Mubvunzo: Ndeapi matekinoroji makuru anoshandiswa muSiC wafer kucheka uye kugadzirisa?

A:Silicon carbide (SiC) ine kuomarara kwechipiri chete kudhaimani uye inoonekwa seyakaomarara uye brittle zvinhu. Maitiro ekuchekeresa, ayo anosanganisira kucheka makristasi akakura kuita zvitete zvitete, zvinotora nguva uye zvinowanzoita chipping. Sedanho rekutanga kupindaSiCsingle crystal processing, kunaka kwekucheka kunobata zvakanyanya kunotevera kukuya, kupukuta, uye kutetepa. Kuchekwa kunowanzo kuunza kutsemuka kwepasi uye kwepasi, kuchiwedzera mazinga ekupwanya uye mitengo yekugadzira. Naizvozvo, kudzora kukuvara kwepasi panguva yekucheka kwakakosha mukusimudzira SiC mudziyo wekugadzira.

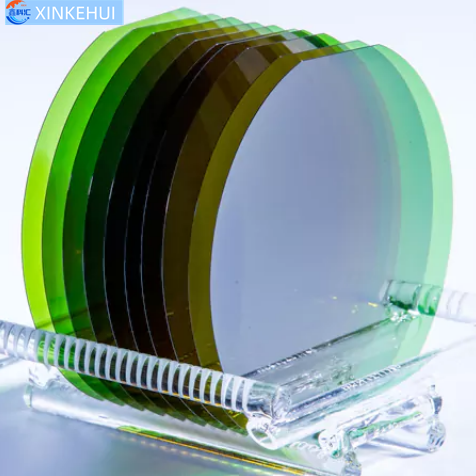

Parizvino yakashumwa SiC slicing nzira dzinosanganisira fixed-abrasive, free-abrasive slicing, laser cutting, layer transfer (inotonhora separation), uye magetsi discharge slicing. Pakati peizvi, kudzoreredza kuwanda-waya slicing ine yakagadziriswa madhaimani abrasives ndiyo inonyanya kushandiswa nzira yekugadzirisa SiC imwechete makristasi. Nekudaro, sezvo saizi yeingot inosvika masendimita masere uye pamusoro, kusaha waya kwechinyakare kunobva kwaita kushomeka nekuda kwekudiwa kwemidziyo yakakwira, mutengo, uye kushomeka. Pane kudiwa kwekukurumidzira kwemutengo wakaderera, wakaderera-kurasikirwa, wakanyanya-kugona kucheka matekinoroji.

Mubvunzo: Ndezvipi zvakanakira laser slicing pamusoro pechinyakare akawanda-waya kucheka?

A: Traditional waya sawing inocheka iyoSiC ingotpamwe negwara chairo kuita zvimedu zvakakora mazana emakironi. Zvimedu zvinobva zvaitwa pasi pachishandiswa dhaimondi slurries kubvisa masaha mamaki uye kukuvara kwepasi, zvichiteverwa nekemikari mechanical polishing (CMP) kuti iwane planarization yepasi rose, uye pakupedzisira inocheneswa kuti iwane SiC wafers.

Nekudaro, nekuda kwekuomarara kweSiC kwakanyanya uye brittleness, nhanho idzi dzinogona kukonzera kurwisana, kutsemuka, kuwedzera kuparara kwemitengo, kukwira kwemitengo yekugadzira, uye kukonzeresa kushata kwepamusoro uye kusvibiswa (guruva, tsvina, nezvimwewo). Pamusoro pezvo, kusevha waya kunononoka uye kune goho rakaderera. Efungidziro dzinoratidza kuti zvechinyakare kuwanda-waya kucheka zvinongokwanisa kuita 50% yekushandiswa kwezvinhu, uye zvinosvika 75% zvezvinhu zvinorasika mushure mekupenya nekukuya. Yekutanga data yekugadzira kunze kwenyika yakaratidza kuti zvinogona kutora mazuva anosvika mazana maviri nemakumi manomwe nematatu ekuenderera mberi kwekugadzirwa kwemaawa makumi maviri nemana kuburitsa zviuru gumi zvewafer-nguva-yakanyanya.

Mumba, mazhinji eSiC crystal makambani ekukura akatarisana nekuwedzera kugona kwechoto. Zvisinei, panzvimbo yekungowedzera kubudiswa, zvakakosha kufunga nezvekuderedza kurasikirwa-kunyanya kana kristall kukura zvibereko zvisati zvakwana.

Laser slicing michina inogona kuderedza zvakanyanya kurasikirwa kwezvinhu uye kugadzirisa goho. Somuenzaniso, kushandisa imwe chete 20 mmSiC ingot:Kucheka kwewaya kunogona kuburitsa 30 mawafers e350 μm ukobvu.Kucheka kwelaser kunogona kuburitsa mawafer anodarika 50. Kana wafer wakadzikiswa kusvika pa200 μm, mawafer anodarika 80 anogona kugadzirwa kubva muingot imwe chete.Kunyange zvazvo wire sawing ichishandiswa zvakanyanya kugadzira mawafers madiki 6 inchi 6 inchi 10-15 mazuva nemaitiro echinyakare, anoda midziyo yepamusoro-soro uye kuunza mutengo wakakwira nekuderera. Pasi pemamiriro aya, mabhenefiti elaser slicing anova pachena, zvichiita kuti ive tekinoroji yeramangwana ye8-inch wafers.

Nekucheka kwelaser, nguva yekucheka pa8-inch wafer inogona kunge iri pasi pemaminitsi makumi maviri, nekurasikirwa kwezvinhu pawafer pasi pe60 μm.

Muchidimbu, kana tichienzaniswa neakawanda-waya kucheka, laser slicing inopa kukurumidza kukurumidza, goho riri nani, kurasikirwa kwezvinhu zvakaderera, uye kuchenesa kugadzirisa.

Q: Ndeapi makuru ehunyanzvi matambudziko muSiC laser slicing?

A: Iyo laser slicing process inosanganisira matanho maviri makuru: Laser gadziriso uye wafer kupatsanurwa.

Iyo yakakosha yelaser gadziriso ndeye danda kuumbwa uye parameter optimization. Maparamendi akadai sesimba relaser, dhayamita yenzvimbo, uye scan speed zvese zvinokanganisa kunaka kwekubviswa kwezvinhu uye kubudirira kwekuzopatsanurwa kwewafer. Iyo geometry yenzvimbo yakagadziridzwa inosarudza kushata kwepamusoro uye kuoma kwekuparadzanisa. Kukasharara kwepamusoro kunoomesa gare gare kukuya uye kunowedzera kurasikirwa kwezvinhu.

Mushure mekugadziriswa, kupatsanurwa kwewaferi kunowanzo kuwanikwa kuburikidza neshear masimba, senge kutonhora kuputsika kana kushushikana kwemagetsi. Mamwe masisitimu emumba anoshandisa ma ultrasonic transducers kukonzeresa vibrations yekuparadzana, asi izvi zvinogona kukonzera chipping uye kumucheto kuremara, kudzikisa goho rekupedzisira.

Kunyange zvazvo nhanho mbiri idzi dzisiri dzakaoma, kusapindirana mumhando yekristal-nekuda kwemaitiro akasiyana ekukura, mazinga edoping, uye kugovera kwemukati kunetseka-kunokanganisa zvakanyanya kuoma kwekucheka, goho, uye kurasikirwa kwezvinhu. Kungoona nzvimbo dzine dambudziko uye kugadzirisa laser scanning zones zvinogona kusanyanya kunatsiridza mhedzisiro.

Kiyi yekugamuchirwa kwakapararira iri mukugadzira nzira dzehunyanzvi uye zvishandiso zvinogona kuchinjika kune hwakasiyana hunhu hwekristaro kubva kune vakasiyana vagadziri, optimize process paramita, uye kuvaka laser slicing masisitimu ane universal applicability.

Mubvunzo: Ko laser slicing tekinoroji inogona kuiswa kune zvimwe semiconductor zvinhu kunze kweSiC?

A: Laser yekucheka tekinoroji yakagara ichishandiswa kune dzakasiyana siyana zvinhu. Mune semiconductors, yakatanga kushandiswa kugadzira wafer dicing uye kubva ipapo yakawedzera kusvika pakuchekerera makristasi makuru akawanda.

Beyond SiC, laser slicing inogona zvakare kushandiswa kune zvimwe zvakaoma kana brittle zvinhu zvakaita sedhaimani, gallium nitride (GaN), uye gallium oxide (Ga₂O₃). Zvidzidzo zvekutanga pazvinhu izvi zvakaratidza kugona uye zvakanakira laser slicing kune semiconductor application.

Mubvunzo: Parizvino pane akakura epamba laser slicing michina zvigadzirwa? Tsvagiridzo yako iri padanho ripi?

A: Yakakura-dhayamita SiC laser slicing midziyo inoonekwa zvakanyanya musimboti midziyo yeramangwana re8-inch SiC wafer kugadzirwa. Parizvino, Japan chete ndiyo inogona kupa masisitimu akadaro, uye anodhura uye ari pasi pezvirambidzo kunze kwenyika.

Kudiwa kwemukati kwelaser slicing / kuonda masisitimu kunofungidzirwa kunge kunosvika chiuru chezvikamu, zvichibva paSiC hurongwa hwekugadzira uye iripo waya saw size. Makambani makuru epamba akadyara mari yakawanda mukusimudzira, asi hapana midziyo yemumba inotengeswa isati yasvika pakutumirwa kwemaindasitiri.

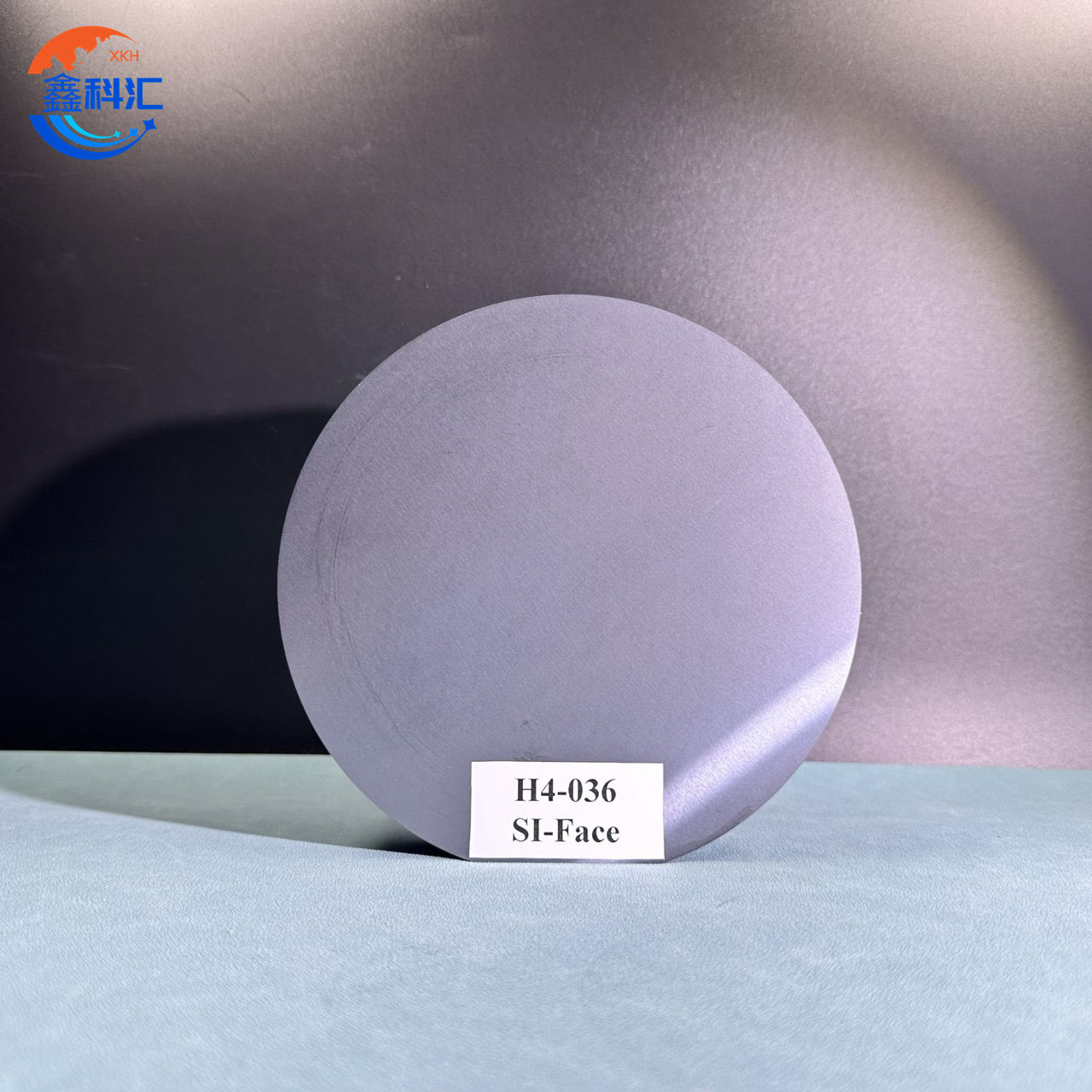

Mapoka ekutsvagisa anga achigadzira tekinoroji yekusimudza laser kubva 2001 uye ikozvino awedzera izvi kune yakakura-dhayamita SiC laser kucheka uye kutetepa. Vakagadzira prototype system uye slicing process inokwanisa:Kucheka nekuonda 4–6 inch semi-insulating SiC wafersSlicing 6–8 inch conductive SiC ingotsPerformance benchmarks:6–8 inch semi-insulating SiC: slicing time 10–15 maminitsi/wafer; kurasikirwa kwezvinhu <30 μm6-8 inch conductive SiC: slicing nguva 14-20 maminitsi / wafer; kurasikirwa kwezvinhu <60 μm

Inofungidzirwa kuti goho rewafer rakawedzera neinopfuura 50%

Post-slicing, mawaferi anosangana nemiyero yenyika yejometri mushure mekukuya nekupukuta. Zvidzidzo zvakare zvinoratidza kuti laser-induced thermal mhedzisiro haina zvakanyanya kukanganisa kushushikana kana geometry mumawafers.

Mudziyo mumwe chete iwoyo wakashandiswawo kuona kugona kwekucheka madhaimondi, GaN, uye Ga₂O₃ makristasi mamwechete.

Nguva yekutumira: May-23-2025