Infrared Picosecond Dual-Platform Laser Kucheka michina yeOptical Glass/Quartz/Sapphire Processing

Main parameter

| Laser Type | Infrared Picosecond |

| Platform Size | 700×1200 (mm) |

| 900×1400 (mm) | |

| Kucheka Ukobvu | 0.03-80 (mm) |

| Kucheka Speed | 0-1000 (mm/s) |

| Cutting Edge Breakage | <0.01 (mm) |

| Cherechedza: Saizi yepuratifomu inogona kugadzirwa. | |

Key Features

1.Ultrafast Laser Technology:

· Picosecond-level mapfupi pulses (10⁻¹²s) akasanganiswa neMOPA tuning tekinoroji anowana peak simba density >10¹² W/cm².

· Infrared wavelength (1064nm) inopinda mukati mezvinhu zvakajeka kuburikidza nekunyura kusingaite, kudzivirira kubviswa kwepasi.

· Proprietary multi-focus optical system inogadzira ina yakazvimirira yekugadzirisa nzvimbo panguva imwe chete.

2.Dual-Station Synchronization System:

· Granite-base dual linear motor stages (kumira kwechokwadi: ± 1μm).

· Chiteshi chekuchinja nguva <0.8s, ichigonesa zvakafanana "kugadzirisa-kurodha / kurodha" mashandiro.

· Yakazvimirira tembiricha yekudzora (23 ± 0.5 ° C) pachiteshi inovimbisa kwenguva refu machining kugadzikana.

3.Intelligent Process Control:

· Yakabatanidzwa dhatabhesi yezvinyorwa (200+ girazi paramita) ye otomatiki parameter inoenderana.

· Chaiyo-nguva plasma yekutarisa dynamically inogadzirisa laser simba (kugadzirisa kugadzirisa: 0.1mJ).

· Kudzivirirwa kweketeni remhepo kunoderedza kumucheto madiki madiki (<3μm).

Mune yakajairika application kesi inosanganisira 0.5mm-gobvu sapphire wafer dicing, sisitimu inowana kumhanya kwekucheka kwe300mm/s ine chipping dimensions <10μm, inomiririra 5x kunyatsoshanda kunatsiridza pamusoro pechinyakare nzira.

Kugadzirisa Zvakanakira

1.Integrated dual-station yekucheka uye kupatsanura hurongwa hwekushanda kunoshanduka;

2.High-speed machining ye geometries yakaoma inovandudza nzira yekushandura kubudirira;

3.Taper-yemahara yekucheka mipendero ine shoma chipping (<50μm) uye opareta-yakachengeteka kubata;

4.Seamless shanduko pakati pezvigadzirwa zvechigadzirwa neine intuitive operation;

5.Kuderedza kushandiswa kwemari, mitero yakakwirira yezvibereko, kushandiswa-kusina uye kusvibiswa-kusina nzira;

6.Zero chizvarwa che slag, tsvina yemvura kana tsvina ine vimbiso yepamusoro pekuvimbika;

Muenzaniso kuratidza

Typical Applications

1.Consumer Electronics Manufacturing:

· Precision contour yekucheka kwe smartphone 3D yekuvhara girazi (R-angle kunyatsoita: ± 0.01mm).

· Micro-gomba kuchera mumasafire wachi lenzi (minimum aperture: Ø0.3mm).

· Kupedzwa kwemagirazi egirazi anotapurirana nzvimbo dzepasi-kuratidza makamera.

2.Optical Chikamu Kugadzirwa:

· Microstructure machining yeAR/VR lens arrays (saizi yemhando ≥20μm).

· Angled kucheka kwequartz prisms ye laser collimators (angular kushivirira: ± 15").

· Profile kuumbwa kwe infrared mafirita (kucheka taper <0.5 °).

3.Semiconductor Packaging:

Girazi kuburikidza ne-via (TGV) kugadzirisa pawafer level (chikamu chechiyero 1:10).

· Microchannel etching pagirazi substrates for microfluidic chips (Ra <0.1μm).

· Frequency-tuning kucheka kweMEMS quartz resonators.

Yemotokari LiDAR yekugadzira hwindo rekugadzira hwindo, sisitimu inogonesa kucheka kwecontour ye2mm-yakakora quartz girazi ine yakachekwa perpendicularity ye89.5 ± 0.3 °, kusangana nemotokari-giredhi vibration bvunzo zvinodiwa.

Gadzirisa Zvikumbiro

Yakagadzirirwa chaizvo kucheka kwebrittle / yakaoma zvinhu zvinosanganisira:

1.Standard glass & optical glasses (BK7, fused silica);

2. Makristasi equartz & nesafire substrates;

3. Girazi rakadzikama & mafirita emaziso

4. Mirror substrates

Inokwanisa zvese zviri zviviri kucheka contour uye kunyatso chera mukati gomba (zvishoma Ø0.3mm)

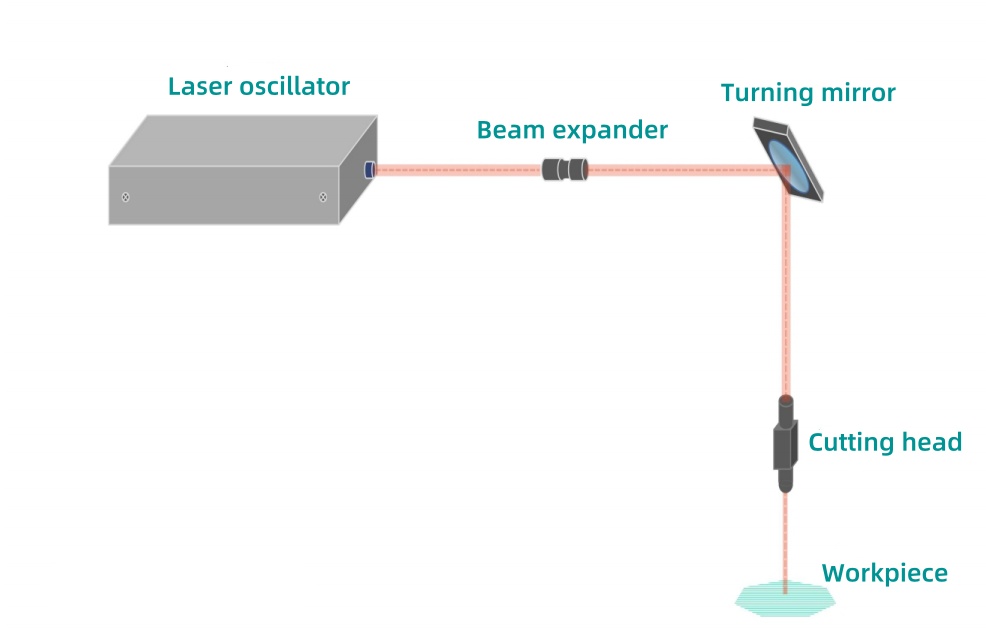

Laser Cutting Principle

Iyo laser inogadzira ultrashort pulses ine yakanyanyisa simba simba rinopindirana neworkpiece mukati mefemtosecond-to-picosecond timescales. Panguva yekuparadzira kuburikidza nechinhu, danda rinokanganisa chimiro chayo chekushushikana kuita micron-scale filamentation maburi. Yakakwenenzverwa gomba spacing inogadzira inodzorwa madiki-akatsemuka, ayo anosanganiswa neanocheka tekinoroji kuti awane chaiyo kupatsanurwa.

Laser Kucheka Zvakanakira

1.High automation integration (yakasanganiswa yekucheka / kuchenesa kushanda) ine simba shoma rekushandisa uye nyore kushanda;

2.Non-contact processing inogonesa kugona kwakasiyana kusingawanikwe kuburikidza neyakajairwa nzira;

3.Consumable-isina kushanda kunoderedza kumhanya mari uye inosimudzira kuchengetedza kwezvakatipoteredza;

4.Superior precision ne zero taper angle uye kubviswa kwechipiri workpiece kukuvara;

XKH inopa masevhisi akazara ekugadzirisa masisitimu edu ekucheka laser, anosanganisira akarongedzerwa papuratifomu masisitimu, yakasarudzika process parameter kusimudzira, uye maapplication-chaiwo mhinduro kusangana neyakasiyana kugadzirwa zvinodiwa mumaindasitiri akasiyana siyana.