Seyechitatu-chizvarwa semiconductor substrate zvinhu,silicon carbide (SiC)Single crystal ine tarisiro yakafara yekushandiswa mukugadzirwa kweyepamusoro-frequency uye yakakwirira-simba zvemagetsi zvishandiso. Iyo tekinoroji yekugadzirisa yeSiC inoita basa rakasimba mukugadzirwa kwemhando yepamusoro substrate zvinhu. Ichi chinyorwa chinosuma mamiriro azvino ekutsvagisa pamusoro peSiC kugadzirisa matekinoroji muChina nekune dzimwe nyika, achiongorora nekuenzanisa maitirwo ekucheka, kukuya, nekupukuta maitirwo, pamwe nemafambiro ewafer flatness uye kushata kwepasi. Inotaridzawo matambudziko aripo muSiC wafer processing uye inokurukura mafambiro ebudiriro.

Silicon carbide (SiC)mawaferi zvinhu zvakakosha zvekutanga zvechizvarwa chechitatu semiconductor zvishandiso uye zvine kukosha kwakakosha uye musika mukana muminda yakaita semicroelectronics, magetsi emagetsi, uye semiconductor mwenje. Nekuda kwekuoma kwakanyanya uye kugadzikana kwemakemikari kweSiC single makristasi, tsika dzechinyakare semiconductor kugadzirisa nzira hadzina kunyatsokodzera machining avo. Kunyangwe makambani mazhinji epasi rese akaita tsvakiridzo yakadzama pahunyanzvi hunoda kugadziriswa kweSiC imwe makristasi, matekinoroji akakodzera anochengetwa akavanzika.

Mumakore achangopfuura, China yakawedzera kuedza mukuvandudza kweSiC single crystal zvinhu nemidziyo. Nekudaro, kufambira mberi kweSiC mudziyo tekinoroji munyika parizvino yakamanikidzwa nezvisingakwanisi mukugadzirisa matekinoroji uye mhando yewafer. Naizvozvo, zvakakosha kuti China ivandudze SiC kugadzirisa hunyanzvi kusimudzira mhando yeSiC single crystal substrates uye kuzadzisa yavo inoshanda uye kugadzirwa kwakawanda.

Matanho makuru ekugadzirisa anosanganisira: kucheka → kugaya kwakakasharara → kugaya zvakanaka → kukwenenzverwa kwekasha (makanika kuporiswa) → kukwenenzvera (kemikari mechanical polishing, CMP) → kuongorora.

| Danho | SiC Wafer Processing | Traditional Semiconductor Single-Crystal Material Processing |

| Kucheka | Inoshandisa multi-waya sawing tekinoroji kucheka maSiC ingots kuita mawafer matete | Kazhinji inoshandisa mukati-dhayamita kana yekunze-dhayamita yekucheka blade matekiniki |

| Kukuya | Yakakamurwa kuita yakakasharara uye yakatsetseka kugaya kubvisa mavanga esaha uye kukuvara kunokonzerwa nekucheka | Nzira dzekukuya dzingasiyana, asi chinangwa chacho chimwe chete |

| Kupukuta | Inosanganisira hutsinye uye hwekupedzisira-chaizvo kukwenenzverwa uchishandisa michina uye makemikari mechanical polishing (CMP) | Kazhinji inosanganisira kemikari mechanical polishing (CMP), kunyange matanho chaiwo anogona kusiyana |

Kucheka kweSiC Single Crystals

Mukugadzirisa kweSiC single makristasi, kucheka ndiro danho rokutanga uye rinokosha zvikuru. Uta hwewafer, warp, uye kuenzana kwehupamhi hwekusiyanisa (TTV) inokonzerwa nekucheka inogadzirisa kunaka uye kushanda kwekutevera kwekukuya nekupukuta.

Maturusi ekucheka anogona kukamurwa nechimiro kuita dhaimondi mukati dhayamita (ID) masaha, dhayamita rekunze (OD) masaha, masaha emabhendi, nemasaha ewaya. Wire saws, zvakare, inogona kukamurwa nemhando yavo yekufamba kuita inodzoreredza uye loop (isingagumi) waya masisitimu. Zvichienderana nemagadzirirwo ekucheka kweabrasive, waya saw slicing matekiniki anogona kupatsanurwa mumhando mbiri: yemahara abrasive waya sawing uye yakagadziriswa abrasive diamond waya sawing.

1.1 Nzira dzeKucheka dzechinyakare

Iyo yekucheka kudzika kwekunze kwedhayamita (OD) saw inogumira nehupamhi hweblade. Munguva yekucheka, blade inogara ichidedera uye kutsauka, zvichikonzera kukwirira kweruzha uye kusasimba kusimba. Inner dhayamita (ID) masaha anoshandisa madhaimondi abrasives pamukati medenderedzwa rebadza semupendero wekucheka. Aya mashizha anogona kutetepa se 0.2 mm. Panguva yekucheka, blade yeID inotenderera nekumhanya kukuru apo zvinhu zvinotemwa zvinofamba zvine mwero zvichienderana nepakati peblade, zvichiwana kucheka kuburikidza neichi chinhanho chehukama.

Dhaimondi bhendi masaha inoda kugara ichimira uye kudzokororwa, uye kumhanya kwekucheka kwakadzikira-kazhinji haapfuuri 2 m/s. Ivo zvakare vanotambura nekupfeka kwakakosha kwemechini uye mitengo yepamusoro yekugadzirisa. Pamusana pehupamhi hwejecha resaha, radius yekucheka haigoni kuva duku, uye kucheka kwezvidimbu zvakasiyana-siyana hazvibviri. Aya maturusi echinyakare ekuchekesa anoganhurirwa nekuoma kwegasi uye haakwanise kugadzira akakombama kucheka kana kudzora kutendeuka radii. Dzinongokwanisa kucheka zvakatwasuka, kugadzira kerfs dzakafara, dzine goho rakaderera, nekudaro hadzina kukodzera kucheka.SiC makristasi.

1.2 Yemahara Abrasive Wire Akaona Multi-Waya Kucheka

Iyo yemahara abrasive wire saw slicing tekinoroji inoshandisa kukurumidza kufamba kwewaya kutakura slurry mukefi, ichigonesa kubviswa kwezvinhu. Iyo inonyanya kushandisa chimiro chinodzoreredza uye parizvino inzira yakakura uye inoshandiswa zvakanyanya yeanoshanda akawanda-wafer kucheka kwesingle-crystal silicon. Nekudaro, kushandiswa kwayo muSiC kucheka kwave kushoma kudzidzwa.

Mawaya emahara abrasive anogona kugadzira mawafer ane ukobvu ari pasi pe300 μm. Ivo vanopa yakaderera kerf kurasikirwa, kashoma kukonzera chipping, uye inokonzeresa yakanaka yemhando yepamusoro. Nekudaro, nekuda kweiyo nzira yekubvisa zvinhu-yakavakirwa pakukunguruka uye indentation yeabrasives-iyo wafer yepasi inokonzeresa kukudziridza kwakakosha kusara kushushikana, microcracks, uye yakadzama kukuvara maseru. Izvi zvinotungamira kune wafer warping, zvinoita kuti zviome kudzora kurongeka kweprofile, uye kuwedzera mutoro pamatanho anotevera ekugadzirisa.

Kuita kwekucheka kunonyanya kukonzerwa ne slurry; zvakakosha kuchengetedza kupinza kweabrasives uye kusungirirwa kwe slurry. Kurapa slurry nekudzokorodza kunodhura. Kana uchicheka ingots dzakakura, mabrasives ane dambudziko rekupinda mukati makadzika uye marefu kerfs. Pasi pehukuru hwakafanana hwezviyo, kurasikirwa kwekefi kwakakura kupfuura iyo yakagadziriswa-abrasive wire saw.

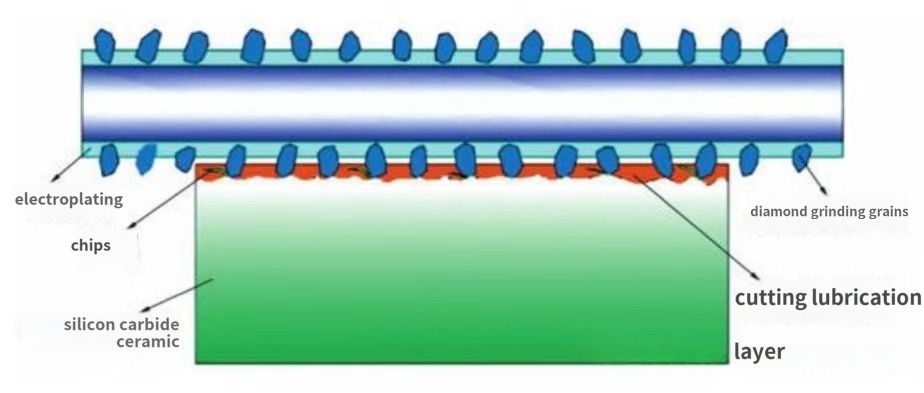

1.3 Yakagadziriswa Abrasive Diamond Wire Yakaona Multi-Waya Kucheka

Fixed abrasive diamond wire saws anowanzo gadzirwa nekumisikidza zvidimbu zvedhaimani pane simbi substrate kuburikidza ne electroplating, sintering, kana resin bonding nzira. Electroplated diamond waya saws inopa zvakanakira senge yakatetepa kerfs, nani chidimbu chemhando, kugona kwepamusoro, kusvibiswa kwakadzikira, uye kugona kucheka zvinhu zvekuomarara.

The reciprocating electroplated diamond wire saw ndiyo inonyanya kushandiswa nzira yekucheka SiC. Mufananidzo 1 (usiri kuratidzwa pano) unoratidza kupfava kwepamusoro kweSiC wafers akachekwa uchishandisa nzira iyi. Sezvo kucheka kunofambira mberi, wafer warpage inowedzera. Izvi zvinodaro nekuti nzvimbo yekubatana pakati pewaya uye zvinhu zvinowedzera sezvo waya ichidzika ichidzika, ichiwedzera kuramba uye kudengenyeka kwewaya. Kana waya yasvika pakureba kwedhayamita yewaferi, kutenheka kuri pakakwirira, zvichiita kuti pave nehondo yakanyanya.

Mumatanho ekupedzisira ekucheka, nekuda kwewaya irikumhanyisa, yakagadzikana-kumhanya kufamba, kudzikisira, kumira, uye kudzosera kumashure, pamwe nekunetseka mukubvisa marara neinotonhodza, kunaka kwepamusoro kwewafer kunoderera. Kudzoserwa kwewaya uye kuchinjika kwekumhanya, pamwe nezvidimbu zvedhaimondi zvakakura pawaya, ndizvo zvinonyanya kukonzera kukwenya kwepasi.

1.4 Cold Separation Technology

Cold kupatsanurwa kweSiC single crystals inzira yekuvandudza mumunda wechitatu-chizvarwa semiconductor zvinhu kugadzirisa. Mumakore achangopfuura, yakakwezva kutariswa kwakakosha nekuda kwemabhenefiti ayo anozivikanwa mukuvandudza goho uye kuderedza kurasikirwa kwezvinhu. Iyo tekinoroji inogona kuongororwa kubva kune matatu maficha: kushanda musimboti, process kuyerera, uye yakakosha mabhenefiti.

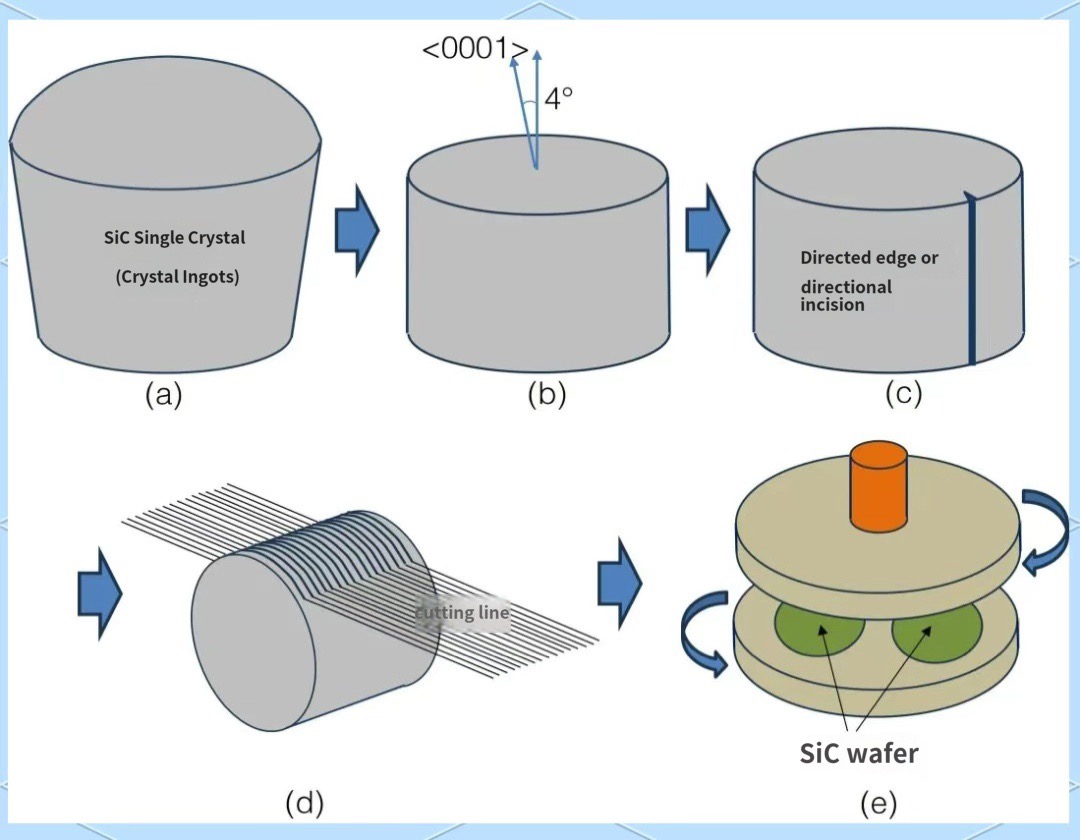

Crystal Oriental Kutsinhana uye Outer Diameter Kukuya: Isati yagadziriswa, iyo yekristaro yekumisikidza yeSiC ingot inofanirwa kutsanangurwa. Iyo ingot inozoumbwa kuita cylindrical chimiro (inowanzonzi SiC puck) kuburikidza nekunze dhayamita kugaya. Iyi nhanho inoisa hwaro hwekuzotevera kutungamira kwekucheka uye kucheka.

Multi-Waya Kucheka: Iyi nzira inoshandisa abrasive particles akasanganiswa nekucheka waya kucheka cylindrical ingot. Nekudaro, inotambura nekurasikirwa kukuru kwekerf uye kusaenzana kwepamusoro nyaya.

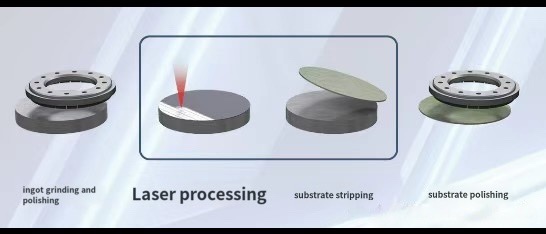

Laser Kucheka Tekinoroji: Laser inoshandiswa kugadzira yakagadziridzwa dhizaini mukati mekristaro, kubva mairi matete zvimedu anogona kuvharwa. Iyi nzira inoderedza kurasikirwa kwezvinhu uye inowedzera kushanda zvakanaka, zvichiita kuti ive nzira itsva inovimbisa yeSiC wafer yekucheka.

Kucheka Process Optimization

Yakagadziriswa Abrasive Multi-Waya Kucheka: Iyi ndiyo parizvino tekinoroji yemazuva ese, yakanyatsokodzera kuoma kwakanyanya kweSiC.

Electrical Discharge Machining (EDM) uye Cold Separation Technology: Nzira idzi dzinopa mhinduro dzakasiyana-siyana dzakagadzirirwa kune zvimwe zvinodiwa.

Polishing Maitiro: Izvo zvakakosha kuenzanisa chiyero chekubvisa zvinhu uye kukuvara kwepasi. Chemical Mechanical Polishing (CMP) inoshandiswa kuvandudza kufanana kwepamusoro.

Real-Nguva Monitoring: Online yekuongorora matekinoroji anounzwa kuti atarise kushata kwepamusoro munguva chaiyo.

Laser Slicing: Iyi nzira inoderedza kerf kurasikirwa uye kupfupisa magadzirirwo ekugadzirisa, kunyangwe iyo inopisa yakakanganiswa nzvimbo inoramba iri dambudziko.

Hybrid Processing Technologies: Kubatanidza michina uye nzira dzemakemikari kunowedzera kugadzirisa kushanda.

Iyi tekinoroji yakatowana kushandiswa kwemaindasitiri. Infineon, semuenzaniso, yakawana SILTECTRA uye ikozvino inobata ma patents anotsigira kugadzirwa kwakawanda kwema 8-inch wafers. KuChina, makambani akaita seDelong Laser akawana hunyanzvi hwekubuda kwemawafesi makumi matatu paingot ye6-inch wafer processing, inomiririra kuvandudzwa kwe40% pamusoro pemaitiro echinyakare.

Sezvo kugadzirwa kwemidziyo yemumba kunowedzera, tekinoroji iyi inotarisirwa kuve mhinduro huru yeSiC substrate kugadzirisa. Nekuwedzera kwedhayamita yemidziyo yesemiconductor, nzira dzekucheka dzechinyakare dzave kusashanda. Pakati pezvisarudzo zvazvino, kudzokorora tekinoroji yewaya yedhaimani inoratidza tarisiro yakanyanya kuvimbiswa yekushandisa. Laser yekucheka, senzira inobuda, inopa zvakakosha zvakakosha uye inotarisirwa kuve nzira yekutanga yekucheka mune ramangwana.

2,SiC Imwe Crystal Kukuya

Semumiriri wechitatu-chizvarwa semiconductors, silicon carbide (SiC) inopa zvakakosha zvakakosha nekuda kwekufara kwayo bandgap, yakakwira breakdown yemagetsi munda, yakakwira saturation electron drift velocity, uye yakanakisa kupisa kwemafuta. Izvi zvivakwa zvinoita kuti SiC inyanyo batsira mune yakakwira-voltage application (semuenzaniso, 1200V nharaunda). Iyo tekinoroji yekugadzirisa yeSiC substrates chikamu chakakosha chekugadzira mudziyo. Unhu hwepamusoro uye hutsanana hwe substrate hunokanganisa zvakananga hutano hwe epitaxial layer uye kushanda kwechigadzirwa chekupedzisira.

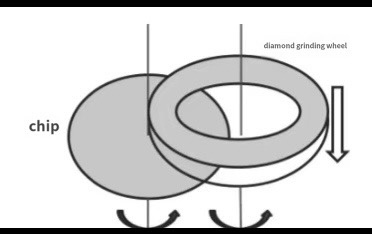

Chinangwa chekutanga chekugaya ndechekubvisa mamaki epasi uye kukuvara kwakakonzerwa panguva yekucheka, uye kugadzirisa deformation inokonzerwa nekucheka maitiro. Tichifunga kuomarara kweSiC zvakanyanya, kukuya kunoda kushandiswa kwemabrasives akaomarara senge boron carbide kana diamondi. Kukuya kwechinyakare kunowanzo kukamurwa kuita kugaya kwakakora uye kukuya.

2.1 Kukuya uye Kwakanaka Kukuya

Kukuya kunogona kukamurwa zvichienderana neabrasive particle size:

Coarse Grinding: Inoshandisa mabrasives akakura kunyanya kubvisa masaha mamaki uye kukuvara kwakakonzerwa panguva yekuchekerera, kunatsiridza mashandiro ekugadzirisa.

Kukuya Kwakanaka: Kunoshandisa mabrasives akakwenenzverwa kubvisa kukuvara kwakasiiwa nekukuya kwakakasharara, kuderedza kushata kwepasi, uye kuwedzera kunaka kwepamusoro.

Vazhinji vekumba SiC substrate vagadziri vanoshandisa hukuru-hukuru hwekugadzira maitiro. Nzira yakajairika inosanganisira kukuya-mativi maviri uchishandisa simbi yakakandwa ndiro uye monocrystalline diamond slurry. Iyi nzira inonyatso bvisa kukuvara kwakasiiwa newaya sawing, inogadzirisa chimiro chewafer, uye inoderedza TTV (Total Thickness Variation), Bow, uye Warp. Chiyero chekubvisa zvinhu chakagadzikana, chinowanzosvika 0.8-1.2 μm/min. Nekudaro, iyo inokonzeresa wafer pamusoro ndeye matte ine yakakwira roughness-kazhinji yakatenderedza 50 nm-iyo inoisa yakakwira zvinodiwa pamatanho anotevera ekupukuta.

2.2 Kukuya Kudivi Rimwechete

Kukuya kwedivi rimwe chete divi rimwe chete rechingwa panguva. Panguva iyi, chidimbu chinoiswa wakisi pandiro yesimbi. Pasi pekumanikidzwa kwekushandiswa, iyo substrate inopinda zvishoma zvishoma, uye nzvimbo yepamusoro inoputika. Mushure mekugaya, nzvimbo yepasi inogadziriswa. Kana dzvinyiriro yacho yabviswa, nzvimbo yekumusoro inoita kuti idzoke pachimiro chayo chepakutanga, izvo zvinokanganisawo pasi nechekare pasi—zvichikonzera kuti mativi ose ari maviri apenye uye adzikire mukupfava.

Uyezve, ndiro yekukuya inogona kuita concave munguva pfupi, zvichiita kuti wafer iite convex. Kuti uchengetedze flatness yeplate, kupfeka nguva dzose kunodiwa. Nekuda kwekushomeka kwakanaka uye kushata kwewafer flatness, kugaya kwedivi rimwe hakuna kukodzera kugadzirwa kwakawanda.

Kazhinji, #8000 mavhiri ekukuya anoshandiswa pakukuya zvakanaka. MuJapan, maitiro aya anenge akura uye anoshandisa #30000 ekupukuta mavhiri. Izvi zvinobvumira kushata kwepamusoro kwezvimedu zvakagadziriswa kusvika pazasi 2 nm, zvichiita kuti mawafesi agadzirire CMP yekupedzisira (Chemical Mechanical Polishing) pasina kumwe kugadzirisa.

2.3 Single Side Thinning Technology

Diamondi Single-Sided Thinning Tekinoroji inzira itsva yekukuya-padivi. Sezvinoratidzwa muMufananidzo 5 (isina kuratidzwa pano), maitiro anoshandisa ndiro yedhaimondi-yakasungwa. Iyo wafer inogadziriswa kuburikidza ne vacuum adsorption, nepo zvese zvinyoro uye dhaimondi rekukuya vhiri rinotenderera panguva imwe chete. Gumbo rekukuya rinofamba zvishoma nezvishoma richidzika kuti ritete pfumbu kusvika pakukora. Mushure mekunge rimwe divi rapedzwa, wafer inopepetwa kuti igadzirise rimwe divi.

Mushure mekutetepa, 100 mm wafer inogona kuwana:

Bow <5 μm

TTV <2 μm

Kushata kwepamusoro <1 nm

Iyi nzira yekugadzira imwe-wafer inopa kugadzikana kwepamusoro, kuwirirana kwakanaka, uye chiyero chepamusoro chekubvisa zvinhu. Kuenzaniswa neyakajairwa mativi maviri-kukuya, nzira iyi inonatsiridza kugaya nepamusoro pe50%.

2.4 Kukuya-Mamativi maviri

Kukuya kwemativi maviri kunoshandisa ndiro yekumusoro neyezasi yekukuya panguva imwe chete mativi ese e substrate, kuve nechokwadi chemhando yepamusoro yepasi pamativi ese.

Munguva yekuita, mahwendefa ekukuya anotanga kuisa kumanikidza kune epamusoro mapoinzi ebasa, zvichikonzera deformation uye zvishoma nezvishoma kubviswa kwezvinhu panzvimbo idzodzo. Sezvo nzvimbo dzakakwirira dzichikwiridzirwa, kudzvinyirirwa kwe substrate zvishoma nezvishoma kunowedzera kufanana, zvichiita kuti kugadzikana kusingagumi kumativi ose. Izvi zvinobvumira zvose zviri pamusoro nepasi kuti zvive pasi zvakaenzana. Kana kukuya kwapera uye kumanikidzwa kwasunungurwa, chikamu chimwe nechimwe che substrate chinodzoka zvakafanana nekuda kwehutano hwakaenzana hwayakawana. Izvi zvinotungamira kune kushoma warping uye yakanaka flatness.

Kushata kwepamusoro pechimedu mushure mekukuya kunoenderana nekukura kwechidimbu chechidimbu — twudiki twunopa nzvimbo dzakatsetseka. Paunenge uchishandisa 5 μm mabrasives ekukuya-mativi maviri, wafer flatness uye ukobvu kusiyanisa kunogona kudzorwa mukati me5 μm. Atomic Force Microscopy (AFM) zviyero zvinoratidza kukwasharara kwepasi (Rq) kwe 100 nm, nemakomba ekukuya anosvika 380 nm akadzika uye anooneka mitsetse mamaki anokonzerwa neabrasive action.

Imwe nzira yepamberi inosanganisira kukuya mativi maviri uchishandisa polyurethane foam pads akasanganiswa ne polycrystalline diamond slurry. Iyi nzira inogadzira mawafer ane yakanyanya kuderera pamusoro roughness, kuwana Ra <3 nm, iyo inobatsira zvikuru kune kunotevera kupenya kweSiC substrates.

Zvisinei, kukwenya kwepamusoro kunoramba kuri nyaya isina kugadziriswa. Pamusoro pezvo, iyo polycrystalline diamond inoshandiswa mukuita uku inogadzirwa kuburikidza nekuputika synthesis, iyo inonetsa nehunyanzvi, inopa huwandu hwakaderera, uye inodhura zvakanyanya.

Kupenya kweSiC Single Crystals

Kuti uwane nzvimbo yepamusoro yakakwenenzverwa pasilicon carbide (SiC) wafers, kukwenenzvera kunofanira kubvisa zvachose makomba ekukuya uye nanometer-scale surface undulations. Chinangwa ndechekugadzira nzvimbo yakatsetseka, isina kukanganisa-isina kusvibiswa kana kushatisa, isina kukuvara kwepasi, uye isina kusara kwepasi kushushikana.

3.1 Mechanical Polishing uye CMP yeSiC Wafers

Mushure mekukura kweSiC single crystal ingot, kuremara kwepamusoro kunodzivirira kuti irege kushandiswa zvakananga kune epitaxial kukura. Naizvozvo, kumwe kugadzirisa kunodiwa. Iyo ingot inotanga kuumbwa kuita yakajairwa cylindrical fomu kuburikidza nekutenderera, yobva yachekwa kuita mawafer uchishandisa waya yekucheka, ichiteverwa necrystallographic orientation verification. Kuchenesa inhanho yakakosha mukuvandudza mhando yewafer, kugadzirisa kukuvara kwepasi kunokonzerwa nekristaro kukura kuremara uye matanho ekutanga ekugadzirisa.

Pane nzira ina huru dzekubvisa kukuvara kwepasi paSiC:

Mechanical polishing: Nyore asi inosiya mikwenya; akakodzera kutanga polishing.

Chemical Mechanical Polishing (CMP): Inobvisa zvikwambo kuburikidza nemakemikari etching; yakakodzera kunyatsokwenenzverwa.

Hydrogen etching: Inoda midziyo yakaoma, inowanzoshandiswa muHTCVD maitiro.

Plasma-inobatsira kupurisa: Yakaoma uye isingawanzo shandiswa.

Mechanical-chete polishing inokonzeresa kukwenya, nepo kupenya kwemakemikari chete kunogona kutungamirira kune kusaenzana etching. CMP inosanganisa zvese zvakanaka uye inopa inoshanda, inodhura-inoshanda mhinduro.

CMP Kushanda Nheyo

CMP inoshanda nekutenderedza wafer iri pasi pekudzvanywa kweseti ichipokana nepedhi inotenderera yekupukuta. Uku kufamba kwehukama, kwakasanganiswa ne mechanical abrasion kubva ku nano-size abrasives mu slurry uye kemikari chiito che reactive agents, inobudirira pamusoro pe planarization.

Zvinhu zvakakosha zvakashandiswa:

Polishing slurry: Iine abrasives uye makemikari reagents.

Polishing pad: Inopera panguva yekushandiswa, kuderedza pore saizi uye slurry kuburitsa kunyatsoita. Kupfeka nguva dzose, kazhinji kushandisa dhizaini yedhaimani, kunodiwa kudzorera hukasha.

Yakajairika CMP Maitiro

Abrasive: 0.5 μm diamond slurry

Target pamusoro roughness: ~ 0.7 nm

Chemical Mechanical Polishing:

Kupukuta midziyo: AP-810 single-sided polisher

Kudzvinyirira: 200 g / cm²

Plate kumhanya: 50 rpm

Ceramic inobata kumhanya: 38 rpm

Slurry composition:

SiO₂ (30 wt%, pH = 10.15)

0–70 wt% H₂O₂ (30 wt%, reagent giredhi)

Gadzirisa pH kusvika 8.5 uchishandisa 5 wt% KOH uye 1 wt% HNO₃

Slurry flow rate: 3 L / min, yakadzokororwa

Iyi nzira inobudirira inovandudza SiC wafer mhando uye inosangana nezvinodiwa kune yakadzika maitiro.

Matambudziko ehunyanzvi muMechanical polishing

SiC, seyakafara bandgap semiconductor, inoita basa rakakosha muindasitiri yemagetsi. Iine zvakanakisa zvemuviri uye zvemakemikari zvimiro, SiC imwe chete makristasi akakodzera kune yakanyanyisa nharaunda, senge tembiricha yepamusoro, yakakwirira frequency, yakakwirira simba, uye neradiation kuramba. Nekudaro, chimiro chayo chakaomarara uye chine brittle chinopa matambudziko makuru ekukuya nekupukuta.

Sekutungamira kwevagadziri vepasirese shanduko kubva pa6-inch kusvika 8-inch wafers, nyaya dzakadai sekupaza uye kukuvara kwewafer panguva yekugadziriswa zvave zvakanyanya kusimba, zvichikanganisa goho. Kugadzirisa matambudziko ehunyanzvi e8-inch SiC substrates ikozvino ndiyo yakakosha bhenji yekufambira mberi kweindasitiri.

Munguva ye8-inch, SiC wafer processing inotarisana nematambudziko akawanda:

Wafer scaling inodiwa kuti uwedzere kuburitsa chip pabatch, kuderedza kurasikirwa kwemupendero, uye kuderera kwemitengo yekugadzira-kunyanya kupihwa kukwira kuri kudiwa mumashandisirwo emotokari yemagetsi.

Nepo kukura kwe8-inch SiC single crystals yakura, kumashure-ekupedzisira maitiro senge kukuya nekupukuta kuchiri kutarisana nemabhodhoro, zvichikonzera goho rakaderera (chete 40-50%).

Mawaferi akakura anosangana nekuomesesa kugovaniswa, zvichiwedzera kuoma kwekugadzirisa kukwenenzverwa kwekuporesa uye kuenderana kwegoho.

Kunyangwe ukobvu hwema 8-inch wafers hwave kusvika kune iyo 6-inch wafers, ivo vanonyanya kukuvara panguva yekubata nekuda kwekushushikana uye warping.

Kudzikisa kushushikana kwakabatana nekucheka, warpage, uye kuputika, laser yekucheka iri kuwedzera kushandiswa. Zvisinei:

Marefu-wavelength lasers anokonzera kupisa kukuvadza.

Mapfupi-wavelength lasers anogadzira marara anorema uye anodzamisa iyo yekukuvadza layer, ichiwedzera kukwenenzverwa kuoma.

Mechanical Polishing Workflow yeSiC

General process inoyerera inosanganisira:

Oriental kucheka

Kukuya

Kukuya zvakanaka

Mechanical polishing

Chemical Mechanical Polishing (CMP) sedanho rekupedzisira

Sarudzo yeCMP nzira, dhizaini dhizaini, uye optimization yemaparamita kwakakosha. Mukugadzira semiconductor, CMP ndiyo nhanho yekugadzira yekugadzira SiC wafers ine Ultra-yakapfava, isina hurema, uye isina kukuvara nzvimbo, izvo zvakakosha pakukura kwemhando yepamusoro epitaxial.

(a) Bvisa iyo SiC ingot kubva kune crucible;

(b) Ita kuumba kwekutanga uchishandisa dhayamita rekunze kukuya;

(c) Sarudza kutaridzika kwekristaro uchishandisa kurongeka kwemafurati kana notches;

(d) Cheka ingot kuita mawafer matete uchishandisa kuwanda-waya sawing;

(e) Wana kutsvedzerera kwegirazi-sepasi kuburikidza nekukuya nekupukuta matanho.

Mushure mekupedza nhevedzano yematanho ekugadzirisa, mupendero wekunze weSiC wafer unowanzo kuve wakapinza, izvo zvinowedzera njodzi yekupwanya panguva yekubata kana kushandiswa. Kuti udzivise fragility yakadaro, kugaya kumucheto kunodiwa.

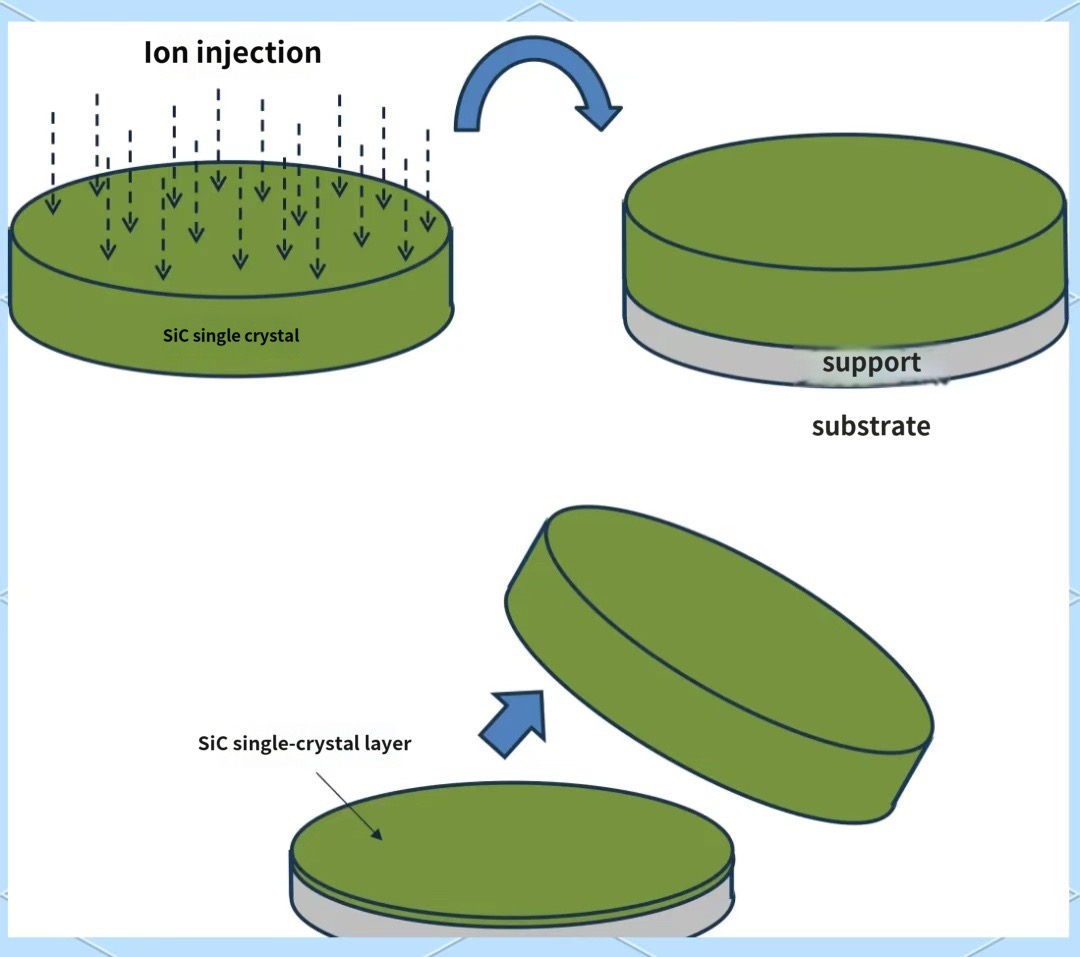

Pamusoro pemaitiro echinyakare ekuchekesa, nzira itsva yekugadzirira SiC wafers inosanganisira bonding tekinoroji. Iyi nzira inogonesa kugadzirwa kwewafer nekubatanidza iyo yakaonda SiC single-crystal layer kune heterogeneous substrate (inotsigira substrate).

Mufananidzo 3 unoratidza nzira yekuyerera:

Chekutanga, delamination layer inoumbwa pane yakadzama yakadzama pamusoro peiyo SiC single crystal kuburikidza nehydrogen ion implantation kana maitiro akafanana. Iyo yakagadziriswa SiC imwe kristaro inobva yasungirirwa kune flat inotsigira substrate uye inoiswa pasi pekumanikidzwa uye kupisa. Izvi zvinobvumira kufambisa kwakabudirira uye kupatsanurwa kweSiC single-crystal layer pane inotsigira substrate.

Iyo yakaparadzaniswa yeSiC layer inobata kurapwa kwepamusoro kuti iwane inodiwa flatness uye inogona kushandiswa zvakare mune inotevera bonding maitiro. Kuenzaniswa nekuchekwa kwechinyakare kweSiC makristasi, nzira iyi inoderedza kudiwa kwezvinhu zvinodhura. Kunyangwe zvipingamupinyi zvetekinoroji zvichiripo, kutsvagisa nekusimudzira kuri kufambira mberi kugonesa kugadzirwa kwewafer-mutengo wakaderera.

Tichifunga nezvekuoma kwepamusoro uye kugadzikana kwemakemikari eSiC-izvo zvinoita kuti irege kupindirana nekuita pane imwe tembiricha - kukwenenzverwa kwemuchina kunodiwa kubvisa makomba ekukuya, kuderedza kukuvadzwa kwepamusoro, kubvisa makwara, gomba, uye kuremara kweganda reorenji, kuderera kwepasi, kunatsiridza flatness, uye kuwedzera kunaka kwepamusoro.

Kuti uwane nzvimbo yemhando yepamusoro yakakwenenzverwa, zvinodikanwa:

Gadzirisa mhando dzeabrasive,

Deredza particle size,

Optimize process parameters,

Sarudza zvinhu zvekunatsa uye mapedhi ane hurema hwakakwana.

Mufananidzo 7 unoratidza kuti kupenya kwemativi maviri ne1 μm mabrasives kunogona kudzora flatness uye ukobvu kusiyana mukati me10 μm, uye kuderedza kushata kwepamusoro kusvika 0.25 nm.

3.2 Chemical Mechanical polishing (CMP)

Chemical Mechanical Polishing (CMP) inosanganisa ultrafine particle abrasion nekemikari etching kuti iite yakatsetseka, yakarongwa pamusoro pezvinhu zviri kugadziriswa. Nheyo yakakosha ndeiyi:

Kemikari inopindirana inoitika pakati pekupenya slurry newafer pamusoro, ichigadzira yakapfava layer.

Kukakavadzana pakati pezvimedu zvinoputika uye nyoro inobvisa zvinhu.

CMP zvakanakira:

Inokunda zvipingamupinyi zvemagetsi chete kana makemikari polishing,

Inowana zvese zviri zviviri zvepasirese uye zvemuno planarization,

Inogadzira nzvimbo ine flatness yakakwira uye yakaderera roughness,

Haisiyi kukuvara kwepamusoro kana pasi pepasi.

Zvakadzama:

Wafer inofamba ichienderana neporishe pad pasi pekumanikidzwa.

Nanometer-scale abrasives (semuenzaniso, SiO₂) mune slurry inotora chikamu mukuveura, kunetesa Si-C covalent bond uye kuwedzera kubviswa kwezvinhu.

Mhando dzeCMP Techniques:

Yemahara Abrasive Polishing: Abrasives (eg, SiO₂) yakamiswa muslurry. Kubviswa kwezvinhu kunoitika kuburikidza neabrasion-miviri mitatu (wafer-pad-abrasive). Saizi yeabrasive (kazhinji 60-200 nm), pH, uye tembiricha zvinofanirwa kudzorwa nenzira kwayo kuti iwedzere kufanana.

Fixed Abrasive Polishing: Abrasives akaiswa mupolishi pad kudzivirira agglomeration-yakanakira yakakwirira-chaiyo kugadzirisa.

Post-Polishing Cleaning:

Zvimedu zvakapfava zvinopinda:

Kemikari yekuchenesa (kusanganisira DI mvura uye slurry yakasara kubviswa),

DI mvura yekugeza, uye

Kuomesa nitrogen

kuderedza kusvibiswa kwepamusoro.

Surface Quality & Performance

Kushata kwepamusoro kunogona kudzikiswa kusvika kuRa <0.3 nm, kusangana semiconductor epitaxy zvinodiwa.

Global Planarization: Iko kusanganiswa kwemakemikari kupfavisa uye kubviswa kwemuchina kunoderedza zvikwambo uye kusaenzana etching, kupfuura nzira dzakachena dzemuchina kana makemikari.

Kubudirira Kwepamusoro: Inokodzera kuomarara uye brittle zvinhu seSiC, ine mareti ekubvisa zvinhu pamusoro pe200 nm/h.

Mamwe Emerging Polishing Techniques

Pamusoro peCMP, dzimwe nzira dzakarongwa, dzinosanganisira:

Electrochemical polishing, Catalyst-inobatsira kupurisa kana etching, uye

Tribochemical polishing.

Nekudaro, nzira idzi dzichiri mudanho rekutsvagisa uye dzakakura zvishoma nezvishoma nekuda kweSiC's inonetsa zvinhu zvinhu.

Pakupedzisira, SiC kugadzirisa inzira zvishoma nezvishoma yekudzikisa warpage uye kushata kuti uvandudze kunaka kwepamusoro, uko kufuratira uye hutsinye kudzora kwakakosha padanho rega rega.

Processing Technology

Munguva yekukuya nhanho, dhaimondi slurry ine akasiyana particle saizi inoshandiswa kukuya wafer kune inodiwa flatness uye pamusoro roughness. Izvi zvinoteverwa nekukwenenzverwa, uchishandisa ese ari maviri emakanika uye makemikari mechanical polishing (CMP) matekiniki ekugadzira-isina kukuvadzwa akakwenenzverwa silicon carbide (SiC) wafers.

Mushure mekupenya, maSiC wafers anotariswa nemhando yepamusoro achishandisa zviridzwa zvakaita semakorosikopu emaziso uye X-ray diffractometers kuona kuti ese tekinoroji paramita anoenderana nezvinodiwa. Chekupedzisira, mawafer akakwenenzverwa anocheneswa uchishandisa nyanzvi yekuchenesa maajenti uye ultrapure mvura kubvisa zvinosvibisa pamusoro. Ivo vanobva vaomeswa vachishandisa ultra-yakakwirira kuchena nitrogen gasi uye spin dryer, kupedzisa iyo yese yekugadzira maitiro.

Mushure memakore ekuedza, kufambira mberi kwakakosha kwakaitwa muSiC single crystal processing mukati meChina. Mumba, 100 mm doped semi-insulating 4H-SiC single makristasi akagadzirwa zvakabudirira, uye n-mhando 4H-SiC uye 6H-SiC makristasi mamwechete anogona ikozvino kugadzirwa mumabhechi. Makambani akaita seTankeBlue uye TYST akatogadzira 150 mm SiC imwe makristasi.

Panyaya yeSiC wafer processing tekinoroji, masangano epamba akatanga aongorora maitiro uye nzira dzekucheka kwekristaro, kukuya, uye kupukuta. Ivo vanokwanisa kugadzira sampuli dzinosangana nezvinodiwa pakugadzira mudziyo. Nekudaro, zvichienzaniswa nemazinga epasi rose, iyo yepamusoro yekugadzirisa mhando yewafers epamba ichiri kusarira kumashure zvakanyanya. Pane nyaya dzakawanda:

International SiC dzidziso uye matekinoroji ekugadzirisa akadzivirirwa zvakasimba uye haawanikwe nyore.

Iko kushomeka kwekutsvagisa kwe theoretical uye rutsigiro rwekuvandudza maitiro uye optimization.

Mutengo wekupinza midziyo yekune dzimwe nyika uye zvikamu zvakakwirira.

Tsvagiridzo yemumba padhizaini dhizaini, kunyatsogadzirisa, uye zviwanikwa zvichiri kuratidza mapundu akakura zvichienzaniswa nemazinga epasi rese.

Parizvino, zviridzwa zvemhando yepamusoro-soro zvinoshandiswa muChina zvinotengeswa kunze kwenyika. Midziyo yekuyedza uye nzira dzinodawo imwe kuvandudzwa.

Nekuenderera mberi kwekusimudzirwa kweyechitatu-chizvarwa semiconductors, dhayamita yeSiC single crystal substrates iri kuwedzera zvishoma nezvishoma, pamwe chete nepamusoro zvinodiwa zvekugadzirisa kwepamusoro. Wafer processing tekinoroji yave imwe yeakanyanya kunetsa nhanho mushure meSiC imwe chete yekristaro kukura.

Kugadzirisa matambudziko aripo mukugadzirisa, zvakakosha kuti uenderere mberi nekudzidza nzira dzinobatanidzwa mukucheka, kukuya, nekupukuta, uye kuongorora nzira dzakakodzera dzekuita uye nzira dzeSiC wafer kugadzira. Panguva imwecheteyo, zvinodikanwa kuti udzidze kubva kumatekinoroji epamberi epasirese uye kutora mamiriro-e-the-art ekupedzisira-chaiyo machining matekiniki uye michina kugadzira emhando yepamusoro substrates.

Sezvo saizi yewafer inowedzera, kuoma kwekristaro kukura uye kugadzirisa zvakare kunokwira. Zvisinei, kubudirira kwekugadzira kwemidziyo yepasi kunovandudza zvikuru, uye mari yeyuniti inoderedzwa. Parizvino, vatengesi vakuru veSiC wafer pasi rose vanopa zvigadzirwa kubva pa4 inches kusvika 6 inches mudhayamita. Makambani anotungamira akadai seCree neII-VI akatotanga kuronga kugadzirwa kwe8-inch SiC wafer kugadzira mitsetse.

Nguva yekutumira: May-23-2025