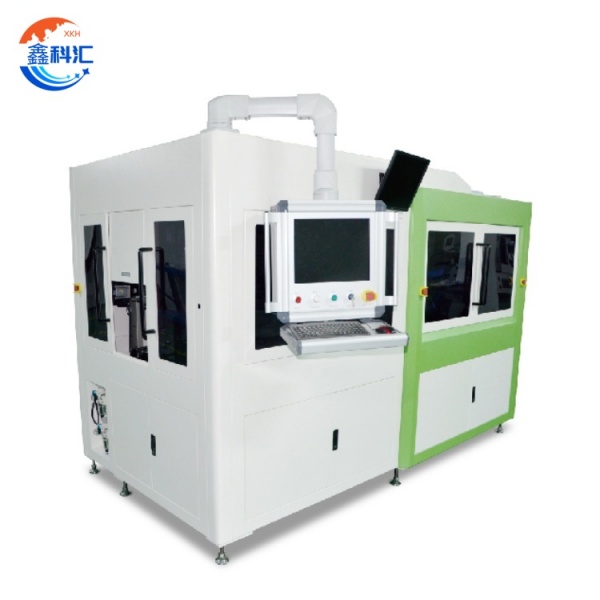

Yakakwira chaiyo laser yekuchera muchina wesafire ceramic zvinhu gem inobereka nozzle kuchera

Product Sumo

Zvishandiso zvinoshandiswa: Inokodzera simbi yechisikigo, polycrystalline simbi, ruby, safiro, mhangura, ceramics, rhenium, simbi isina tsvina, kabhoni simbi, alloy simbi uye zvimwe zvakaomesesa, yakakwirira tembiricha inodzivirira maumbirwo akasiyana, madhayamita, kudzika uye taper drilling.

Mamiriro ekushanda

1. Inokodzera kushanda pasi petembiricha ye18℃-28℃ uye humidity yakaenzana ye30% -60%.

2. Inokodzera maviri-chikamu magetsi /220V/50HZ/10A.

3. Gadzirisa mapulagi anoenderana nezvinodiwa zveakakodzera maChinese mwero. Kana pasina plug yakadaro, adapta yakakodzera inofanira kupihwa.

4. Inoshandiswa zvakanyanya mudhaimani waya yekudhirowa inofa, inononoka waya inofa, muffler gomba, buri retsono, kutakura gem, muromo uye mamwe maindasitiri anotumbura.

Technical parameters

| Zita | Data | Function |

| Optical maser wavelength | 354.7nm kana 355nm | Inotaridza kugovera kwesimba uye kugona kupinda kweiyo laser beam, uye inokanganisa chiyero chekunyudza kwezvinhu uye kugadzirisa maitiro. |

| Avhareji yekubuda simba | 10.0 / 12.0/15.0 w@40khz | Inokanganisa mashandiro ekugadzirisa uye kumhanya kwekubaya, iyo yakakwirira simba, inokurumidza kukurumidza kugadzirisa. |

| Pulse width | isingasviki 20ns@40KHz | Iyo pfupi pulse hupamhi inoderedza kupisa kwakakanganisika nzvimbo, inovandudza machining iko, uye inodzivirira kukuvara kwekupisa kwezvinhu. |

| Pulse repetition rate | 10 ~ 200KHz | Sarudza iyo frequency yekutapurirana uye punching kunyatsoshanda kwelaser beam, iyo yakakwira frequency, inokurumidza kukurumidza kubaya. |

| optical beam quality | M²<1.2 | Matanda emhando yepamusoro anovimbisa kudhirowa kwakaringana uye kumucheto kwemhando, kuderedza kurasikirwa kwesimba. |

| Spot dhayamita | 0.8±0.1mm | Sarudza iyo shoma aperture uye machining kurongeka, iyo diki nzvimbo, iyo diki iyo aperture, iyo yakakwirira yekururama. |

| beam-divergence angle | Kupfuura 90% | Iko kutarisisa kugona uye kubaya kudzika kweiyo laser beam kunokanganisa. Iyo idiki iyo Divergence Engle, iyo yakasimba yekutarisisa kugona. |

| Beam ellipcity | Isingasviki 3% RMS | Iyo diki iyo ellipticity, iyo iri pedyo nechimiro chegomba kune denderedzwa, iyo yakakwirira machining accuracy. |

Processing capacity

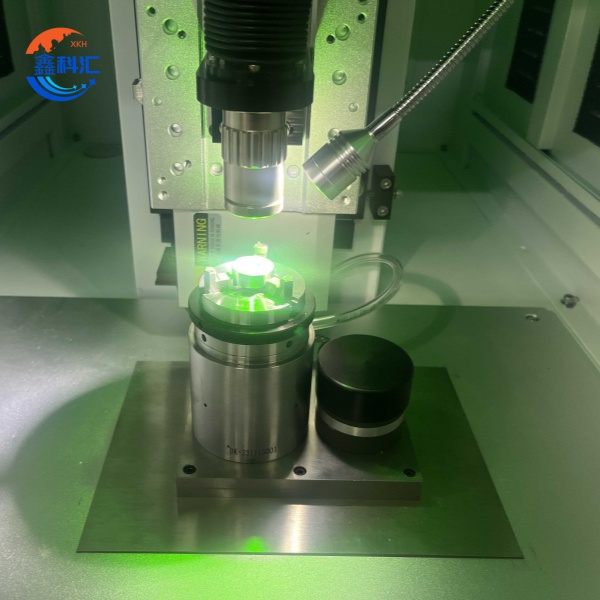

Yakakwirira-chaiyo laser yekuchera michina ine simba rekugadzirisa masimba uye inogona kuchera makomba kubva kune mashoma mamicrons kusvika mashoma mamirimita padhayamita, uye chimiro, saizi, chinzvimbo uye Angle yemakomba anogona kunyatso dzorwa. Panguva imwecheteyo, midziyo inotsigira 360-degree yose-kutenderera kuchera, iyo inogona kusangana nezvinodiwa zvekuchera zvakasiyana-siyana zvakaoma maumbirwo uye zvimiro. Uye zvakare, iyo yakakwira chaiyo laser punching muchina zvakare ine yakanakisa kumucheto mhando uye pamusoro pekupedzisira, maburi akagadziriswa haana burr emahara, hapana mupendero kunyungudika, uye gomba repamusoro rakatsetseka uye rakapfava.

Kushandiswa kweakanyanya precision laser punching muchina:

1. Indasitiri yemagetsi:

Yakadhindwa yedunhu bhodhi (PCB): inoshandiswa kugadzirisa microhole kusangana nezvinodiwa zvehupamhi-density yekubatanidza.

Semiconductor packaging: Punch maburi mumawafers uye zvinhu zvekurongedza kuti uvandudze hunyoro hwepakeji uye kuita.

2. Muchadenga:

Engine blade kutonhora makomba: Micro kutonhora maburi anogadzirwa pa superalloy blades kuvandudza injini kushanda zvakanaka.

Kugadziriswa kweComposite: Kwepamusoro-chaiyo kuchera kwekabhoni fiber composites kuve nechokwadi chesimba rechimiro.

3. Zvishandiso zvekurapa:

Minimally invasive yekuvhiya zviridzwa: Machining microholes muzviridzwa zvekuvhiya kuti uvandudze huchokwadi uye kuchengeteka.

Mishonga yekuendesa zvinodhaka: rova maburi mumudziyo wekuendesa zvinodhaka kudzora mwero wekuburitswa kwezvinodhaka.

4. Kugadzira Motokari:

Fuel jekiseni system: Machina madiki-maburi pane iyo mafuta jekiseni nozzle kukwirisa iyo mafuta atomization maitiro.

Kugadzira Sensor: Kuchera maburi mune sensor element kuti ivandudze kunzwa kwayo uye kumhanya kwekupindura.

5. Optical midziyo:

Optical fiber connector: Machining microholes pane optical fiber connector kuti ive nechokwadi chekufambiswa kwechiratidzo.

Optical sefa: Punch maburi muoptical sefa kuti uwane chaiyo wavelength kusarudzwa.

6. Precision muchina:

Precision mold: Machina ma microholes pane mold kuvandudza mashandiro uye hupenyu hwesevhisi ye mold.

Zvikamu zvidiki: rova maburi pazvikamu zvidiki kuti usangane nezvinodiwa zvekusangana kwepamusoro-chaizvo.

XKH inopa huwandu hwakazara hwepamusoro-chaiyo laser yekuchera muchina masevhisi, anosanganisira kutengesa kwemidziyo, tsigiro yehunyanzvi, yakagadziridzwa mhinduro, kuisirwa uye kutumira, kudzidziswa kwekushanda uye mushure mekutengesa kugadzirisa, nezvimwewo, kuve nechokwadi chekuti vatengi mukushandiswa kwehunyanzvi, hunoshanda uye hwakazara rutsigiro.

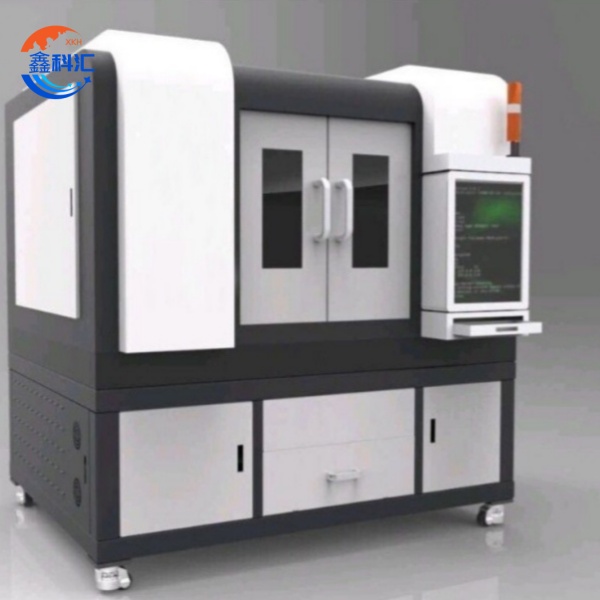

Detailed Diagram