Yepamusoro-Kuita Alumina Ceramic End Effector (Fork Arm) yeSemiconductor uye Cleanroom Automation.

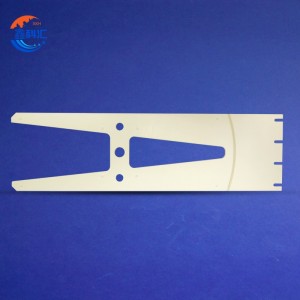

Detailed Diagram

Product Sumo

Iyo Alumina Ceramic End Effector, inonziwo ceramic forogo ruoko kana robhoti keramic ruoko, ndeye yakakwirira-chaiyo yekubata chikamu chakagadzirirwa otomatiki masisitimu mu semiconductor, photovoltaic, panel kuratidza, uye yakakwirira-kuchena marabhoritari nharaunda. Yakagadzirwa kuti ipe yakasarudzika yekudziya kugadzikana, kusimba kwemechini, uye makemikari kuramba, ichipa yakachena, yakavimbika, uye yakachengeteka kutakura kwezvinhu zvinorema senge silicon wafers, girazi substrates, uye zvemagetsi zvidiki-zvikamu.

Semhando yerobhoti yekupedzisira effector, iyi ceramic chikamu ndiyo yekupedzisira interface pakati peautomation system uye workpiece. Inotamba basa rakakosha mukufambiswa, kurongeka, kurodha / kurodha, uye kuisa mabasa mudzimba dzakachena uye nzvimbo dzevacuum.

Material Overview – Alumina Ceramic (Al₂O₃)

Alumina ceramic chinhu chakanyanya kugadzikana uye chemakemikari inert tekinoroji ceramic zvinhu zvinozivikanwa nekunaka kwemakanika uye magetsi zvivakwa. Iyo yakakwirira-kuchena (≥ 99.5%) alumina inoshandiswa mune izvi magumo ekupedzisira inovimbisa:

-

Kuoma kwepamusoro (Mohs 9): Chechipiri chete kune diamond, alumina inopa yakanyanyisa kupfeka kuramba.

-

Kugona kwepamusoro-tembiricha: Inochengetedza kutendeseka kwechimiro pamusoro pe1600 ° C.

-

Kemikari inertness: Inopikisa acids, alkalis, solvents, uye plasma etching nharaunda.

-

Kuiswa kwemagetsi: Nepamusoro dielectric simba uye yakaderera dielectric kurasikirwa.

-

Kuwedzera kwekushisa kwepasi: Inovimbisa kugadzikana kwedimensional munzvimbo dzinopisa dzemabhasikoro.

-

Low particle generation: Yakakosha pakushambidzika kwekamuri (Kirasi 10 kusvika Kirasi 1000).

Aya maficha anoita kuti alumina ceramic ive yakanaka kune mishoni-yakakosha mashandiro mumaindasitiri anonzwa kusvibiswa.

Functional Applications

Iyo alumina ceramic end effector inogamuchirwa zvakanyanya mu-high-tech maindasitiri maitiro, kunyanya apo zvechinyakare simbi kana zvepurasitiki zvinhu zvinodonha nekuda kwekuwedzera kwekupisa, kusvibiswa, kana ngura nyaya. Zvikamu zvekushandisa zvakakosha zvinosanganisira:

- Semiconductor wafer transfer

- Photolithography kurodha uye kurodha masisitimu

- Girazi substrate inobata muOLED uye LCD mitsetse

- Crystalline silicon wafer yekuchinjisa mune solar cell kugadzirwa

- Automated optical kana microelectronic inspection

- Sample yekufambisa mune analytical kana biomedical labs

- Vacuum nharaunda otomatiki masisitimu

Kugona kwayo kuita pasina kuunza zvimedu kana static charge inoita kuti ive yakakosha kune chaiyo marobhoti mashandiro mukuchenesa otomatiki.

Dhizaini Zvimiro & Kugadzirisa

Imwe neimwe ceramic end effector inogadzirwa kuti ikwane chaiyo robhoti ruoko kana wafer inobata system. Isu tinotsigira zvizere kugadzirisa kwakavakirwa pa:

-

Wafer saizi kuenderana: 2", 4", 6", 8", 12" nezvimwe

-

Slot geometry uye spacing: Inogara kumucheto grip, kumashure kwedivi rutsigiro, kana notched wafer dhizaini

-

Suction ports: Yakabatanidzwa vacuum maburi kana chiteshi chevasina-kubata kubata

-

Mounting kugadzirisa: Makomba, shinda, slots akagadzirirwa robhoti yako yekupedzisira chishandiso flange

-

Kurapa kwepamusoro: Yakakwenenzverwa, yakapwanyika, kana kupera-pasi (Ra <0.2 µm iripo)

-

Kudzivirira kumucheto: Makona akatenderedzwa kana chamfering kudzivirira kukuvara kwewafer

Nekushandisa CAD kudhirowa kana 3D modhi inopihwa nevatengi, mainjiniya edu anogona kukwidziridza ruoko rweforogo imwe neimwe kurema, simba, uye kuchena.

Zvakanakira Ceramic End Effects

| Feature | Benefit |

|---|---|

| Yakakwira Mechanical Kuomarara | Inochengetedza dimensional chaiyo pasi pemarobhoti ekurodha masimba |

| Yakanakisa Thermal Performance | Inoita zvakavimbika munzvimbo dzepamusoro-temp kana plasma |

| Zero Metal Kusvibiswa | Hapana njodzi yekusvibiswa kweion mune yakakosha semiconductor kugadzirisa |

| Low Friction Surface | Inoderedza njodzi yekukwenya pane wafer kana girazi substrates |

| Anti-Static uye Non-Magnetic | Haikwezve guruva kana kukanganisa magineti-sensitive zvikamu |

| Hupenyu Hurefu Hwebasa | Superior kupfeka kuramba mukudzokororwa kwepamusoro-kumhanya otomatiki mitsetse |

| Ultra-Yakachena Kugarisana | Inokodzera ISO 14644 dzimba dzekuchenesa (Kirasi 100 uye pazasi) |

Kuenzaniswa nepurasitiki kana aruminiyamu maoko, alumina ceramic inopa zvinoshamisa yakagadziridzwa kemikari uye kugadzikana kwemuviri nekushomeka kwekugadzirisa zvinodiwa.

| Property | Metal Arm | Plastic Arm | Alumina Ceramic Arm |

|---|---|---|---|

| Kuoma | Pakati nepakati | Low | Yakakwira zvakanyanya (Mohs 9) |

| Thermal Kugadzikana | ≤ 500°C | ≤ 150°C | ≥ 1600°C |

| Chemical Resistance | Pakati nepakati | Murombo | Excellent |

| Cleanroom Kukodzera | Pakati | Low | High High |

| Pfeka Resistance | Pakati | Low | Outstanding |

| Dielectric Simba | Low | Pakati | High |

| Custom Machining Precision | Limited | Pakati nepakati | Kukwirira (± 0.01mm zvinogoneka) |

Zvidimbu zvehunyanzvi

| Parameter | Value |

|---|---|

| Material | High-kuchena Alumina (≥ 99.5%) |

| Kushanda Tembiricha | Kusvikira ku1600 ° C |

| Kukasharara Kwepamusoro | Ra ≤ 0.2 µm (sarudzo) |

| Inoenderana Wafer Saizi | 2" kusvika 12" kana tsika |

| Flatness Kushivirira | ± 0.01 mm (zvinoenderana nechishandiso) |

| Vacuum Suction Support | Optional, customizable channels |

| Mounting Options | Bolt-kuburikidza, flange, maburi akaiswa |

Mibvunzo Inowanzo bvunzwa (FAQ)

Q1: Iyo yekupedzisira effector inogona kubatanidzwa mune iripo marobhoti masisitimu?

A1:Ehe. Isu tinotsigira kugadzirisa kwakavakirwa pane yako robotic interface. Iwe unogona kutitumira CAD dhizaini kana flange zviyero zvekunyatso kuchinjika.

Q2: Ko maoko eceramic achaputika nyore panguva yekushandiswa?

A2:Nepo ceramic ine brittle nemasikirwo, madhizaini edu anoshandisa optimized geometry kuderedza kushushikana. Pasi pemamiriro ekushandisa akakodzera, vanopa hupenyu hurefu hwesevhisi kupfuura simbi kana plastiki.

Q3: Zvinoita here kushandisa izvi mu-ultra-high vacuum kana plasma etching makamuri?

A3:Ehe. Alumina ceramic is not-outgassing, thermally stable, and corrosion resistant-yakanyatsokodzera high-vacuum, reactive gasi, kana plasma nharaunda.

Q4: Izvi zvikamu zvinocheneswa kana kuchengetedzwa sei?

A4:Ivo vanogona kucheneswa vachishandisa DI mvura, doro, kana yakachena-inoenderana detergents. Hapana kuchengetedza kwakakosha kunodiwa nekuda kwekugadzikana kwavo kwemakemikari uye inert pamusoro.

Nezvedu

XKH inyanzvi mukusimudzirwa kwepamusoro-soro, kugadzira, uye kutengesa kwegirazi remaziso uye zvinhu zvitsva zvekristaro. Zvigadzirwa zvedu zvinoshanda zvemagetsi zvemagetsi, zvemagetsi zvevatengi, uye mauto. Isu tinopa Sapphire optical components, nharembozha lens inovhara, Ceramics, LT, Silicon Carbide SIC, Quartz, uye semiconductor crystal wafers. Nehunyanzvi hunyanzvi uye yekucheka-kumucheto michina, isu tinokunda mune isiri-yakajairwa chigadzirwa kugadzirisa, tichivavarira kuve inotungamira optoelectronic zvinhu zvepamusoro-tech bhizinesi.