Robotic Polishing Machine - Yepamusoro-Precision Automated Surface Kupedzisa

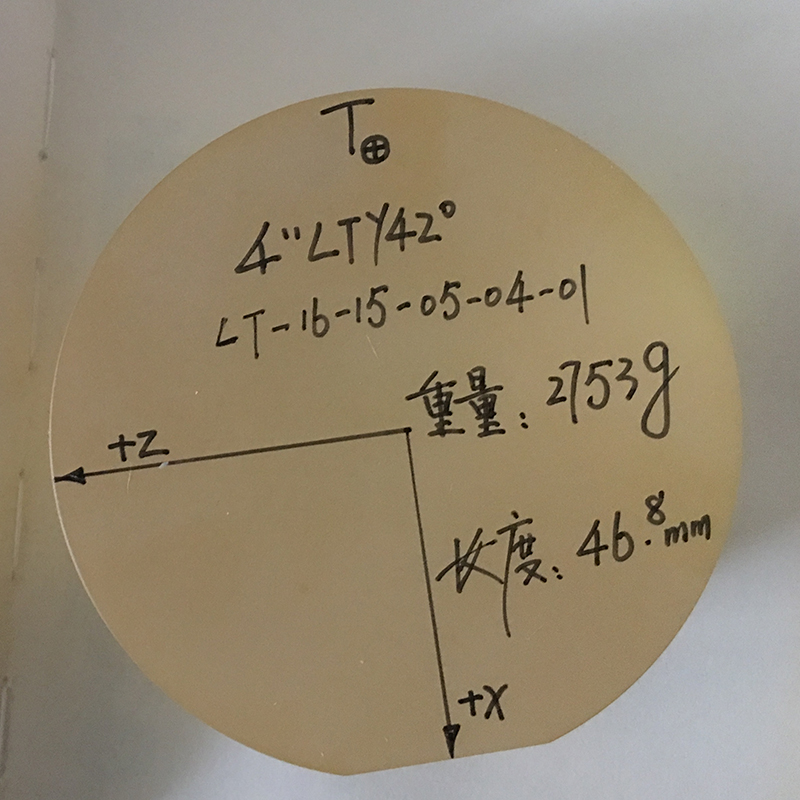

Detailed Diagram

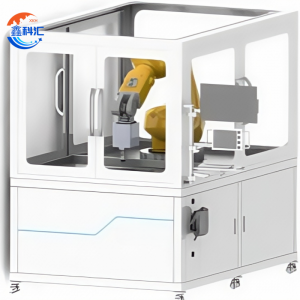

Mhedziso yeRobotic Polishing Machine

Iyo Robotic Polishing Machine ndeye yepamusoro, yakazara otomatiki pamusoro pekugadzirisa system yakagadzirirwa kusangana nepamusoro zvinodiwa mukugadzira chaiko. Iyo inosanganisa matanhatu-axis robhoti kutonga, kumanikidza-mhinduro yekupolisha tekinoroji, uye mbiri-yemusoro gadziriso yekubata yakawandisa yemidziyo uye yakaoma geometries nekunyatso kunoshamisa uye kuenderana.

Zvingave zvemalenzi emaziso, zvikamu zvemuchadenga, zvimiro zveinjiniya, kana semiconductor maapplication, muchina uyu unoburitsa yakagadzika, inodzokororwa, uye yepamusoro-soro yepamusoro pekupedzisira-kunyangwe pa nanometer-level kushivirira.

Yakazara Workpiece Kuenderana kweRobotic Polishing Machine

Iyo sisitimu inotsigira kugadzirisa kwe:

-

Nzvimbo dzakatsetsekazvegirazi, ceramics, uye marata esimbi

-

Cylindrical uye conical maumbirwozvakadai sema rollers, shafts, uye machubhu

-

Spherical uye aspherical zvikamuye optical systems

-

Freeform uye off-axis nzvimbonema curves akaoma uye shanduko

Kuwanda kwayo kunoita kuti ive yakakodzerazvose kugadzirwa kwehuwandu uye yakakwirira-chaiyo tsika yekugadzira.

Core Zvimiro & Zvakanakira zveRobotic Polishing Machine

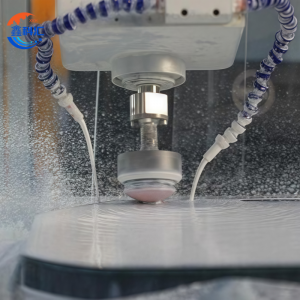

1. Dual Polishing Head Technology

-

Akashongedzerwa neimwe-kutendererauyekuzvitenderedzakukwenenzvera misoro kuitira kusanduka.

-

Rapid tool shanduko inokwanisa inotsigira akawanda ekugadzirisa modes pasina nguva refu yekudzikira.

-

Yakanakira kushandura pakati peakakasharara uye akatsetseka polishing nhanho.

2. Precision Force-Control System

-

Real-time monitoring yedzvinyiriro, tembiricha, uye kupenya kwemvura inoyerera.

-

Consistent force application inovimbisa yunifomu yekumusoro kupera mukati meiyo workpiece.

-

Inokwanisa kugadzirisa kune zvisakarurama zvepasi otomatiki.

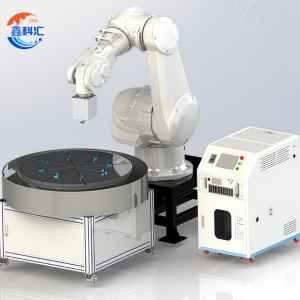

3. Six-Axis Robotic Control

-

Rusununguko rwakazara rwekufamba kubata geometri dzakaoma.

-

Yakapfava, nzira dzekufamba dzakaverengerwa kuburikidza nepamusoro algorithms.

-

Yakakwirira kudzokorora kumira kwechokwadi kubva ± 0.04 mm kusvika ± 0.1 mm zvichienderana nemuenzaniso.

4. Smart Automation & Measurement

-

Auto-calibration maturusi ekunyatso kuseta uye kurongeka.

-

Coordinate yekuyera sisitimu yekumisikidza kwakaringana.

-

Optionalonline ukobvu monitoringyenguva chaiyo yekutonga kwehutano.

5. Industrial-Grade Build Quality

-

Dual servo-motor dhizaini inowedzera kukwenenzvera kugona uye kugadzikana.

-

Rigid mechanical chimiro chinoderedza vibration uye inova nechokwadi chekugara kwenguva refu.

Mamiriro ehunyanzvi eRobotic Polishing Machine

| Equipment Model | Robot Muviri | Dzokorora Positioning Kururama | Kugadzirisa Diameter Range | Single Rotation Polishing Head | Multi-Rotation Polishing Head | Diki Turusi | Main Wheel Type Polishing | Spherical Head Polishing | Pedzisa Kuchinja Kwekukurumidza | Auto Calibration Tool | Coordinate Measurement Head | Online Makobvu Monitoring | Numerical Control Platform |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IRP500S | Staubli TX2-90L | ± 0.04mm / yakazara renji | Φ50~Φ500mm | √ | × | √ | √ | √ | × | ○ | ○ | ○ | ○ |

| IRP600S | Staubli TX2-140 | ± 0.05mm / yakazara renji | Φ50~Φ600mm | √ | × | √ | √ | √ | × | ○ | ○ | ○ | ○ |

| IRP800S | Staubli TX2-160 | ± 0.05mm / yakazara renji | Φ80~Φ800mm | √ | √ | √ | √ | √ | ○ | ○ | ○ | ○ | ○ |

| IRP1000S | Staubli TX200/L | ± 0.06mm / yakazara renji | Φ100~Φ1000mm | √ | ○ | √ | √ | √ | ○ | ○ | ○ | ○ | ○ |

| IRP1000A | ABB IRB6700-200/2.6 | ± 0.1mm / yakazara renji | Φ100~Φ1000mm | √ | ○ | √ | √ | √ | ○ | ○ | ○ | ○ | ○ |

| IRP2000A | ABB IRB6700-150/3.2 | ± 0.1mm / yakazara renji | Φ200~Φ2000mm | √ | ○ | √ | √ | √ | × | × | × | ○ | ○ |

| IRP2000AD | ABB IRB6700-150/3.2 | ± 0.1mm / yakazara renji | Φ200~Φ2000mm | √ | ○ | √ | √ | √ | × | × | × | ○ | ○ |

FAQ – Robhoti Polishing Machine

1. Ndeapi marudzi ezvishandiso zvinogona kuitwa nerobhoti yekupolisha muchina?

Robhoti yedu yekupukuta muchina inotsigira akasiyana maumbirwo uye nzvimbo, kusanganisira flat, curved, spherical, freeform, uye yakaoma contours. Inokodzera maoptical components, precision molds, metal surfaces, uye mamwe ma-high-precision polishing applications.

2. Ndeupi musiyano uripo pakati peSingle Rotation uye Multi-Rotation polishing misoro?

-

Single Rotation Polishing Head: Chishandiso chinotenderera chakatenderedza axis imwe chete, yakanakira kupedzisa kwepamusoro pekupedzisira uye nekumhanya-mhanya kubvisa zvinhu.

-

Multi-Rotation Polishing Head: Chishandiso chinosanganisa kutenderera nekuzvitenderedza (kutenderera), zvichiita kuti mamwe mayunifomu apeperese panzvimbo yakakombama uye isina kurongeka.

3. Ndeipi iyo yakawanda yekugadzirisa dhayamita?

Zvichienderana nemuenzaniso:

-

Compact modhi (semuenzaniso, IRP500S) mubatoΦ50–Φ500mm.

-

Mahombe-mwero mhando (semuenzaniso, IRP2000AD) kubata kusvikaΦ2000mm.

Nezvedu

XKH inyanzvi mukusimudzirwa kwepamusoro-soro, kugadzira, uye kutengesa kwegirazi remaziso uye zvinhu zvitsva zvekristaro. Zvigadzirwa zvedu zvinoshanda zvemagetsi zvemagetsi, zvemagetsi zvevatengi, uye mauto. Isu tinopa Sapphire optical components, nharembozha lens inovhara, Ceramics, LT, Silicon Carbide SIC, Quartz, uye semiconductor crystal wafers. Nehunyanzvi hunyanzvi uye yekucheka-kumucheto michina, isu tinokunda mune isiri-yakajairwa chigadzirwa kugadzirisa, tichivavarira kuve inotungamira optoelectronic zvinhu zvepamusoro-tech bhizinesi.