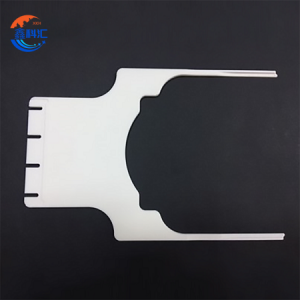

Alumina Ceramic End Effector / Fork Arm yeWafer uye Substrate Kubata

Detailed Diagram

Mhedziso yeAlumina Ceramic End Effector

Iyo Alumina Ceramic End Effector, inowanzonzi seceramic forogo ruoko kana ceramic gripper, chishandiso chakakosha chinoshandiswa murobhoti otomatiki uye mitsara yekugadzira yekuchenesa. Alumina Ceramic End Effector inoiswa paruoko rwerobhoti seyekupedzisira interface nechigadzirwa, ine basa rekutora, kubata, kurongedza, uye kuendesa zvakanyanya kusimba senge silicon wafers, girazi mapaneru, kana microelectronic zvinhu.

Yakagadzirwa kubva ku-ultra-pure alumina ceramic (Al2O3), urwu ruoko rweforogo runopa yakasarudzika yakachena uye yakagadzikana mhinduro kune nharaunda umo kusvibiswa kwesimbi, kugadzirwa kwepurasitiki, kana chidimbu chizvarwa chisingagoni kushivirirwa.

Material Properties - Sei Alumina

Nezve Alumina Ceramic End Effector,Alumina (Al2O3) ndeimwe yeakanyanya kusimbiswa uye akavimbika.advanced engineering ceramics. Giredhi ratinoshandisa (≥99.5% kuchena) rinopa musanganiswa wakasarudzika wehunhu hwemuviri nemakemikari hunhu hunoita kuti ive chinhu chesarudzo chesemiconductor uye vacuum application:

-

Kuomarara kwakanyanya-Nekuomarara kweMohs ye9, inopa kusimba kwenguva refu uye kuramba kukwenya.

-

Thermal endurance-Inochengetedza kutendeseka kwechimiro kupfuura 1600 ° C, inodarika simbi uye polymer vamwe.

-

Kuiswa kwemagetsi- Inobvisa static kuvaka uye inopa yakazara dielectric dziviriro.

-

Kemikari immunity-Kusakanganiswa nemaasidhi, alkalis, magasi eplasma, uye zvine hukasha kuchenesa mhinduro.

-

Ultra-yakaderera kusvibiswa njodzi-Isina-outgassing, yakaderera-inokweshana nzvimbo inoderedza kuburitswa kwechikamu mudzimba dzakachena.

Aya hunhu anobvumira alumina ceramic end effectors kuti ishande zvisina mhosva munzvimbo dzakaoma, dzepamusoro-chaizvo.

Core Zvishandiso zveAlumina Ceramic End Effector

Iko kushandiswa kwakasiyana-siyana kwealumina ceramic end effectorfork maoko kunoita kuti ive yakakosha mumaindasitiri epamusoro-tech:

-

Semiconductor wafer transport systems-Yakachengeteka kufambisa silicon wafers kubva pakugadziriswa kuenda kune kugadzirwa pasina diki-zvikwenya.

-

Flat panel display production-Kubata isina kusimba girazi substrates yeOLED, LCD, kana microLED kugadzirwa.

-

Photovoltaic (PV) kugadzira-Kutsigira solar wafer kurodha uye kurodha pasi pepamusoro-kumhanya robhoti kutenderera.

-

Optical uye electronic chikamu musangano-Kubata zvakapfava senge ma sensors, resistors, uye madiki machipisi.

-

Vacuum uye yekuchenesa imba otomatiki-Kuita mabasa akajeka mumamiriro ekupedzisira-akachena, anodzorwa nechikamu.

Mune ese mamiriro, iyo Alumina Ceramic End Effector inopa yakakosha chinongedzo pakati perobhoti otomatiki uye chigadzirwa chiri kufambiswa.

Dhizaini uye Kugadzirisa Sarudzo dzeAlumina Ceramic End Effector

Yese yekugadzira mutsara ine yakasarudzika zvinodiwa. Naizvozvo, isu tinopa yakasarudzika-yakagadzirwa Alumina Ceramic End Effector mhinduro dzeakasiyana saizi saizi, marobhoti masisitimu, uye nzira dzekubata:

Wafer kuenderana: Inobata mawafer kubva ku2 "kusvika ku12" uye inogona kuyerwa kune yakajairwa zvikamu.

Sarudzo dzeGeometry: Imwe forogo, mbiri-forogo, akawanda-slot, kana maumbirwo echinyakare ane zvakabatanidzwa recesses.

Vacuum kubata: Optional vacuum suction chiteshi kune isina contact wafer rutsigiro.

Kukwirisa nzvimbo dzekusangana: Tsika mabhoti maburi, flanges, kana slotted dhizaini kuti ikwane chero ruoko rwerobhoti.

Surface inopedza: Yakakwenenzverwa kana yepamusoro-yakapedzwa nzvimbo (pasi kusvika kuRa <0.15 μm).

Edge profiles: Chamfered kana mipendero yakatenderedzwa yekudzivirira kwakanyanya.

Yedu Alumina Ceramic End Effector engineering timu inogona kushanda kubva kune mutengi CAD kudhirowa kana zvikamu zvemuenzaniso, kuve nechokwadi chekubatanidza isina musono mune iripo otomatiki masisitimu.

Mabhenefiti Akakosha eAlumina Ceramic End Effects

| Feature | Nei Zvichikosha |

|---|---|

| Dimensional kunyatsojeka | Inochengeta kurongeka kwakakwana kunyangwe mukumhanya-mhanya, kudzokororwa kutenderera. |

| Kwete-kusvibisa | Inogadzira chero zvidimbu, inosangana nezvinodiwa mudzimba dzakachena. |

| Kupisa nekuora | Inotsungirira hutsinye hwekugadzirisa matanho uye kupisa kunotyisa. |

| Hapana static charge | Inodzivirira mawaferi anonzwisisika uye zvikamu kubva panjodzi ye electrostatic. |

| Chiremba asi chakaoma | Inopa kuomarara kwakanyanya pasina kukanganisa robhoti ruoko mutoro. |

| Hupenyu hwesevhisi hwakawedzerwa | Inodarika simbi uye maoko epolymer muhupenyu uye kuvimbika. |

Material Kuenzanisa kweAlumina Ceramic End Effector

| Attribute | Plastic Fork Arm | Aluminium / Metal Fork Arm | Alumina Ceramic Fork Arm |

|---|---|---|---|

| Kuoma | Low | Pakati | High High |

| Thermal Range | ≤ 150°C | ≤ 500°C | Kusvikira ku1600 ° C |

| Kugadzikana Kwemakemikari | Murombo | Pakati nepakati | Excellent |

| Cleanroom Rating | Low | Avhareji | Yakanakira Kirasi 100 kana zvirinani |

| Pfeka Resistance | Limited | Kugona | Outstanding |

| Customization Level | Pakati nepakati | Limited | Zvakawanda |

Mibvunzo Inowanzo bvunzwa (FAQ) yeAlumina Ceramic End Effector

Q1: Chii chinoita kuti alumina ceramic end effector isiyane nesimbi?

A1:Kusiyana nealuminium kana maoko esimbi, alumina ceramic haiparadzi, kushatisa, kana kuunza simbi ions mune semiconductor maitiro. Inoramba yakagadzikana pasi pemamiriro ezvinhu akanyanya uye inoburitsa pasina zvidimbu.

Q2: Ko idzi Alumina Ceramic End Effector inogona kushandiswa mune yakakwirira-vacuum uye plasma makamuri?

A2:Ehe. Alumina ceramic ndiyokusabvisa mariuye inopokana neplasma, inoita kuti ive chinhu chakasarudzika chevacuum kugadzirisa uye etching michina.

Q3: Anogona kugadzirisika sei aya maAlumina Ceramic End Effector fork maoko?

A3:Yese unit inogona kuvazvizere customized-kusanganisira chimiro, nzvimbo dzinotsvedza, maburi ekukweva, chimiro chekukwira, uye kupera kwemupendero-kuenderana nezvinodiwa nerobhoti system yako.

Q4: Ivo vasina kusimba here?

A4:Nepo ceramic ine brittleness yechisikigo, dhizaini yedu yekugadzira inogovera mitoro zvakaenzana uye inoderedza kushushikana pfungwa. Kana yakabatwa nemazvo, hupenyu hwesevhisi hunowanzopfuura iyo yesimbi kana polymer dzimwe nzira.

Nezvedu

XKH inyanzvi mukusimudzirwa kwepamusoro-soro, kugadzira, uye kutengesa kwegirazi remaziso uye zvinhu zvitsva zvekristaro. Zvigadzirwa zvedu zvinoshanda zvemagetsi zvemagetsi, zvemagetsi zvevatengi, uye mauto. Isu tinopa Sapphire optical components, nharembozha lens inovhara, Ceramics, LT, Silicon Carbide SIC, Quartz, uye semiconductor crystal wafers. Nehunyanzvi hunyanzvi uye yekucheka-kumucheto michina, isu tinokunda mune isiri-yakajairwa chigadzirwa kugadzirisa, tichivavarira kuve inotungamira optoelectronic zvinhu zvepamusoro-tech bhizinesi.