SiC wafers ma semiconductors akagadzirwa kubva kusilicon carbide. Ichi chinyorwa chakagadzirwa muna 1893 uye chakanakira kushandiswa kwakasiyana-siyana. Kunyanya yakakodzera Schottky diodes, junction barrier Schottky diodes, switches uye metal-oxide-semiconductor field-effect transistors. Nekuda kwekuoma kwayo kwakanyanya, isarudzo yakanakisa yemagetsi emagetsi zvikamu.

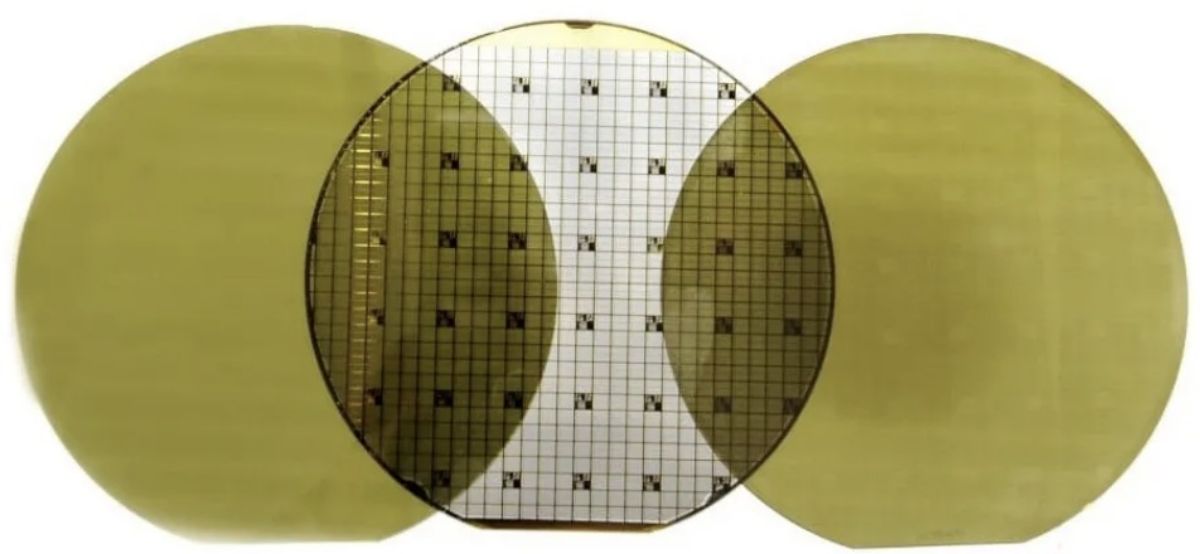

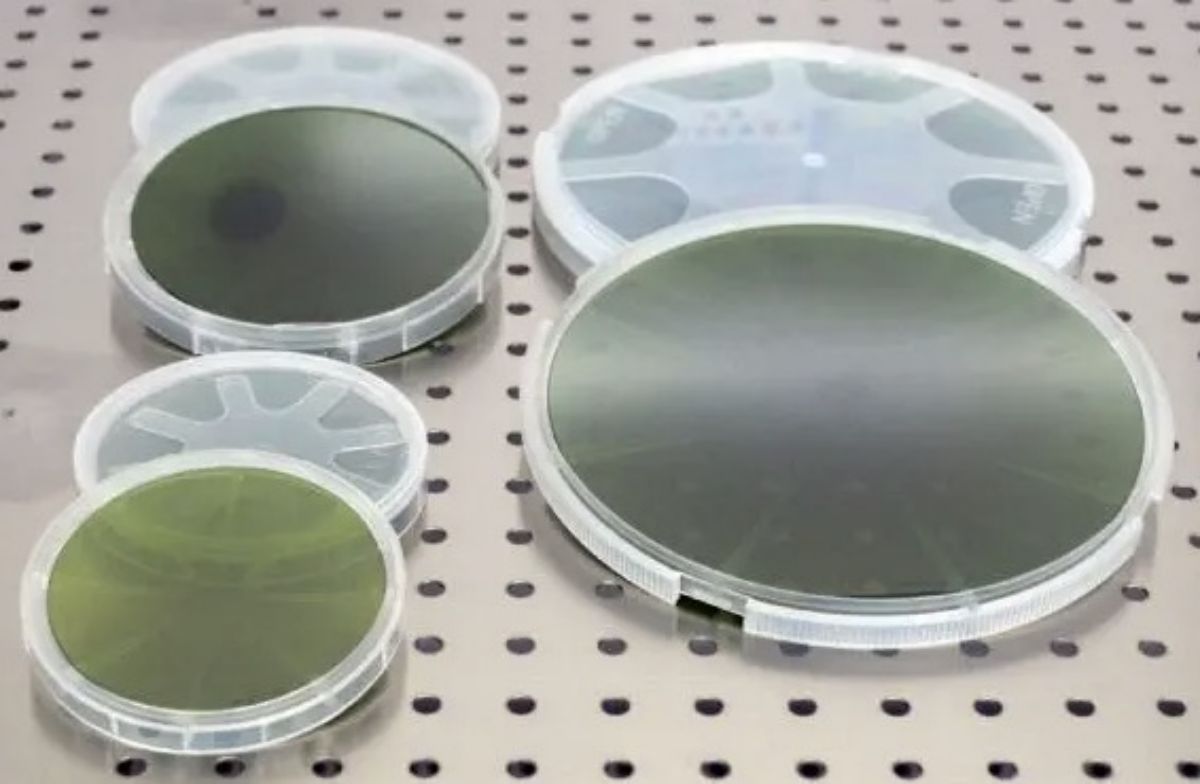

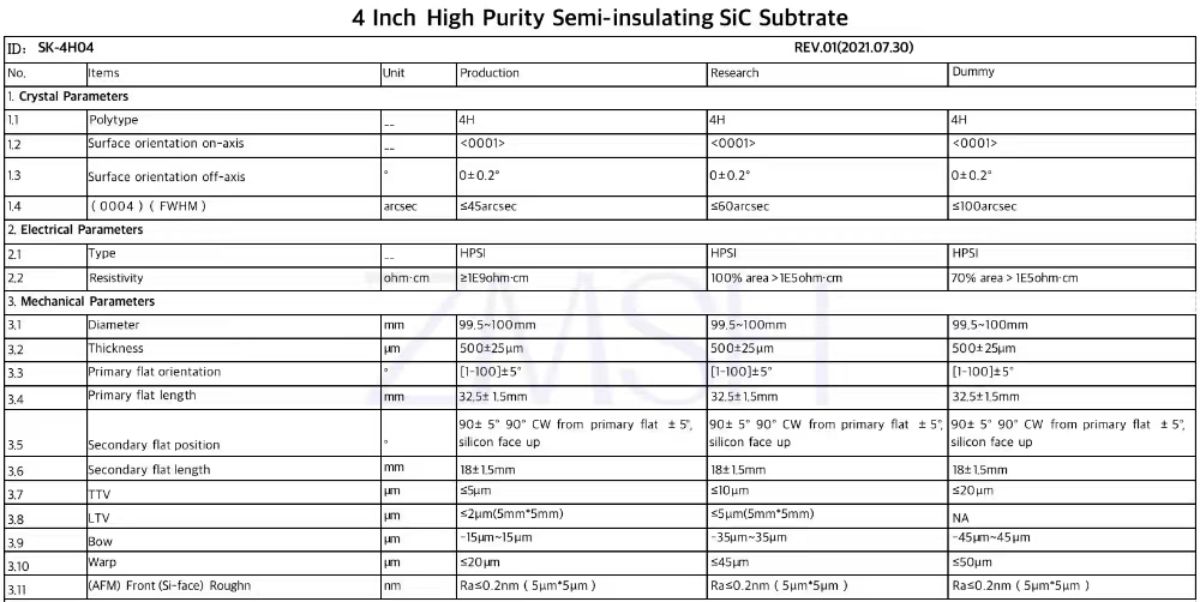

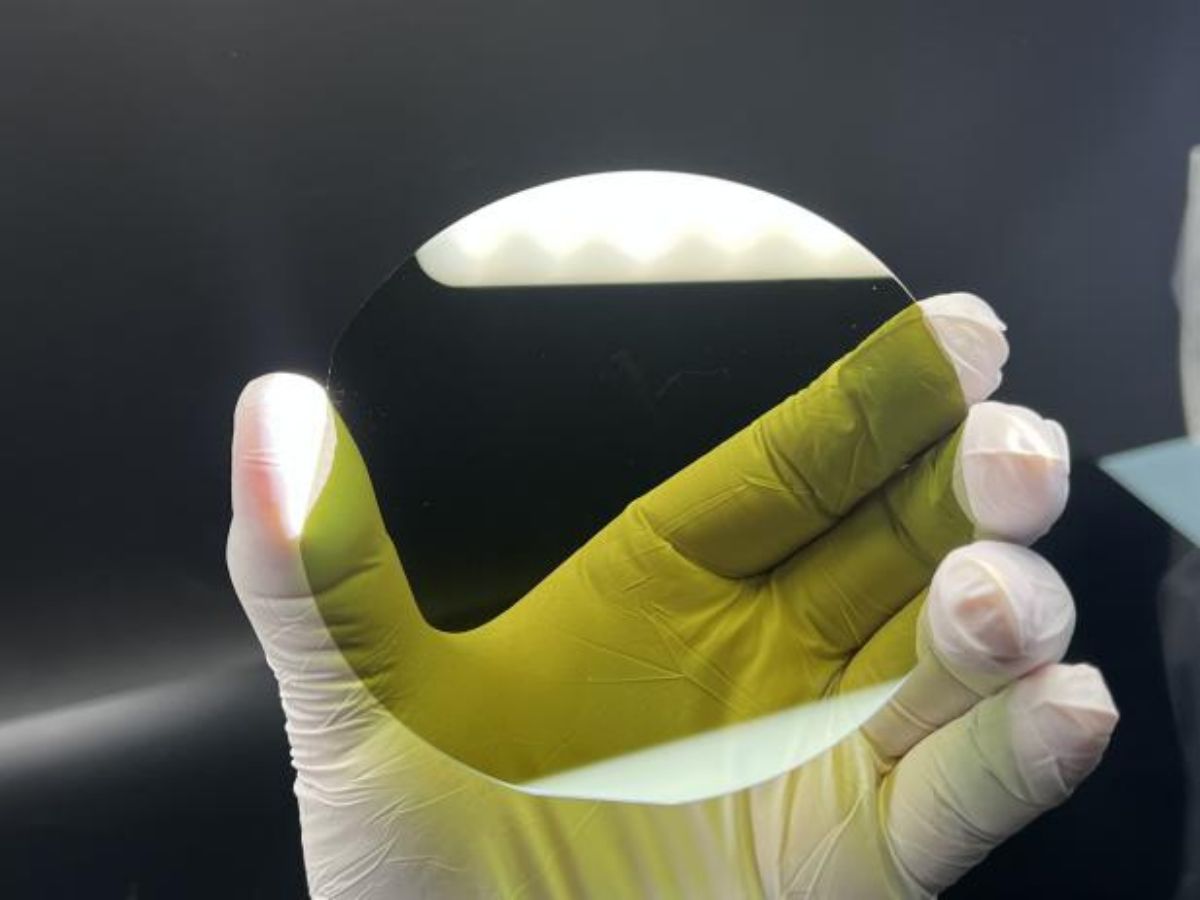

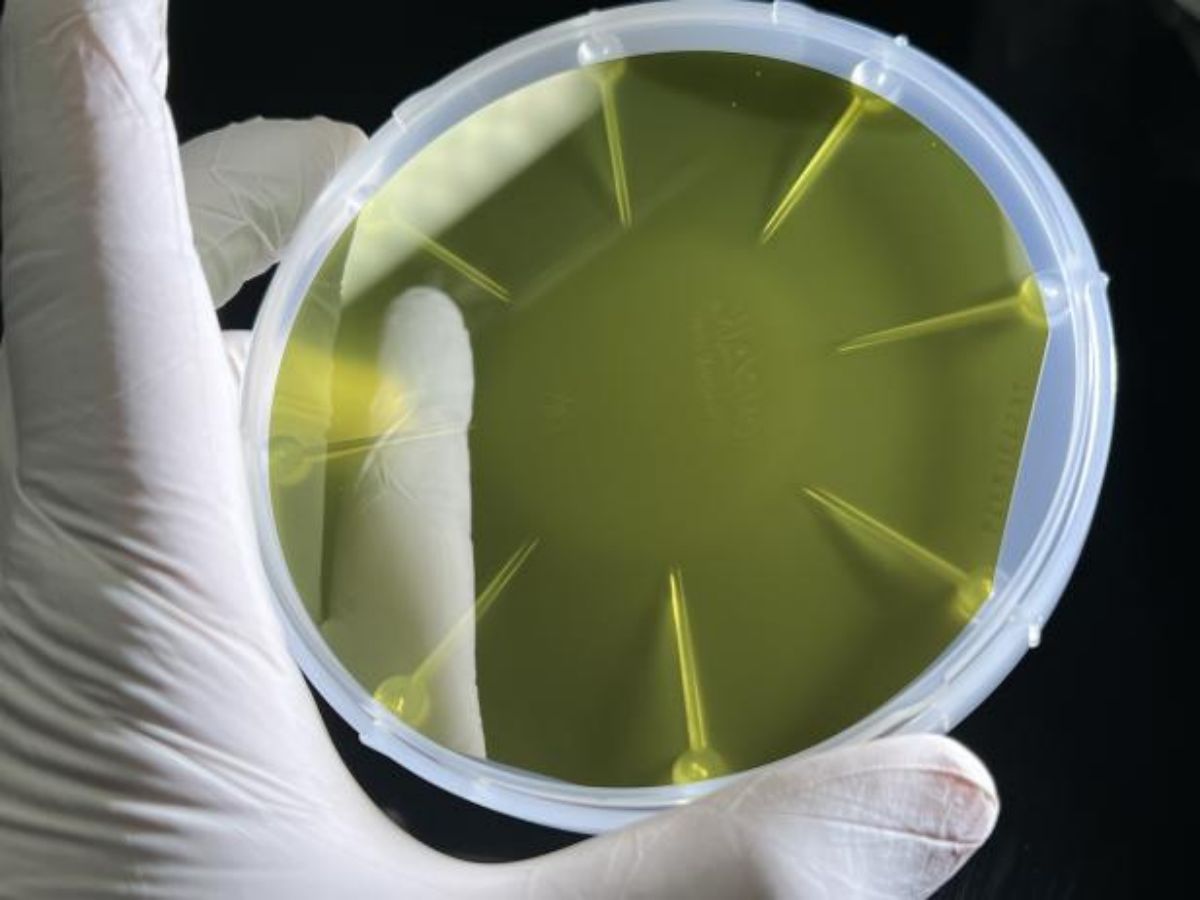

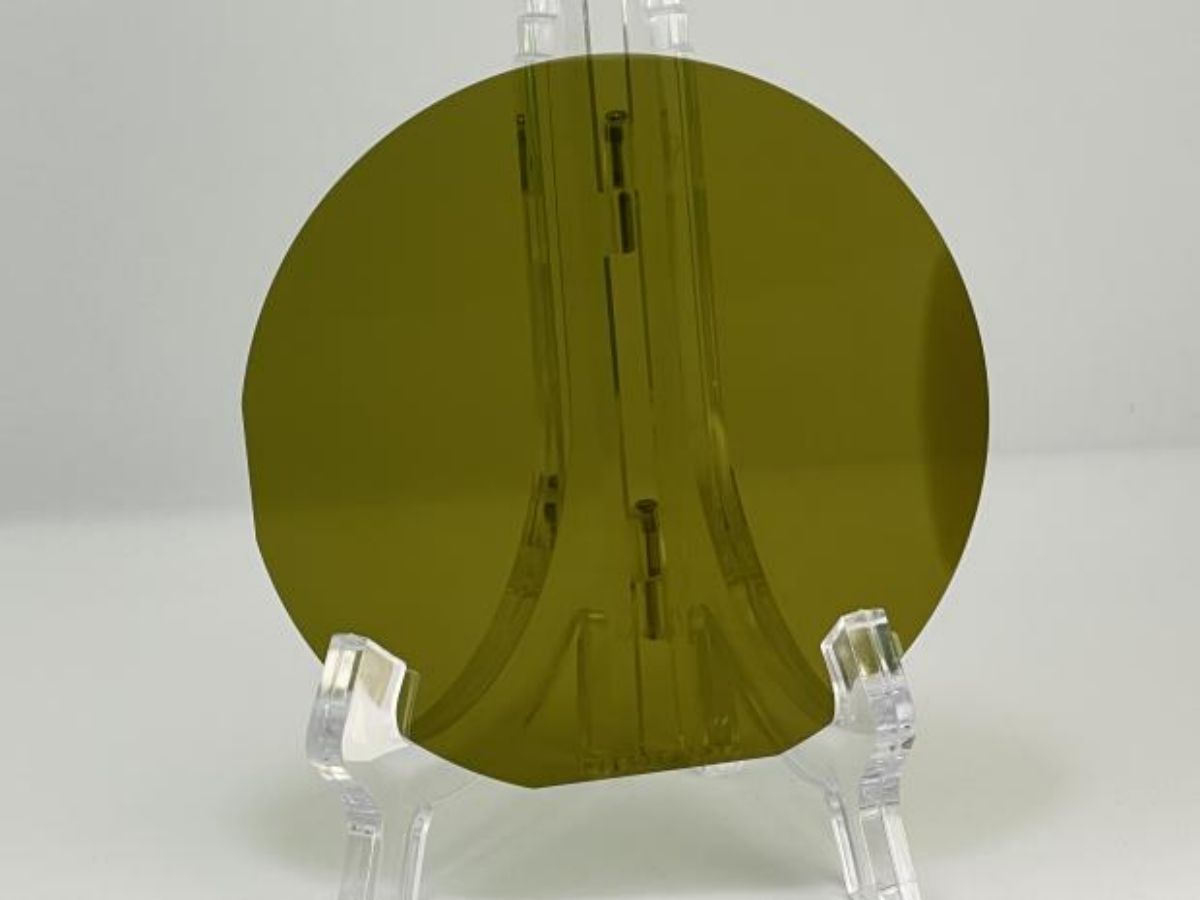

Parizvino, kune maviri makuru marudzi eSiC wafers. Yekutanga iwafer yakakwenenzverwa, inova imwechete silicon carbide wafer. Yakagadzirwa nehutsanana hweSiC makristasi uye inogona kuve 100mm kana 150mm mudhayamita. Inoshandiswa mumagetsi emagetsi emagetsi. Rudzi rwechipiri ndeye epitaxial crystal silicon carbide wafer. Iri rudzi rwewaferi rinogadzirwa nekuwedzera imwe chete layer yesilicon carbide makristasi kumusoro. Iyi nzira inoda kunyatso kudzora ukuru hwezvinhu uye inozivikanwa seN-mhando epitaxy.

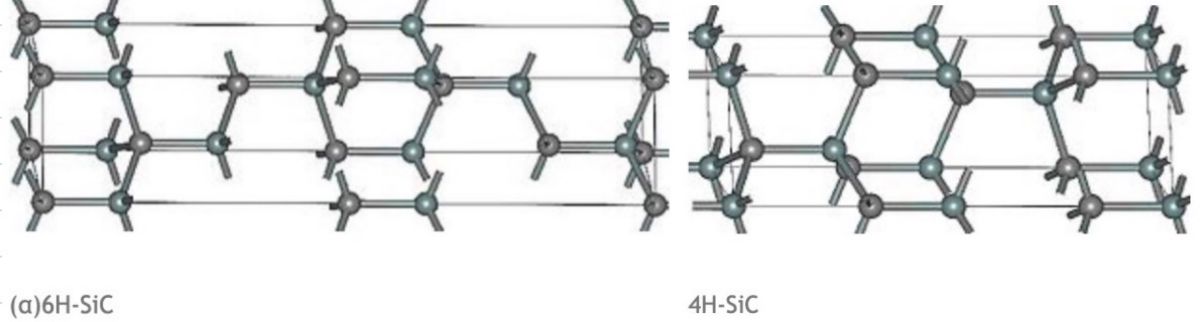

Mhando inotevera ndeye beta silicon carbide. Beta SiC inogadzirwa patembiricha inopfuura 1700 degrees Celsius. Alpha carbides ndiyo inonyanya kuzivikanwa uye ine hexagonal crystal structure yakafanana newurtzite. Iyo beta fomu yakafanana nedhaimondi uye inoshandiswa mune mamwe maapplication. Yagara iri yekutanga sarudzo yemagetsi emagetsi emagetsi semi-akapedza zvigadzirwa. Vanoverengeka vechitatu-bato silicon carbide wafer suppliers vari kushanda pachinhu ichi chitsva.

ZMSH SiC wafers anonyanya kufarirwa semiconductor zvinhu. Iyo yemhando yepamusoro semiconductor zvinhu inonyatso inokodzera kune akawanda maapplication. ZMSH silicon carbide wafers chinhu chinobatsira kwazvo kune zvakasiyana siyana zvemagetsi. ZMSH inopa huwandu hwakasiyana hwemhando yepamusoro SiC wafers uye substrates. Iwo anowanikwa muN-mhando uye semi-insulated mafomu.

2---Silicon Carbide: Kusvika kune imwe nguva itsva yewafers

Zvenyama zvimiro uye hunhu hwesilicon carbide

Silicon carbide ine yakakosha crystal chimiro, inoshandisa hexagonal yakavharwa-yakazara chimiro chakafanana nedhaimondi. Ichi chimiro chinogonesa silicon carbide kuve yakanakisa yekupisa conductivity uye yakakwirira tembiricha kuramba. Kana ichienzaniswa neyechinyakare silicon zvinhu, silicon carbide ine hombe bhendi gap upamhi, iyo inopa yakakwirira erekitironi bhendi spacing, zvichikonzera yakakwira erekitironi kufamba uye kuderera kwekudonha ikozvino. Uye zvakare, silicon carbide zvakare ine yakakwira electron saturation drift kumhanya uye yakaderera resistivity yezvinhu pachayo, ichipa kuita kurinani kweakakwira masimba ekushandisa.

Makesi ekushandisa uye tarisiro yesilicon carbide wafers

Zvishandiso zvemagetsi zvemagetsi

Silicon carbide wafer ine yakafara application tarisiro musimba remagetsi munda. Nekuda kwekufamba kwavo kwerekitironi yakakwira uye yakanakisa kupisa kwemafuta, SIC wafers inogona kushandiswa kugadzira yakakwirira-simba density switching zvishandiso, senge magetsi modules emagetsi mota uye solar inverters. Iyo yakanyanya kugadzikana tembiricha yesilicon carbide wafers inoita kuti zvishandiso izvi zvishande munzvimbo dzakanyanya tembiricha, zvichipa kugona kukuru uye kuvimbika.

Optoelectronic zvikumbiro

Mumunda wezvigadzirwa zveoptoelectronic, silicon carbide wafers inoratidza zvakanakira zvakasarudzika. Silicon carbide zvinhu zvine yakafara bhendi gap maitiro, izvo zvinoita kuti iwane yakakwira photonon simba uye yakaderera mwenje kurasikirwa mune optoelectronic zvishandiso. Silicon carbide wafers inogona kushandiswa kugadzirira yakakwira-kumhanya michina yekutaurirana, mafotodetectors uye lasers. Yayo yakanaka kwazvo yekupisa conductivity uye yakaderera crystal defect density inoita kuti ive yakakodzera kugadzirira kwemhando yepamusoro optoelectronic zvishandiso.

Outlook

Nekukura kuri kudiwa kwezvishandiso zvepamusoro zvemagetsi, masilicon carbide wafers ane ramangwana rinovimbisa sechinhu chine zvivakwa zvakanakisa uye yakafara yekushandisa mukana. Nekuenderera mberi kwekuvandudza tekinoroji yekugadzirira uye kudzikiswa kwemutengo, kushandiswa kwekutengesa kwesilicon carbide wafers kuchasimudzirwa. Zvinotarisirwa kuti mumakore mashoma anotevera, silicon carbide wafers zvishoma nezvishoma inopinda mumusika uye ive sarudzo huru yesimba repamusoro, yakakwirira frequency uye yakanyanya tembiricha yekushandisa.

3---Kuongorora kwakadzama kweSiC wafer musika uye tekinoroji maitiro

Kuongorora kwakadzama kwesilicon carbide (SiC) wafer market driver

Kukura kweiyo silicon carbide (SiC) musika wewafer kunopesvedzerwa nezvinhu zvakati wandei zvakakosha, uye kuongorora kwakadzama kwemabatiro ezvinhu izvi pamusika kwakakosha. Heano mamwe eakakosha emusika anotyaira:

Kuchengetedza magetsi uye kuchengetedzwa kwezvakatipoteredza: Kuita kwepamusoro uye kuderera kwesimba rekushandisa maitiro esilicon carbide zvinhu zvinoita kuti ive yakakurumbira mumunda wekuchengetedza simba uye kuchengetedza kwezvakatipoteredza. Iko kudiwa kwemotokari dzemagetsi, solar inverters uye mamwe magetsi ekushandura magetsi kuri kufambisa kukura kwemusika kwesilicon carbide wafers sezvo ichibatsira kuderedza kupera kwesimba.

Simba reMagetsi mashandisirwo: Silicon carbide inokunda mumagetsi emagetsi maapplication uye inogona kushandiswa mumagetsi emagetsi pasi pekumanikidzwa kwakanyanya uye nepamusoro tembiricha nharaunda. Nekuzivikanwa kwesimba rinodzokororwa uye kusimudzira shanduko yemagetsi emagetsi, kudiwa kwemasilicon carbide wafers mumusika wemagetsi emagetsi kuri kuramba kuchiwedzera.

SiC wafers ramangwana rekugadzira tekinoroji yekuvandudza maitiro akadzama kuongororwa

Kugadzirwa kwakawanda uye kuderedzwa kwemutengo: Yemberi SiC wafer yekugadzira ichatarisa zvakanyanya pakugadzirwa kwehuwandu uye kuderedzwa kwemutengo. Izvi zvinosanganisira nzira dzakavandudzwa dzekukura dzakadai semakemikari vapor deposition (CVD) uye muviri vapor deposition (PVD) kuwedzera kugadzirwa uye kuderedza mari yekugadzira. Pamusoro pezvo, kugamuchirwa kwehungwaru uye otomatiki maitiro ekugadzira anotarisirwa kuwedzera kuvandudza kushanda.

Saizi nyowani uye chimiro: Saizi uye chimiro cheSiC wafers inogona kuchinja mune ramangwana kuti isangane nezvinodiwa zvekushandisa kwakasiyana. Izvi zvinogona kusanganisira hombe dhayamita mawafer, heterogeneous zvimiro, kana multilayer wafers kuti ape mamwe dhizaini kuchinjika uye sarudzo dzekuita.

Kubudirira Kwesimba uye Green Manufacturing: Kugadzirwa kweSiC wafers mune ramangwana kuchaisa simbiso huru pakushanda kwesimba uye kugadzira kwegirinhi. Mafekitori anofambiswa nesimba rinodzokororwa, zvinhu zvakasvibirira, kudzoreredza marara uye maitiro ekugadzira kabhoni anozove maitiro ekugadzira.

Nguva yekutumira: Jan-19-2024