Zviri Mukati

1. Zvinangwa Zvikuru uye Kukosha kweWafer Yekuchenesa

2.Kusvibisa Ongororo uye Yepamberi Analytical Techniques

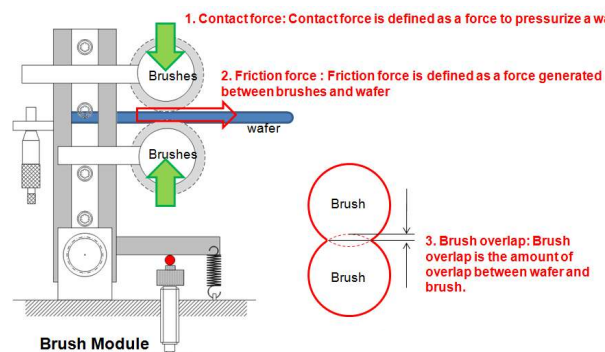

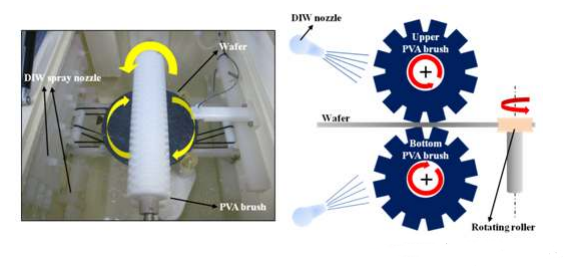

3.Dzidziso dzekuchenesa nzira uye tekinoroji Nheyo

4.Technical Implementation uye Process Control Essentials

5.Mafambiro Emangwana uye Mafambisirwo Azvinoitwa

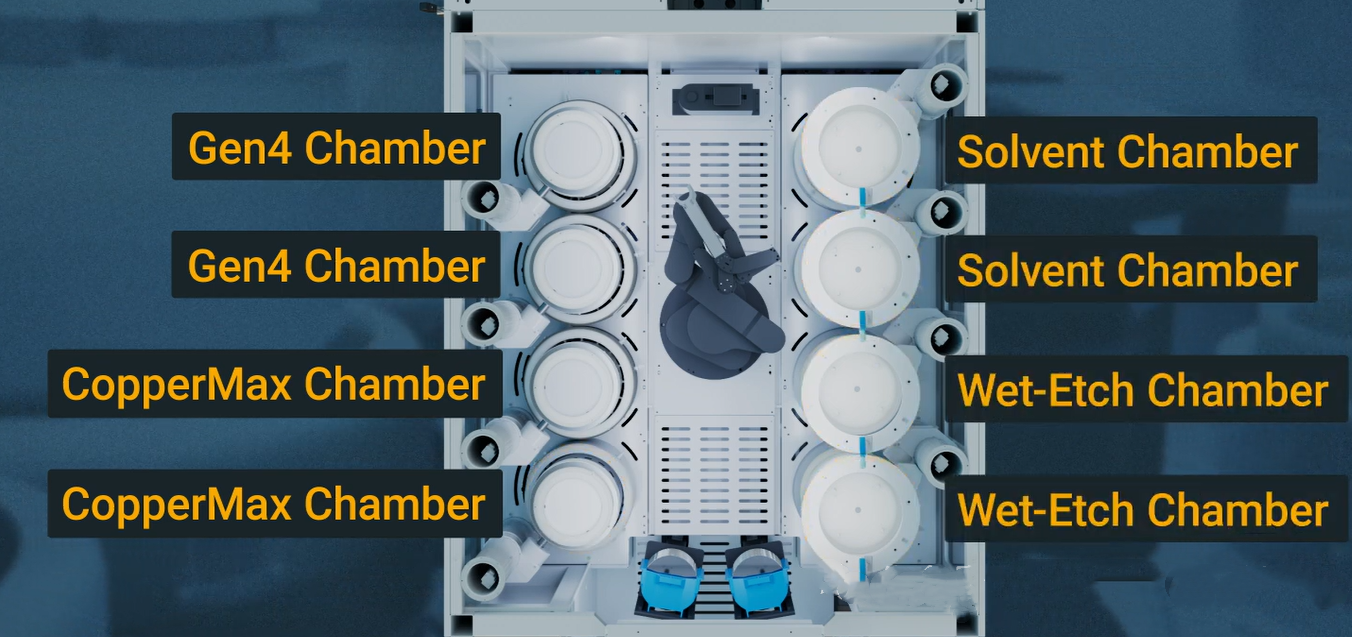

6. XKH End-to-End Solutions uye Service Ecosystem

Wafer kucheneswa ibasa rakakosha mukugadzira semiconductor, sezvo nyangwe atomic-level inosvibisa inogona kukanganisa mashandiro echishandiso kana goho. Maitiro ekuchenesa anowanzo sanganisira matanho akati wandei ekubvisa akasiyana zvinosvibisa, senge organic masara, tsvina yesimbi, zvimedu, uye maokisi ekuzvarwa.

1. Zvinangwa zveWafer Cleaning

- Bvisa organic contaminants (semuenzaniso, photoresist residues, zvigunwe).

- Bvisa tsvina yesimbi (semuenzaniso, Fe, Cu, Ni).

- Bvisa kusvibiswa kwezvinhu (semuenzaniso, guruva, zvimedu zvesilicon).

- Bvisa maokisidi ekuzvarwa (semuenzaniso, SiO₂ layers akaumbwa panguva yekuratidzwa kwemhepo).

2. Kukosha kweRigorous Wafer Cleaning

- Inovimbisa yakakwira process goho uye mashandiro echishandiso.

- Inoderedza kuremara uye wafer zvimedu mitengo.

- Inovandudza pamusoro pemhando uye kuenderana.

Usati wacheneswa zvakanyanya, zvakakosha kuti uongorore kusvibiswa kwepasi kuripo. Kunzwisisa mhando, saizi yekugovera, uye kurongeka kwenzvimbo yezvinosvibisa pane wafer pamusoro inokwenenzvera kuchenesa chemistry uye mechanic simba rekuisa.

3. Yepamberi Analytical Techniques yeKusvibisa Ongororo

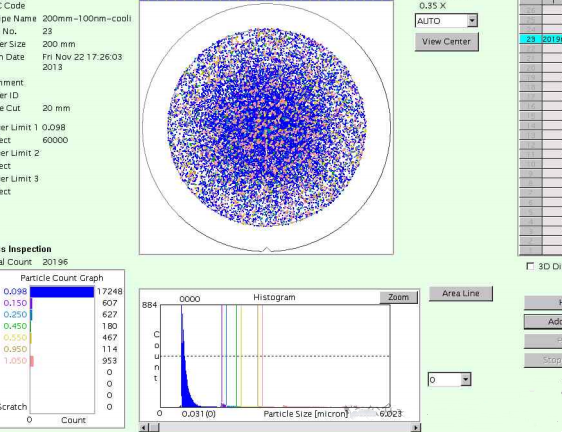

3.1 Surface Particle Analysis

- Specialized particle counters anoshandisa laser kuparadzira, kana kuona komputa kuverenga, saizi, uye mepu pamusoro pemarara.

- Kupararira kwechiedza kunoenderana nehukuru hudiki semakumi ema nanometers, uye densities zvakaderera se 0.1 particles/cm².

- Calibration ine zviyero inovimbisa kuvimbika kwehardware. Pre-uye mushure mekuchenesa scans inosimbisa kubviswa kwekubudirira, kutyaira maitiro ekuvandudza.

3.2 Elemental Surface Analysis

- Masikirwo epamusoro-soro anotaridza kuumbwa kwekutanga.

- X-ray Photoelectron Spectroscopy (XPS/ESCA): Inoongorora mamiriro emakemikari epamusoro nekudiridza chipfu neX-ray uye kuyera maerekitironi anoburitswa.

- Glow Discharge Optical Emission Spectroscopy (GD-OES) : Inotsveta zvakanyanya-yakatetepa pamusoro peturu zvakatevedzana uku ichiongorora yakaburitswa spectra kuona kudzika-inotsamira elemental kuumbwa.

- Yekuona miganho inosvika zvikamu pamiriyoni (ppm), inotungamira yakakwana yekuchenesa chemistry kusarudzwa.

3.3 morphological Contamination Analysis

- Scanning Electron Microscopy (SEM)—yakakwirira-resolution mifananidzo kuratidza yakasvibiswa’ maumbirwo uye aspect ratios, achiratidza adhesion michina (kemikari vs. Mechini).

- Atomic Force Microscopy (AFM): Mepu nanoscale topography kuyera kureba kwechikamu uye michina zvivakwa.

- Yakatarisana neIon Beam (FIB) Milling + Transmission Electron Microscopy (TEM): Inopa maonero emukati ezvakavigwa zvakasvibiswa.

4. Advanced Kuchenesa Nzira

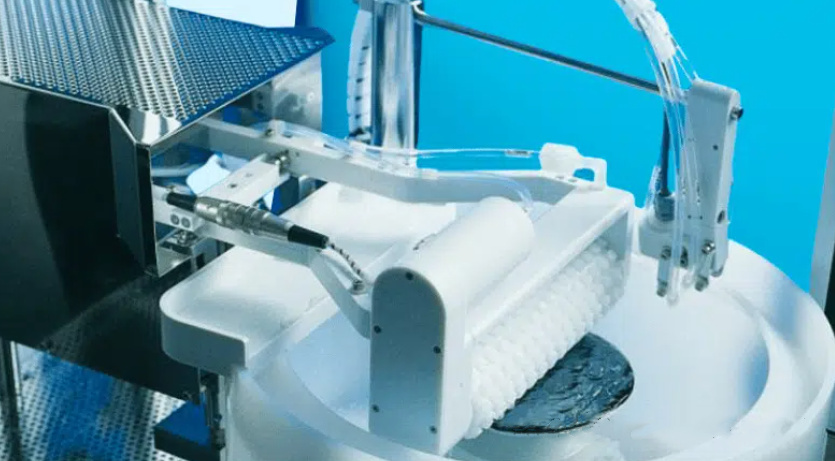

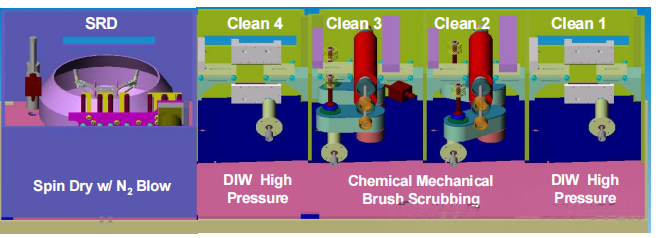

Nepo kuchenesa kwesolvent kuchibvisa zvinosvibisa organic, humwe hunyanzvi hwepamberi hunodiwa kune inorganic particles, metallic residues, uye ionic zvinosvibisa:

.

4.1 RCA Kuchenesa

- Yakagadzirwa neRCA Laboratories, iyi nzira inoshandisa maviri-yekugeza maitiro ekubvisa zvinosvibisa polar.

- SC-1 (Standard Clean-1): Inobvisa organic zvinosvibisa uye zvidimbu uchishandisa musanganiswa weNH₄OH, H₂O₂, neH₂O (semuenzaniso, 1:1:5 reshiyo pa ~20°C). Inoumba chidimbu chesilicon dioxide layer.

- SC-2 (Standard Clean-2): Inobvisa tsvina yesimbi uchishandisa HCl, H₂O₂, neH₂O (semuenzaniso, 1:1:6 reshiyo pa ~80°C). Inosiya nzvimbo yakapfuura.

- Kuenzanisa utsanana nekudzivirirwa kwepamusoro.

.

4.2 Kucheneswa kweOzone

- Inonyudza mawafer mumvura ine ozone-yakazara deionized mvura (O₃/H₂O).

- Inonyatso oxidize uye inobvisa organics pasina kukuvadza wafer, ichisiya nzvimbo ine makemikari passivated.

.

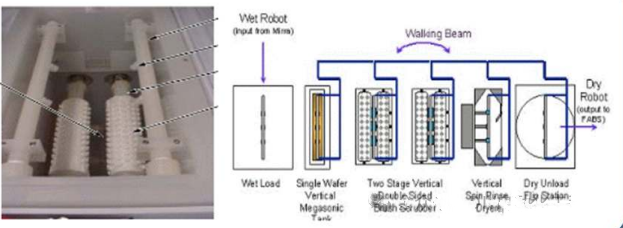

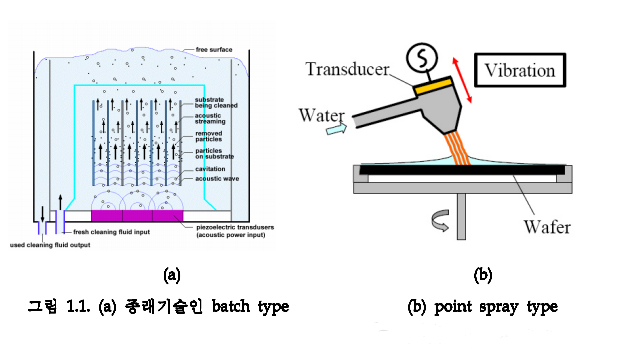

4.3 Megasonic Kuchenesa.

- Inoshandisa high-frequency ultrasonic energy (kazhinji 750–900 kHz) pamwe chete nekuchenesa mhinduro.

- Inogadzira cavitation bubbles anobvisa zvinosvibisa. Inopinda yakaoma geometries uku ichideredza kukuvadzwa kune dzakapfava zvimiro.

4.4 Cryogenic Kuchenesa

- Inokurumidza kutonhora zvimedu kune tembiricha ye cryogenic, zvinosvibisa zvinosvibisa.

- Kuzogeza kana kukwesha zvinyoro nyoro kunobvisa zvidimbu zvakasununguka. Inodzivirira kusvibiswa zvakare uye kupararira mukati mepamusoro.

- Inokurumidza, yakaoma maitiro ane kushoma kemikari kushandiswa.

Mhedziso:

Seanotungamira akazara-cheni semiconductor mhinduro mupi, XKH inotungamirwa nehunyanzvi hwekuvandudza tekinoroji uye mutengi anofanirwa kuendesa yekupedzisira-kusvika-kumagumo sevhisi ecosystem, inosanganisira yepamusoro-yekupedzisira michina yekugovera, kugadzira wafer, uye kunyatso kuchenesa. Hatingope michina inocherechedzwa pasi rose inocherechedzwa semiconductor (semuenzaniso, michina yelithography, etching masisitimu) ine mhinduro dzakagadzirirwa asiwo tekinoroji yevaridzi-kusanganisira RCA yekuchenesa, kucheneswa kweozone, uye kuchenesa megasonic - kuti ive nechokwadi chehutsanana hweatomiki, pakugadzira wafer, kusimudzira zvakanyanya goho revatengi. Kushandisa zvikwata zvekukurumidza-mhinduro zvikwata, uye akangwara masevhisi network, tinopa rutsigiro rwakakwana kubva pakumisikidzwa kwemidziyo uye kugadzirisa mashandiro kusvika kugadziriso yekufungidzira, tichipa vatengi simba rekukunda zvipingamupinyi zvehunyanzvi uye kufambira mberi kusvika padanho repamusoro uye kusimudzira semiconductor. Sarudza isu kune mbiri-kuhwina synergy yehunyanzvi hunyanzvi uye kukosha kwekutengesa.

Nguva yekutumira: Sep-02-2025