Yakagadzirirwa SiC Mbeu YeCrystal Substrates Dia 205/203/208 4H-N Rudzi rweOptical Communications

Technical parameters

Silicon carbide seed wafer | |

Polytype | 4H |

Kutadza kwekutarisa pamusoro | 4°kunanga<11-20>±0.5º |

Resistivity | customization |

Diameter | 205±0.5mm |

Ukobvu | 600±50μm |

Kukasharara | CMP, Ra≤0.2nm |

Micropipe Density | ≤1 ea/cm2 |

Makwara | ≤5,Kureba Kwakazara≤2*Diameter |

Edge chips/indents | Hapana |

Front laser marking | Hapana |

Makwara | ≤2, Hurefu Hwose≤Diameter |

Edge chips/indents | Hapana |

Polytype nzvimbo | Hapana |

Back laser marking | 1mm (kubva kumusoro kumucheto) |

Edge | Chamfer |

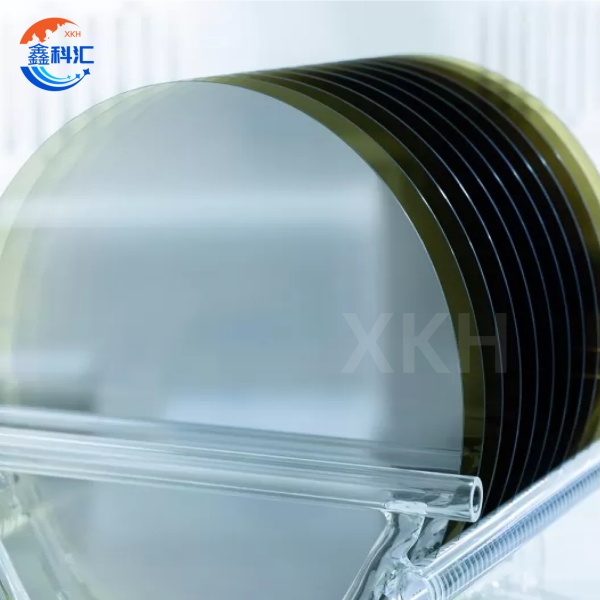

Packaging | Multi-wafer cassette |

Hunhu Hunokosha

1. Chimiro cheCrystal uye Kuita Kwemagetsi

· Crystallographic Stability: 100% 4H-SiC polytype dominance, zero multicrystalline inclusions (eg, 6H / 15R), ine XRD rocking curve yakazara-hupamhi pahafu-maximum (FWHM) ≤32.7 arcsec.

· High Carrier Mobility: Electron mobility ye5,400 cm²/V·s (4H-SiC) uye kufamba kwegomba kwe380 cm²/V·s, zvichiita kuti dhizaini yedhizaini yakakwira-frequency.

·Radiation Hardness: Inomira 1 MeV neutron irradiation ine displacement kukuvara kwechikumbaridzo che 1×10¹⁵ n/cm², yakanakira aerospace uye kushandisa kwenyukireya.

2. Thermal uye Mechanical Properties

· Exceptional Thermal Conductivity: 4.9 W/cm·K (4H-SiC), katatu iyo yesilicon, inotsigira kushanda pamusoro pe200 ° C.

· Low Thermal Expansion Coefficient: CTE ye 4.0 × 10⁻⁶/K (25–1000 ° C), kuve nechokwadi chekuenderana nesilicon-based packaging uye kuderedza kushushikana kwekushisa.

3. Kudzora Kukanganisa uye Kugadzirisa Kururamisa

· Micropipe Density: <0.3 cm⁻² (8-inch wafers), dislocation density <1,000 cm⁻² (yakasimbiswa kuburikidza neKOH etching).

· Unhu Hwepamusoro: CMP-yakakwenenzverwa kuRa <0.2 nm, inosangana neEUV lithography-giredhi flatness zvinodiwa.

Key Applications

| Domain | Application Scenarios | Technical Advantages |

| Optical Communications | 100G/400G lasers, silicon photonics hybrid modules | InP yembeu substrates inogonesa bandgap yakananga (1.34 eV) uye Si-based heteroepitaxy, kuderedza kurasikirwa kwekubatanidza kwemaziso. |

| New Energy Vehicles | 800V high-voltage inverters, onboard charger (OBC) | 4H-SiC substrates inomira> 1,200 V, kuderedza conduction kurasikirwa ne50% uye system volume ne40%. |

| 5G Communications | Millimeter-wave RF zvishandiso (PA/LNA), base chiteshi magetsi amplifiers | Semi-insulating SiC substrates (resistivity >10⁵ Ω·cm) inogonesa high-frequency (60 GHz+) passive integration. |

| Industrial Equipment | High-temperature sensors, ikozvino transformers, nuclear reactor monitors | InSb mhodzi substrates (0.17 eV bandgap) inopa magineti kunzwa kusvika pa300%@10 T. |

Makomborero Anokosha

SiC (silicon carbide) seed crystal substrates inopa kushanda kusingaenzaniswi ne 4.9 W/cm·K thermal conductivity, 2–4 MV/cm breakdown field simba, uye 3.2 eV wide bandgap, inogonesa high-power, high-frequency, and high-temperature applications. Inosanganisira zero micropipe density uye <1,000 cm⁻² dislocation density, aya ma substrates anovimbisa kuvimbika mumamiriro akanyanya. Kemikari yavo inertness uye CVD-inoenderana nzvimbo (Ra <0.2 nm) inotsigira yakakura heteroepitaxial kukura (semuenzaniso, SiC-on-Si) ye optoelectronics uye EV masimba emagetsi.

XKH Services:

1. Customized Production

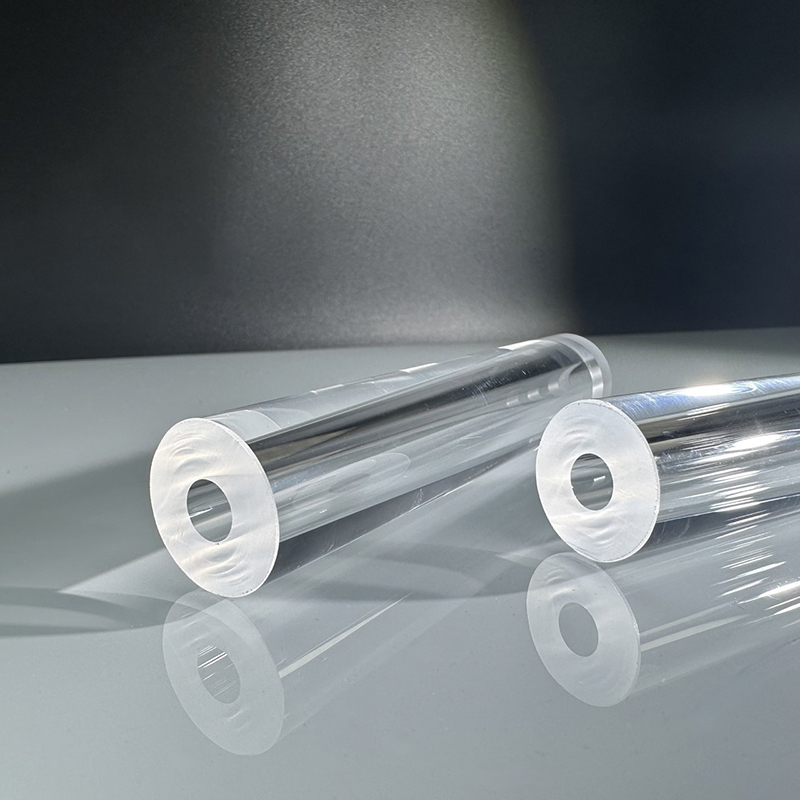

· Flexible Wafer Formats: 2–12-inch wafers ane denderedzwa, rectangular, kana dhizaini-akachekwa akachekwa (± 0.01 mm kushivirira).

· Doping Control: Precise nitrogen (N) uye aluminium (Al) doping kuburikidza neCVD, kuwana resistivity siyana kubva pa10⁻³ kusvika 10⁶ Ω·cm.

2. Advanced Process Technologies.

· Heteroepitaxy: SiC-on-Si (inoenderana ne8-inch silicon mitsara) uye SiC-on-Diamond (thermal conductivity> 2,000 W / m · K).

· Kukanganisa Kuderedza: Hydrogen etching uye annealing kuderedza micropipe / density density, kuvandudza goho rewafer kusvika> 95%.

3. Quality Management Systems.

· Kupera-kusvika-Kupera Kuedzwa: Raman spectroscopy (polytype verification), XRD (crystallinity), uye SEM (kukanganisa kuongorora).

· Zvitupa: Zvinoenderana neAEC-Q101 (yemotokari), JEDEC (JEDEC-033), uye MIL-PRF-38534 (yemauto-giredhi).

4. Global Supply Chain Support.

· Kukwanisa Kugadzira: Mwedzi unobuda> gumi, 000 wafers (60% 8-inch), ine 48-awa yekukurumidza kuendesa.

· Logistics Network: Kuvharwa muEurope, North America, uye Asia-Pacific kuburikidza nemhepo/mugungwa zvinhu zvine tembiricha inodzorwa kurongedza.

5. Technical Co-Development.

· Joint R&D Labs: Batanidza paSiC simba module yekurongedza optimization (semuenzaniso, DBC substrate kubatanidzwa).

· IP Licensing: Ipa GaN-on-SiC RF epitaxial kukura tekinoroji rezenisi kudzikisa mutengi R&D mutengo.

Summary

SiC (silicon carbide) mhodzi yekristaro substrates, sechinhu chehunyanzvi, iri kugadziridza cheni dzemaindasitiri epasi rose kuburikidza nekubudirira mukukura kwekristaro, kudzora kukanganisa, uye kusanganisa kwakasiyana. Nekuenderera mberi nekufambisira mberi kuderedzwa kwewafer defect, kuyera 8-inch kugadzirwa, uye kuwedzera heteroepitaxial mapuratifomu (eg, SiC-on-Diamond), XKH inopa yakavimbika-yakakwirira, inodhura-inoshanda mhinduro dzeoptoelectronics, simba idzva, uye kugadzirwa kwepamberi. Kuzvipira kwedu kune innovation kunoita kuti vatengi vatungamire mune kabhoni kusarerekera uye nehungwaru masisitimu, kutyaira inotevera nguva yehupamhi-bandgap semiconductor ecosystems.