SiC ceramic ndiro/tireyi ye4inch 6inch wafer holder yeICP

SiC ceramic ndiro Abstract

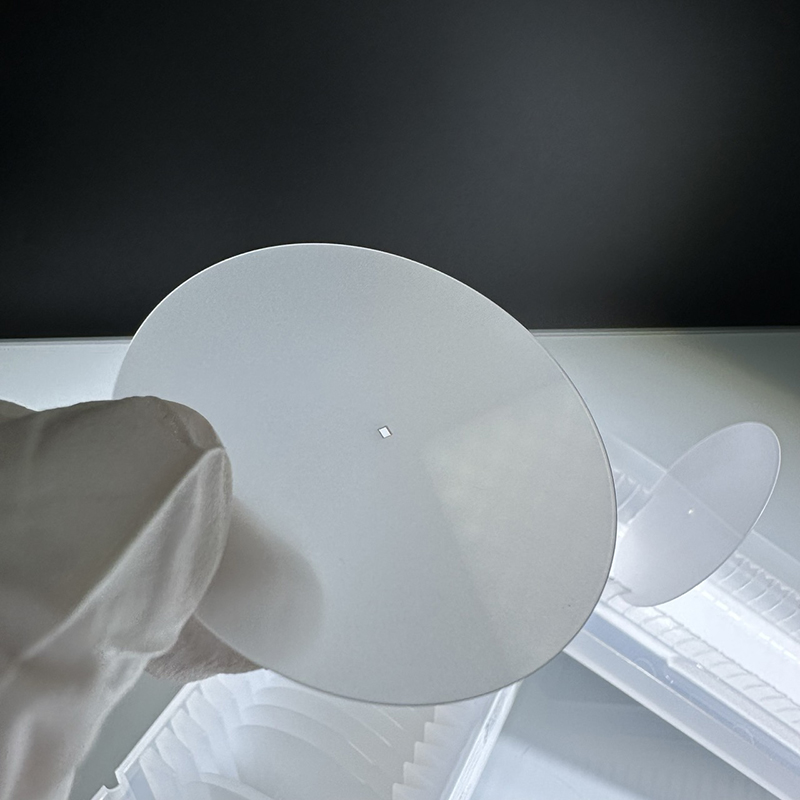

Iyo SiC ceramic plate ibasa repamusoro-soro rakagadzirwa kubva kuchena-kuchena Silicon Carbide, yakagadzirirwa kushandiswa mukupisa kwakanyanya, kemikari, uye mekiniki nharaunda. Inozivikanwa nekuomarara kwayo kwakasarudzika, kupisa kwemafuta, uye kusagadzikana kwekuora, iyo SiC plate inoshandiswa zvakanyanya sewafer carrier, susceptor, kana chimiro chechikamu mune semiconductor, LED, photovoltaic, uye aerospace maindasitiri.

Nekudzikama kwekupisa kwekushisa kusvika ku1600 ° C uye kupikisa kwakanyanya kumagasi anoshanda uye nharaunda dzeplasma, iyo SiC plate inova nechokwadi chekushanda kwakafanana panguva yekupisa kwepamusoro etching, deposition, uye diffusion process. Yayo dense, isina-porous microstructure inoderedza kugadzirwa kwezvikamu, zvichiita kuti ive yakakodzera kune yakanyanya-yakachena maapplication muvacuum kana yekuchenesa marongero.

SiC ceramic ndiro Application

1. Semiconductor Manufacturing

SiC ceramic plates anowanzo shandiswa sewafer carriers, susceptors, uye pedestal plates mune semiconductor yekugadzira michina yakadai seCVD (Chemical Vapor Deposition), PVD (Physical Vapor Deposition), uye etching masisitimu. Yavo yakanakisa yekupisa yekupisa uye kuderera kwekuwedzera kwemafuta inovatendera kuchengetedza yunifomu yekugovera tembiricha, iyo yakakosha kune yakakwirira-chaiyo wafer processing. Kupokana kweSiC kune gasi rinoparadza uye plasmas inovimbisa kusimba munzvimbo dzakaoma, zvichibatsira kuderedza kusvibiswa kwechikamu uye kugadzirisa kwemidziyo.

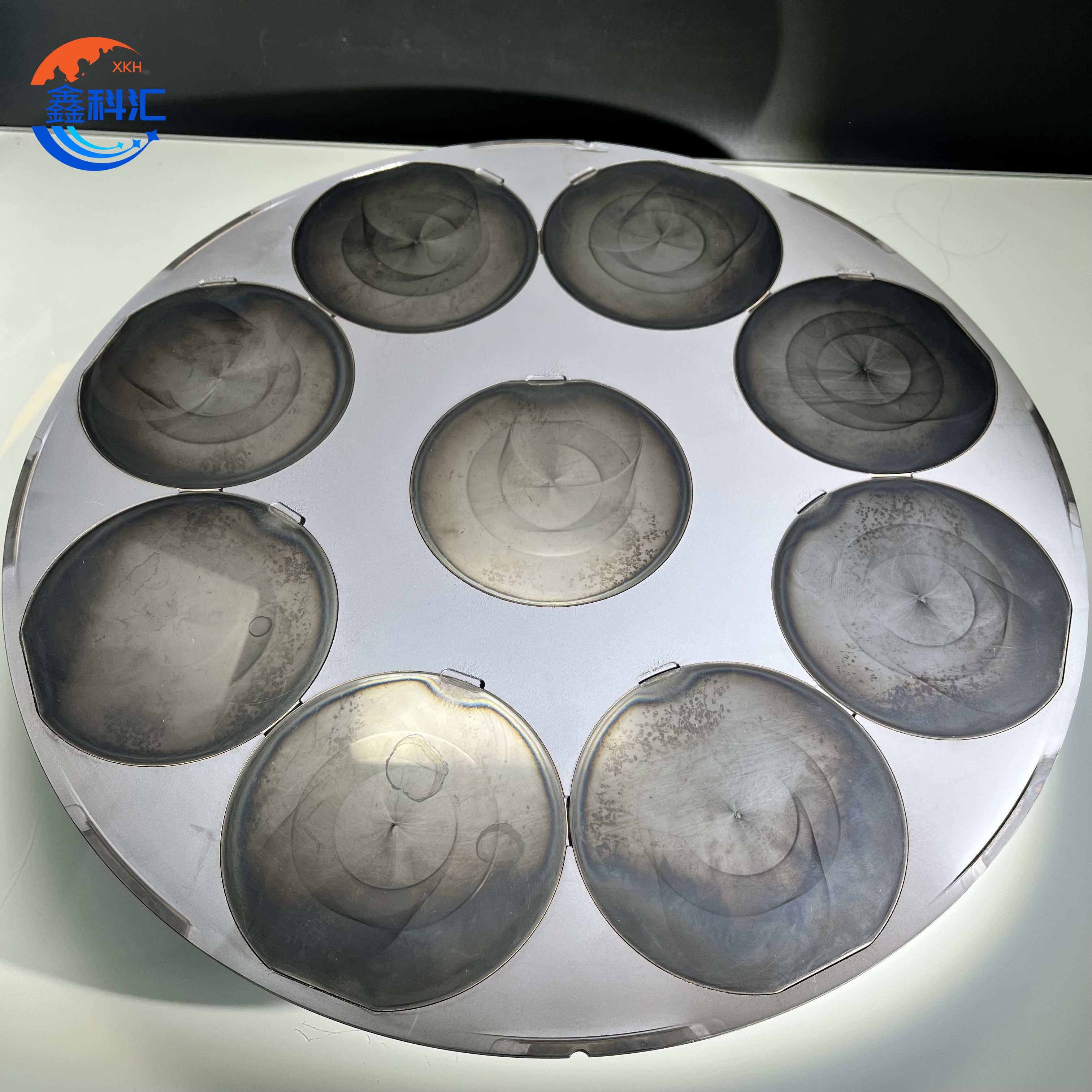

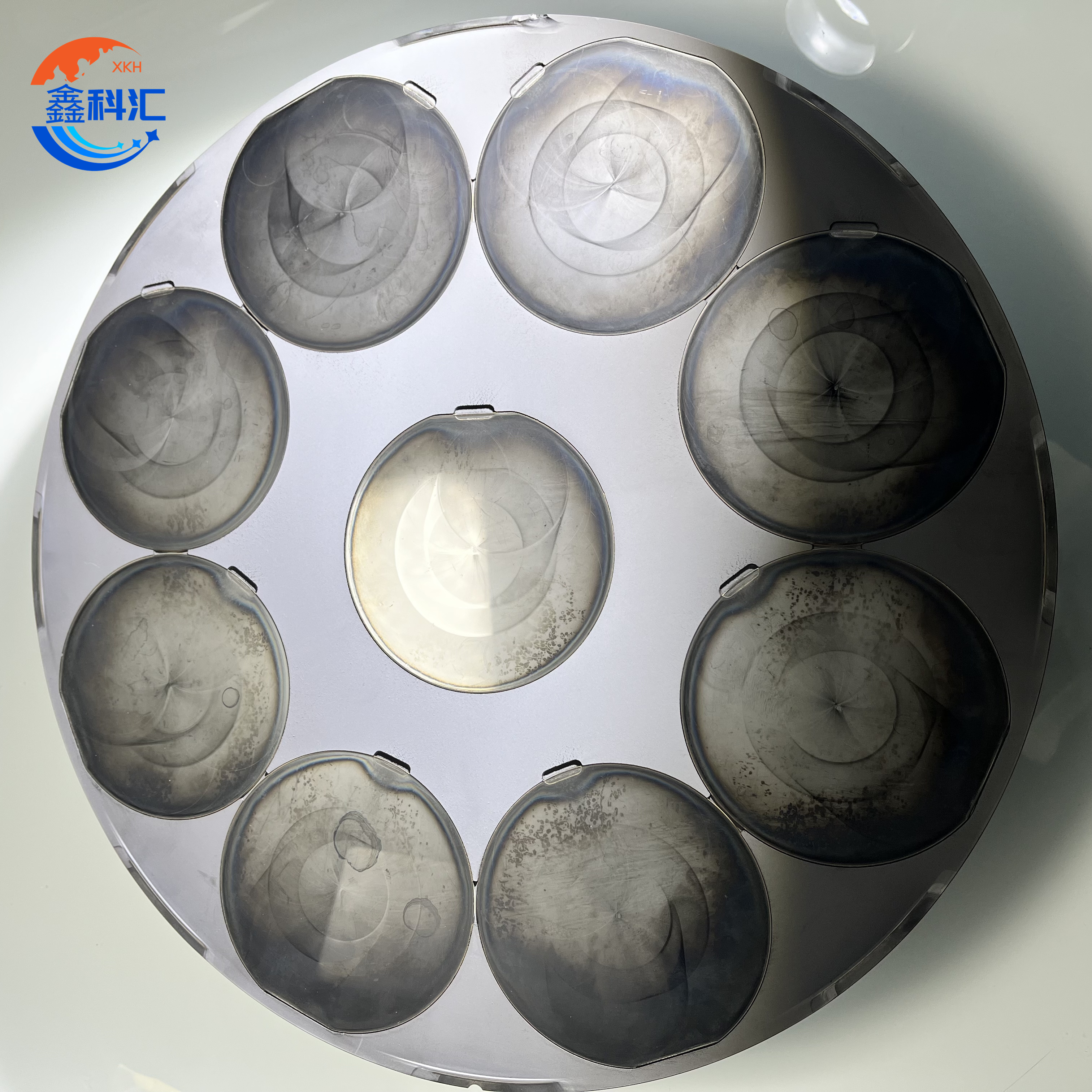

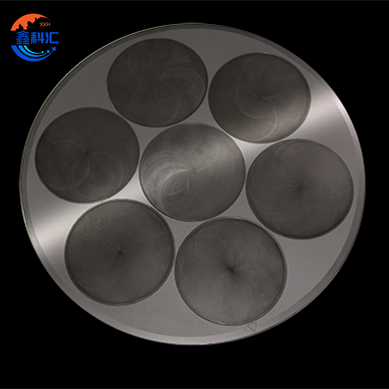

2. Indasitiri ye LED - ICP Etching

Muchikamu chekugadzira LED, maSiC mahwendefa zvinhu zvakakosha muICP (Inductively Coupled Plasma) etching masisitimu. Vachishanda sezvimedu zvimedu, vanopa chikuva chakagadzika uye chakasimba chekutsigira safire kana GaN wafers panguva yekugadzirisa plasma. Yavo yakanakisa plasma kuramba, kupfava kwepamusoro, uye kugadzikana kwedimensional kunobatsira kuve nechokwadi chepamusoro etching kurongeka uye kufanana, zvichitungamira mukuwedzera goho uye kuita kwechishandiso mumachipi e LED.

3. Photovoltaics (PV) uye Solar Energy

SiC ceramic mahwendefa anoshandiswawo mukugadzira masero ezuva, kunyanya panguva yekupisa-kupisa sintering uye annealing matanho. Inertness yavo patembiricha yakakwira uye kugona kuramba warping inovimbisa kuenderana kugadzirisa kwesilicon wafers. Pamusoro pezvo, njodzi yavo yekusvibiswa yakaderera yakakosha pakuchengetedza kushanda kwemasero ephotovoltaic.

SiC ceramic ndiro Properties

1. Inoshamisa Mechanical Simba uye Kuoma

SiC Ceramic mahwendefa anoratidza akanyanya kusimba emagetsi, ane akajairika flexural simba rinopfuura 400 MPa uye Vickers kuoma kunosvika> 2000 HV. Izvi zvinovaita kuti varambe vakanyanya kushivirira kumakanika kupfeka, abrasion, uye deformation, kuve nechokwadi chehupenyu hurefu hwesevhisi kunyangwe pasi pemutoro wakakwira kana kudzokororwa kupisa bhasikoro.

2. High Thermal Conductivity

SiC ine yakanakisa yekupisa conductivity (kazhinji 120–200 W/m·K), ichiibvumira kugovera kupisa zvakaenzana pamusoro payo. Ichi chivakwa chakakosha mumatanho akadai sewafer etching, deposition, kana sintering, uko kufanana kwetembiricha kunokanganisa zvakananga goho uye kunaka kwechigadzirwa.

3. Superior Thermal Stability

Nekunyungudika kwakakwirira (2700 ° C) uye yakaderera coefficient yekuwedzera kwekushisa (4.0 × 10⁻⁶/K), SiC ceramic plates inochengetedza dimensional kurongeka uye kuvimbika kwechimiro pasi pekukurumidza kupisa uye kutonhora kutenderera. Izvi zvinoita kuti ive yakanakira maapplication muchoto chepamusoro-tembiricha, vacuum chamber, uye plasma nharaunda.

| Technical Properties | ||||

| Index | Unit | Value | ||

| Zita rezvinhu | Rection Sintered Silicon Carbide | Pressureless Sintered Silicon Carbide | Recrystallized Silicon Carbide | |

| Composition | RBSiC | SSiC | R-SiC | |

| Bulk Density | g/cm3 | 3 | 3.15 ± 0.03 | 2.60-2.70 |

| Flexural Strength | MPa (kpsi) | 338(49) | 380(55) | 80-90 (20°C) 90-100(1400°C) |

| Compressive Strength | MPa (kpsi) | 1120(158) | 3970(560) | > 600 |

| Kuoma | Knoop | 2700 | 2800 | / |

| Breaking Tenacity | MPa m1/2 | 4.5 | 4 | / |

| Thermal Conductivity | W/mk | 95 | 120 | 23 |

| Coefficient of Thermal Expansion | 10-6.1/°C | 5 | 4 | 4.7 |

| Specific Heat | Joule/g 0k | 0.8 | 0.67 | / |

| Max tembiricha mumhepo | ℃ | 1200 | 1500 | 1600 |

| Elastic Modulus | Gpa | 360 | 410 | 240 |

SiC ceramic ndiro Q&A

Q:Ndezvipi zvimiro zvesilicon carbide plate?

A: Silicon carbide (SiC) mahwendefa anozivikanwa nekusimba kwawo kwepamusoro, kuoma, uye kugadzikana kwekupisa. Ivo vanopa yakanakisa thermal conductivity uye kuderera kwekuwedzera kwemafuta, kuve nechokwadi chekuita kwakavimbika pasi pekupisa kwakanyanya. SiC zvakare ine makemikari inert, inoshingirira kune acids, alkali, uye plasma nharaunda, zvichiita kuti ive yakanaka kune semiconductor uye LED kugadzirisa. Yayo yakaoma, yakatsetseka inoderedza kugadzirwa kwezvikamu, kuchengetedza kuenderana kwemukamuri. SiC mahwendefa anoshandiswa zvakanyanya sewafer vatakuri, susceptors, uye zvikamu zvekutsigira mune yakakwirira-tembiricha uye inoparadza nharaunda munzvimbo dzese semiconductor, photovoltaic, uye aerospace maindasitiri.