Kaviri chiteshi sikweya muchina monocrystalline silicon tsvimbo kugadzirisa 6/8/12 inch pamusoro flatness Ra≤0.5μm

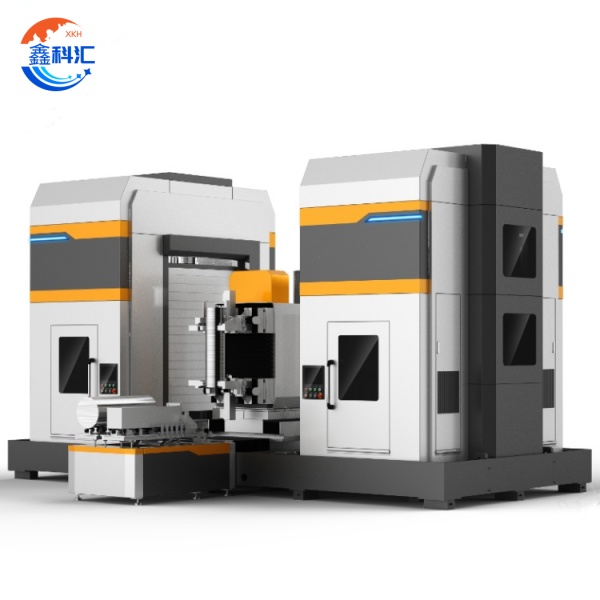

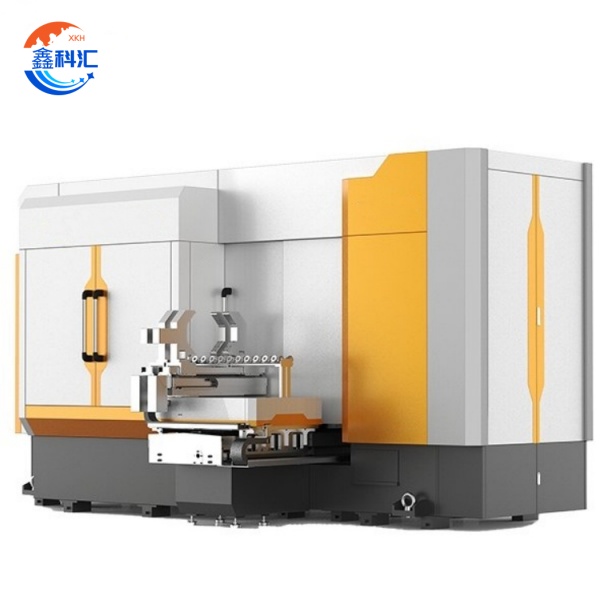

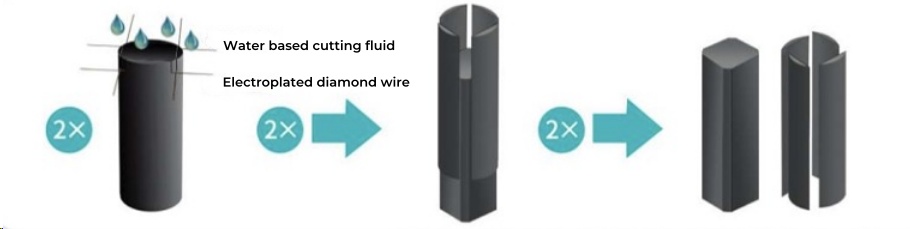

Equipment maitiro:

(1) Kaviri chiteshi synchronous kugadzirisa

· Kubudirira kaviri: Kugadziriswa panguva imwe chete kwesimbi mbiri dzesilicon (Ø6 "-12") kunowedzera kugadzirwa ne40% -60% vs. Simplex michina.

· Kuzvimiririra kuzvidzora: Imwe neimwe chiteshi inogona kuzvimiririra kugadzirisa maparamendi ekucheka (tension, feed speed) kuti ienderane kune akasiyana silicon tsvimbo yakatarwa.

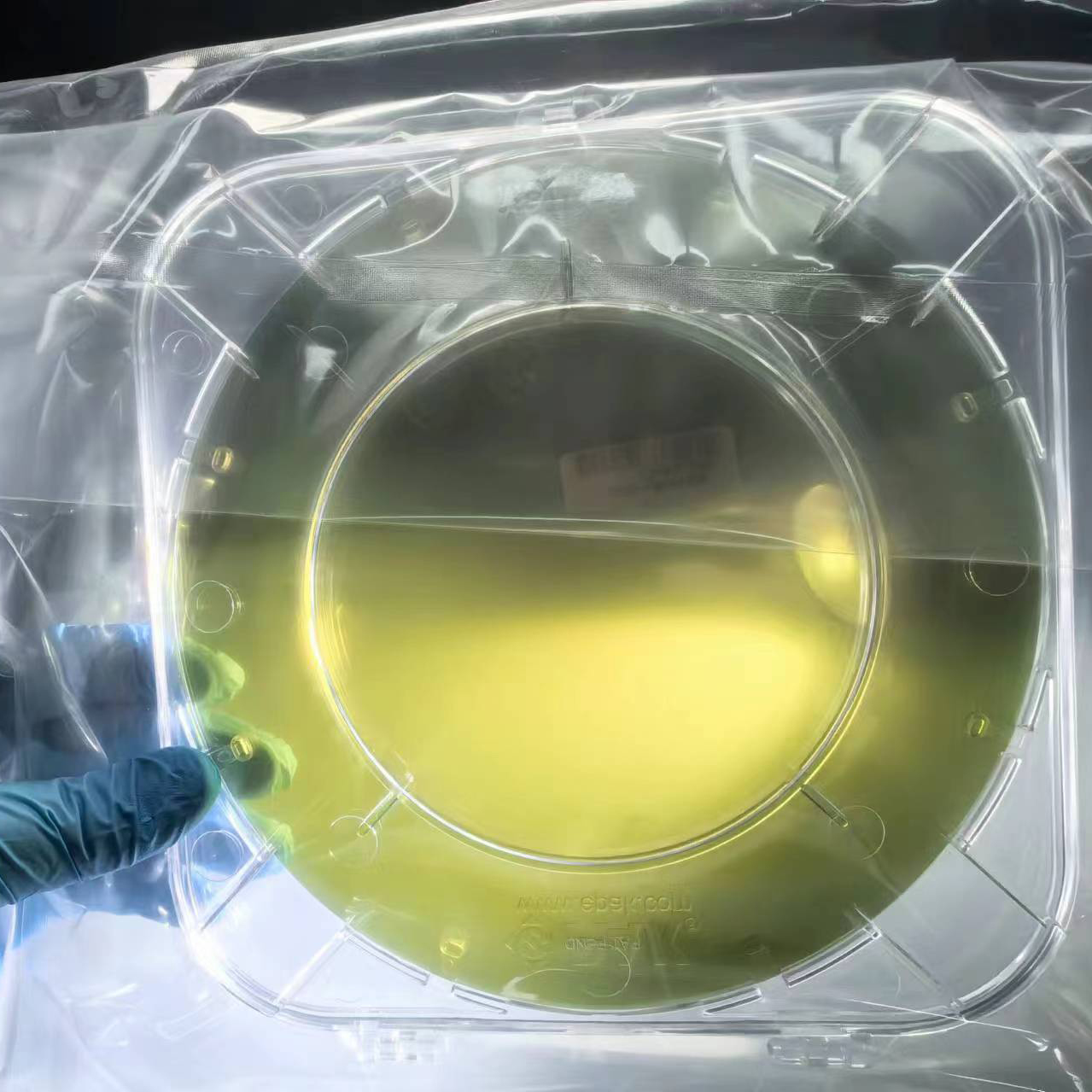

(2) Kucheka kwepamusoro-soro

· Dimensional kurongeka: sikweya bhaa parutivi kureba kushivirira ± 0.15mm, renji ≤0.20mm.

· Unhu hwepamusoro: kucheka kumucheto <0.5mm, kuderedza huwandu hwekukuya kunotevera.

(3) Kudzora noungwaru

* Adaptive kucheka: chaiyo-nguva yekutarisisa yesilicon tsvimbo morphology, shanduko inosimba yekucheka nzira (senge kugadzirisa yakabhenda silicon tsvimbo).

· Dhata traceability: rekodha magadzirirwo maparamita ega ega silicon tsvimbo kutsigira MES system docking.

(4) Mutengo wakaderera

· Diamond waya kushandiswa: ≤0.06m/mm (silicon tsvimbo kureba), waya dhayamita ≤0.30mm.

· Inotonhorera kutenderera: Iyo filtration system inowedzera hupenyu hwesevhisi uye inoderedza kuraswa kwemarara.

Technology uye budiriro zvakanakira:

(1) Kucheka tekinoroji optimization

- Multi-line yekucheka: 100-200 mitsara yedhaimondi inoshandiswa mukufanana, uye kukurumidza kucheka kuri ≥40mm / min.

-Tension control: Yakavharwa loop gadziriso system (± 1N) kuderedza njodzi yekutyoka waya.

(2) Kuenderana kwekuwedzera

- Material adaptation: Tsigiro P-mhando / N-mhando monocrystalline silicon, inoenderana neTOPCon, HJT uye mamwe mabheti esilicon tsvimbo yakakwirira.

- Flexible saizi: silicon tsvimbo kureba 100-950mm, sikweya tsvimbo parutivi kureba 166-233mm inogadziriswa.

(3) Kuvandudza otomatiki

-Robhoti kurodha uye kurodha: otomatiki kurodha / kuburitsa esilicon tsvimbo, kurova ≤3 maminetsi.

-Akangwara diagnostics: Predictive gadziriso yekudzikisa isina kurongeka yekudzika.

(4) Utungamiri hweindasitiri

- Wafer rutsigiro: inogona kugadzira ≥100μm Ultra-yakaonda nesilicon ine sikweya tsvimbo, kupatsanurwa mwero <0.5%.

- Simba rekushandisa optimization: Kushandiswa kwesimba pachikamu chesilicon tsvimbo kunoderedzwa ne30% (vs.

Technical parameters:

| Zita reparameter | Index value |

| Nhamba yemabhawa akagadziriswa | 2 zvidimbu / set |

| Kugadzirisa bhaa kureba | 100 ~ 950mm |

| Machining margin range | 166 ~ 233mm |

| Cutting speed | ≥40mm/min |

| Diamond wire speed | 0~35m/s |

| Diamond dhayamita | 0.30 mm kana pasi |

| Linear kushandiswa | 0.06 m/mm kana pasi |

| Inopindirana denderedzwa tsvimbo dhayamita | Yakapedzwa sikweya tsvimbo dhayamita +2mm, Iva nechokwadi chekupukuta chiyero chekupasa |

| Kucheka kumucheto breakage control | Raw mupendero ≤0.5mm, Hapana chipping, yepamusoro yepamusoro mhando |

| Arc kureba kufanana | Projection range <1.5mm, Kunze kwekukanganiswa kwesilicon tsvimbo |

| Zviyero zvemuchina (muchina mumwechete) | 4800×3020×3660mm |

| Total rated power | 56kW |

| Uremu hwakafa hwemidziyo | 12t |

Machining accuracy index tafura:

| Precision chinhu | Tolerance range |

| Square bar margin kushivirira | ± 0.15mm |

| Square bar edge range | ≤0.20mm |

| Angle kumativi ose eskweya tsvimbo | 90°±0.05° |

| flatness of square rod | ≤0.15mm |

| Robhoti yakadzokorodza kumira zvakanaka | ± 0.05mm |

XKH's masevhisi:

XKH inopa yakazara-kutenderera masevhisi e-mono-crystalline silicon dual-station machines, kusanganisira kugadzirisa midziyo (inoenderana nematanda makuru esilicon), maitiro ekutumira (kucheka parameter optimization), kudzidziswa kwekushanda uye mushure mekutengesa-rutsigiro (makiyi zvikamu kupa, kuremerwa kuongororwa), kuve nechokwadi chekuti vatengi vanowana goho rakawanda (> 99%) uye yakaderera consumable mutengo kugadzirwa, uye kupa tekinoroji kukwidziridzwa kweA. Nguva yekuendesa ndeye 2-4 mwedzi.

Detailed Diagram