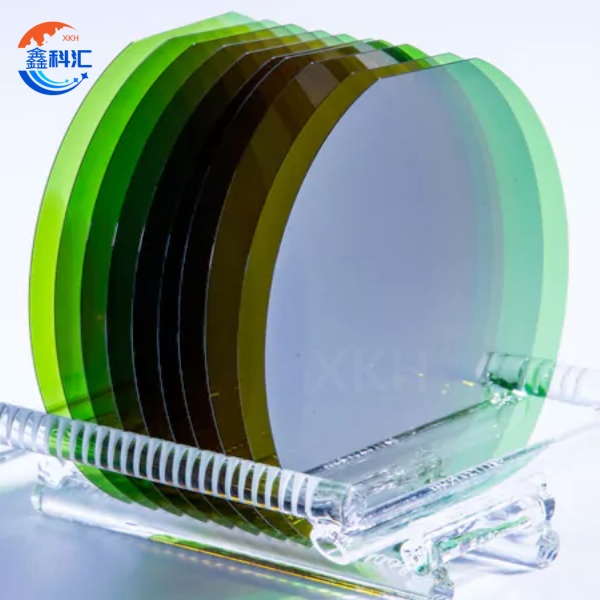

12 inch SiC Substrate N Type Yakakura Saizi Yakakwirira Kuita RF Zvikumbiro

Technical parameters

| 12 inch Silicon Carbide (SiC) Substrate Kutsanangurwa | |||||

| Giredhi | ZeroMPD Kugadzirwa Giredhi(Z Giredhi) | Standard Production Giredhi(P Giredhi) | Dummy Grade (D giredhi) | ||

| Diameter | 3 0 0 mm ~ 1305mm | ||||

| Ukobvu | 4H-N | 750μm±15 μm | 750μm±25 μm | ||

| 4H-SI | 750μm±15 μm | 750μm±25 μm | |||

| Wafer Orientation | Kunze kweaxis : 4.0° yakananga <1120 >±0.5° ye4H-N, Paaxis: <0001>±0.5° ye4H-SI | ||||

| Micropipe Density | 4H-N | ≤0.4cm-2 | ≤4cm-2 | ≤25cm-2 | |

| 4H-SI | ≤5cm-2 | ≤10cm-2 | ≤25cm-2 | ||

| Resistivity | 4H-N | 0.015~0.024 Ω·cm | 0.015~0.028 Ω·cm | ||

| 4H-SI | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |||

| Yekutanga Flat Oriental | {10-10} ±5.0° | ||||

| Primary Flat Length | 4H-N | N/A | |||

| 4H-SI | Notch | ||||

| Kusabatanidzwa kumucheto | 3 mm | ||||

| LTV/TTV/Bow/Warp | ≤5μm/≤15μm/≤35 μm/≤55 μm | ≤5μm/≤15μm/≤35 □ μm/≤55 □ μm | |||

| Kukasharara | Polish Ra≤1 nm | ||||

| CMP Ra≤0.2 nm | Ra≤0.5 nm | ||||

| Edge Cracks By High Intensity Chiedza Hex Plates By High Intensity Chiedza Polytype Nzvimbo NeKusimba Kwakanyanya Chiedza Visual Carbon Inclusions Silicon Surface Scratches By High Intensity Chiedza | Hapana Cumulative area ≤0.05% Hapana Cumulative area ≤0.05% Hapana | Cumulative kureba ≤ 20 mm, single kureba≤2 mm Cumulative area ≤0.1% Cumulative area≤3% Yakawedzerwa nzvimbo ≤3% Cumulative kureba≤1×wafer dhayamita | |||

| Edge Chips By High Intensity Chiedza | Hapana anotenderwa ≥0.2mm hupamhi nekudzika | 7 inotenderwa, ≤1 mm imwe neimwe | |||

| (TSD) Threading screw dislocation | ≤500 cm-2 | N/A | |||

| (BPD) Base plane dislocation | ≤1000 cm-2 | N/A | |||

| Silicon Surface Kusvibiswa NeKunyanya Kusimba Chiedza | Hapana | ||||

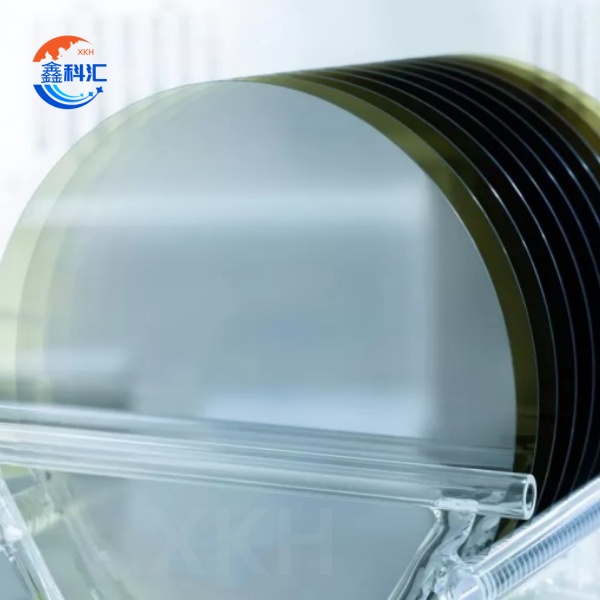

| Packaging | Multi-wafer Cassette Kana Single Wafer Container | ||||

| Notes: | |||||

| 1 Miganho yekuremara inoshanda kune yese wafer pamusoro kunze kweiyo yekumucheto nzvimbo yekusarudzika. 2Kukwenya kunofanirwa kutariswa paSi face chete. 3 Iyo dislocation data inongobva kuKOH etched wafers. | |||||

Key Features

1. Yakakura Kukura Kunobatsira: Iyo 12-inch SiC substrate (12-inch silicon carbide substrate) inopa nzvimbo yakakura ye-single-wafer, zvichiita kuti machipisi akawanda abudiswe pamucheka, nokudaro kuderedza mari yekugadzira uye kuwedzera zvibereko.

2. High-Performance Material: Silicon carbide yekudzivirira kwekushisa kwepamusoro uye simba rekuparara kwemunda rinoita kuti 12-inch substrate yakanaka kune yakakwirira-voltage uye high-frequency applications, yakadai seEV inverters uye kukurumidza-charging systems.

3. Kugadzirisa Kuenderana: Pasinei nekuoma kwakanyanya uye kugadzirisa matambudziko eSiC, iyo 12-inch SiC substrate inowana hurema hwepasi pasi kuburikidza neakagadziridzwa kucheka uye kupukuta maitiro, kunatsiridza goho remudziyo.

4. Superior Thermal Management: Nekupisa kwekushisa kwepamusoro pane silicon-based materials, 12-inch substrate inonyatsogadzirisa kupisa kwekushisa mumagetsi emagetsi, kuwedzera hupenyu hwemichina.

Main Applications

1. Motokari dzeMagetsi: The 12-inch SiC substrate (12-inch silicon carbide substrate) inhengo yenheyo yemagetsi emagetsi emagetsi anotevera, zvichiita kuti inverters yakakwirira iwedzere kuwedzera uye kuderedza nguva yekuchaja.

2. 5G Base Stations: Makuru makuru eSiC substrates anotsigira ma-high-frequency RF zvishandiso, achisangana nezvinodiwa zve5G base stations kune simba guru uye kurasikirwa kwakaderera.

3.Industrial Power Supplies: Mune solar inverters uye smart grids, iyo 12-inch substrate inogona kumira yakakwira voltages ichideredza kurasikirwa kwesimba.

4.Consumer Electronics: Ramangwana rinokurumidza majaja uye data centre simba rekushandisa rinogona kutora 12-inch SiC substrates kuti iwane compact size uye kushanda kwepamusoro.

XKH's Services

Isu tinonyanya kugadzira masevhisi ekugadzirisa 12-inch SiC substrates (12-inch silicon carbide substrates), kusanganisira:

1. Dicing & Polishing: Yakaderera-kukuvadza, high-flatness substrate processing yakagadzirirwa kune zvinodiwa nevatengi, kuve nechokwadi chekushanda kwechigadzirwa chakagadzikana.

2. Epitaxial Growth Support: High-quality epitaxial wafer masevhisi kuti akurumidze kugadzira chip.

3. Diki-Batch Prototyping: Inotsigira R&D kusimbiswa kwemasangano ekutsvagisa nemabhizinesi, kupfupisa kutenderera kwebudiriro.

4. Technical Consulting: Kuguma-ku-kuguma mhinduro kubva pakusarudzwa kwezvinhu kusvika pakugadzirisa optimization, kubatsira vatengi kukunda SiC kugadzirisa matambudziko.

Ingave yekugadzirwa kwakawanda kana hunyanzvi kugadzirisa, yedu 12-inch SiC substrate masevhisi anowirirana nezvido zvepurojekiti yako, achisimbisa kufambira mberi kwetekinoroji.