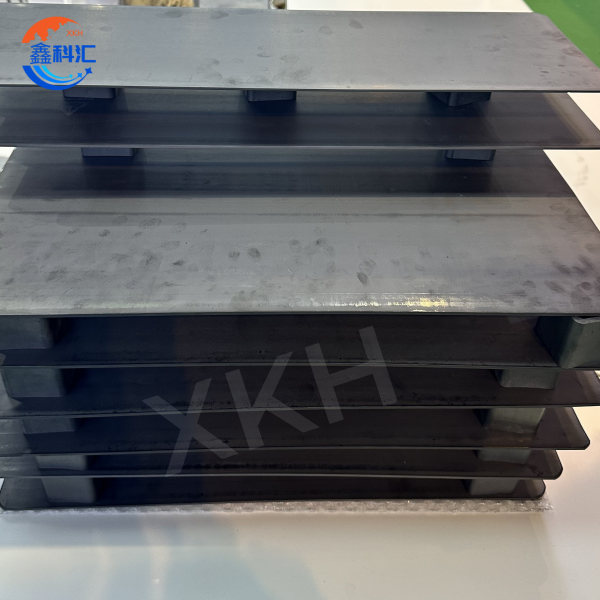

2. Silicon carbide ceramic chubhu

-Kupikisa kwekushisa kwepamusoro: Inogona kushanda munzvimbo yakakwirira yekushisa inopfuura 1600 ° C kwenguva yakareba, yakakodzera semiconductor yakakwirira yekushisa.

Yakanakisa corrosion resistance: inopikisa acids, alkalis uye akasiyana siyana emakemikari zvinonyungudutsa, akakodzera kune dzakaomarara maitiro nharaunda.

-Kuomarara kwepamusoro uye kuramba kwekupfeka: kuramba kukukurwa kwechikamu uye kupfeka kwemuchina, kuwedzera hupenyu hwebasa.

- High thermal conductivity uye yakaderera coefficient yekuwedzera kwekushisa: kukurumidza kufambisa kwekupisa uye kugadzikana kwedimensional, kuderedza deformation kana kuputika kunokonzerwa nekupisa kwekushisa.

Product parameter:

Silicon carbide ceramic tray parameter:

| (Zvinhu) | (Chikwata) | (sic) | |

| (SiC zvirimo) | (Wt)% | >99 | |

| (Avhareji saizi yezviyo) | micron | 4-10 | |

| (Density) | kg/dm3 | >3.14 | |

| (Inooneka porosity) | Vo1% | <0.5 | |

| (Vickers kuoma) | HV 0.5 | GPa | 28 |

| *() Flexural simba * (mapoinzi matatu) | 20ºC | MPa | 450 |

| (Compressive simba) | 20ºC | MPa | 3900 |

| (Elastic Modulus) | 20ºC | GPa | 420 |

| (Kutyoka kuoma) | MPa/m'% | 3.5 | |

| (Thermal conductivity) | 20°C | W/(m*K) | 160 |

| (Resistivity) | 20°C | Ohm.cm | 106-108 |

(Thermal yekuwedzera coefficient) | a(RT**...80ºC) | K-1*10-6 | 4.3 |

(Kunyanya kupisa tembiricha) | oºC | 1700 | |

Silicon carbide ceramic tube parameter:

| Items | Index |

| α-SIC | 99% min |

| Inooneka Porosity | 16% max |

| Bulk Density | 2.7g/cm3 min |

| Kubhenda Simba paKupisa Kwepamusoro | 100 Mpa min |

| Coefficient of Thermal Expansion | K-1 4.7x10 -6 |

| Coefficient of Thermal Conductivity (1400ºC) | 24 W/mk |

| Max. Kushanda Tembiricha | 1650ºC |

Main applications:

1. Silicon carbide ceramic ndiro

- Wafer yekucheka uye kupukuta: inoshanda sepuratifomu inotakura kuti ive nechokwadi chepamusoro uye kugadzikana panguva yekucheka nekupukuta.

- Lithography process: Iyo wafer inogadziriswa mumushini welithography kuti ive nechokwadi chepamusoro chakanyanya kumira panguva yekuratidzwa.

- Chemical Mechanical Polishing (CMP) : inoshanda senge chikuva chekutsigira chekupukuta mapadhi, ichipa yunifomu kumanikidza uye kugovera kupisa.

2. Silicon carbide ceramic chubhu

- Yakakwira tembiricha yevira chubhu: inoshandiswa kune yakakwira tembiricha michina senge diffusion choto uye oxidation choto kutakura wafers yekupisa tembiricha kurapwa.

- CVD/PVD maitiro: Sechubhu inotakura mukamuri yekupindura, inopesana nekupisa kwakanyanya uye gasi rinoparadza.

- Semiconductor midziyo yemidziyo: yekuchinjana kupisa, mapaipi egasi, nezvimwe, kuvandudza mashandiro ekupisa kwemidziyo.

XKH inopa huwandu hwakazara hwetsika masevhisi esilicon carbide ceramic tireyi, makapu ekuyamwa uye silicon carbide ceramic chubhu. Silicon carbide ceramic trays uye makapu ekuyamwa, XKH inogona kugadzirwa maererano nezvinodiwa nevatengi zvehukuru hwakasiyana, maumbirwo uye kushata kwepamusoro, uye kutsigira kwakakosha kurapwa kurapwa, kusimudzira kusapfeka uye kusagadzikana kwekuora; Kune silicon carbide ceramic machubhu, XKH inogona kugadzirisa akasiyana dhayamita yemukati, yekunze dhayamita, kureba uye yakaoma chimiro (senge yakaumbwa chubhu kana porous chubhu), uye inopa kupukuta, anti-oxidation coating uye mamwe maitiro ekurapa pamusoro. XKH inovimbisa kuti vatengi vanogona kushandisa zvizere mabhenefiti ekuita kwesilicon carbide ceramic zvigadzirwa kuti vasangane nezvinodiwa zvinodikanwa zvepamusoro-yekupedzisira minda yekugadzira semiconductors, leds uye photovoltaics.

Detailed Diagram