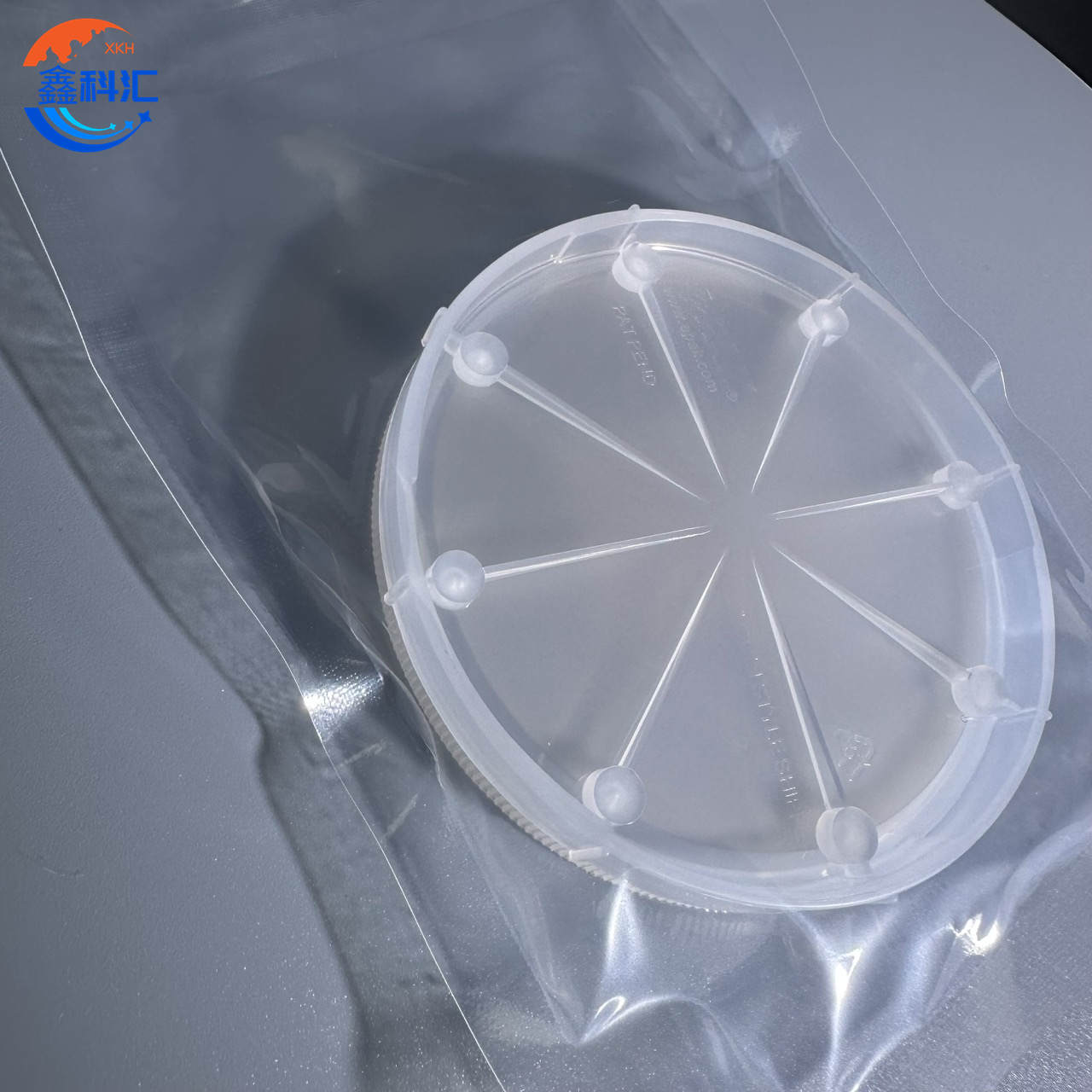

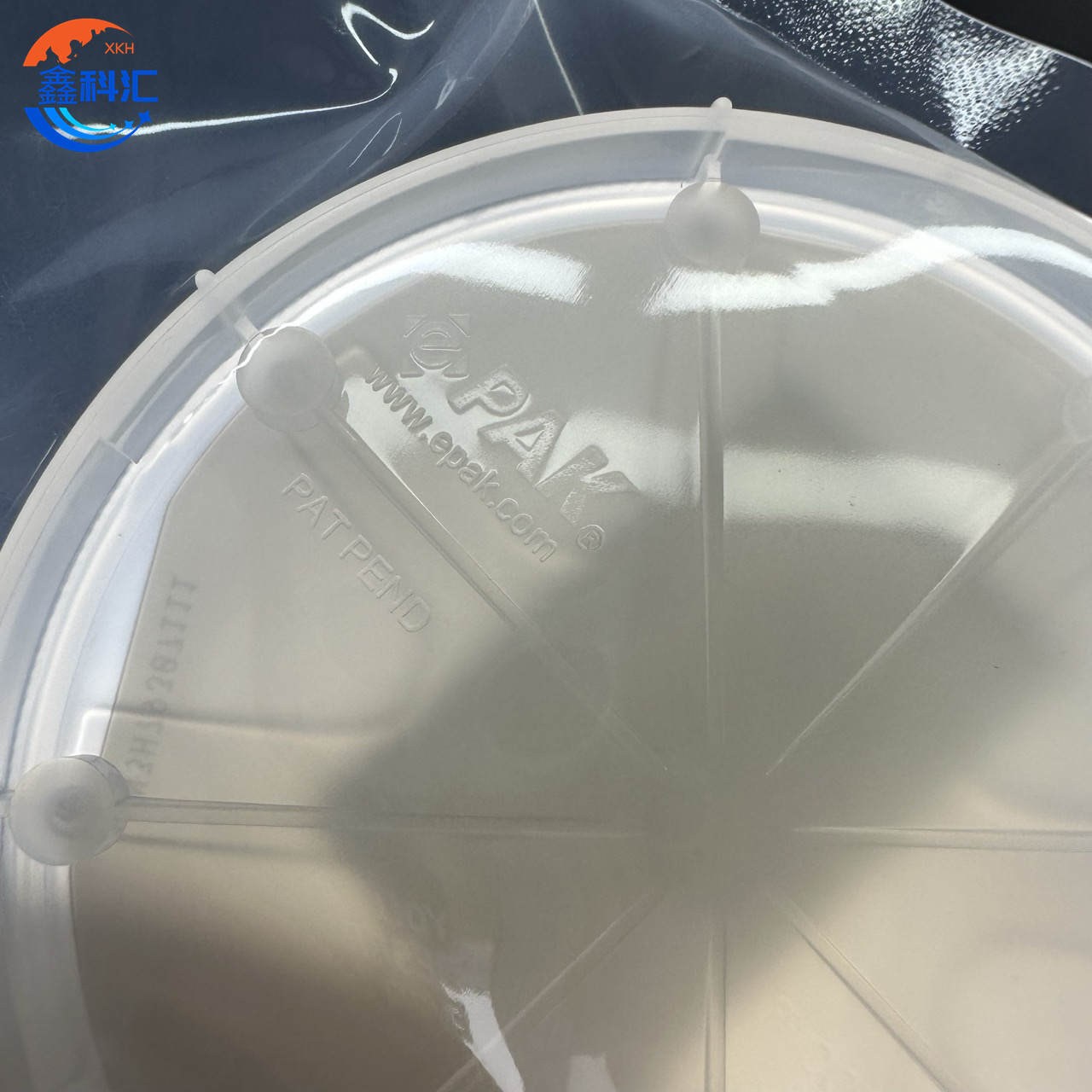

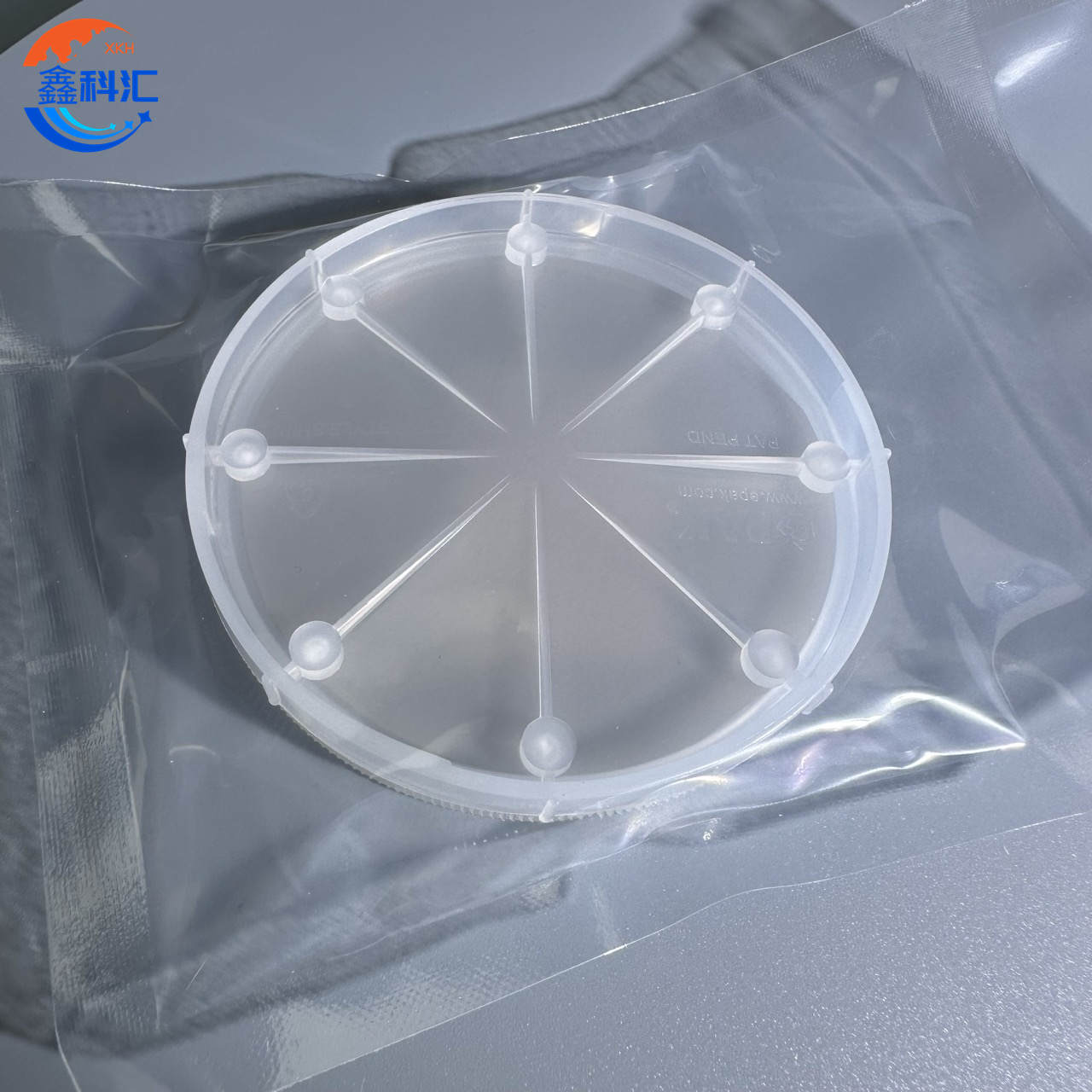

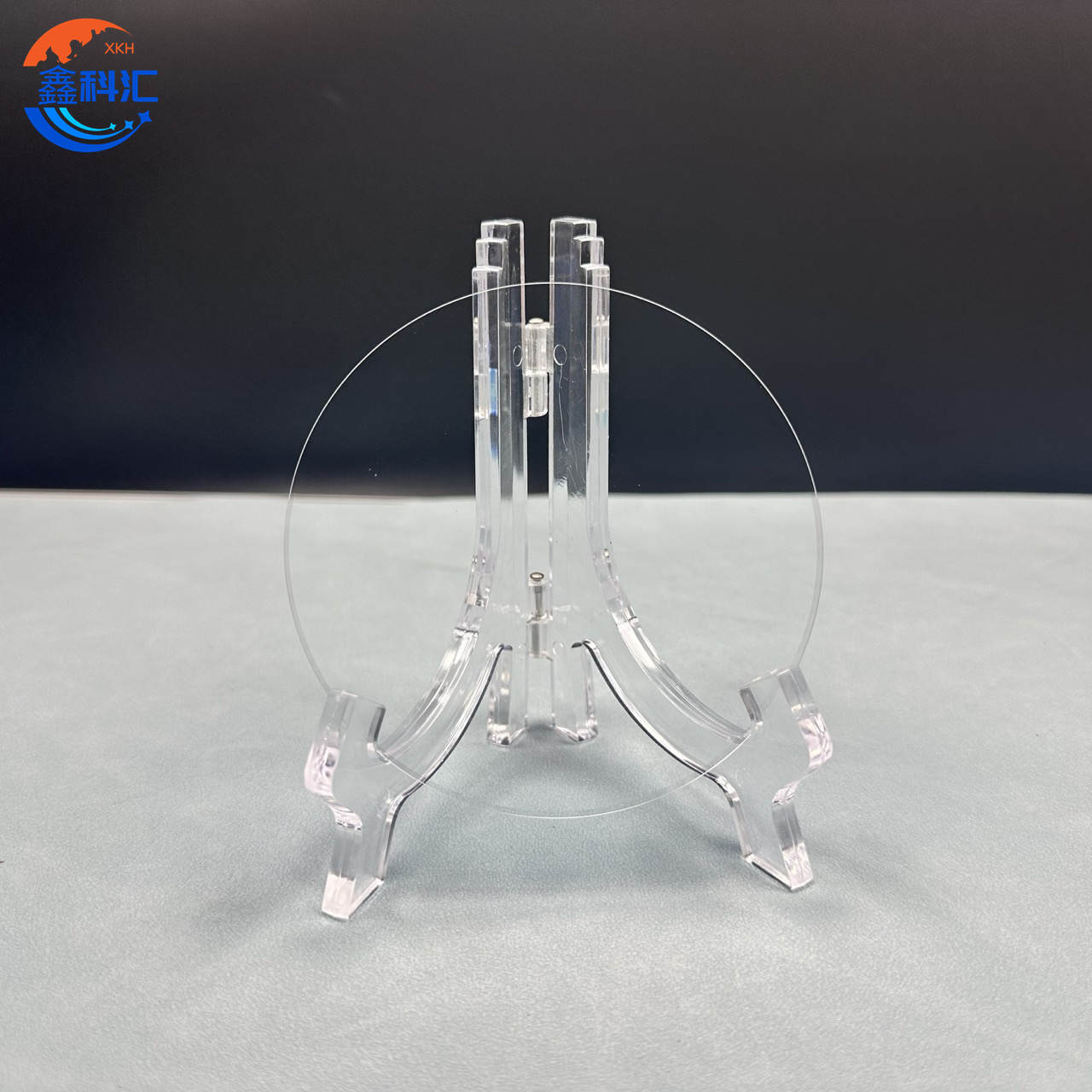

3inch High kuchena Semi-Insulating (HPSI)SiC wafer 350um Dummy giredhi Prime giredhi

Application

HPSI SiC wafers akakosha mukugonesa chizvarwa chinotevera magetsi emagetsi, ayo anoshandiswa mumhando dzakasiyana-siyana dzepamusoro-kuita maapplication:

Simba Rekushandura Sisitimu: SiC wafers anoshanda sechinhu chakakosha chemidziyo yemagetsi senge simba MOSFETs, diodes, uye IGBTs, ayo akakosha pakushandurwa kwesimba kwakanaka mumaseketi emagetsi. Izvi zvikamu zvinowanikwa mune yakakwirira-inoshanda magetsi emagetsi, mota madhiraivha, uye maindasitiri inverters.

Mota dzemagetsi (EVs):Kukura kuri kudiwa kwemotokari dzemagetsi kunoda kushandiswa kwemagetsi emagetsi anoshanda zvakanyanya, uye maSiC wafers ari pamberi peshanduko iyi. MuEV powertrains, aya mawafer anopa kushanda kwepamusoro uye kukurumidza kushandura masimba, ayo anobatsira kukurumidza kuchaja nguva, kureba, uye kukwidziridzwa kwese kuita kwemotokari.

Renewable Energy:Mumagetsi emagetsi anogona kudzokororwa senge solar uye simba remhepo, maSiC wafers anoshandiswa mune inverters uye anoshandura anogonesa kunyatsoita simba kutora uye kugovera. Iyo yakakwira yekupisa yekupisa uye yakanyanya kuparara voltage yeSiC inovimbisa kuti masisitimu aya anoshanda akavimbika, kunyangwe pasi pemamiriro ekunze akanyanya.

Industrial Automation uye Robotics:Yepamusoro-inoshanda magetsi emagetsi mumaindasitiri otomatiki masisitimu uye marobhoti anoda michina inokwanisa kushandura nekukurumidza, kubata mikuru mikuru yemagetsi, uye kushanda pasi pekunetseka kwakanyanya. SiC-based semiconductors inosangana nezvinodiwa izvi nekupa kugona kwepamusoro uye kusimba, kunyangwe munzvimbo dzakaomarara dzekushanda.

Telecommunication Systems:Mumafashamu enharembozha, uko kuvimbika kwakanyanya uye kushandurwa kwesimba kwakakosha, maSiC wafers anoshandiswa mumagetsi emagetsi uye DC-DC inoshandura. Zvishandiso zveSiC zvinobatsira kuderedza kushandiswa kwesimba uye kuwedzera mashandiro ehurongwa munzvimbo dzedata uye network yekutaurirana.

Nekupa hwaro hwakasimba hwemashandisirwo emagetsi epamusoro-soro, iyo HPSI SiC wafer inogonesa kuvandudzwa kwemidziyo inoshanda nesimba, ichibatsira maindasitiri shanduko kuenda kune yakasvibira, mhinduro dzakasimba.

Properties

| orty | Kugadzira Giredhi | Research Giredhi | Dummy Grade |

| Diameter | 75.0 mm ± 0.5 mm | 75.0 mm ± 0.5 mm | 75.0 mm ± 0.5 mm |

| Ukobvu | 350 µm ± 25 µm | 350 µm ± 25 µm | 350 µm ± 25 µm |

| Wafer Orientation | Paaxis: <0001> ± 0.5° | Paaxis: <0001> ± 2.0° | Paaxis: <0001> ± 2.0° |

| Micropipe Density ye95% yeWafers (MPD) | ≤ 1cm⁻² | ≤ 5cm⁻² | ≤ 15 cm⁻² |

| Electrical Resistivity | ≥ 1E7 Ω·cm | ≥ 1E6 Ω·cm | ≥ 1E5 Ω·cm |

| Dopant | Undoped | Undoped | Undoped |

| Yekutanga Flat Oriental | {11-20} ± 5.0° | {11-20} ± 5.0° | {11-20} ± 5.0° |

| Primary Flat Length | 32.5 mm ± 3.0 mm | 32.5 mm ± 3.0 mm | 32.5 mm ± 3.0 mm |

| Secondary Flat Length | 18.0 mm ± 2.0 mm | 18.0 mm ± 2.0 mm | 18.0 mm ± 2.0 mm |

| Secondary Flat Orientation | Kutarisa kumusoro: 90 ° CW kubva kupuraimari flat ± 5.0 ° | Kutarisa kumusoro: 90 ° CW kubva kupuraimari flat ± 5.0 ° | Kutarisa kumusoro: 90 ° CW kubva kupuraimari flat ± 5.0 ° |

| Kusabatanidzwa kumucheto | 3 mm | 3 mm | 3 mm |

| LTV/TTV/Bow/Warp | 3 µm / 10 µm / ±30 µm / 40 µm | 3 µm / 10 µm / ±30 µm / 40 µm | 5 µm / 15 µm / ±40 µm / 45 µm |

| Kukasharara Kwepamusoro | C-chiso: Yakapenya, Si-chiso: CMP | C-chiso: Yakapenya, Si-chiso: CMP | C-chiso: Yakapenya, Si-chiso: CMP |

| Cracks (yakaongororwa nechiedza chakasimba) | Hapana | Hapana | Hapana |

| Hex Plates (yakaongororwa nechiedza chakasimba) | Hapana | Hapana | Cumulative area 10% |

| Polytype Nzvimbo (inoongororwa nechiedza chakanyanya) | Cumulative area 5% | Cumulative area 5% | Cumulative area 10% |

| Kukwenya (kuongororwa nechiedza chakanyanya) | ≤ 5 scratches, cumulative kureba ≤ 150 mm | ≤ 10 scratches, cumulative kureba ≤ 200 mm | ≤ 10 scratches, cumulative kureba ≤ 200 mm |

| Edge Chipping | Hapana anotenderwa ≥ 0.5 mm hupamhi nekudzika | 2 inobvumirwa, ≤ 1 mm yakafara nekudzika | 5 inobvumirwa, ≤ 5 mm hupamhi nekudzika |

| Surface Contamination (inoongororwa nechiedza chakanyanya) | Hapana | Hapana | Hapana |

Hunhu Hunokosha

Superior Thermal Performance: SiC's high thermal conductivity inogonesa kupisa kupisa mumidziyo yemagetsi, ichivabvumira kushanda pamazinga emagetsi epamusoro uye mafrequency pasina kupisa. Izvi zvinoturikira kune madiki, anoshanda masisitimu uye kwenguva refu yekushanda yehupenyu.

High Breakdown Voltage: Iine bandgap yakafara kana ichienzaniswa nesilicon, maSiC wafers anotsigira ma-high-voltage application, achiaita akanakira zvinhu zvemagetsi zvemagetsi zvinoda kushingirira kuparara kwakanyanya, senge mumotokari dzemagetsi, masystem emagetsi egidhi, uye masisitimu emagetsi anovandudzwa.

Kudzikira Kurasika Kwesimba: Iyo yakaderera pa-resistance uye nekukurumidza kushandura kumhanya kweSiC zvishandiso zvinoguma nekudzikira kurasikirwa kwesimba panguva yekushanda. Izvi hazvingogadziri kushanda zvakanaka chete asiwo zvinowedzera kuchengetedza kwese kwesimba kwemasisitimu maanoshandiswa.

Kuvimbika Kwakawedzerwa Munzvimbo Dzakaoma: SiC's robust material properties inobvumira kuti iite mumamiriro ezvinhu akanyanyisa, akadai sekushisa kwakanyanya (kusvika ku600 ° C), high voltages, uye high frequencies. Izvi zvinoita kuti maSiC wafers akwane kuda maindasitiri, mota, uye simba rekushandisa.

Kubudirira Kwesimba: Zvishandiso zveSiC zvinopa huwandu hwesimba hwepamusoro pane echinyakare silicon-based zvishandiso, kuderedza saizi uye huremu hwemagetsi masisitimu emagetsi uku uchivandudza kugona kwavo kwese. Izvi zvinotungamira mukuchengetwa kwemutengo uye diki nharaunda yenzvimbo mumashandisirwo akadai sesimba rinodzokororwa uye mota dzemagetsi.

Scalability: Iyo 3-inch dhayamita uye kwakanyatso kushivirira kwekugadzira kweHPSI SiC wafer inovimbisa kuti inokonzeresa kugadzirwa kwakawanda, ichisangana zvese zvekutsvaga uye zvekutengesa zvinodiwa zvekugadzira.

Mhedziso

Iyo HPSI SiC wafer, ine 3-inch dhayamita uye 350 µm ± 25 µm ukobvu, ndiyo yakakwana zvinhu zvechizvarwa chinotevera chepamusoro-inoshanda magetsi emagetsi emagetsi. Musanganiswa wayo wakasarudzika wekupisa kwekushisa, kuparara kwemagetsi, kuderera kwesimba, uye kuvimbika pasi pemamiriro akanyanya kuita kuti ive chinhu chakakosha chekushandisa kwakasiyana-siyana mukushandurwa kwemagetsi, simba rinogoneka, mota dzemagetsi, masisitimu emaindasitiri, uye kufonera.

Iyi SiC wafer inonyanya kukodzera maindasitiri ari kutsvaga kuwana hunyanzvi hwepamusoro, kuchengetedza kwesimba kukuru, uye kuvimbika kwehurongwa. Sezvo tekinoroji yemagetsi ichiri kuramba ichishanduka, iyo HPSI SiC wafer inopa hwaro hwekuvandudzwa kwechizvarwa chinotevera, simba-rinoshanda mhinduro, kufambisa shanduko kuenda kune yakagadzikana, yakaderera-kabhoni ramangwana.

Detailed Diagram