Diamond-Mhangura Inoumba Thermal Management Materials

Detailed Diagram

Product Sumo

TheDiamond-Mhangura Inoumbwa (Cu-Diamond)iri anultra-high-performance thermal management materialiyo inosanganisa yakanakisa kupisa conductor pasirese -diamond- nemhando yepamusoro yemagetsi nemagetsi emhangura.

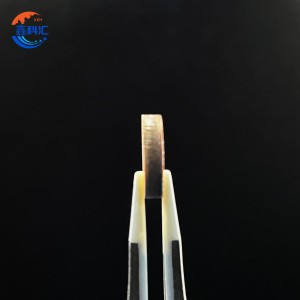

Yakagadzirirwa yekucheka-kumucheto zvemagetsi uye magetsi emagetsi, iyi inoumbwa inowana yakasarudzika chiyero cheyakanyanya kupisa conductivity, controllable thermal kuwedzera,uyemechanical kugadzikana, kugonesa kushanda kwakavimbika kunyangwe pasi penzvimbo dzinopisa zvakanyanya.

Kusiyana nemhangura yakajairwa, tungsten, kana molybdenum-based substrates, Diamond-Copper macomposites anoburitsa.kusvika kaviri thermal conductivitynepo ichideredza uremu zvakanyanya, ichivaita sarudzo yakasarudzikasemiconductor packaging, laser systems, aerospace electronics, uye high-power LED modules.

Nheyo Yezvinhu

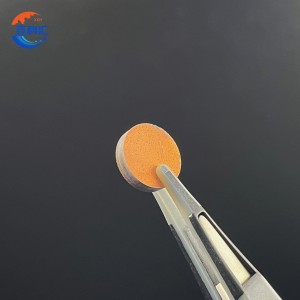

Pamwoyo wemubatanidzwa manyepodiamond particleszvakaenzana zvakaiswa mukati amhangura matrix.

Imwe neimwe chidimbu chedhaimani chinoshanda senge micro heat sink, ichiparadzira kupisa nekukurumidza, nepo matrix yemhangura inovimbisa kufambiswa kwemagetsi uye kurongeka kwechimiro.

Kuburikidza nenzira dzepamusoro dzekugadzira - kusanganisiravacuum infiltration, makemikari kupfeka,uyeSpark plasma sintering (SPS)- yakasimba uye yakagadzikana interface bond inoumbwa, inovimbisa kuvimbika kwenguva refu pasi pekuenderera kwekupisa bhasikoro.

Zvinokosha Zveunyanzvi

| | |

|---|---|

| | |

| | |

| | |

| | |

| | |

Applications

-

Yakakwirira-Simba Semiconductor Modules(GBT, MOSFET, RF & microwave mapakeji)

-

Laser Diodes uye Optoelectronic Devices

-

Aerospace uye Dziviriro Kutonhora Systems

-

High-Performance LED Heat Spreaders

-

IC uye CPU Heat Sinks yeAdvanced Computing

-

Simba Amplifiers uye Optical Communication Equipment

Sei Kusarudza Diamond-Mhangura Inoumbwa?

Nokutikupisa nyaya.

Munguva yeminiaturization uye yakakwira simba density, kutonga kupisa zvinonyatso tsanangura hupenyu hwese uye kuita kwese mudziyo.

Iyo Cu-Diamond inoumbwa inovimbisa:

-

Hurefu hwehupenyu hwechigadzirwa

-

Kuwedzera kugadzikana kwekushanda

-

Kuvandudzwa kwesimba rekushandisa

-

Kuderedza kupisa kuneta

FAQ yeMagirazi eQuartz

Q1: Ko Cu-Diamond composites inogona kugadziridzwa kune chaiyo chip zvinhu?

Ehe. Chikamu chedhaimani vhoriyamu uye CTE inogona kunyatsogadziriswa kuti ienderane neSi, GaN, kana SiC-based zvishandiso.

Q2: Is metallization inodiwa isati yatengeswa?

Ehe. Surface metallization (Ni/Au, Ti/Ni/Au) inokurudzirwa kuti ive nechokwadi chekubatana kwakanaka uye kushoma kwemafuta kuramba.

Q3: Inoita sei pasi pe-high-frequency kana pulsed heat condition?

Kupararira kwepamusoro kwedhaimondi kunovimbisa kukurumidza kuenzana kwekushisa, zvichiita kuti ive yakakodzera kune yakakwirira-frequency uye pulse-yakatakura zvinhu.

Q4: Ndeipi yakanyanya kupisa tembiricha?

Iyo composite inoramba yakagadzikana kusvika600°Cmune inert kana vacuum nharaunda, zvichienderana nekupfeka uye bonding interface.

Nezvedu

XKH inyanzvi mukusimudzirwa kwepamusoro-soro, kugadzira, uye kutengesa kwegirazi remaziso uye zvinhu zvitsva zvekristaro. Zvigadzirwa zvedu zvinoshanda zvemagetsi zvemagetsi, zvemagetsi zvevatengi, uye mauto. Isu tinopa Sapphire optical components, nharembozha lens inovhara, Ceramics, LT, Silicon Carbide SIC, Quartz, uye semiconductor crystal wafers. Nehunyanzvi hunyanzvi uye yekucheka-kumucheto michina, isu tinokunda mune isiri-yakajairwa chigadzirwa kugadzirisa, tichivavarira kuve inotungamira optoelectronic zvinhu zvepamusoro-tech bhizinesi.