SICOI (Silicon Carbide pane Insulator) Wafers SiC Firimu PASilicon

Detailed Diagram

Kusuma Silicon Carbide pane Insulator (SICOI) zvimedu

Silicon Carbide paIsulator (SICOI) mawafers anotevera-chizvarwa semiconductor substrates anobatanidza epamusoro emuviri uye emagetsi zvimiro zvesilicon carbide (SiC) neakasarudzika magetsi ega ega ega inodzivirira buffer layer, sesilicon dioxide (SiO₂) kana silicon nitride (Si₃N₄). Yakajairika SICOI wafer ine yakaonda epitaxial SiC layer, yepakati insulating firimu, uye inotsigira base substrate, inogona kunge iri silicon kana SiC.

Ichi chimiro chehybrid chakagadzirwa kuti chisangane nezvinoda kuomesesa zvesimba repamusoro, repamusoro-frequency, uye rinopisa-tembiricha zvigadzirwa zvemagetsi. Nekubatanidza iyo insulating layer, SICOI wafers inoderedza parasitic capacitance uye kudzvanya mafungu ekudonha, nekudaro kuve nechokwadi chepamusoro chekushanda, kushanda zvakanaka, uye kuvandudzwa kwekutonga kwemafuta. Mabhenefiti aya anovaita kuti vanyanyokosha muzvikamu zvakaita semota dzemagetsi, 5G telecommunication infrastructure, aerospace systems, advanced RF electronics, uye MEMS sensor technologies.

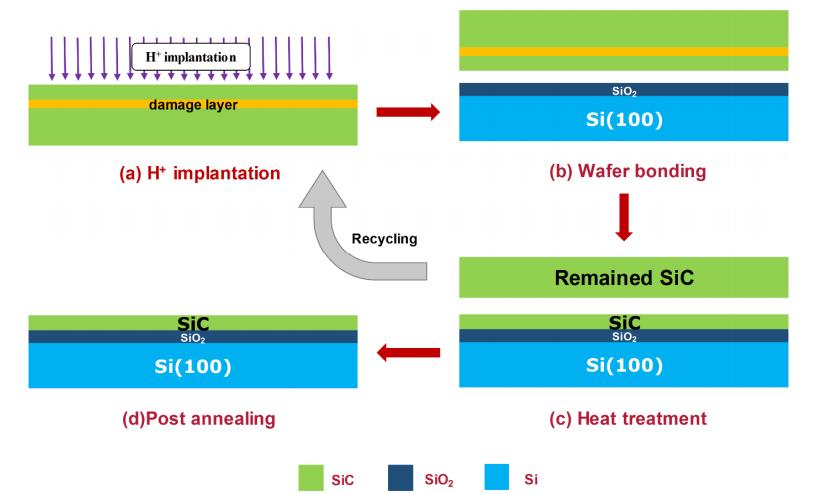

Kugadzira Nheyo yeSICOI Wafers

SICOI (Silicon Carbide pane Insulator) mawaferi anogadzirwa kuburikidza neyepamberiwafer bonding uye kuonda nzira:

-

SiC Substrate Kukura-Iyo yepamusoro-yepamusoro-yekristaro SiC wafer (4H / 6H) inogadzirirwa sechinhu chevanopa.

-

Insulating Layer Deposition- Iyo inodzivirira firimu (SiO₂ kana Si₃N₄) inoumbwa pane inotakura wafer (Si kana SiC).

-

Wafer Bonding- Iyo SiC wafer uye inotakura wafer inosungirirwa pamwechete pasi pekushisa kwakanyanya kana rubatsiro rweplasma.

-

Kuonda & kupukuta-SiC donor wafer yakatetepa kusvika kune mashoma mamicrometer uye yakakwenenzverwa kuti iwane nzvimbo yakatsetseka yeatomu.

-

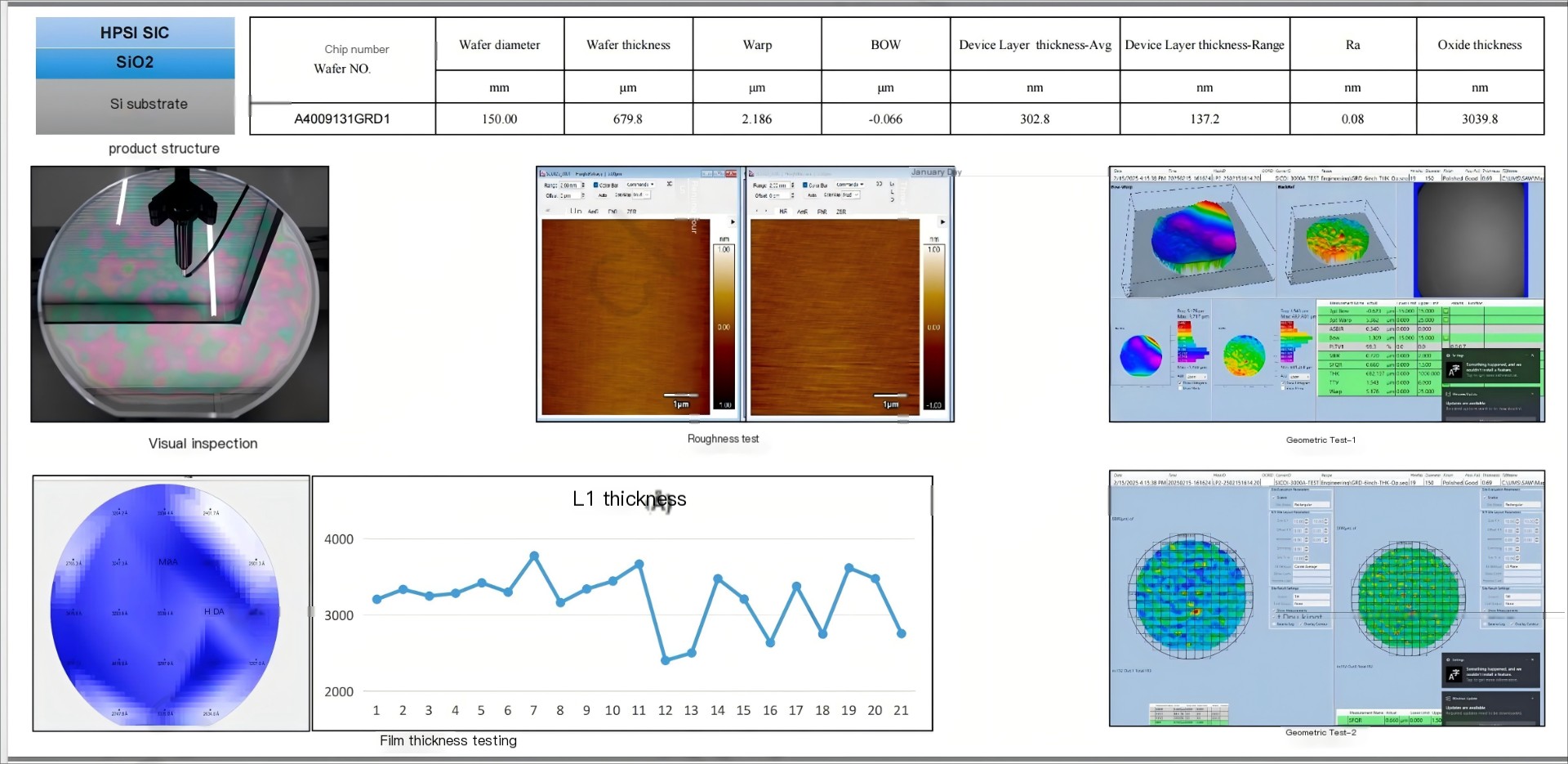

Kuongorora Kwekupedzisira- Iyo yakapedzwa SICOI wafer inoedzwa kuti ukobvu hwakafanana, kushata kwepamusoro, uye kuita kwekudzivirira.

Kuburikidza nemaitiro aya, amutete anoshanda SiC layerine yakanakisa magetsi uye yekupisa zvimiro inosanganiswa neinodzivirira firimu uye substrate yekutsigira, kugadzira yakakwirira-inoshanda chikuva chechizvarwa chinotevera simba uye RF zvishandiso.

Mabhenefiti Akakosha eSICOI Wafers

| Feature Category | Technical Characteristics | Core Benefits |

|---|---|---|

| Chimiro Chezvinhu | 4H/6H-SiC inoshanda layer + insulating firimu (SiO₂/Si₃N₄) + Si kana SiC mutakuri | Inowana simba rakasimba rekuparadzaniswa kwemagetsi, inoderedza kupindira kweparasitic |

| Electrical Properties | Simba rekuparara kwepamusoro (> 3 MV / cm), yakaderera dielectric kurasikirwa | Yakagadzirirwa kushanda kwepamusoro-voltage uye yakakwirira-frequency |

| Thermal Properties | Thermal conductivity inosvika 4.9 W/cm·K, yakagadzikana pamusoro pe500°C | Kushanda kupisa kupisa, kuita kwakanakisa pasi pemitoro yakaoma yekupisa |

| Mechanical Properties | Kunyanya kuoma (Mohs 9.5), yakaderera coefficient yekuwedzera kwekupisa | Yakasimba pakurwisa kushushikana, inowedzera hupenyu hurefu hwechishandiso |

| Surface Quality | Ultra-yakatsetseka pamusoro (Ra <0.2 nm) | Inosimudzira yakaremara-isina epitaxy uye yakavimbika mudziyo kugadzirwa |

| Insulation | Resistivity >10¹⁴ Ω·cm, yakaderera leakage ikozvino | Kuvimbika kushanda muRF uye yakakwirira-voltage isolation application |

| Saizi & Customization | Inowanikwa mu4, 6, uye 8-inch mafomati; SiC ukobvu 1-100 μm; kuvhara 0.1–10 μm | Flexible dhizaini kune akasiyana application zvinodiwa |

Core Application Areas

| Sector Yekushandisa | Yakajairika Kushandisa Nyaya | Performance Advantages |

|---|---|---|

| Power Electronics | EV inverters, zviteshi zvekuchaja, maindasitiri emagetsi emagetsi | High breakdown voltage, yakaderedzwa switching kurasikirwa |

| RF & 5G | Base chiteshi simba amplifiers, millimeter-wave zvikamu | Low parasitics, inotsigira GHz-range mashandiro |

| MEMS Sensors | Harsh-environment pressure sensors, navigation-giredhi MEMS | Kugadzikana kwepamusoro kwekushisa, kunopesana nemwaranzi |

| Aerospace & Defense | Satellite kutaurirana, avionics simba modules | Kuvimbika mukupisa kwakanyanya uye kuratidzwa kwemwaranzi |

| Smart Grid | HVDC converters, solid-state circuit breakers | High insulation inoderedza kurasikirwa kwesimba |

| Optoelectronics | UV LEDs, laser substrates | High crystalline quality inotsigira kushanda kwechiedza |

Kugadzirwa kwe4H-SiCOI

Kugadzirwa kwe4H-SiCOI wafers kunowanikwa kuburikidzawafer bonding uye kuonda maitiro, inogonesa yakakwirira-yemhando insulating interfaces uye hurema-isina SiC inoshanda maseru.

-

a: Schematic ye4H-SiCOI yekugadzira zvinhu papuratifomu.

-

b: Mufananidzo we4-inch 4H-SiCOI wafer uchishandisa bonding uye kuonda; nzvimbo dzakakanganiswa dzakamakwa.

-

c: Hukobvu hunoenderana maitiro eiyo 4H-SiCOI substrate.

-

d: Optical mufananidzo we4H-SiCOI inofa.

-

e: Maitiro ekuyerera kwekugadzira SiC microdisk resonator.

-

f: SEM yeakapedzwa microdisk resonator.

-

g: Yakakura SEM inoratidza resonator sidewall; AFM inset inoratidza nanoscale surface smoothness.

-

h: Muchinjikwa-sectional SEM inoratidza parabolic-yakaita yekumusoro pamusoro.

FAQ paSICOI Wafers

Q1: Ndeapi mabhenefiti ane SICOI mawaferi pamusoro pechinyakare SiC wafers?

A1: Kusiyana neyakajairwa SiC substrates, SICOI wafers anosanganisira insulating layer iyo inoderedza parasitic capacitance uye leakage currents, zvichitungamira kune yakanyanya kushanda zvakanaka, zvirinani frequency mhinduro, uye yepamusoro yekupisa kwekuita.

Q2: Ndeapi mawafer saizi anowanzo kuwanikwa?

A2: SICOI wafers anowanzo gadzirwa 4-inch, 6-inch, uye 8-inch mafomati, ane customized SiC uye insulating layer ukobvu inowanikwa zvichienderana mudziyo zvinodiwa.

Q3: Ndeapi maindasitiri anobatsira zvakanyanya kubva kuSICOI wafers?

A3: Maindasitiri akakosha anosanganisira magetsi emagetsi emotokari dzemagetsi, RF zvemagetsi zve5G network, MEMS yeaerospace sensors, uye optoelectronics senge UV LEDs.

Q4: Iyo insulating layer inovandudza sei mashandiro echishandiso?

A4: Iyo insulating firimu (SiO₂ kana Si₃N₄) inodzivirira kubuda kwezvino uye inoderedza magetsi kuyambuka-kutaura, ichigonesa kutsungirira kwemagetsi epamusoro, kushandura kunoshanda, uye kuderedza kupisa.

Q5: Ko SICOI wafers akakodzera kune yakakwirira-tembiricha application?

A5: Hongu, nekukwirira kwekushisa kwekushisa uye kupikisa kudarika 500 ° C, zvimedu zveSICOI zvakagadzirirwa kushanda zvakavimbika pasi pekupisa kwakanyanya uye munzvimbo dzakaoma.

Q6: Ko SICOI wafers anogona customized?

A6: Ndizvozvo. Vagadziri vanopa madhizaini akakwenenzverwa ehukobvu chaihwo, mazinga edoping, uye musanganiswa wesubstrate kusangana nekutsvagisa kwakasiyana uye zvinodiwa mumaindasitiri.