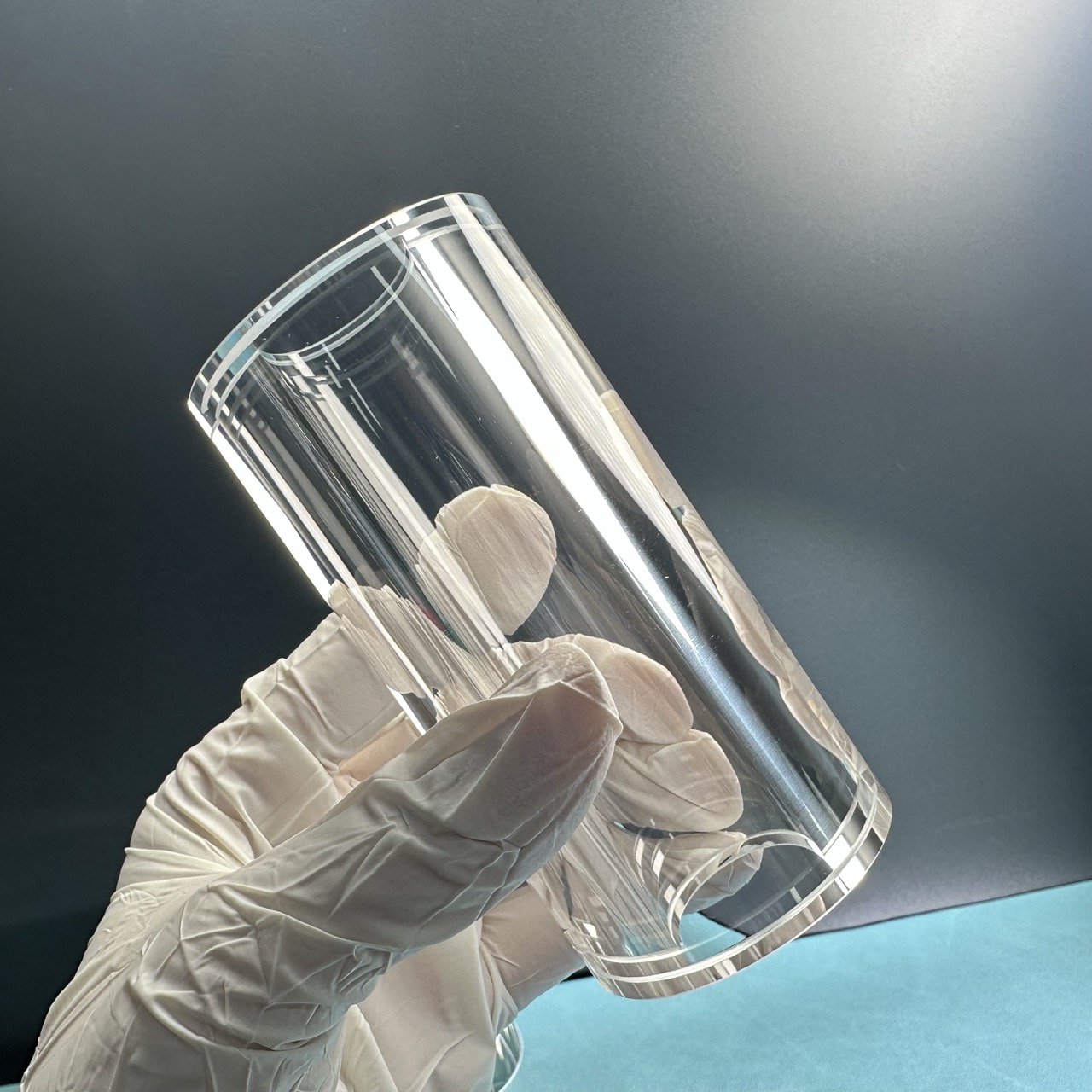

Yakakwirira-Kuchena Fused Quartz Wafers yeSemiconductor, Photonics Optical Applications 2″4″6″8″12″

Detailed Diagram

Mhedziso yeQuartz Glass

Quartz wafers inoumba musana wezvisingaverengeke zvemazuva ano zvishandiso zvinotyaira nyika yanhasi yedhijitari. Kubva pakufamba mune yako smartphone kusvika kumusana we5G base zviteshi, quartz inoburitsa chinyararire kugadzikana, kuchena, uye nemazvo anodiwa mumhando yepamusoro yemagetsi uye mafotonics. Kunyangwe ichitsigira inochinjika yedunhu, inogonesa MEMS sensors, kana kugadzira hwaro hwehuwandu komputa, yakasarudzika quartz maitiro anoita kuti ive yakakosha mumaindasitiri.

"Fused Silica" kana "Fused Quartz" inova chikamu cheamorphous chequartz (SiO2). Kana ichienzaniswa negirazi yeborosilicate, silica yakasanganiswa haina zvinowedzera; saka iripo mune yayo yakachena fomu, SiO2. Fused silica ine yakanyanya kutapurirana mune infrared uye ultraviolet spectrum kana ichienzaniswa neyakajairwa girazi. Fused silica inogadzirwa nekunyunguduka uye kusimbisazve ultrapure SiO2. Synthetic fused silica kune rumwe rutivi inogadzirwa kubva kune-silicon-rich makemikari precursors seSiCl4 iyo inogadziriswa gasi uye yozoiswa oxidized muH2 + O2 mhepo. Iyo SiO2 guruva rakaumbwa mune iyi kesi rinosanganiswa kune silica pane substrate. Iwo akasanganiswa silica block anochekwa kuita wafers mushure mezvo mawafer anozopedzwa.

Makiyi Zvimiro uye Mabhenefiti eQuartz Glass Wafer

-

Kuchena Kwepamusoro-soro (≥99.99% SiO2)

Yakanakira Ultra-yakachena semiconductor uye photonics maitiro uko kusvibiswa kwezvinhu kunofanirwa kudzikiswa. -

Wide Thermal Operating Range

Inochengetedza kutendeseka kubva kune cryogenic tembiricha kusvika pamusoro pe1100 ° C pasina kuputika kana kushatisa. -

Yakanakisa UV uye IR Transmission

Inoburitsa yakanakisa kujeka kwemaziso kubva pakadzika ultraviolet (DUV) kuburikidza nepedyo-infrared (NIR), inotsigira chaiyo optical application. -

Yakaderera Thermal Kuwedzera Coefficient

Inovandudza dimensional kugadzikana pasi pekuchinja kwekushisa, kuderedza kushushikana uye kugadzirisa kuvimbika kwemaitiro. -

Superior Chemical Resistance

Inert kune akawanda acids, alkalis, uye zvinonyungudutsa-zvichiita kuti zvinyatsoenderana nemakemikari ane hukasha. -

Surface Finish Flexibility

Inowanikwa ne-ultra-smooth, single-side kana kaviri-side polished finishes, inoenderana nephotonics uye MEMS zvinodiwa.

Kugadzira Maitiro eQuartz Glass Wafer

Fused quartz wafers anogadzirwa kuburikidza neakateedzana anodzorwa uye chaiwo matanho:

-

Raw Material Selection

Kusarudzwa kwepamusoro-kuchena kwechisikigo quartz kana synthetic SiO₂ masosi. -

Kunyunguduka uye Fusion

Quartz yakanyungudutswa pa ~ 2000 ° C mumagetsi emagetsi pasi pemhepo inodzorwa kuti ibvise inclusions uye mabhubhu. -

Block Kuumba

Iyo silica yakanyungudutswa inotonhodzwa kuita mabhuroko akasimba kana ingots. -

Wafer Slicing

Precision madhaimani kana waya masaha anoshandiswa kucheka ingots kuita mawafer blanks. -

Lapping & polishing

Zvose zviri zviviri zvakapfapfaidzwa uye kukwenenzverwa kuti zvisangane nemaziso chaiwo, ukobvu, uye hukasha. -

Kuchenesa & Kuongorora

Wafers anocheneswa muISO Kirasi 100/1000 dzimba dzakachena uye dzinoiswa pasi pekuongororwa kwakasimba kwehurema uye kuenderana kwedimensional.

Zvivakwa zveQuartz Glass wafer

| spec | unit | 4" | 6" | 8" | 10" | 12" |

|---|---|---|---|---|---|---|

| Diameter / saizi (kana square) | mm | 100 | 150 | 200 | 250 | 300 |

| Kushivirira (±) | mm | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Ukobvu | mm | 0.10 kana kupfuura | 0.30 kana kupfuura | 0.40 kana kupfuura | 0.50 kana kupfuura | 0.50 kana kupfuura |

| Primary reference flat | mm | 32.5 | 57.5 | Semi-notch | Semi-notch | Semi-notch |

| LTV (5mm×5mm) | μm | <0.5 | <0.5 | <0.5 | <0.5 | <0.5 |

| TTV | μm | <2 | <3 | <3 | <5 | <5 |

| Bow | μm | ±20 | ±30 | ±40 | ±40 | ±40 |

| Warp | μm | ≤ 30 | ≤ 40 | ≤ 50 | ≤ 50 | ≤ 50 |

| PLTV (5mm×5mm) <0.4μm | % | ≥95% | ≥95% | ≥95% | ≥95% | ≥95% |

| Edge Rounding | mm | Inoenderana neSEMI M1.2 Yakajairwa / tarisa kuIEC62276 | ||||

| Surface Type | Rutivi Rumwechete rwakaporeswa / Mativi maviri akapukutwa | |||||

| Rutivi rwakapenya Ra | nm | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| Back Side Criteria | μm | general 0.2-0.7 kana customized | ||||

Quartz vs. Zvimwe Zvinhu Zvakajeka

| Property | Quartz Girazi | Borosilicate Girazi | Safiya | Standard Glass |

|---|---|---|---|---|

| Max Operating Temp | ~1100°C | ~500°C | ~2000°C | ~200°C |

| UV Transmission | Zvakanakisa (JGS1) | Murombo | Kugona | Murombo zvikuru |

| Chemical Resistance | Excellent | Pakati nepakati | Excellent | Murombo |

| Kuchena | Kunyanya kukwirira | Yakaderera kusvika pakati | High | Low |

| Thermal Kuwedzera | Yakaderera kwazvo | Pakati nepakati | Low | High |

| Mutengo | Pakati nepakati | Low | High | Yakaderera kwazvo |

FAQ yeQuartz Glass Wafer

Q1: Ndeupi musiyano uripo pakati peiyo fused quartz uye fused silica?

Nepo ese ari maviri amorphous mafomu eSiO₂, yakasanganiswa quartz inowanzobva kune yakasarudzika quartz masosi, nepo fused silica inogadzirwa. Nekushanda, ivo vanopa kuita kwakafanana, asi yakasanganiswa silica inogona kunge iine kuchena kwepamusoro uye homogeneity.

Q2: Ko akasanganiswa quartz wafers anogona kushandiswa munzvimbo dzakakwirira-vacuum?

Ehe. Nekuda kwekushomeka kwavo kwekubuda kunze uye nekukwirira kupisa kwemafuta, akasanganiswa quartz wafers akanakisa kune vacuum masisitimu uye aerospace application.

Q3: Aya mawafer akakodzera kudzika-UV laser application?

Zvamazvirokwazvo. Fused quartz ine yakakwira transmittance pasi kusvika ~185 nm, ichiita kuti ive yakanakira DUV optics, lithography masks, uye excimer laser system.

Q4: Iwe unotsigira tsika yechingwa kugadzirwa?

Ehe. Isu tinopa yakazara yakasarudzika inosanganisira dhayamita, ukobvu, pamusoro pemhando, mafurati / notchi, uye laser pateni, zvichibva pane yako chaiyo application zvinodiwa.

Nezvedu

XKH inyanzvi mukusimudzirwa kwepamusoro-soro, kugadzira, uye kutengesa kwegirazi remaziso uye zvinhu zvitsva zvekristaro. Zvigadzirwa zvedu zvinoshanda zvemagetsi zvemagetsi, zvemagetsi zvevatengi, uye mauto. Isu tinopa Sapphire optical components, nharembozha lens inovhara, Ceramics, LT, Silicon Carbide SIC, Quartz, uye semiconductor crystal wafers. Nehunyanzvi hunyanzvi uye yekucheka-kumucheto michina, isu tinokunda mune isiri-yakajairwa chigadzirwa kugadzirisa, tichivavarira kuve inotungamira optoelectronic zvinhu zvepamusoro-tech bhizinesi.