HPSI SiCOI wafer 4 6inch Hydropholic Bonding

SiCOI Wafer (Silicon Carbide-on-Insulator) Properties Overview

SiCOI wafers ichizvarwa chitsva semiconductor substrate inosanganisa Silicon Carbide (SiC) ine insulating layer, kazhinji SiO₂ kana safiri, kuvandudza kushanda mumagetsi emagetsi, RF, uye mafotonics. Pazasi pane ratidziro yakadzama yezvivakwa zvavo zvakakamurwa muzvikamu zvakakosha:

| Property | Tsanangudzo |

| Kuumbwa Kwezvinhu | Silicon Carbide (SiC) layer yakasungirirwa pane insulating substrate (kazhinji SiO₂ kana safiri) |

| Crystal Structure | Kazhinji 4H kana 6H polytypes yeSiC, inozivikanwa nehupamhi hwekristaro uye kufanana |

| Electrical Properties | Munda wemagetsi wakaparara wakakwira (~ 3 MV/cm), bhendi rakafara (~3.26 eV ye4H-SiC), yakaderera kuvuza |

| Thermal Conductivity | High thermal conductivity (~ 300 W/m·K), zvichiita kuti kupisa kugone kuparara |

| Dielectric Layer | Insulating layer (SiO₂ kana safiri) inopa kuparadzaniswa kwemagetsi uye inoderedza parasitic capacitance. |

| Mechanical Properties | Kuoma kwepamusoro (~ 9 Mohs chiyero), simba rakanakisa remuchina, uye kugadzikana kwekupisa |

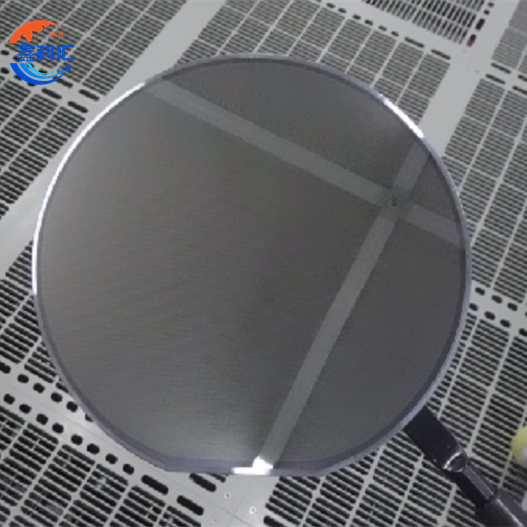

| Surface Finish | Kazhinji ultra-smooth ine low defect density, yakakodzera kugadzirwa kwemudziyo |

| Applications | Magetsi emagetsi, midziyo yeMEMS, RF zvishandiso, masensa anoda kupisa kwakanyanya uye kushivirira kwemagetsi |

SiCOI wafers (Silicon Carbide-on-Insulator) inomiririra yepamberi semiconductor substrate chimiro, inosanganisira yemhando yepamusoro yakatetepa yesilicon carbide (SiC) yakasungirirwa pane insulating layer, kazhinji silicon dioxide (SiO₂) kana safiri. Silicon carbide is wide-bandgap semiconductor inozivikanwa nekugona kwayo kushingirira kukwira kwemagetsi uye tembiricha yakakwira, pamwe neakanakisa ekupisa kwemafuta uye kuoma kwemagetsi, zvichiita kuti ive yakakodzera kune yakakwirira-simba, yakakwirira-frequency, uye yakakwirira-tembiricha yemagetsi application.

Iyo insulating layer muSiCOI wafers inopa inoshanda yekuzviparadzanisa nemagetsi, ichideredza zvakanyanya parasitic capacitance uye leakage currents pakati pemidziyo, nekudaro inosimudzira kuita kwese kwechishandiso uye kuvimbika. Iyo wafer pamusoro yakanyatsokwenenzverwa kuti iwane yekupedzisira-yakapfava isina hurema hudiki, ichisangana nezvinoda kuomesesa zve micro- uye nano-scale mudziyo wekugadzira.

Ichi chimiro chemidziyo hachingonatsiridza hunhu hwemagetsi eSiC zvishandiso asi zvakare inosimudzira zvakanyanya kudziya kwekutonga uye kugadzikana kwemichina. Nekuda kweizvozvo, SiCOI wafers anoshandiswa zvakanyanya mumagetsi emagetsi, radio frequency (RF) zvikamu, microelectromechanical system (MEMS) sensors, uye yakakwirira-tembiricha yemagetsi. Pakazere, SiCOI wafers anosanganisa akasarudzika emuviri zvimiro zvesilicon carbide nemagetsi ega mabhenefiti eiyo insulator layer, ichipa hwaro hwakakodzera kuchizvarwa chinotevera chepamusoro-inoshanda semiconductor zvishandiso.

SiCOI wafer's application

Simba Electronics Zvishandiso

High-voltage uye yakakwirira-simba switch, MOSFETs, uye diode

Batsirwa kubva kuSiC's wide bandgap, yakakwira breakdown voltage, uye kugadzikana kwemafuta

Yakaderedzwa kurasikirwa kwemagetsi uye nekuvandudza kushanda zvakanaka mumagetsi ekushandura masisitimu

Radio Frequency (RF) Zvikamu

High-frequency transistors uye amplifiers

Yakaderera parasitic capacitance nekuda kwe insulating layer inosimudzira RF kuita

Inokodzera 5G kutaurirana uye radar masisitimu

Microelectromechanical Systems (MEMS)

Sensors uye actuators inoshanda munzvimbo dzakaoma

Mechanical kusimba uye kusagadzikana kwemakemikari kunowedzera hupenyu hwechishandiso

Inosanganisira ma sensors ekumanikidza, accelerometers, uye gyroscopes

High-Temperature Electronics

Electronics yemotokari, aerospace, uye maindasitiri ekushandisa

Shanda zvakavimbika pane tembiricha dzakakwirira uko silicon inotadza

Photonic Devices

Kubatanidzwa ne optoelectronic components pane insulator substrates

Inogonesa on-chip photonics ine yakagadziridzwa yekudziya manejimendi

SiCOI wafer's Q&A

Q:chii chinonzi SiCOI wafer

A:SiCOI wafer inomirira Silicon Carbide-on-Insulator wafer. Iyo imhando ye semiconductor substrate apo yakatetepa yesilicon carbide (SiC) inosungirirwa pane insulating layer, kazhinji silicon dioxide (SiO₂) kana dzimwe nguva safiri. Ichi chimiro chakafanana nemafungiro kune anozivikanwa Silicon-on-Insulator (SOI) mawafers asi anoshandisa SiC panzvimbo yesilicon.

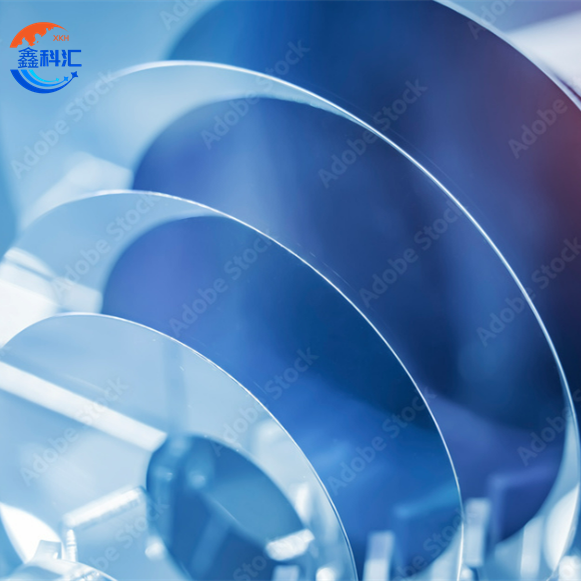

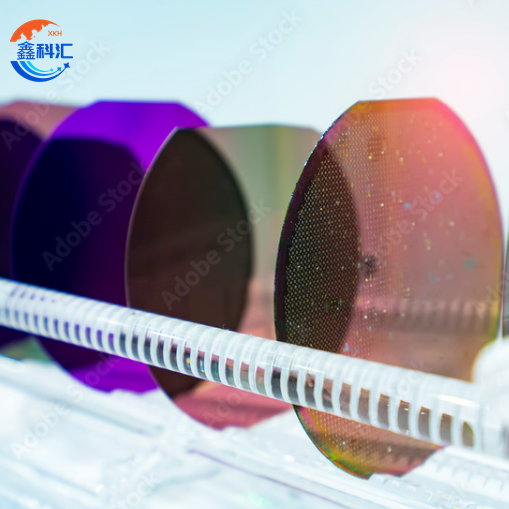

Mufananidzo