Nekuenderera mberi kwekuvandudza tekinoroji yesemiconductor, muindasitiri yesemiconductor uye kunyangwe iyo indasitiri yephotovoltaic, zvinodiwa zvemhando yepamusoro yewafer substrate kana epitaxial sheet zvakare zvakaomesesa. Saka, ndezvipi zvinodikanwa zvemhando yewafers? Kutorachimedu chesafires semuenzaniso, ndezvipi zviratidzo zvinogona kushandiswa kuongorora kunaka kwepamusoro kwewafers?

Ndeapi mawafer evaluation zviratidzo?

The Three indicators

Kune zvimedu zvesafire, zviratidzo zvayo zvekuongorora ndezvekutsauka kwese (TTV), bend (Bow) uye Warp (Warp). Aya maparamita matatu pamwe chete anoratidza kupfava uye ukobvu kufanana kwesilicon wafer, uye anogona kuyera dhigirii reripple yewafer. Iyo corrugation inogona kusanganiswa nekudzika kuti uongorore kunaka kweiyo wafer pamusoro.

Chii chinonzi TTV, BOW, Warp?

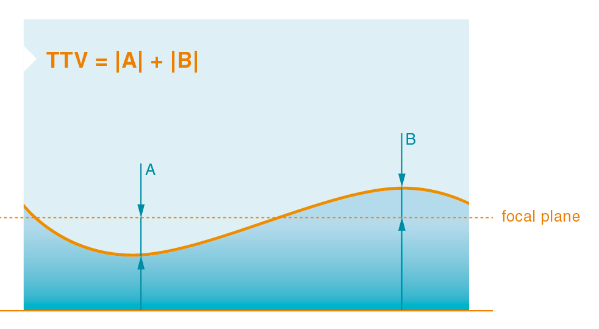

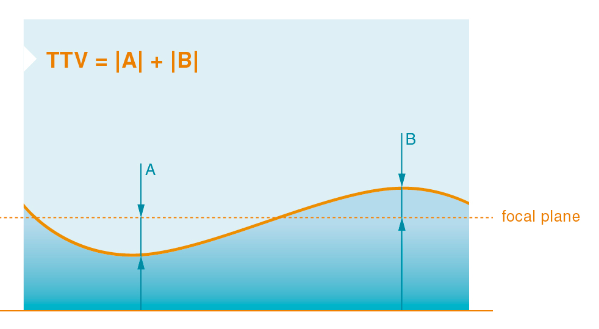

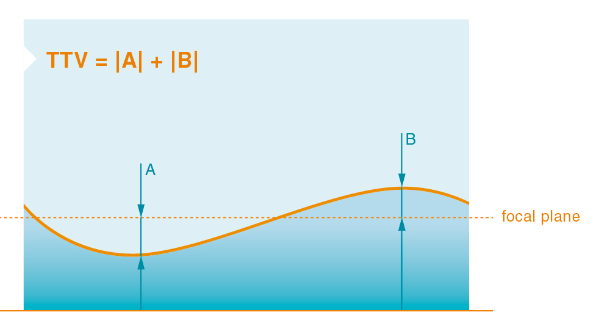

TTV (Total Thickness Variation)

TTV ndiyo mutsauko uripo pakati pehupamhi uye hudiki ukobvu hwewafer. Iyi parameter indekisi yakakosha inoshandiswa kuyera wafer ukobvu kufanana. Mune semiconductor process, ukobvu hwewafer hunofanirwa kunge hwakafanana zvakanyanya pamusoro pese pese. Zviyero zvinowanzoitwa munzvimbo shanu pane wafer uye mutsauko unoverengerwa. Pakupedzisira, kukosha uku ihwaro hwakakosha hwekutonga kunaka kwechingwa.

Bow

Bow in semiconductor kugadzira zvinoreva kubhenda kwewafer, kusunungura chinhambwe chiri pakati pepakati pechimedu chisina kuvharwa nendege yereferensi. Shoko racho ringangodaro rinobva pakutsanangura maumbirwo echinhu kana chakakombama, kufanana neuta. Kukosha kweBow kunotsanangurwa nekuyera kutsauka pakati pepakati uye kumucheto kwesilicon wafer. Kukosha uku kunowanzo kuratidzwa mumamicrometer (µm).

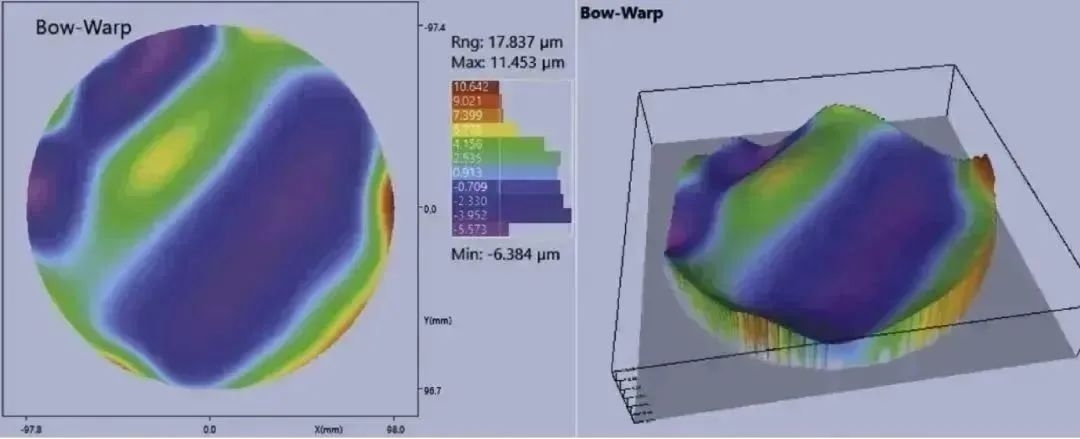

Warp

Warp inzvimbo yepasi rose yewafer inoyera mutsauko uripo pakati pehupamhi uye hudiki chinhambwe pakati pepakati pechifukidzo chisina kuvharwa nendege. Inomiririra chinhambwe kubva kumusoro kwesilicon wafer kuenda kundege.

Ndeupi musiyano uripo pakati peTTV, Bow, Warp?

TTV inotarisa pane shanduko muhukobvu uye haina hanya nekukotama kana kukanganisa kwewafer.

Bow inotarisa pane bend rose, kunyanya kufunga nezve bend yepakati poindi uye kumucheto.

Warp yakawedzera kuwanda, kusanganisira kukotama uye kumonyoroka kwenzvimbo yese yakapfava.

Kunyangwe aya maparamita matatu ane hukama nechimiro uye geometric zvimiro zvesilicon wafer, iwo anoyerwa uye anotsanangurwa zvakasiyana, uye maitiro avo pane semiconductor maitiro uye wafer processing zvakare akasiyana.

Iyo diki iyo mitatu paramita, zviri nani, uye yakakura parameter, iyo yakakura kukanganisa kwakashata pane semiconductor process. Naizvozvo, semiconductor practitioner, isu tinofanirwa kuziva kukosha kwewafer profile paramita kune yese process process, ita semiconductor process, inofanirwa kutarisisa kune ruzivo.

(censoring)

Nguva yekutumira: Jun-24-2024