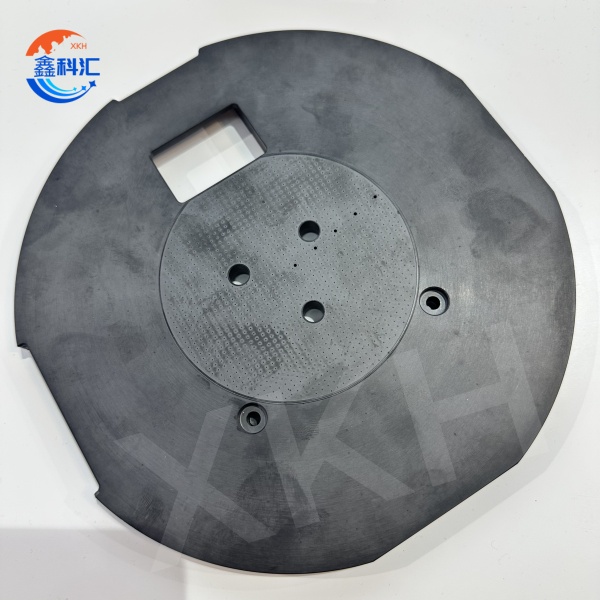

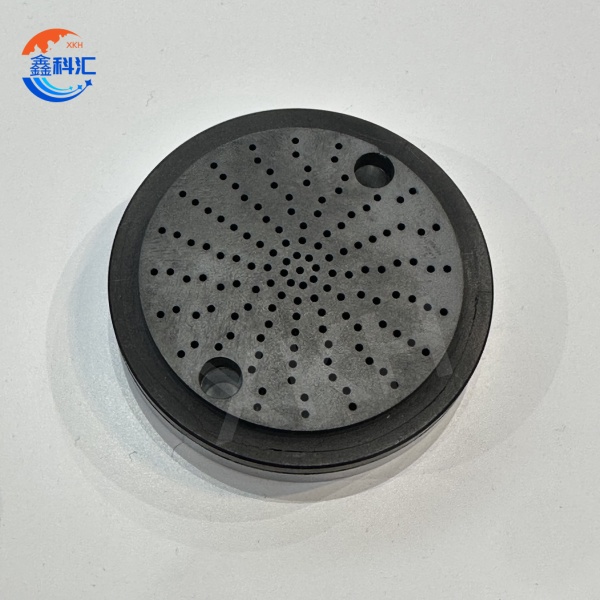

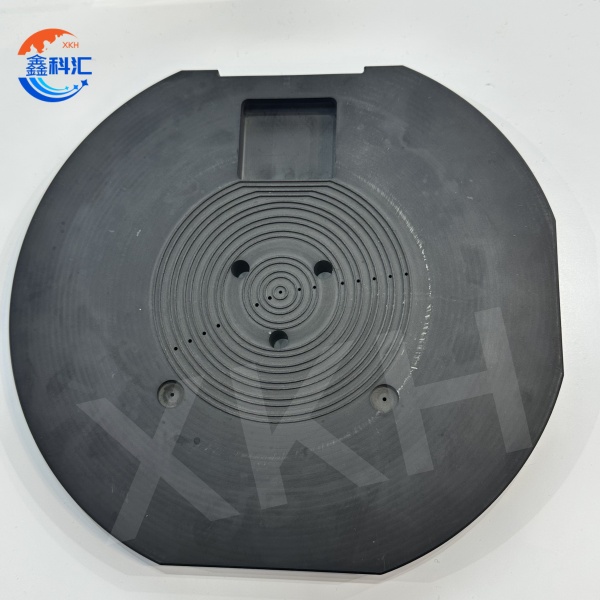

SiC ceramic chuck tireyi Ceramic suction cups precision machining yakagadzirirwa

Material features:

1.Kuoma kwepamusoro: kuoma kweMohs yesilicon carbide ndeye 9.2-9.5, yechipiri chete kune diamond, ine simba rakasimba rekudzivirira.

2. High thermal conductivity: thermal conductivity yesilicon carbide yakakwirira se 120-200 W / m · K, inogona kubvisa kupisa nokukurumidza uye inokodzera nzvimbo yakakwirira yekushisa.

3. Low thermal expansion coefficient: silicon carbide thermal expansion coefficient yakaderera (4.0-4.5 × 10⁻⁶/K), inogona kuchengetedza kugadzikana kwedimensional pakupisa kwepamusoro.

4. Kugadzikana kwemakemikari: silicon carbide acid uye alkali corrosion resistance, yakakodzera kushandiswa mumakemikari anoparadza mamiriro.

5. High mechanical simba: silicon carbide ine simba rekukotama rakakwirira uye simba rinomanikidzira, uye rinogona kumira kushushikana kukuru kwemichina.

Features:

1. Muindasitiri ye semiconductor, zvitete zvakaonda zvakanyanya zvinoda kuiswa pakapu yekusveta yevacuum, iyo yekutsvaira yevacuum inoshandiswa kugadzirisa mawaferi, uye maitiro ewakisi, kuonda, wakisi, kuchenesa uye kucheka kunoitwa pamawafers.

2.Silicon carbide sucker ine yakanaka yekupisa conductivity, inogona kunyatso kupfupisa waxing uye waxing nguva, kuvandudza kugadzirwa kwehunyanzvi.

3.Silicon carbide vacuum sucker inewo acid yakanaka uye alkali corrosion resistance.

4.Kufananidzwa neyechinyakare corundum carrier plate, kupfupisa kurodha uye kuburitsa kupisa uye kutonhora nguva, kunatsiridza kushanda zvakanaka; Panguva imwecheteyo, inogona kuderedza kupfeka pakati pepamusoro uye pasi mahwendefa, kuchengetedza kunaka kwendege, uye kuwedzera hupenyu hwebasa ne40%.

5.Chikamu chezvinyorwa zvishoma, uremu huremu. Zviri nyore kuti vashandisi vatakure mapallets, zvichideredza njodzi yekudhumhana kunokonzerwa nekunetsa kwekufambisa ne20%.

6.Size: yakakura dhayamita 640mm; Flatness: 3um kana pasi

Nzvimbo yekushandisa:

1. Semiconductor kugadzira

● Wafer processing:

Yekugadzirisa wafer mu photolithography, etching, yakaonda firimu deposition uye mamwe maitiro, kuve nechokwadi chepamusoro kurongeka uye kuenderana kwemaitiro. Kupisa kwayo kwepamusoro uye kushorwa kwecorrosion kwakakodzera kune yakaoma semiconductor yekugadzira nharaunda.

●Epitaxial growth:

MuSiC kana GaN epitaxial kukura, semutakuri wekupisa nekugadzirisa zvitete, kuve nechokwadi chekufanana kwetembiricha uye mhando yekristaro pakudziya kwepamusoro, kuvandudza kushanda kwechishandiso.

2. Photoelectric midziyo

● LED Manufacturing:

Inoshandiswa kugadzirisa safire kana SiC substrate, uye semutakuri wekudziya muMOCVD process, kuve nechokwadi chekufanana kwekukura kwe epitaxial, kunatsiridza LED inopenya kunyatso uye kunaka.

●Laser diode:

Seyepamusoro-chaiyo gadziriso, kugadzirisa uye kupisa substrate kuti ive nechokwadi chekugadzirisa tembiricha, kuvandudza simba rekubuda uye kuvimbika kweiyo laser diode.

3. Precision machining

●Optical component processing:

Inoshandiswa pakugadzirisa zvinhu zvakanyatsorongeka zvakadai se optical lenses uye mafirita kuti ive nechokwadi chepamusoro uye kusvibiswa kwakaderera panguva yekugadzirisa, uye inokodzera kushandiswa kwepamusoro-soro.

● Ceramic processing:

Seyakanyanya kugadzikana gadziriso, inokodzera kurongeka machining emidziyo yeceramic kuve nechokwadi chekugadzira machining uye kuenderana pasi pekushisa kwepamusoro uye nharaunda inoparadza.

4. Kuedza kwesainzi

●Kuyedza tembiricha yepamusoro:

Seyemuyero yekumisikidza mudziyo munzvimbo dzekushisa kwepamusoro, inotsigira tembiricha yakanyanyisa kuyedza pamusoro pe1600 ° C kuve nechokwadi chekufanana kwetembiricha uye kugadzikana kwemuenzaniso.

● Vacuum test:

Semuenzanisi wekugadzirisa uye kupisa mutakuri munzvimbo yevacuum, kuve nechokwadi chechokwadi uye kudzokorora kwekuyedza, kwakakodzera vacuum coating uye kupisa kurapwa.

Technical specifications:

| (Zvinhu) | (Chikwata) | (sic) | |

| (SiC zvirimo) |

| (Wt)% | >99 |

| (Avhareji saizi yezviyo) |

| micron | 4-10 |

| (Density) |

| kg/dm3 | >3.14 |

| (Inooneka porosity) |

| Vo1% | <0.5 |

| (Vickers kuoma) | HV 0.5 | GPa | 28 |

| *(Flexural simba) | 20ºC | MPa | 450 |

| (Compressive simba) | 20ºC | MPa | 3900 |

| (Elastic Modulus) | 20ºC | GPa | 420 |

| (Kutyoka kuoma) |

| MPa/m'% | 3.5 |

| (Thermal conductivity) | 20°C | W/(m*K) | 160 |

| (Resistivity) | 20°C | Ohm.cm | 106-108 |

|

| a(RT**...80ºC) | K-1*10-6 | 4.3 |

|

|

| oºC | 1700 |

Nemakore ekuunganidza tekinoroji uye ruzivo rweindasitiri, XKH inokwanisa kugadzirisa akakosha ma paramita senge saizi, nzira yekudziya uye vacuum adsorption dhizaini yechuck zvinoenderana nezvinodiwa nemutengi, kuve nechokwadi chekuti chigadzirwa chakanyatso kuenderana nemaitiro emutengi. SiC silicon carbide ceramic chucks zvave zvinhu zvakakosha mukugadzira wafer, epitaxial kukura uye mamwe maitiro akakosha nekuda kweakanakisa ekupisa kwekupisa, kugadzikana kwekushisa kwakanyanya uye kugadzikana kwemakemikari. Kunyanya mukugadzira yechitatu-chizvarwa semiconductor zvinhu zvakaita seSiC neGaN, kudiwa kwesilicon carbide ceramic chucks kuri kuramba kuchikura. Mune ramangwana, nekukurumidza kusimudzira kwe5G, mota dzemagetsi, hungwaru hwekugadzira uye humwe matekinoroji, tarisiro yekushandiswa kwesilicon carbide ceramic chucks muindasitiri yesemiconductor ichave yakakura.

Detailed Diagram