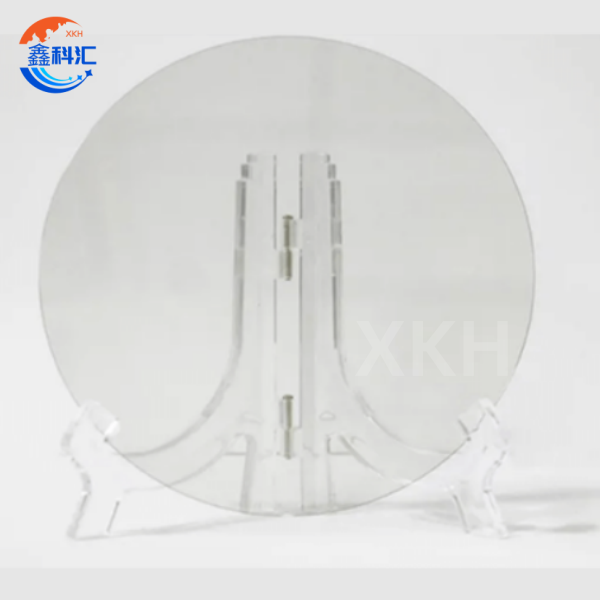

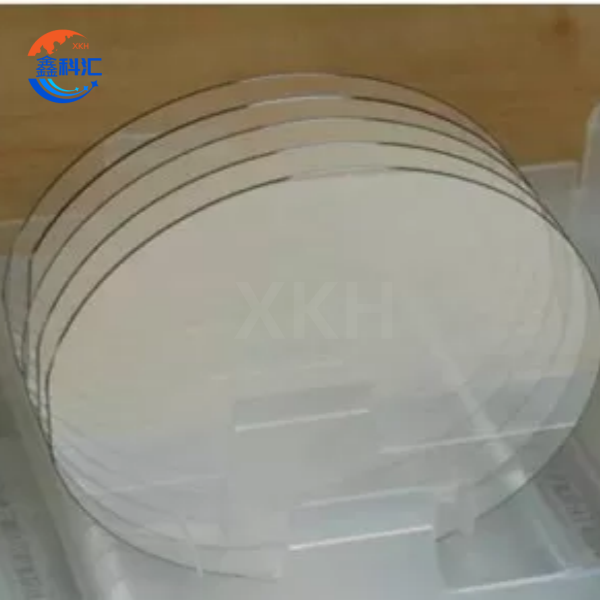

6 Inch 4H SEMI Rudzi rweSiC inoumba substrate Hukobvu 500μm TTV≤5μm MOS giredhi

Technical parameters

| Items | Tsanangudzo | Items | Tsanangudzo |

| Diameter | 150±0.2 mm | Mberi (Si-face) hukasha | Ra≤0.2 nm (5μm×5μm) |

| Polytype | 4H | Edge Chip, Scratch, Crack (kutarisa kwekuona) | Hapana |

| Resistivity | ≥1E8 Ω·cm | TTV | ≤5 μm |

| Kutamisa layer Hukobvu | ≥0.4 μm | Warp | ≤35 μm |

| Hapana (2mm>D>0.5mm) | ≤5 ea/Wafer | Ukobvu | 500±25 μm |

Key Features

1. Inoshamisa Yepamusoro-Frequency Performance

Iyo 6-inch semi-insulating SiC composite substrate inoshandisa giredhi dielectric layer dhizaini, kuve nechokwadi chekuti dielectric inogara ichisiyana ye <2% muKa-band (26.5-40 GHz) uye kuvandudza chikamu chisingachinji ne40%. 15% kuwedzera mukubudirira uye 20% yakaderera simba rekushandisa muT / R modules uchishandisa iyi substrate.

2. Breakthrough Thermal Management

Yakasarudzika "thermal bridge" inoumbwa chimiro inogonesa lateral thermal conductivity ye400 W/m·K. Mu 28 GHz 5G base station PA modules, tembiricha yejunction inokwira ne28 ° C chete mushure memaawa makumi maviri nemana ekuenderera mberi kwekushanda-50 ° C yakaderera pane yakajairwa mhinduro.

3. Superior Wafer Quality

Kuburikidza neyakagadziridzwa Physical Vapor Transport (PVT) nzira, tinowana dislocation density <500/cm² uye Total Thickness Variation (TTV) <3 μm.

4. Manufacturing-Hushamwari Processing

Yedu laser annealing process yakanyatso kugadzirirwa iyo 6-inch semi-insulating SiC composite substrate inodzikisa pasi density nemirairo miviri yehukuru pamberi pe epitaxy.

Main Applications

1. 5G Base Station Core Zvikamu

MuMassive MIMO antenna arrays, GaN HEMT zvishandiso pa6-inch semi-insulating SiC composite substrates inowana 200W yekubuda simba uye> 65% kunyatsoita. Miedzo yemunda pa 3.5 GHz yakaratidza kuwedzera kwe30% mukuvhara radius.

2. Satellite Communication Systems

Low-Earth orbit (LEO) satellite transceivers vachishandisa iyi substrate inoratidza 8 dB yepamusoro EIRP muQ-band (40 GHz) ichidzikisa huremu ne40%. SpaceX Starlink terminals vakaitora kuti igadzire hukuru.

3. Military Radar Systems

Phased-array radar T/R modules pane iyi substrate inosvika 6-18 GHz bandwidth uye ruzha nhamba yakadzikira se1.2 dB, ichiwedzera chiyero chekuonekwa ne50 km mukutanga-yambiro radar masisitimu.

4. Automotive Millimeter-Wave Radar

79 GHz mota radar machipisi uchishandisa iyi substrate inovandudza angular resolution kusvika 0.5 °, ichisangana neL4 inozvimiririra yekutyaira zvinodiwa.

Isu tinopa yakazara yakagadziriswa sevhisi mhinduro ye6-inch semi-insulating SiC composite substrates. Panyaya yekugadzirisa maparamendi, isu tinotsigira chaiyo mutemo weresistive mukati meiyo 10⁶-10¹⁰ Ω·cm. Kunyanya zvekushandisa zvechiuto, tinogona kupa yakanyanya-yepamusoro kuramba sarudzo ye>10⁹ Ω·cm. Inopa matatu ukobvu kutsanangurwa kwe200μm, 350μm uye 500μm panguva imwe chete, nekushivirira kwakanyatso kudzorwa mukati me ± 10μm, kusangana nezvinodiwa zvakasiyana kubva kune yakakwira-frequency zvishandiso kusvika kune yakakwirira-simba maapplication.

Panyaya yemaitiro ekurapa kwepamusoro, tinopa mhinduro mbiri dzehunyanzvi: Chemical Mechanical Polishing (CMP) inogona kuwana atomic-level surface flatness neRa<0.15nm, kusangana nezvinodiwa zvakanyanya epitaxial kukura zvinodiwa; Iyo epitaxial yakagadzirira pamusoro pekurapa tekinoroji yekukurumidza kugadzirwa zvinodiwa inogona kupa ekupedzisira-yakatsetseka nzvimbo ine Sq<0.3nm uye yakasara oxide ukobvu <1nm, ichirerutsa maitiro ekutanga ekurapa pakupedzisira kwemutengi.

XKH inopa yakakwana yakagadziridzwa mhinduro ye6-inch semi-insulating SiC composite substrates.

1. Material Parameter Customization

Isu tinopa chaiyo resistivity tuning mukati mechikamu che10⁶-10¹⁰ Ω·cm, iine nyanzvi dzepamusoro-soro dzekudzivirira sarudzo >10⁹ Ω·cm inowanika kumauto/muchadenga maapplication.

2. Makobvu Specifications

Zvitatu zvakajairwa ukobvu sarudzo:

200μm (yakagadziridzwa kune yakakwira-frequency zvishandiso)

350μm (yakajairwa yakatarwa)

500μm (yakagadzirirwa kushandiswa kwesimba repamusoro)

+ Ese akasiyana anochengetedza kushivirira kwakasimba kwe ± 10μm.

3. Surface Treatment Technologies

Chemical Mechanical Polishing (CMP): Inowana atomic-level surface flatness neRa <0.15nm, inosangana neyakaomesesa epitaxial kukura zvinodiwa zveRF nemagetsi zvishandiso.

4. Epi-Ready Surface Processing

· Inoburitsa nzvimbo dzakapfava dzine Sq <0.3nm roughness

· Inodzora ukobvu hweiyo oxide kusvika <1nm

· Inobvisa anosvika matatu ekutanga kugadzirisa matanho panzvimbo yevatengi