Microjet Laser tekinoroji mudziyo wafer yekucheka SiC zvinhu kugadzirisa

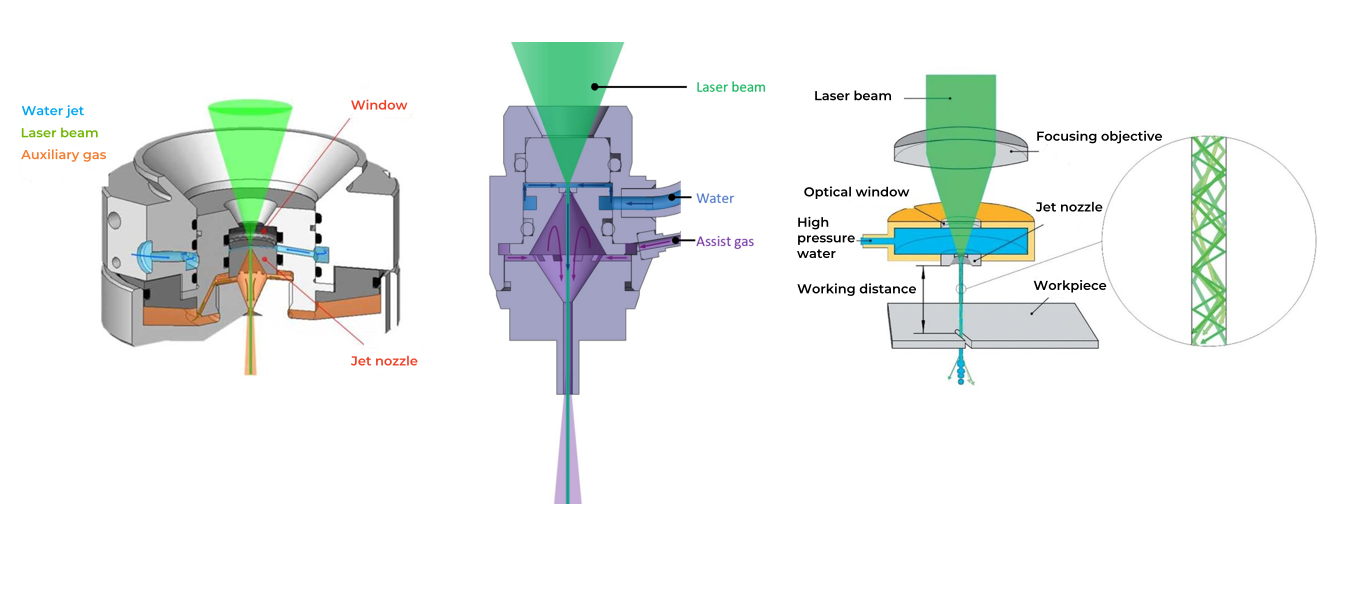

Kushanda musimboti:

1. Laser coupling: pulsed laser (UV / green / infrared) inotariswa mukati mejet yemvura kuti igadzire chiteshi chemagetsi chakagadzikana.

2. Kutungamirirwa kwemvura: jet yakakwirira-yekuyerera (yekuyerera 50-200m / s) inotonhorera nzvimbo yekugadzirisa uye kubvisa tsvina kuti irege kuunganidza kupisa uye kusvibiswa.

3. Kubviswa kwezvinhu: Simba relaser rinokonzera cavitation effect mumvura kuti iwane kutonhora kushandiswa kwezvinhu (kupisa kunokanganisa nzvimbo <1μm).

4. Dynamic control: chaiyo-nguva kugadziriswa kwe laser parameters (simba, nguva yakawanda) uye jet pressure kuti isangane nezvinodiwa zvezvinhu zvakasiyana-siyana uye zvivako.

Key parameters:

1. Laser simba: 10-500W (inogadziriswa)

2. Jet dhayamita: 50-300μm

3.Machining kururama: ± 0.5μm (kucheka), kudzika kusvika pahupamhi reshiyo 10: 1 (kuchera)

Technical zvakanakira:

(1) Inenge zero kupisa kukuvadza

- Liquid jet cooling inodzora kupisa kunokanganisa nzvimbo (HAZ) kusvika ** <1μm **, kudzivisa micro-cracks inokonzerwa neyakajairwa laser processing (HAZ inowanzo > 10μm).

(2) Ultra-yakakwirira chaiyo machining

- Kucheka / kuchera kurongeka kusvika ku ** ± 0.5μm **, kumucheto roughness Ra <0.2μm, kuderedza kudiwa kwekuzopenya kunotevera.

- Tsigira yakaoma 3D chimiro kugadzirisa (senge conical maburi, akaumbwa slots).

(3) Wide zvinhu kugarisana

- Zvakaoma uye brittle zvinhu: SiC, safiro, girazi, ceramics (nzira dzechinyakare dziri nyore kupwanya).

- Zvishandiso zvinopisa zvinopisa: mapolymer, biological tissues (hapana njodzi yekupisa denaturation).

(4) Kuchengetedzwa kwezvakatipoteredza uye kushanda zvakanaka

- Hapana kusvibiswa kweguruva, mvura inogona kushandiswazve uye kusefa.

- 30% -50% kuwedzera mukugadzirisa kasi (vs. machining).

(5) Kudzora noungwaru

- Yakabatanidzwa yekuona chinzvimbo uye AI parameter optimization, inogadzirisa zvinhu ukobvu uye hurema.

Technical specifications:

| Countertop volume | 300*300*150 | 400*400*200 |

| Linear axis XY | Linear mota. Linear mota | Linear mota. Linear mota |

| Linear axis Z | 150 | 200 |

| Kuisa chokwadi μm | +/-5 | +/-5 |

| Kudzokororwa kwenzvimbo chaiyo μm | +/-2 | +/-2 |

| Kuwedzera G | 1 | 0.29 |

| Numerical control | 3 axis / 3+1 axis / 3+2 axis | 3 axis / 3+1 axis / 3+2 axis |

| Numerical control type | DPSS Nd:YAG | DPSS Nd:YAG |

| Wavelength nm | 532/1064 | 532/1064 |

| Yakayerwa simba W | 50/100/200 | 50/100/200 |

| Jet yemvura | 40-100 | 40-100 |

| Nozzle pressure bar | 50-100 | 50-600 |

| Dimensions (muchina chishandiso) (hupamhi * kureba * kureba) mm | 1445*1944*2260 | 1700*1500*2120 |

| Saizi (control cabinet) (W * L * H) | 700*2500*1600 | 700*2500*1600 |

| Huremu (midziyo) T | 2.5 | 3 |

| Kurema (control cabinet) KG | 800 | 800 |

| Processing kugona | Kukasharara kwepamusoro Ra≤1.6um Kuvhura kumhanya ≥1.25mm/s Denderedzwa yekucheka ≥6mm/s Linear yekucheka kumhanya ≥50mm/s | Kukasharara kwepamusoro Ra≤1.2um Kuvhura kumhanya ≥1.25mm/s Denderedzwa yekucheka ≥6mm/s Linear yekucheka kumhanya ≥50mm/s |

| Kune gallium nitride crystal, ultra-wide band gap semiconductor zvinhu (diamond/Gallium oxide), aerospace special materials, LTCC carbon ceramic substrate, photovoltaic, scintillator crystal nezvimwe zvinhu kugadzirisa. Ongorora: Kugadziriswa kwesimba kunosiyana zvichienderana nehunhu hwezvinhu

| ||

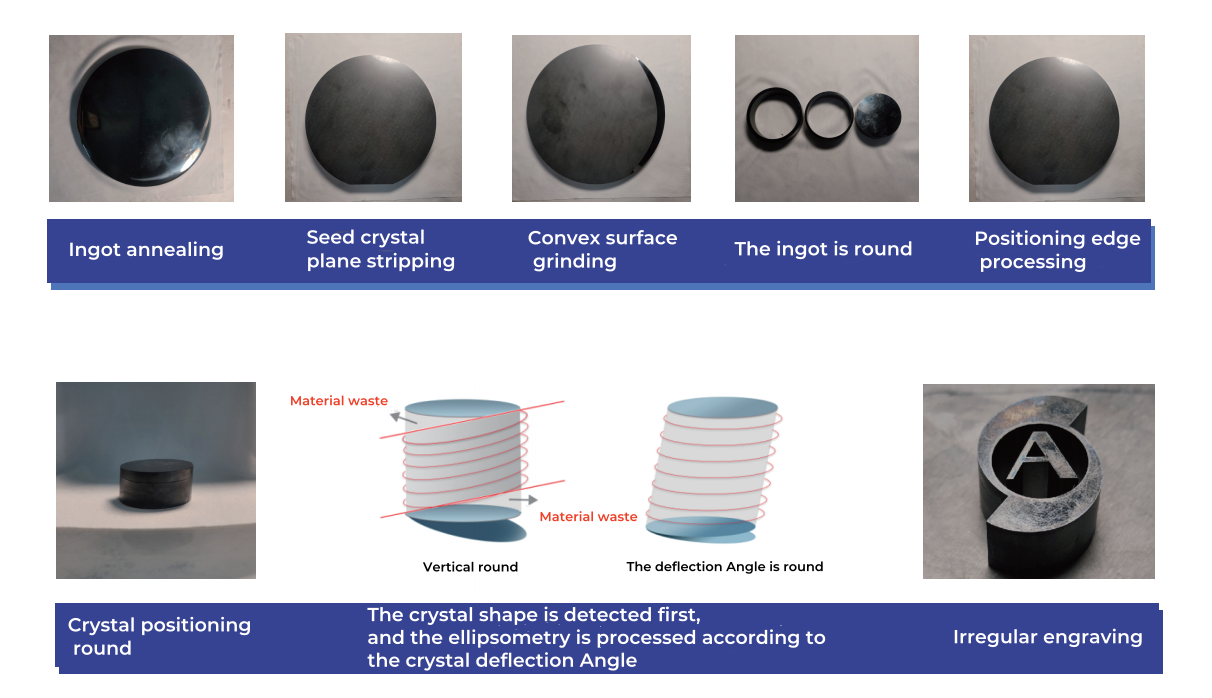

Processing case:

XKH's masevhisi:

XKH inopa huwandu hwakazara hwehupenyu hwakazara kutenderera sevhisi yekutsigira microjet laser tekinoroji zvishandiso, kubva pakatanga kugadzirwa uye kusarudzwa kwemidziyo kubvunzana, kusvika pakati-temu customized sisitimu yekubatanidza (kusanganisira iyo yakakosha yekufananidza yelaser sosi, jet system uye otomatiki module), kune yakazoshanda uye kugadzirisa kudzidziswa uye kuenderera kwekuita optimization, iyo yese maitiro akashongedzerwa nehunyanzvi tekinoroji timu rutsigiro; Kubva pamakore makumi maviri ehunyanzvi hwekugadzira machining, tinogona kupa mhinduro-yekumira zvinosanganisira kuongororwa kwemidziyo, kugadzirwa kwehuwandu uye mushure mekutengesa nekukurumidza mhinduro (maawa makumi maviri nemana erutsigiro rwehunyanzvi + makiyi ezvimedu zvakachengeterwa) kune akasiyana maindasitiri akadai semiconductor uye zvekurapa, uye kuvimbisa 12 mwedzi yakareba waranti uye kuchengetedza kwehupenyu hwese uye kusimudzira sevhisi. Ita shuwa kuti michina yevatengi inogara ichichengetedza indasitiri-inotungamira kugadzirisa kuita uye kugadzikana.

Detailed Diagram