SiC Ceramic Tray yeWafer Carrier ine High-Temperature Resistance

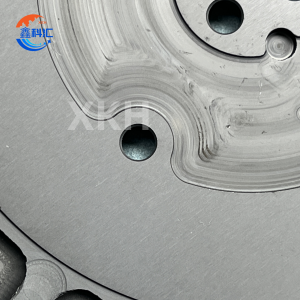

Silicon Carbide Ceramic Tray (SiC Tray).

Chinhu chepamusoro-chekuita checeramic chikamu chakavakirwa pasilicon carbide (SiC) zvinhu, zvakagadzirirwa zvemhando yepamusoro maindasitiri senge semiconductor kugadzira uye kugadzirwa kweLED. Basa rayo rekutanga rinosanganisira kushanda senge wafer carrier, etching process platform, kana yakakwirira-tembiricha process tsigiro, leveraging yakasarudzika yekupisa conductivity, yakakwirira-tembiricha kuramba, uye kugadzikana kwemakemikari kuve nechokwadi chekufanana kwemaitiro uye goho rechigadzirwa.

Key Features

1. Thermal Performance

- High Thermal Conductivity: 140–300 W/m·K, inodarika zvechinyakare graphite (85 W/m·K), ichigonesa kukurumidza kupera kwekupisa uye kuderedza kushushikana kwekupisa.

- Yakaderera Thermal Kuwedzera Coefficient: 4.0 × 10⁻⁶/℃ (25-1000 ℃), yakanyatso enderana nesilicon (2.6 × 10⁻⁶/℃), kuderedza kupisa kwekupisa njodzi.

2. Mechanical Properties

- High Strength: Flexural simba ≥320 MPa (20 ℃), inopesana nekumanikidza uye kukanganisa.

- Kuoma Kwepamusoro: Mohs kuomarara 9.5, yechipiri chete kune dhaimondi, inopa yepamusoro kupfeka kuramba.

3. Kugadzikana Kwemakemikari

- Corrosion Resistance: Inopokana kune yakasimba acids (semuenzaniso, HF, H₂SO₄), inokodzera etching process nharaunda.

- Non-Magnetic: Intrinsic magineti susceptibility <1×10⁻⁶ emu/g, kudzivirira kukanganiswa nezviridzwa.

4. Kushivirira Kwakanyanya Kwenzvimbo

- High-Temperature Durability: Yenguva refu yekushanda tembiricha inosvika 1600-1900 ℃; kupikisa kwenguva pfupi kusvika ku2200 ℃ (nzvimbo isina oxygen).

- Thermal Shock Resistance: Inomira nekukurumidza kuchinja kwekushisa (ΔT> 1000 ℃) pasina kutsemuka.

Applications

| Nzvimbo yeApplication | Specific Scenarios | Technical Value |

| Semiconductor Manufacturing | Wafer etching (ICP), yakaonda-firimu deposition (MOCVD), CMP polishing | High thermal conductivity inovimbisa yunifomu tembiricha minda; kuderera kwekuwedzera kwekushisa kunoderedza wafer warpage. |

| Kugadzirwa kwe LED | Epitaxial kukura (semuenzaniso, GaN), wafer dicing, kurongedza | Inodzvanya kukanganisa kwemhando dzakasiyana-siyana, inosimudzira mwenje we LED uye hupenyu hurefu. |

| Photovoltaic Indasitiri | Silicon wafer sintering mavira, PECVD michina inotsigira | Yepamusoro-tembiricha uye kupisa kuvhunduka kuramba kunowedzera hupenyu hwemidziyo. |

| Laser & Optics | Yakakwira-simba laser kutonhora substrates, optical system inotsigira | High thermal conductivity inogonesa kukurumidza kupisa kupera, kudzikamisa optical components. |

| Analytical Instruments | TGA/DSC samples holders | Kupisa kwakaderera uye nekukurumidza kupisa kwemhinduro kunovandudza kuyerwa kwechiyero. |

Produc Advantages

- Performance Performance: Thermal conductivity, simba, uye corrosion resistance inodarika alumina nesilicon nitride ceramics, inosangana nezvinodiwa zvakanyanya zvekushanda.

- Chiremera Dhizaini: Density ye3.1–3.2 g/cm³ (40% yesimbi), inoderedza inertial mutoro uye inonatsiridza kufamba chaiko.

- Hurefu uye Kuvimbika: Hupenyu hwebasa hunodarika makore mashanu pa1600 ℃, kuderedza nguva yekudzikira uye kudzikisa mutengo wekushandisa ne30%.

- Customization: Inotsigira yakaoma geometries (semuenzaniso, porous suction cups, multi-layer tireyi) ine flatness kukanganisa <15 μm kune chaiyo maapplication.

Technical Specifications

| Parameter Category | Indicator |

| Physical Properties | |

| Density | ≥3.10 g/cm³ |

| Flexural Simba (20 ℃) | 320–410 MPa |

| Thermal Conductivity (20 ℃) | 140–300 W/(m·K) |

| Thermal Kuwedzera Coefficient (25–1000℃) | 4.0×10⁻⁶/℃ |

| Chemical Properties | |

| Kuramba Asidhi (HF/H₂SO₄) | Hapana ngura mushure mekunyudzwa kwemaawa makumi maviri nemana |

| Machining Precision | |

| Flatness | ≤15 μm (300×300 mm) |

| Kushata Kwepamusoro (Ra) | ≤0.4 μm |

XKH's Services

XKH inopa yakazara maindasitiri mhinduro inotora kusimudzira tsika, chaiyo machining, uye kuomarara kwemhando yekudzora. Nekusimudzira tsika, inopa kuchena kwepamusoro (> 99.999%) uye porous (30-50% porosity) zvigadziriso zvezvinhu, zvakapetwa ne 3D modhi uye simulation kukwirisa yakaoma geometries yekushandisa semiconductors uye aerospace. Kunyatsogadzira machining kunotevera maitiro akagadziridzwa: kugadzirwa kwehupfu → isostatic / yakaoma kudzvanya → 2200 ° C sintering → CNC/dhaimondi kugaya → kuongorora, kuona nanometer-level polishing uye ± 0.01 mm dimensional kushivirira. Kudzora kwehunhu kunosanganisira kuzere-maitiro ekuyedzwa (XRD kuumbwa, SEM microstructure, 3-point bending) uye tsigiro yehunyanzvi (process optimization, 24/7 kubvunza, 48-awa sampuli kuendesa), kuendesa yakavimbika, yepamusoro-inoita zvikamu zvezvinodiwa zvemaindasitiri.

Mibvunzo Inowanzo bvunzwa (FAQ)

1. Q: Ndeapi maindasitiri anoshandisa silicon carbide ceramic trays?

A: Inoshandiswa zvakanyanya mukugadzira semiconductor (wafer kubata), simba rezuva (PECVD maitiro), midziyo yekurapa (MRI zvikamu), uye aerospace (yakakwirira-tembiricha zvikamu) nekuda kwekunyanya kupisa kwekudzivirira uye kugadzikana kwemakemikari.

2. Q: Ko silicon carbide inoita sei kukunda quartz/matireyi egirazi?

A: Higher thermal shock resistance(kusvika 1800°C vs. quartz's 1100°C), zero magnetic interference, uye hupenyu hurefu (5+ years vs. quartz's 6-12 months).

3. Q: Matireyi esilicon carbide anogona kubata nzvimbo dzine acidic?

A: Hongu. Inoshingirira kuHF, H2SO4, uye NaOH ine <0.01mm corrosion/gore, zvichiita kuti dzive dzakanakira etching kemikari uye kuchenesa wafer.

4. Q: Matireyi esilicon carbide anowirirana ne otomatiki here?

A: Hongu. Yakagadzirirwa vacuum pickup, uye robhoti inobata, ine pamusoro flatness <0.01mm kudzivirira kusvibiswa kwechikamu mune otomatiki machira.

5. Q: Ndeipi mutengo wekuenzanisa nemidziyo yechinyakare?

A: Mutengo wepamusoro wepamberi (3-5x quartz) asi 30-50% yakaderera TCO, nekuda kwehupenyu hwakareba, kuderedzwa nguva, uye kuchengetedza kwesimba kubva kune yepamusoro yekupisa conductivity.