Silicon Carbide Ceramic Tray - Yakasimba, Yakakwirira-Kuita Matireyi eThermal uye Chemical Applications.

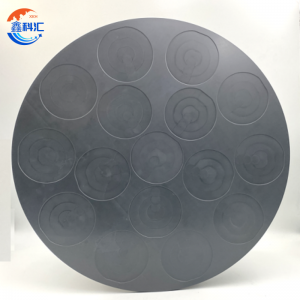

Detailed Diagram

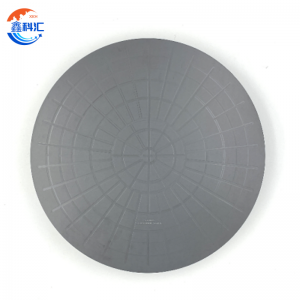

Product Sumo

Silicon carbide (SiC) matireyi eceramic zvinhu zvepamusoro-soro zvinoshandiswa zvakanyanya mukupisa-kupisa, kurema, uye makemikari ane hukasha maindasitiri nharaunda. Yakagadzirwa kubva kumberi silicon carbide ceramic zvinhu, matireyi aya akagadzirirwa kuendesa yakasarudzika mechanicha simba, yepamusoro yekupisa conductivity, uye yakanakisa kuramba kuvhunduka kwekupisa, oxidation, uye ngura. Hunhu hwavo hwakasimba hunovaita kuti vanyatsokodzera kune akasiyana maindasitiri ekushandisa anosanganisira semiconductor kugadzira, photovoltaic processing, sintering yepoda metallurgy zvikamu, nezvimwe.

Silicon carbide matireyi anoshanda sevatakuri akakosha kana tsigiro panguva yekupisa kwekurapa maitiro uko kurongeka kwedimensional, kurongeka kwechimiro, uye makemikari kuramba kwakakosha. Kuenzaniswa nemidziyo yechinyakare yeceramic senge alumina kana mullite, SiC matireyi anopa zvakanyanya kukwirira kuita, kunyanya mumamiriro ezvinhu anosanganisira kudzokororwa kuchovha bhasikoro uye hutsinye hwemhepo.

Manufacturing Process & Material Composition

Kugadzirwa kweSiC ceramic tireyi kunosanganisira chaiyo engineering uye advanced sintering matekinoroji kuti ive nechokwadi chepamusoro density, yunifomu microstructure, uye kuita kunoenderana. Matanho akajairika anosanganisira:

-

Raw Material Selection

Yakakwirira-kuchena silicon carbide poda (≥99%) inosarudzwa, kazhinji iine chaiyo particle size control uye kusvibiswa kushoma kuvimbisa yakakwirira mechini uye inopisa zvivakwa. -

Kuumba Nzira

Zvichienderana nekutsanangurwa kwetireyi, nzira dzakasiyana dzekugadzira dzinoshandiswa:-

Cold Isostatic Pressing (CIP) yepamusoro-density, yunifomu compacts

-

Extrusion kana slip casting yezvimiro zvakaoma

-

Jekiseni molding yechokwadi, yakadzama geometries

-

-

Sintering Techniques

Muviri wakasvibira wakanyungudutswa patembiricha yepamusoro-soro, kazhinji mumhando ye2000 ° C, pasi peinert kana vacuum atmospheres. Nzira dzinowanzoita sintering dzinosanganisira:-

Reaction Bonded SiC (RB-SiC)

-

Pressureless Sintered SiC (SSiC)

-

Recrystallized SiC (RBSiC)

Imwe neimwe nzira inoguma neyakasiyana zvishoma zvinhu zvinhu, senge porosity, simba, uye kupisa conductivity.

-

-

Precision Machining

Mushure mekunyungudika, matireyi anogadzirwa kuti awane kushivirira kwakasimba, kutsetseka kwepamusoro, uye kupfava. Kurapa kwepamusoro senge kupeta, kukuya, uye kupukuta kunogona kuiswa zvichienderana nezvinodiwa nevatengi.

Typical Applications

Silicon carbide ceramic trays inoshandiswa mumaindasitiri akasiyana siyana nekuda kwekusiyana-siyana uye kusimba. Zvishandiso zvakajairika zvinosanganisira:

-

Semiconductor Indasitiri

SiC trays inoshandiswa sevatakuri panguva yewafer annealing, diffusion, oxidation, epitaxy, uye implantation process. Kugadzikana kwavo kunovimbisa kugovera kwekushisa kwakafanana uye kusvibiswa kuduku. -

Photovoltaic (PV) Indasitiri

Mukugadzirwa kwesero rezuva, SiC trays inotsigira silicon ingots kana wafers panguva yekupisa-tembiricha kupararira uye sintering matanho. -

Upfu Metallurgy uye Ceramics

Inoshandiswa kutsigira zvinhu panguva yekupisa simbi hupfu, ceramics, uye composite zvinhu. -

Girazi uye Display Panels

Inoshandiswa sematireyi emoto kana mapuratifomu ekugadzira magirazi akakosha, LCD substrates, kana zvimwe zvinhu zvinoonekwa. -

Chemical Processing uye Thermal Furnaces

Shanda sematakuri asingadziviriri mumakemikoro reactor kana sematireyi ekutsigira anopisa ari muvacuum uye anodzorwa-muchadenga.

Key Performance Features

-

✅Exceptional Thermal Kugadzikana

Inomira kushandiswa kunoramba kuripo mukupisa kusvika 1600-2000 ° C pasina kutenderera kana kushatisa. -

✅High Mechanical Simba

Inopa yakakwirira flexural simba (kazhinji> 350 MPa), kuve nechokwadi chekugara kwenguva refu kunyangwe pasi pemamiriro ekutakura. -

✅Thermal Shock Resistance

Kuita kwakanakisa munzvimbo dzine kukurumidza kushanduka kwekushisa, kuderedza njodzi yekutsemuka. -

✅Corrosion uye Oxidation Resistance

Kemikari yakagadzikana mumaasidhi mazhinji, alkali, uye oxidizing / kuderedza magasi, akakodzera maitiro emakemikari akaomarara. -

✅Dimensional Kururama uye Flatness

Yakagadzirwa kusvika pakurongeka kwepamusoro, kuve nechokwadi chekugadzirisa yunifomu uye kuenderana neatomatiki masisitimu. -

✅Hupenyu Hurefu & Mutengo-Kushanda

Kudzikira kutsiva mitengo uye kuderedzwa kwemitengo yekugadzirisa kunoita kuti ive mhinduro inodhura nekufamba kwenguva.

Zvidimbu zvehunyanzvi

| Parameter | Typical Value |

|---|---|

| Material | Reaction Bonded SiC / Sintered SiC |

| Max. Operating Temperature | 1600–2000°C |

| Flexural Strength | ≥350 MPa |

| Density | ≥3.0 g/cm³ |

| Thermal Conductivity | ~120–180 W/m·K |

| Surface Flatness | ≤ 0.1 mm |

| Ukobvu | 5–20 mm (inogoneka) |

| Dimensions | Standard: 200×200 mm, 300×300 mm, nezvimwewo. |

| Surface Finish | Yakagadzirwa, yakakwenenzverwa (pakukumbira) |

Mibvunzo Inowanzo bvunzwa (FAQ)

Q1: Ko silicon carbide trays inogona kushandiswa muvacuum furnaces?

A:Ehe, matireyi eSiC akanakira nharaunda dzevacuum nekuda kwekuderera kwavo kubuda, kugadzikana kwemakemikari, uye kukwirisa-tembiricha kuramba.

Q2: Maumbirwo etsika kana slots aripo here?

A:Zvamazvirokwazvo. Isu tinopa masevhisi ekugadzirisa anosanganisira saizi yetireyi, chimiro, maficha epamusoro (semuenzaniso, magrooves, maburi), uye kupenya kwepamusoro kusangana nezvinodiwa nevatengi.

Q3: SiC inofananidzwa sei nealumina kana quartz trays?

A:SiC ine simba repamusoro, zvirinani kupisa conductivity, uye kupikisa kwepamusoro kune kuvhunduka kwekupisa uye kemikari corrosion. Nepo alumina ichinyanya kudhura-inoshanda, SiC inoita zvirinani munzvimbo dzinoda.

Q4: Pane mwero wakakora wematireyi aya?

A:Ukobvu hunowanzo muhupamhi hwe5-20 mm, asi isu tinogona kuzvigadzirisa zvichienderana nekushandisa kwako uye zvinotakura zvinotakura.

Q5: Ndeipi yakajairwa nguva yekutungamira yeakagadziridzwa SiC trays?

A:Nguva dzekutungamira dzinosiyana zvichienderana nekuoma uye kuwanda asi kazhinji dzinobva pamavhiki maviri kusvika ku4 kune maodha akasarudzika.

Nezvedu

XKH inyanzvi mukusimudzirwa kwepamusoro-soro, kugadzira, uye kutengesa kwegirazi remaziso uye zvinhu zvitsva zvekristaro. Zvigadzirwa zvedu zvinoshanda zvemagetsi zvemagetsi, zvemagetsi zvevatengi, uye mauto. Isu tinopa Sapphire optical components, nharembozha lens inovhara, Ceramics, LT, Silicon Carbide SIC, Quartz, uye semiconductor crystal wafers. Nehunyanzvi hunyanzvi uye yekucheka-kumucheto michina, isu tinokunda mune isiri-yakajairwa chigadzirwa kugadzirisa, tichivavarira kuve inotungamira optoelectronic zvinhu zvepamusoro-tech bhizinesi.