SiCOI wafer 4inch 6inch HPSI SiC SiO2 Si subatrate chimiro

SiCOI wafer chimiro

HPB (High-Performance Bonding) BIC (Bonded Integrated Circuit) uye SOD (Silicon-on-Diamond kana Silicon-on-Insulator-like teknolojia). Zvinosanganisira:

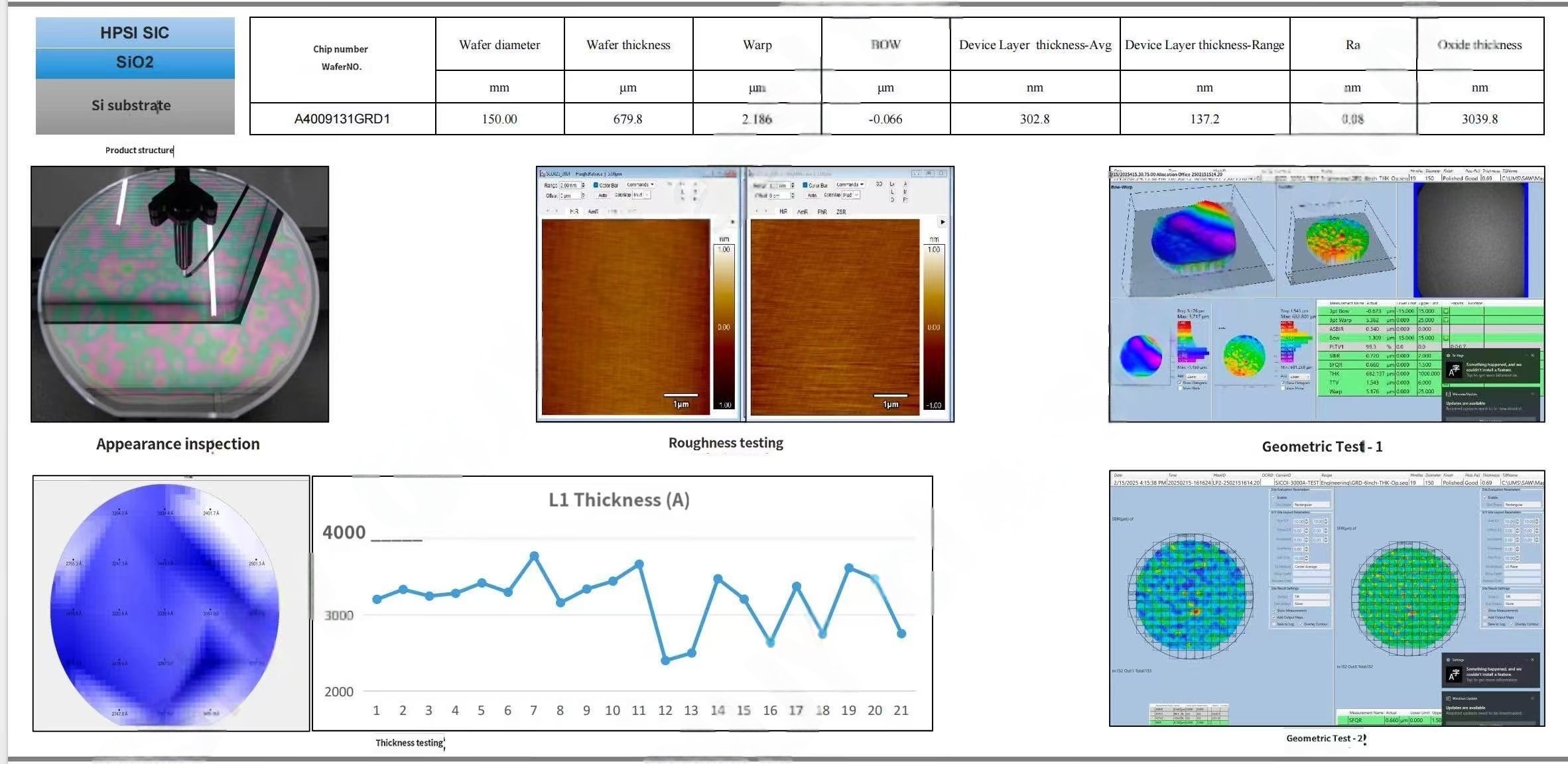

Performance Metrics:

Rinonyora zvimiro zvakaita sekururama, mhando dzezvikanganiso (semuenzaniso, "Hapana kukanganisa," "Kukosha kureba"), uye kuyerwa kweukobvu (semuenzaniso, "Direct-Layer ukobvu/kg").

Tafura ine nhamba dzakakosha (pamwe yekuyedza kana yemaitiro paramita) pasi pemisoro yakaita se "ADDR/SYGBDT," "10/0," nezvimwe.

Layer Thickness Data:

Zvakawanda zvinodzokororwa zvakanzi "L1 Hukobvu (A)" kuenda ku "L270 Hukobvu (A)" (zvichida muÅngströms, 1 Å = 0.1 nm).

Inopa zano remazhinji-layered chimiro chine ukobvu chaihwo chekutonga kune yega yega, yakajairika mune yepamusoro semiconductor wafers.

SiCOI Wafer Structure

SiCOI (Silicon Carbide paIsulator) inyanzvi yewafer chimiro chinosanganisa silicon carbide (SiC) ine insulating layer, yakafanana neSOI (Silicon-on-Insulator) asi yakagadziridzwa kune yakakwirira-simba / yakakwirira-tembiricha maapplication. Zvinhu zvakakosha:

Layer Kuumbwa:

Yepamusoro Layer: Imwe-crystal Silicon Carbide (SiC) yekukwirira kwerekitironi kufamba uye kugadzikana kwekupisa.

Akavigwa Insulator: Kazhinji SiO₂ (oxide) kana diamondi (muSOD) kuderedza parasitic capacitance uye kunatsiridza kuparadzaniswa.

Base Substrate: Silicon kana polycrystalline SiC yekutsigirwa kwemichina

SiCOI wafer's properties

Electrical Properties Wide Bandgap (3.2 eV ye4H-SiC): Inogonesa high breakdown voltage (> 10 × yakakwirira kupfuura silicon) . Inoderedza kubuda kwemvura, inovandudza kushanda mumagetsi emagetsi.

High Electron Mobility:~900 cm²/V·s (4H-SiC) vs. ~1,400 cm²/V·s (Si), asi kuita kuri nani kwepamusoro-soro.

Kudzikira Pa-Resistance:SiCOI-based transistors (semuenzaniso, MOSFETs) inoratidza yakaderera conduction kurasikirwa.

Yakanaka Insulation:Iyo yakavigwa oxide (SiO₂) kana diamond layer inoderedza parasitic capacitance uye crosstalk.

- Thermal PropertiesHigh Thermal Conductivity:SiC (~ 490 W/m·K ye 4H-SiC) vs. Si (~150 W/m·K) .Daimondi (kana rakashandiswa se insulator) rinogona kudarika 2,000 W/m·K, rinowedzera kupera kwekupisa.

Thermal Stability:Inoshanda zvakavimbika pa> 300 ° C (vs. ~ 150 ° C yesilicon). Inoderedza kutonhora zvinodiwa mumagetsi emagetsi.

3. Mechanical & Chemical PropertiesKunyanya Kuoma (~ 9.5 Mohs): Kuramba kupfeka, zvichiita kuti SiCOI igare yakasimba kune nharaunda dzakaoma.

Kemikari Inertness:Inoramba oxidation uye corrosion, kunyangwe mune acidic / alkaline mamiriro.

Kuwedzera Kwekupisa Kwepasi:Inopindirana zvakanaka nezvimwe zvinhu zvepamusoro-tembiricha (semuenzaniso, GaN).

4. Zvakanakira Zvimiro (vs. Bulk SiC kana SOI)

Yakaderedzwa Substrate Kurasikirwa:Insulating layer inodzivirira kubuda kwazvino mu substrate.

Kuvandudzwa kweRF Performance:Lower parasitic capacitance inogonesa kukurumidza kushandura (inobatsira kune 5G/mmWave zvishandiso).

Flexible Design:Yakatetepa SiC yepamusoro layer inobvumira optimized mudziyo kuyera (semuenzaniso, Ultra-yakatetepa chiteshi mune transistors).

Kuenzanisa neSOI & Bulk SiC

| Property | SiCOI | SOI (Si/SiO₂/Si) | Bulk SiC |

| Bandgap | 3.2 eV (SiC) | 1.1 eV (Si) | 3.2 eV (SiC) |

| Thermal Conductivity | Yakakwirira (SiC + diamond) | Yakaderera (SiO₂ inomisa kupisa kuyerera) | High (SiC chete) |

| Kuputsa Voltage | High High | Pakati nepakati | High High |

| Mutengo | Higher | Lower | Yakakwirira (pure SiC) |

SiCOI wafer's application

Power Electronics

SiCOI wafers anoshandiswa zvakanyanya mu-high-voltage uye yakakwirira-simba semiconductor zvishandiso seMOSFETs, Schottky diodes, uye magetsi switch. Iyo yakafara bhendi uye yakakwira yekuputsika voltage yeSiC inogonesa shanduko yesimba inoshanda nekurasikirwa kwakadzikira uye kukwidziridzwa kwekushanda kwemafuta.

Radio Frequency (RF) Devices

Iyo insulating layer muSiCOI wafers inoderedza parasitic capacitance, ichiita kuti ive yakakodzera kune yakakwira-frequency transistors uye amplifiers anoshandiswa munharembozha, radar, uye 5G tekinoroji.

Microelectromechanical Systems (MEMS)

SiCOI wafers inopa chikuva chakasimba chekugadzira MEMS sensors uye actuators inoshanda nekuvimbika munzvimbo dzakaoma nekuda kweSiC's kemikari inertness uye simba remuchina.

High-Temperature Electronics

SiCOI inogonesa zvemagetsi zvinochengetedza kuita uye kuvimbika pakupisa kwakakwira, kubatsira mota, aerospace, uye maindasitiri ekushandisa uko kwakajairika silicon zvishandiso zvinotadza.

Photonic uye Optoelectronic Devices

Iko kusanganiswa kweSiC's optical zvivakwa uye insulating layer inofambisa kubatanidzwa kwemafotonic maseketi ane yakagadziridzwa yekupisa manejimendi.

Radiation-Hardened Electronics

Nekuda kwekushivirira kwemwaranzi yeSiC, maSiCOI mawaferi akanakira nzvimbo uye maapplication enyukireya anoda michina inoshingirira nharaunda yeradiation yakakura.

SiCOI wafer's Q&A

Q1: Chii chinonzi SiCOI wafer?

A: SiCOI inomirira Silicon Carbide-on-Insulator. Iyo semiconductor wafer chimiro apo yakatetepa yesilicon carbide (SiC) inosungirirwa pane insulating layer (kazhinji silicon dioxide, SiO₂), iyo inotsigirwa nesilicon substrate. Ichi chimiro chinosanganisa zvakanaka zveSiC zvivakwa nemagetsi ega kubva kune insulator.

Q2: Ndezvipi zvakakosha zveSiCOI wafers?

A: Iwo mabhenefiti makuru anosanganisira yakakwira breakdown voltage, wide bandgap, yakanakisa yekupisa conductivity, yepamusoro mechanical kuoma, uye kuderedzwa kweparasitic capacitance nekuda kweiyo insulating layer. Izvi zvinotungamira kukuvandudza kushanda kwechishandiso, kugona, uye kuvimbika.

Q3: Ndeapi akajairika mashandisirwo eSiCOI wafers?

A: Iwo anoshandiswa mumagetsi emagetsi, epamusoro-frequency RF zvishandiso, MEMS sensors, yakakwirira-tembiricha yemagetsi, mafotonic zvishandiso, uye nemwaranzi-yakaomeswa zvemagetsi.

Detailed Diagram