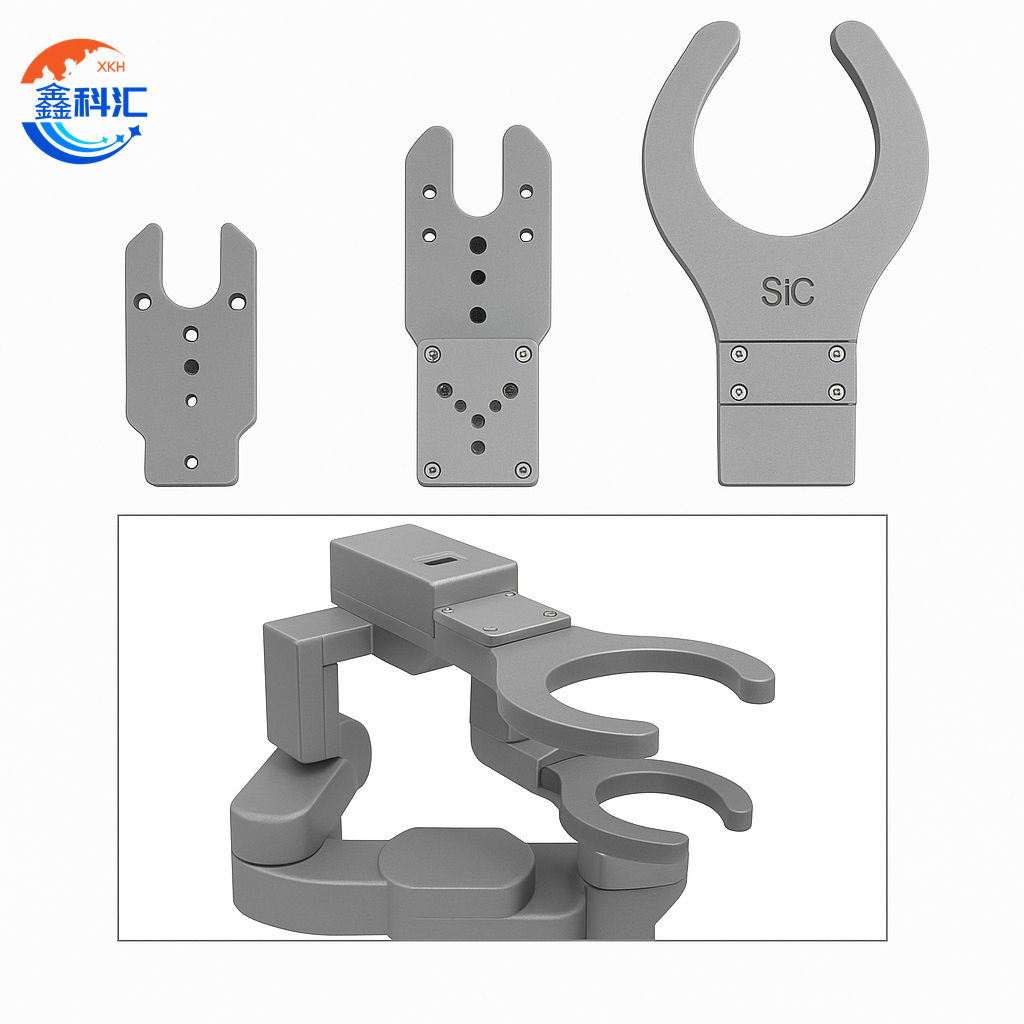

SiC ceramic end effector yekupa ruoko rwe wafer kutakura

SiC ceramic end effector Abstract

Iyo SiC (Silicon Carbide) ceramic end-effector chinhu chakakosha mune yakakwirira-chaiyo wafer yekubata masisitimu anoshandiswa mukugadzira semiconductor uye advanced microfabrication nharaunda. Yakagadzirwa kuti isangane nezvinodiwa zveyakachena-yakachena, yakakwirira-tembiricha, uye yakagadzikana nharaunda, iyi nyanzvi yekupedzisira-inogadzirisa inovimbisa yakavimbika uye isina kusvibiswa-yekufambisa yekufambisa yemawafer panguva dzakakosha nhanho dzekugadzira senge lithography, etching, uye deposition.

Kushandisa epamusoro zvinhu zvesilicon carbide-senge yakakwira yekupisa yekupisa, kuomarara kwakanyanya, yakanakisa makemikari inertness, uye kushoma kwekuwedzera kwemafuta-SiC ceramic end-effector inopa kusingaenzaniswi kwemechani kuomarara uye kugadzikana kwedimensional kunyangwe pasi pekukurumidza kupisa bhasikoro kana mumakamuri ekuora. Yayo yakaderera particle chizvarwa uye plasma kuramba maitiro anoita kuti inyanyo fanirwa kuchena uye vacuum kugadzirisa maapplication, uko kuchengetedza wafer pamusoro pekuvimbika uye kuderedza kusvibiswa kwechikamu kwakakosha.

SiC ceramic end effector Application

1. Semiconductor Wafer Kubata

SiC ceramic end effectors inoshandiswa zvakanyanya muindasitiri yesemiconductor yekubata silicon wafers panguva yekugadzira otomatiki. Aya magumo ekupedzisira anowanzo kuisirwa pamarobhoti maoko kana vacuum kutamisa masisitimu uye akagadzirirwa kugarisa mawafer ehukuru hwakasiyana se200mm uye 300mm. Izvo zvakakosha mumatanho anosanganisira Chemical Vapor Deposition (CVD), Physical Vapor Deposition (PVD), etching, uye diffusion-apo tembiricha yepamusoro, vacuum mamiriro, uye gasi rinoparadza zvakajairika. SiC's yakasarudzika yekupisa kupisa uye kugadzikana kwemakemikari inoita kuti ive chinhu chakakodzera kutsungirira nharaunda dzakaoma kudaro pasina kushatiswa.

2. Yekuchenesa uye Vacuum Compatibility

Muimba yekuchenesa uye vacuum marongero, uko kusvibiswa kwechikamu kunofanirwa kudzikiswa, SiC ceramics inopa zvakakosha. Iyo yakaomeswa, yakatsetseka pamusoro inopikisa chidimbu chizvarwa, ichibatsira kuchengetedza wafer kutendeseka panguva yekufambisa. Izvi zvinoita kuti maSiC apedzisire anonyanya kukodzera maitiro akakosha akadai seExtreme Ultraviolet Lithography (EUV) uye Atomic Layer Deposition (ALD), uko kushambidzika kwakakosha. Uyezve, SiC's low outgassing uye yakakwira plasma kuramba inovimbisa kuita kwakavimbika mumakamuri ekutsvaira, kuwedzera hupenyu hwezvishandiso uye kudzikisa kuwanda kwekugadzirisa.

3. High-Precision Positioning Systems

Kurongeka uye kugadzikana kwakakosha mumhando yepamusoro yekubata masisitimu, kunyanya mune metrology, yekuongorora, uye yekumisikidza michina. SiC ceramics ine yakanyanya kuderera coefficient yekuwedzera kwekupisa uye kuomarara kwepamusoro, izvo zvinobvumira magumo ekupedzisira kuchengetedza kurongeka kwayo kwechimiro kunyangwe pasi pekupisa bhasikoro kana mechanical mutoro. Izvi zvinova nechokwadi chekuti mawaferi anoramba akanyatso kurongeka panguva yekufambisa, achidzikisa njodzi yemadiki-zvikwekwe, misalignment, kana kuyerwa zvikanganiso-zvinhu zviri kuwedzera kunetsa pa sub-5nm process node.

SiC ceramic end effector Properties

1. High Mechanical Simba uye Kuoma

SiC Ceramics ine yakasarudzika mechanicha simba, ine flexural simba rinowanzopfuura 400 MPa uye Vickers kuomarara kukosha pamusoro pe2000 HV. Izvi zvinovaita kuti varambe zvakanyanya kusimba remagetsi, kukanganisa, uye kupfeka, kunyangwe mushure mekushandisa kwenguva refu. Iyo yakanyanya kuomarara yeSiC zvakare inoderedza kutsauka panguva yekumhanyisa-kumhanyisa wafer kutamiswa, kuve nechokwadi chechokwadi uye chinodzokororwa chinzvimbo.

2. Yakanakisa Thermal Kugadzikana

Chimwe chezvinhu zvinonyanya kukosha zveSiC ceramics kukwanisa kwavo kutsungirira kupisa kwakanyanya-kazhinji kusvika 1600 ° C mumhepo inert-pasina kurasikirwa nemagetsi. Yadzo yakaderera coefficient yekuwedzera kwekupisa (~ 4.0 x 10⁻⁶ /K) inovimbisa kugadzikana kwedimensional pasi pemabhasikoro ekupisa, zvichiita kuti zvive zvakanaka kune zvikumbiro zvakaita seCVD, PVD, uye kudziya kwepamusoro-soro.

SiC ceramic end effector Q&A

Q: Ndechipi chinyorwa chinoshandiswa mune wafer end effector?

A:Wafer end effectors anowanzo gadzirwa kubva kuzvinhu zvinopa yakakwira simba, kugadzikana kwemafuta, uye yakaderera particle chizvarwa. Pakati peizvi, Silicon Carbide (SiC) ceramic ndeimwe yemhando yepamusoro uye yakasarudzika zvinhu. SiC Ceramics yakaoma zvakanyanya, yakagadzikana nemafuta, inert yemakemikari, uye inoshingirira kupfeka, ichiita kuti ive yakakodzera kubata dzakapfava silicon wafers munzvimbo dzakachena uye vacuum nharaunda. Kuenzaniswa nequartz kana simbi dzakavharwa, SiC inopa kugadzikana kwepamusoro pasi pekupisa kwakanyanya uye haidonhedze zvidimbu, izvo zvinobatsira kudzivirira kusvibiswa.