Sic Substrate Silicon Carbide Wafer 4H-N Rudzi Rwakakwirira Kuoma Kuora Kupokana Prime Giredhi Polishing

Izvi zvinotevera maitiro esilicon carbide wafer

1. Higher thermal conductivity: Thermal conductivity yeSIC wafers yakakwirira zvikuru kupfuura yesilicon, zvinoreva kuti SIC wafers inogona kunyatsobvisa kupisa uye inokodzera kushanda munzvimbo dzakakwirira dzekushisa.

2. Higher erekitironi kufamba: SIC wafers ane yakakwirira erekitironi kufamba kupfuura nesilicon, achibvumira SIC midziyo kushanda kumhanya yakakwirira.

3. Higher breakdown voltage: SIC wafer material ine yakakwira breakdown voltage, ichiita kuti ive yakakodzera kugadzira yakakwirira-voltage semiconductor zvishandiso.

4. Kugadzikana kwemakemikari epamusoro: SIC wafers ane simba rakasimba remakemikari corrosion resistance, iyo inobatsira kuvandudza kuvimbika uye kusimba kwechigadzirwa.

5. Wider band gap: SIC wafers ane yakafara bhendi gap kupfuura nesilicon, zvichiita SIC midziyo nani uye yakatsiga panguva yakakwirira tembiricha.

Silicon carbide wafer ine akati wandei maapplication

1.Mechanical field: maturusi ekucheka uye kugaya zvinhu; Zvikamu zvinodzivirira kupfeka uye mabhushi; Industrial valves uye zvisimbiso; Bearings nemabhora

2.Electronic simba munda: simba semiconductor zvishandiso; High frequency microwave element; High voltage uye yakakwirira tembiricha magetsi emagetsi; Thermal management material

3.Chemical industry: makemikari reactor uye midziyo; Mapombi asingadziviriri uye matangi ekuchengetedza; Chemical catalyst rutsigiro

4.Energy sector: gas turbine uye turbocharger zvikamu; Nuclear simba musimboti uye zvimiro zvikamu zvakakwirira tembiricha yemafuta maseru zvikamu

5.Aerospace: magadzirirwo ekudzivirira anopisa zvemakomba uye nzvimbo dzemotokari; Jet injini turbine blades; Advanced composite

6.Dzimwe nzvimbo: Kupisa kwepamusoro sensors uye thermopiles; Inofa uye zvishandiso zvekugadzira sintering; Kukuya nekupukuta nekucheka minda

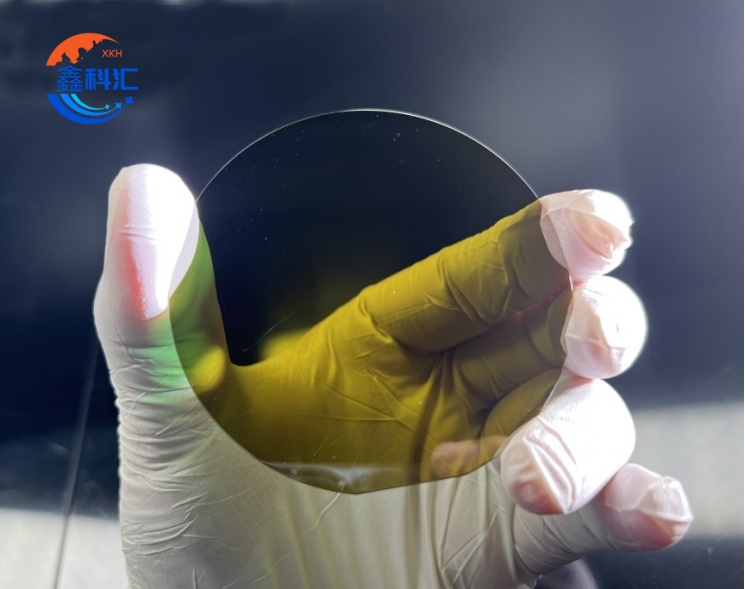

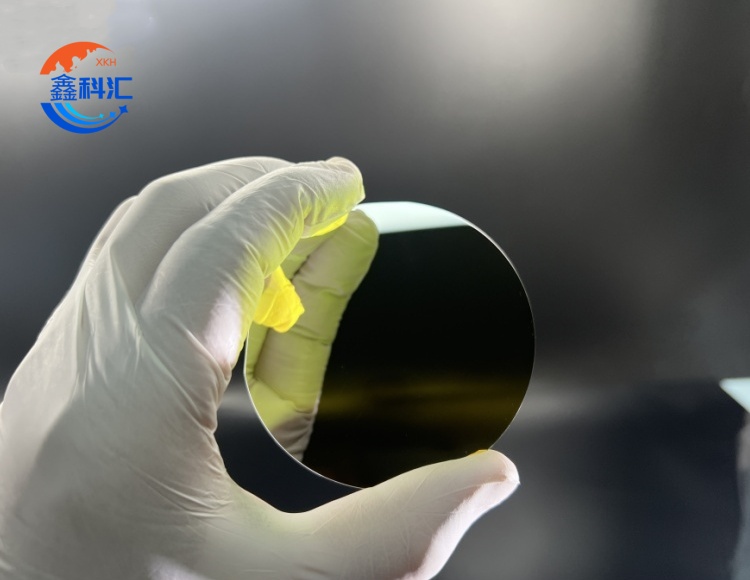

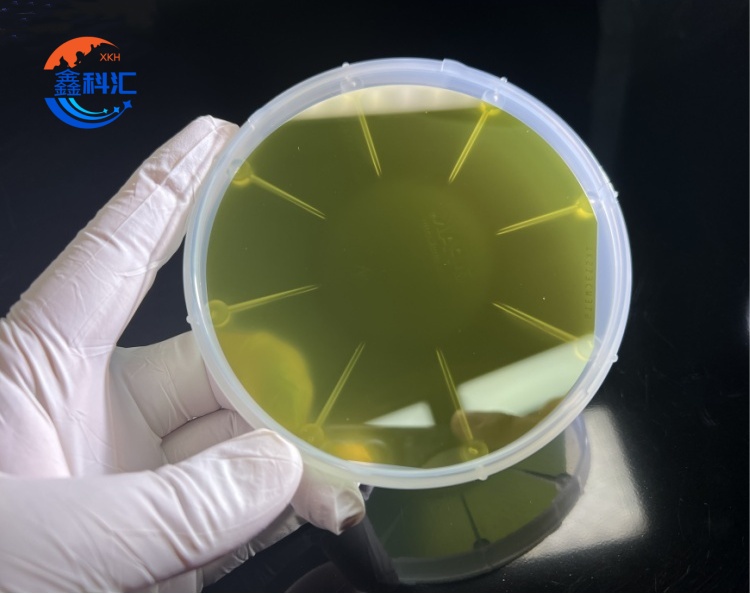

ZMKJ inogona kupa yakakwira mhando imwe crystal SiC wafer (Silicon Carbide) kune zvemagetsi uye optoelectronic indasitiri. SiC wafer ichizvarwa chinotevera semiconductor zvinhu, ine yakasarudzika magetsi zvivakwa uye yakanakisa kupisa zvivakwa, zvichienzaniswa nesilicon wafer uye GaAs wafer, SiC wafer inonyanya kukodzera kupisa kwakanyanya uye yakakwirira simba mudziyo application. SiC wafer inogona kupihwa mudhayamita 2-6 inch, zvese 4H uye 6H SiC, N-mhando, Nitrogen doped, uye semi-inodzivirira mhando iripo. Ndapota taura nesu kuti uwane rumwe ruzivo rwechigadzirwa.

Fekitori yedu ine michina yekugadzira yepamusoro uye tekinoroji timu, inogona kugadzirisa akasiyana siyana, ukobvu uye maumbirwo eSiC wafer zvinoenderana nezvinodiwa nevatengi.

Detailed Diagram