Mukukura kuri kuita indasitiri yesemiconductor, yakakwenenzverwa kristaro imwechetezvimedu zvesiliconkuita basa rinokosha. Ivo vanoshanda sechinhu chakakosha pakugadzirwa kweakasiyana mamicroelectronic zvishandiso. Kubva kumatunhu akaoma uye akanyatsobatanidzwa akabatanidzwa kune akakwira-kumhanya mamicroprocessors uye multifunctional sensors, yakakwenenzverwa imwe kristaro.zvimedu zvesiliconzvakakosha. Misiyano mukuita kwavo uye zvirevo zvinokonzeresa kunaka uye kuita kwezvigadzirwa zvekupedzisira. Pazasi pane zvakajairwa zvinotsanangurwa uye ma paramita eakakwenenzverwa ekristaro imwe silicon wafers:

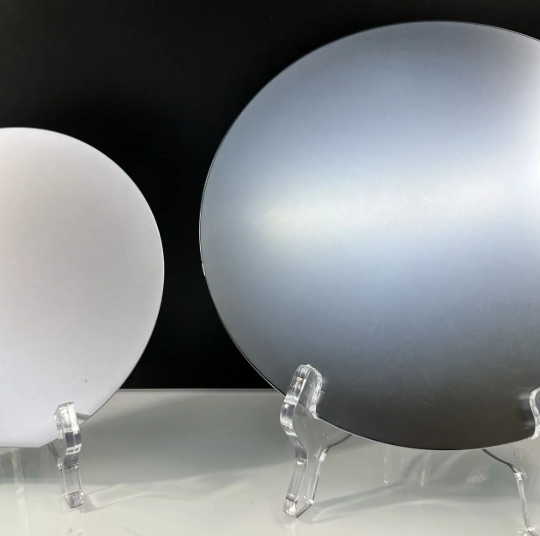

Diameter: Saizi ye semiconductor single crystal silicon wafers inoyerwa nedhayamita yadzo, uye inouya mune akasiyana siyana. Madhayamita akajairika anosanganisira 2 inches (50.8mm), 3 inches (76.2mm), 4 inches (100mm), 5 inches (125mm), 6 inches (150mm), 8 inches (200mm), 12 inches (300mm), uye 18 inches (450mm). Madhayamita akasiyana anokodzera zvakasiyana siyana zvekugadzira zvinodiwa uye maitiro ekuita. Semuyenzaniso, madiki madiki mawaferi anowanzo shandiswa kune akakosha, madiki-vhoriyamu microelectronic zvishandiso, nepo mahombe dhayamita mawafer anoratidza kukwirira kwekugadzira uye mabhenefiti emutengo muhombe-yakasanganiswa yedunhu kugadzira. Zvinodiwa zvepamusoro zvakakamurwa se-single-side polished (SSP) uye kaviri-padivi akakwenenzverwa (DSP). Single-side polished wafers anoshandiswa kune zvishandiso zvinoda yakakwirira flatness kune rimwe divi, senge mamwe masensor. Kaviri-padivi akakwenenzverwa wafers anowanzo shandiswa kune akasanganiswa maseketi uye zvimwe zvigadzirwa zvinoda kurongeka kwepamusoro pane ese ari maviri. Chinodiwa Pamusoro (Pedzisa): Single-side yakakwenenzverwa SSP / Kaviri-padivi yakakwenenzverwa DSP.

Type/Dopant: (1) N-Type Semiconductor: Kana mamwe maatomu ekusachena akaunzwa mukati memukati semiconductor, anochinja maitiro ayo. Semuenzaniso, kana pentavalent zvinhu zvakaita senitrogen (N), phosphorus (P), arsenic (As), kana antimoni (Sb) zvawedzerwa, maerekitironi awo evalence anoumba covalent bonds nemaerekitironi evalence emaatomu esilicon akatenderedza, achisiya imwe erekitironi isina kusungwa necovalent bond. Izvi zvinoguma mukusangana kwema electron yakakura kudarika gomba, kuumba N-type semiconductor, inozivikanwawo se electron-type semiconductor. N-mhando semiconductors yakakosha mukugadzira midziyo inoda maelectrons seanonyanya kubhadharisa anotakura, semamwe magetsi emagetsi. (2) P-mhando Semiconductor: Kana trivalent kusachena zvinhu zvakaita seboron (B), gallium (Ga), kana indium (In) zvinounzwa musilicon semiconductor, maerekitironi evalence emaatomu ekusachena anoumba covalent zvisungo nemaatomu esilicon akatenderedza, asi anoshaya kana erekitironi imwe chete yevalence uye haakwanise kuumba mubatanidzwa wakakwana. Izvi zvinotungamira kune mugomba wakakura kupfuura electron concentration, kugadzira P-type semiconductor, inozivikanwawo sehole-type semiconductor. P-mhando semiconductors inoita basa rakakosha mukugadzira zvishandiso uko maburi anoshanda seanonyanya kubhadharisa vatakuri, senge diode uye mamwe ma transistors.

Resistivity: Resistivity chikamu chakakosha chemuviri chinoyera kufambiswa kwemagetsi kweakakwenenzverwa imwe crystal silicon wafers. Kukosha kwayo kunoratidza maitiro ekuitisa. Iyo yakaderera iyo resistivity, zviri nani conductivity yesilicon wafer; ukuwo, iyo yakakwirira resistivity, varombo ari conductivity. Iyo resistivity yesilicon wafers inotemerwa neyavo yekuzvarwa zvinhu zvivakwa, uye tembiricha ine yakakosha kukanganisa zvakare. Kazhinji, iyo resistivity yesilicon wafers inowedzera nekushisa. Mumashandisirwo anoshanda, akasiyana microelectronic zvishandiso zvine akasiyana resistivity zvinodiwa zvesilicon wafers. Semuyenzaniso, mawaferi anoshandiswa mukugadzira dhizaini yakabatanidzwa anoda kunyatso kudzora kweresistive kuti ive nechokwadi chakagadzikana uye chakavimbika chishandiso kuita.

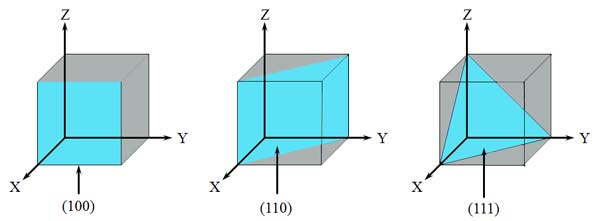

Oriental: The crystal orientation of the wafer inomiririra crystallographic direction yesilicon lattice, inowanzotsanangurwa neMiller indices yakadai se (100), (110), (111), nezvimwewo. Kusiyana kwekristani kutaridzika kune zvakasiyana-siyana zvemuviri, zvakadai semutsara wemutsara, izvo zvinosiyana zvichienderana nekutarisa. Musiyano uyu unogona kukanganisa mashandiro ewaferi mumatanho anotevera ekugadzirisa uye kuita kwekupedzisira kwemidziyo yemicroelectronic. Mukugadzira, kusarudza silicon wafer ine yakanangana neyakasiyana zvinodiwa mudziyo inogona kukwidziridza mashandiro echishandiso, kunatsiridza kugadzirwa kwakanaka, uye kuwedzera kunaka kwechigadzirwa.

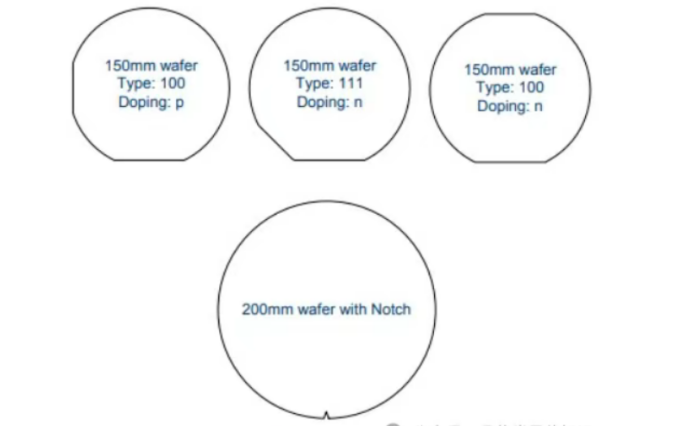

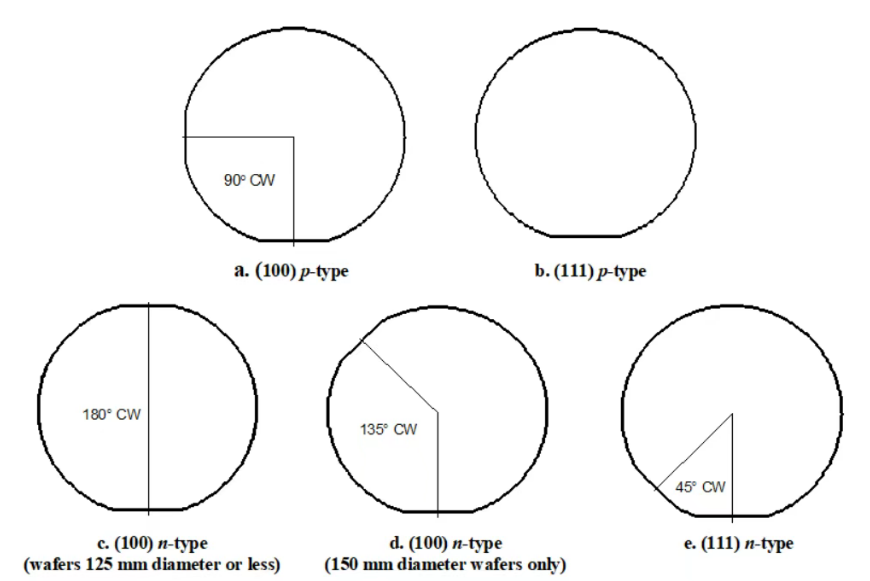

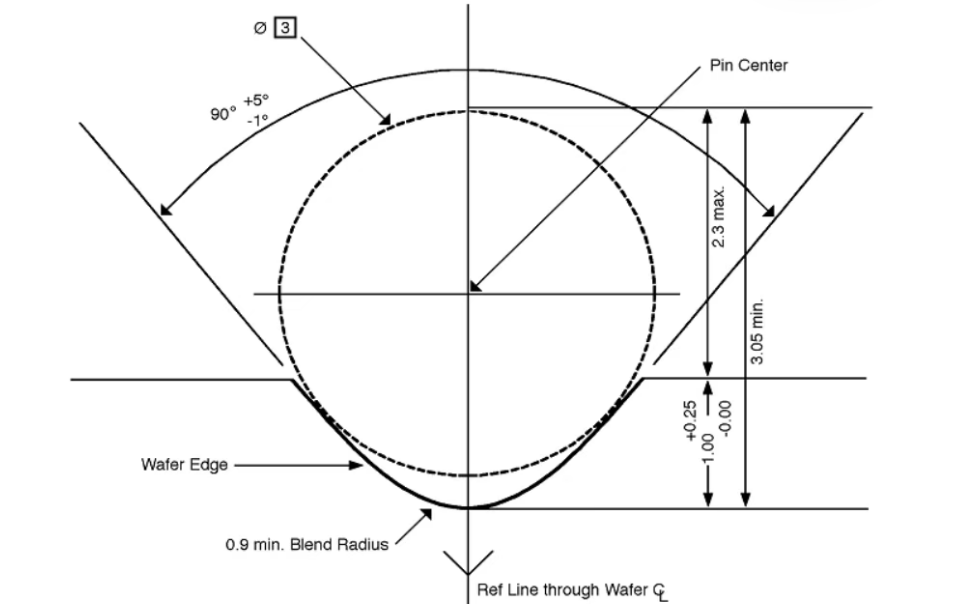

Flat/Notch: Iyo flat mupendero (Flat) kana V-notch (Notch) padenderedzwa resilicon wafer inoita basa rakakosha mukurongeka kwekristaro uye chiziviso chakakosha mukugadzira uye kugadzirisa kwewafer. Wafers emadhayamita akasiyana anoenderana neakasiyana zviyero zvehurefu hweFlat kana Notch. Iyo yekumisikidza mipendero yakakamurwa kuita yekutanga flat uye yechipiri flat. Iyo yekutanga furati inonyanya kushandiswa kuona iyo yakakosha kristaro kutaridzika uye kugadzirisa referensi yewafer, nepo yechipiri flat ichiwedzera kubatsira mukurongeka uye kugadzirisa, kuve nechokwadi chekushanda chaiko uye kuenderana kwewafer mumutsara wekugadzira.

Ukobvu: Ukobvu hwewafer hunowanzo kutsanangurwa mumamicrometers (μm), ine hukobvu hwakajairika pakati pe100μm ne1000μm. Wafers ehukobvu hwakasiyana akakodzera mhando dzakasiyana dzemicroelectronic zvishandiso. Zvitete zvitete (semuenzaniso, 100μm - 300μm) zvinowanzo shandiswa kugadzira chip izvo zvinoda kuomarara kudzora ukobvu, kuderedza saizi uye huremu hwechip uye kuwedzera kusanganisa kwekubatanidza. Mawafer akakora (semuenzaniso, 500μm - 1000μm) anoshandiswa zvakanyanya mumidziyo inoda simba repamusoro remuchina, senge simba semiconductor zvishandiso, kuve nechokwadi kugadzikana panguva yekushanda.

Surface Roughness: Kushata kwepamusoro ndeimwe yeakakosha ma paramita ekuongorora mhando yewafer, sezvo ichikanganisa zvakananga kunamatira pakati pewafer uye inozotevera yakaiswa yakaonda firimu zvinhu, pamwe nekuita kwemagetsi kwechishandiso. Inowanzo kuratidzwa semudzi unoreva square (RMS) roughness (mu nm). Kudzika kwepasi kuoma kunoreva kuti wafer pamusoro wakapfava, izvo zvinobatsira kuderedza zviitiko senge maerekitironi kupararira uye kunatsiridza mashandiro echishandiso uye kuvimbika. Mune epamberi semiconductor yekugadzira maitiro, kushata kwepamusoro zvinodiwa zviri kuwedzera kuomarara, kunyanya kune yakakwirira-yekupedzisira yakasanganiswa yedunhu kugadzira, uko kushata kwepamusoro kunofanirwa kudzorwa kune mashoma nanometers kana kutodzika.

Total Thickness Variation (TTV): Huwandu hwekusiyana kwehukobvu hunoreva musiyano uripo pakati pehupamhi uye hudiki hukobvu hwakayerwa pamapoinzi akawanda pawafer pamusoro, kazhinji inoratidzwa muμm. Iyo TTV yakakwira inogona kutungamira mukutsauka mumatanho senge photolithography uye etching, ichikanganisa mashandiro echishandiso uye goho. Naizvozvo, kudzora TTV panguva yekugadzira wafer inhanho yakakosha mukuve nechokwadi chemhando yechigadzirwa. Pakugadzirwa kwepamusoro-chaiyo microelectronic mudziyo, TTV inowanzodiwa kuti ive mukati memamirimita mashoma.

Bow: Bow inoreva kutsauka pakati pewafer pamusoro uye yakakodzera ndege yakadzikama, inowanzoyerwa mu μm. Wafers akakotama zvakanyanya anogona kutyora kana kusangana nekusagadzikana kusagadzikana panguva inotevera kugadziridzwa, zvichikanganisa kugadzirwa kwemhando uye kunaka kwechigadzirwa. Kunyanya mumatanho anoda kukwirira kwepamusoro, senge photolithography, kukotama kunofanirwa kudzorwa mukati mechikamu chakati kuti ive nechokwadi chekururama uye kuenderana kweiyo photolithographic pateni.

Warp: Warp inoratidza kutsauka pakati pewafer pamusoro uye yakanaka spherical chimiro, zvakare yakayerwa mu μm. Zvakafanana neuta, warp chiratidzo chakakosha chewafer flatness. Yakawandisa warp haingokanganisa kurongeka kweiyo wafer mumidziyo yekugadzirisa asi inogona kukonzera nyaya panguva yekurongedza chip, senge kusabatana kwakashata pakati peiyo chip uye yekurongedza zvinhu, izvo zvinozokanganisa kuvimbika kwechishandiso. Mukugadzira-yekupedzisira semiconductor yekugadzira, warp zvinodiwa zviri kuwedzera kuomarara kuzadzisa zvinodiwa zvepamberi chip kugadzira uye kurongedza maitiro.

Edge Mbiri: Iyo yekumucheto mbiri yewafer yakakosha kune yayo inotevera kugadzirisa uye kubata. Iyo inowanzo tsanangurwa neEdge Exclusion Zone (EEZ), iyo inotsanangura chinhambwe kubva kumucheto wewafesi uko pasina kugadzirisa kunobvumidzwa. Iyo yakanyatso gadzirwa mupendero chimiro uye chaiyo EEZ kudzora inobatsira kudzivirira kumucheto kuremara, kushushikana kwekushushikana, uye zvimwe zvinhu panguva yekugadziriswa, kuvandudza iyo yakazara wafer mhando uye goho. Mune mamwe maitiro epamberi ekugadzira, edge profil chaiyo inodiwa kuti ive pa sub-micron level.

Particle Count: Huwandu uye saizi kugoverwa kwezvimedu pane wafer pamusoro zvinokanganisa zvakanyanya kuita kweiyo microelectronic zvishandiso. Zvimedu zvakawandisa kana zvakakura zvinogona kutungamira mukukundikana kwechigadzirwa, senge mapfupi maseketi kana kuvuza, kuderedza goho rechigadzirwa. Nokudaro, kuverenga kwezvikamu kunowanzoyerwa nekuverenga zvikamu pachikamu chechikamu, sehuwandu hwezvikamu zvakakura kudarika 0.3μm. Kudzora kwakasimba kwehuwandu hwekuverengera panguva yekugadzira wafer chiyero chakakosha chekuve nechokwadi chemhando yechigadzirwa. Yepamberi yekuchenesa matekinoroji uye yakachena kugadzirwa nharaunda inoshandiswa kuderedza kusvibiswa kwechikamu pane wafer pamusoro.

![]()

![]()

![]()

![]()

![]()

Kugadzirwa kwakabatana

Imwe Crystal Silicon Wafer Si Substrate Type N/P Optional Silicon Carbide Wafer

FZ CZ Si wafer mu stock 12inch Silicon wafer Prime kana Test

Nguva yekutumira: Kubvumbi-18-2025