Semiconductor Laser Rift-Off Equipment

Detailed Diagram

Chigadzirwa Overview yeLaser Lift-Off Equipment

Iyo Semiconductor Laser Lift-Off Equipment inomiririra inotevera-chizvarwa mhinduro yepamberi ingot kutetepa mu semiconductor zvinhu kugadzirisa. Kusiyana nemaitiro echinyakare ekuyeresa anovimba nemuchina kukuya, dhaimondi waya sawing, kana kemikari-mechanicha planarization, iyi laser-based platform inopa yemahara-yemahara, isingaparadze imwe nzira yekuvharira ma-ultra-thin layers kubva kune akawanda semiconductor ingots.

Yakagadzirirwa brittle uye yakakwirira-yakakosha zvinhu senge gallium nitride (GaN), silicon carbide (SiC), safiro, uye gallium arsenide (GaAs), iyo Semiconductor Laser Lift-Off Equipment inogonesa kuchekwa kwemafirimu-scale mafirimu zvakananga kubva kukristaro ingot. Iyi tekinoroji yekubudirira inoderedza zvakanyanya kuraswa kwezvinhu, inovandudza kubuda, uye inosimudzira substrate kutendeseka - izvo zvese zvakakosha kune inotevera-chizvarwa zvishandiso mumagetsi emagetsi, RF masisitimu, mafotonic, uye madiki-maratidziro.

Nekusimbisa pane otomatiki kudzora, danda kuumbwa, uye laser-material kupindirana analytics, iyo Semiconductor Laser Lift-Off Equipment yakagadzirirwa kusanganisa isina musono mu semiconductor yekugadzira workflows ichitsigira R&D kuchinjika uye kuwanda kwekugadzira scalability.

Technology & Operating Principle yeLaser Lift-Off Equipment

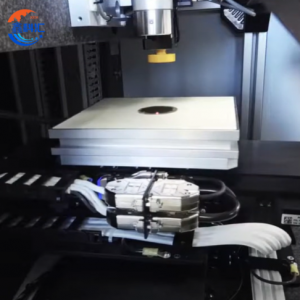

Iyo nzira inoitwa neSemiconductor Laser Lift-Off Equipment inotanga nekudiridza iyo donor ingot kubva kune rumwe rutivi uchishandisa high-energy ultraviolet laser beam. Iri danda rakanyatso tariswa kune chaiyo kudzika kwemukati, kazhinji pamwe neyakagadzirwa interface, uko kunyudzwa kwesimba kunokwidziridzwa nekuda kwekusiyana kwemaziso, kupisa, kana kemikari.

Paiyi simba rekunyudza, kupisa kwenzvimbo kunotungamira kukurumidza kuputika kudiki, kuwedzera gasi, kana kuparara kweiyo interfacial layer (semuenzaniso, firimu rekumanikidza kana chibayiro okisidhi). Uku kukanganisika kwakanyatso kudzora kunokonzeresa iyo yepamusoro crystalline layer - ine ukobvu hwemakumi emamicrometer - kuti ibvise kubva pachigadziko ingot zvakachena.

Iyo Semiconductor Laser Lift-Off Equipment inokwirisa inofamba-yakawiriraniswa scanning misoro, programmable z-axis control, uye chaiyo-nguva reflectometry kuona kuti pulse yega yega inopa simba pane yakananga ndege. Midziyo yacho inogona zvakare kugadziridzwa neburst-mode kana akawanda-pulse kugona kuti uwedzere kutsvedzereka uye kuderedza kusara kunetseka. Zvakakosha, nekuti danda relaser harina kumbobata zvinhu panyama, njodzi ye microcracking, kukotama, kana kuputika kwepasi inodzikiswa zvakanyanya.

Izvi zvinoita kuti iyo laser yekusimudza-kurenda yakatetepa nzira inoshandura mutambo, kunyanya mumashandisirwo apo ma-ultra-flat, matete-wafers anodiwa ane sub-micron TTV (Total Thickness Variation).

Parameter yeSemiconductor Laser Lift-Off Equipment

| Wavelength | IR/SHG/THG/FHG |

|---|---|

| Pulse Width | Nanosecond, Picosecond, Femtosecond |

| Optical System | Fixed optical system kana Galvano-optical system |

| XY Stage | 500 mm × 500 mm |

| Processing Range | 160 mm |

| Movement Speed | Max 1,000 mm/sec |

| Kudzokorora | ± 1 μm kana pasi |

| Absolute Position Accuracy: | ± 5 μm kana pasi |

| Wafer Size | 2-6 inches kana customized |

| Kudzora | Windows 10, 11 uye PLC |

| Power Supply Voltage | AC 200 V ±20 V, Chikamu chimwe chete, 50/60 kHz |

| External Dimensions | 2400 mm (W) × 1700 mm (D) × 2000 mm (H) |

| Kurema | 1,000 kg |

Industrial Applications yeLaser Lift-Off Equipment

Semiconductor Laser Lift-Off Equipment iri kukurumidza kushandura magadzirirwo emidziyo mumatunhu akawanda semiconductor:

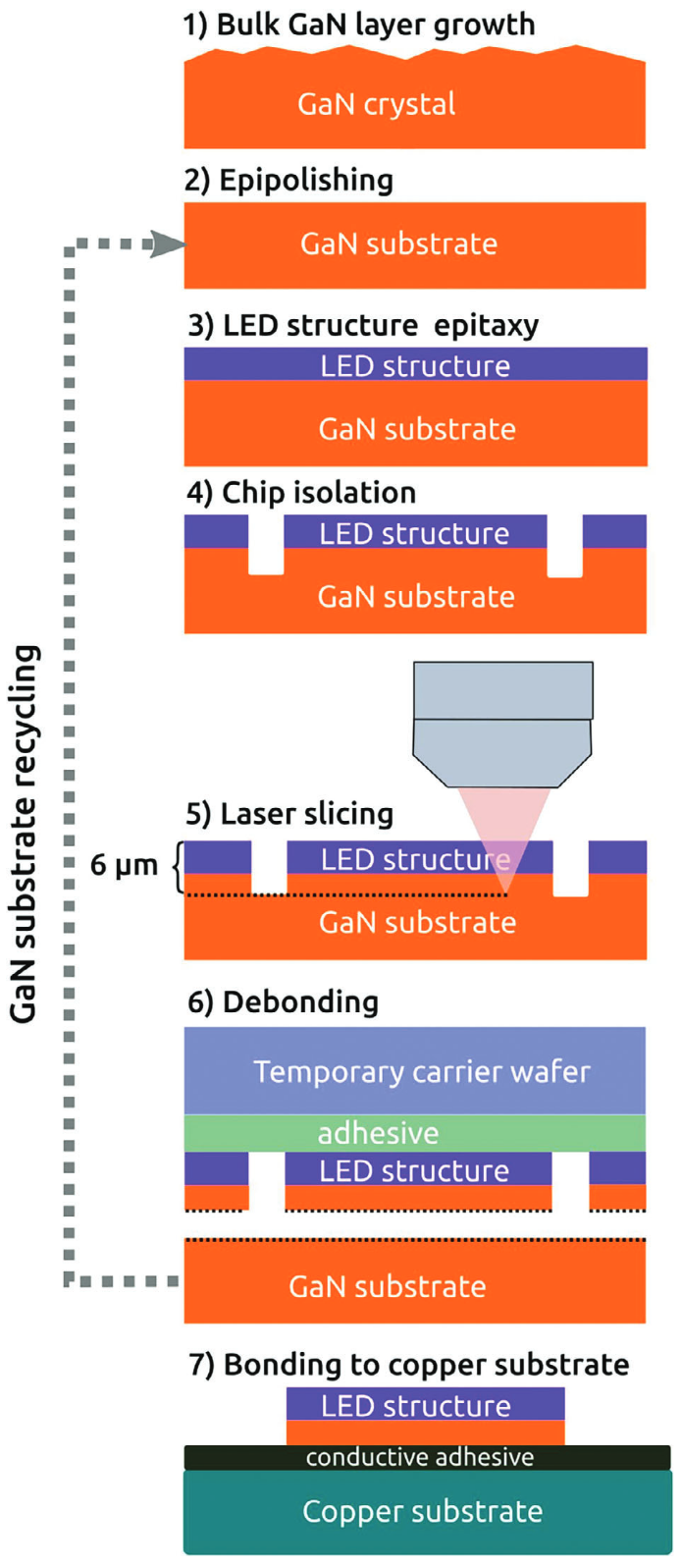

- Vertical GaN Power Devices yeLaser Lift-Off Equipment

Kusimudzwa kwemafirimu ekupedzisira-akatetepa eGaN-on-GaN kubva kune akawanda ingots anogonesa vertical conduction architecture uye kushandiswazve kwema substrates anodhura.

- SiC Wafer Thinning yeSchottky uye MOSFET Zvishandiso

Inoderedza ukobvu hwemudziyo uchichengetedza substrate planarity - yakanakira kukurumidza kushandura magetsi emagetsi.

- Sapphire-Yakavakirwa LED uye Display Zvishandiso zveLaser Lift-Off Equipment

Inogonesa kupatsanurwa kwakanaka kwemidziyo kubva kumasafire boules kuti itsigire yakatetepa, yakakwenenzverwa nekugadzirwa kwemicro-LED.

- III-V Material Engineering yeLaser Lift-Off Equipment

Inofambisa dhipatimendi reGaAs, InP, uye AlGaN maseru epamberi optoelectronic kubatanidzwa.

- Thin-Wafer IC uye Sensor Fabrication

Inogadzira akatetepa anoshanda akaturikidzana ekumanikidza masensa, accelerometers, kana mafotodiode, uko kuwanda ibhodhoro rekuita.

- Flexible uye Transparent Electronics

Inogadzira ma-ultra-thin substrates anokodzera zviratidziro zvinochinjika, maseketi anopfekeka, uye mahwindo akajeka akajeka.

Mune imwe neimwe yenzvimbo idzi, Semiconductor Laser Lift-Off Equipment inoita basa rakakosha mukugonesa miniaturization, kushandiswazve kwezvinhu, uye kuita kurerutsa.

Inowanzo bvunzwa mibvunzo (FAQ) yeLaser Lift-Off Equipment

Q1: Ndeupi hushoma hukobvu hwandinogona kuwana ndichishandisa Semiconductor Laser Lift-Off Equipment?

A1:Kazhinji pakati pe10-30 microns zvichienderana nezvinhu. Iyo nzira inokwanisa kutetepa mhedzisiro ine yakagadziridzwa setups.

Q2: Izvi zvinogona kushandiswa kucheka akawanda wafers kubva kune imwechete ingot?

A2:Ehe. Vatengi vazhinji vanoshandisa nzira yekusimudza-laser kuita serial zvinyorwa zvematehwe akawanda kubva kune imwe ingot yakawanda.

Q3: Ndeapi maficha ekuchengetedza anosanganisirwa epamusoro-simba laser oparesheni?

A3:Kirasi 1 yakavharirwa, interlock masisitimu, danda shielding, uye otomatiki shutoffs ese akajairwa.

Q4: Iyi sisitimu inofananidzwa sei nedhaimani waya masaha maererano nemutengo?

A4:Nepo yekutanga capex inogona kunge yakakwira, laser lift-off inoderedza zvakanyanya mutengo, substrate kukuvara, uye post-processing matanho - kudzikisa yakazara mutengo wevaridzi (TCO) kwenguva refu.

Q5: Maitiro acho anogona scalable kusvika 6-inch kana 8-inch ingots?

A5:Zvamazvirokwazvo. Iyo puratifomu inotsigira anosvika gumi nemaviri-inch substrates ane yunifomu danda kugovera uye yakakura-fomati yekufamba matanho.

Nezvedu

XKH inyanzvi mukusimudzirwa kwepamusoro-soro, kugadzira, uye kutengesa kwegirazi remaziso uye zvinhu zvitsva zvekristaro. Zvigadzirwa zvedu zvinoshanda zvemagetsi zvemagetsi, zvemagetsi zvevatengi, uye mauto. Isu tinopa Sapphire optical components, nharembozha lens inovhara, Ceramics, LT, Silicon Carbide SIC, Quartz, uye semiconductor crystal wafers. Nehunyanzvi hunyanzvi uye yekucheka-kumucheto michina, isu tinokunda mune isiri-yakajairwa chigadzirwa kugadzirisa, tichivavarira kuve inotungamira optoelectronic zvinhu zvepamusoro-tech bhizinesi.