Microjet Mvura-inotungamirirwa Laser Yekucheka Sisitimu yeZvishandiso zvepamusoro

Top Advantages

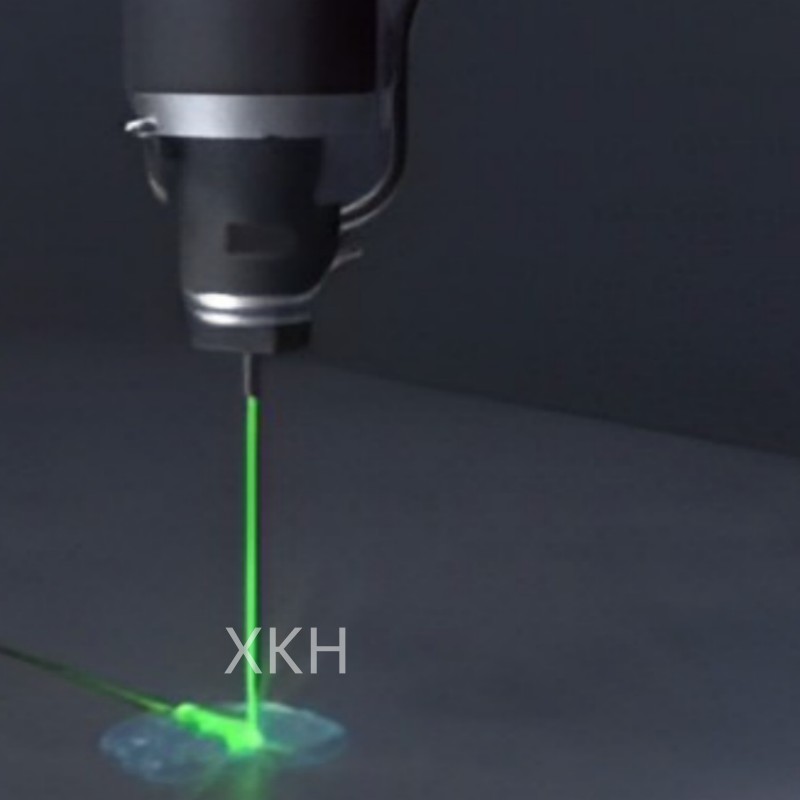

1. Simba Risingaenzaniswi Focus kuburikidza neMvura Guidance

Nekushandisa yakanyatso kudzvanywa yemvura jeti se laser waveguide, iyo system inobvisa kukanganiswa kwemhepo uye inova nechokwadi chakazara laser kutarisa. Mhedzisiro yacho ndeye ultra-narrow cut wides — idiki se20μm — ine mipendero yakapinza, yakachena.

2. Minimal Thermal Footprint

Iyo chaiyo-nguva yekupisa kweiyo system inovimbisa iyo inopisa-yakakanganiswa nzvimbo haipfuure 5μm, yakakosha kuchengetedza kuita kwezvinhu uye kudzivirira microcracks.

3. Wide Material Compatibility

Dual-wavelength kubuda (532nm/1064nm) inopa yakagadziridzwa kunyudzwa tuning, ichiita kuti muchina uenderane neakasiyana ma substrates, kubva kuoptically jekerere kune opaque ceramics.

4. High-Speed, High-Precision Motion Control

Iine sarudzo dzemutsara uye yakananga-kutyaira mota, iyo sisitimu inotsigira yakakwira-kuburikidza zvinodiwa pasina kukanganisa kurongeka. Mafambiro mashanu-axis anoenderera mberi achigonesa kugadzirwa kwemaitiro akaomarara uye akawanda-anotungamira kucheka.

5. Modular uye Scalable Design

Vashandisi vanogona kugadzirisa masisitimu masisitimu zvichienderana nezvido zvekushandisa-kubva lab-based prototyping kusvika kukugadzira-scale deployments-ichiita kuti ive yakakodzera muR&D nemaindasitiri madomasi.

Nzvimbo dzekushandisa

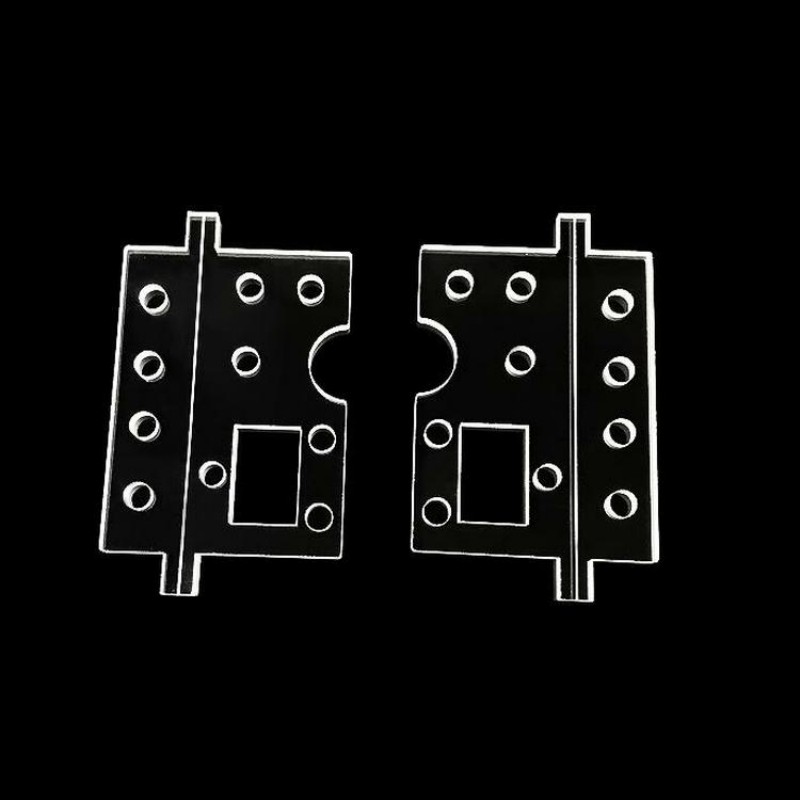

Chechitatu-chizvarwa Semiconductors:

Yakakwana yeSiC neGaN wafers, sisitimu inoita dicing, trenching, uye kucheka zvine mupendero wakasarudzika.

Diamond uye Oxide Semiconductor Machining:

Inoshandiswa kucheka uye kuchera yakakwirira-yakaoma zvinhu senge-crystal diamond uye Ga₂O₃, isina carbonization kana thermal deformation.

Advanced Aerospace Zvikamu:

Inotsigira kuumbwa kwemaitiro epamusoro-tensile ceramic kompositi uye superalloys yejet injini uye setiraiti zvikamu.

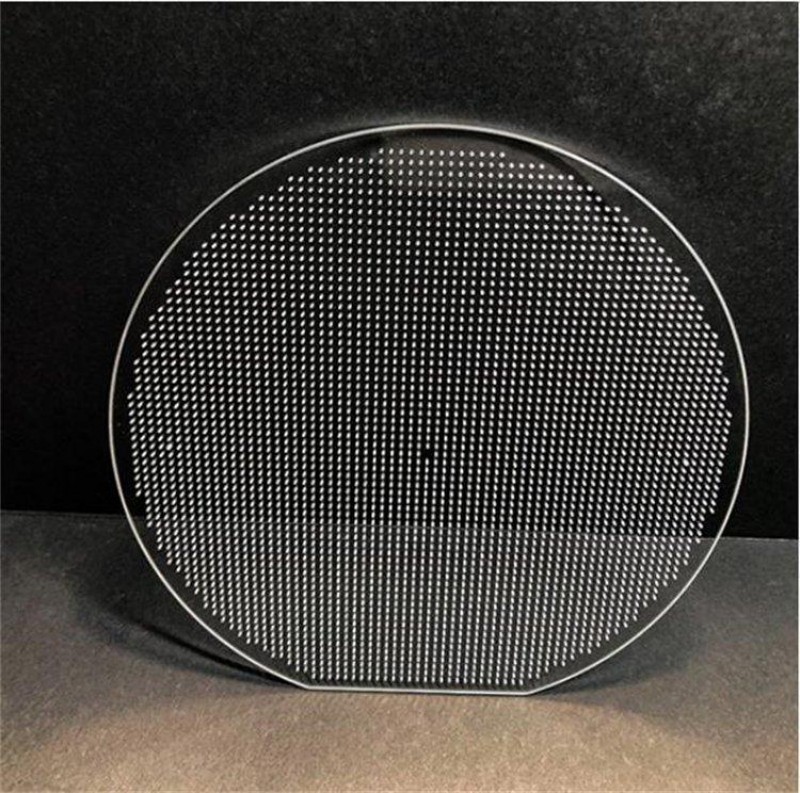

Photovoltaic uye Ceramic Substrates:

Inogonesa kucheka-yemahara kucheka kwemawafer matete uye LTCC substrates, kusanganisira kuburikidza-maburi uye slot milling yekubatanidza.

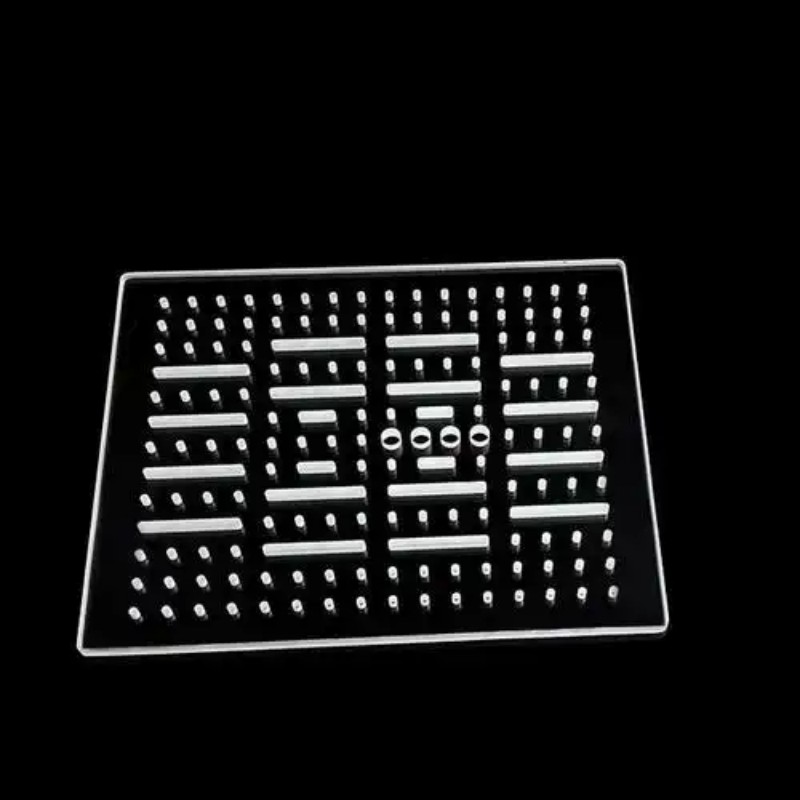

Scintillators uye Optical Components:

Inochengetedza kutsetseka kwepamusoro uye kutapurirana mune zvisina kusimba zvinhu zvemaziso seCe: YAG, LSO, nezvimwe.

Tsanangudzo

| Feature | Tsanangudzo |

| Laser Source | DPSS Nd:YAG |

| Wavelength Options | 532nm / 1064nm |

| Masimba Masimba | 50/100/200 Watts |

| Precision | ±5μm |

| Cut Width | Yakatetepa se20μm |

| Heat Affected Zone | ≤5μm |

| Motion Type | Linear / Direct Drive |

| Zvishandiso Zvinotsigirwa | SiC, GaN, Diamond, Ga₂O₃, nezvimwe. |

Sei Kusarudza Iyi Sistimu?

● Inobvisa zvakajairika laser machining nyaya senge thermal cracking uye edge chipping

● Inovandudza goho uye kuenderana kwezvinhu zvinodhura

● Inochinjika kune ese ari maviri pilot-scale uye maindasitiri kushandiswa

● Future-uchapupu chikuva chekuvandudza zvinhu sainzi

Q&A

Q1: Ndezvipi zvinhu zvinogona kuita system iyi?

A: Iyo sisitimu yakagadzirirwa zvakanyanya kuoma uye brittle yakakwirira-kukosha zvinhu. Inogona kunyatso gadzira silicon carbide (SiC), gallium nitride (GaN), diamondi, gallium oxide (Ga₂O₃), LTCC substrates, aerospace composites, photovoltaic wafers, uye scintillator makristasi akadai seCe: YAG kana LSO.

Q2: Mvura inotungamirwa laser tekinoroji inoshanda sei?

A: Inoshandisa yakakwira-kudzvanywa microjet yemvura kutungamira danda relaser kuburikidza nekuratidzira kwemukati mese, zvinobudirira kufambisa laser simba nekupararira kushoma. Izvi zvinogonesa kutarisisa kwekupedzisira, kudzika kwemafuta, uye kuchekwa chaiko nehupamhi hwemutsara kusvika pa20μm.

Q3: Ndeapi aripo laser simba masisitimu?

A: Vatengi vanogona kusarudza kubva ku50W, 100W, uye 200W laser simba sarudzo zvichienderana nekumhanya kwavo kwekugadzirisa uye kugadzirisa zvinodiwa. Ese sarudzo dzinochengetedza yakakwirira danda kugadzikana uye kudzokorora.

Detailed Diagram